Bad- I'm a numbers guy and went to great effort to produce a flat response at 1 meter. You don't listen at 1 meter and there are reflections and boundaries in your room. Don't get too hung up on response but don't ignore it either. Symmetry seems like a good idea, but not for speakers. Equal distances from drivers to anything tend to be bad. Oddball boxes with sloped fronts are usually better than rectangular easy-to-saw boxes. Cabinet resonances are bad. Use braces. Remember that no amount of tweaking or crossover magic will turn bad drivers into good. Some are only suitable for PA work and emergency sirens. Invest in good drivers. Calculate crossovers but recognize that you rarely have enough information to do better than close. Voicing is always required.

Good- Our test equipment is great today and nearly free. Long ago I went to great lengths to get response curves using old General Radio filters and chart recorder. They were synced together with a stepper motor system. I used hardware filters to get pink noise. My wife hated speaker testing because it was loud and took forever. A PC and free software is 100 times better and more revealing if you have a decent microphone. There are lots of decent microphones now for reasonable money. Our signal sources are way better than they used to be. You can create anything you want using Audacity and burn it to a CD. Or, get real generators. Or, use the PC.

Best advice- You need to balance testing with listening. Either one alone will result in a mediocre design at best.

Good- Our test equipment is great today and nearly free. Long ago I went to great lengths to get response curves using old General Radio filters and chart recorder. They were synced together with a stepper motor system. I used hardware filters to get pink noise. My wife hated speaker testing because it was loud and took forever. A PC and free software is 100 times better and more revealing if you have a decent microphone. There are lots of decent microphones now for reasonable money. Our signal sources are way better than they used to be. You can create anything you want using Audacity and burn it to a CD. Or, get real generators. Or, use the PC.

Best advice- You need to balance testing with listening. Either one alone will result in a mediocre design at best.

The biggest mistake I made when I started building speakers, was to listen to too many "opinions" (parrots) instead of finding the right resources.

That does not only count for the technical aspect but also practical things like woodworking etc.

Second biggest mistake was fussing around way to much instead of enjoying music.

That does not only count for the technical aspect but also practical things like woodworking etc.

Second biggest mistake was fussing around way to much instead of enjoying music.

I make 'mistakes' every build, although I'm probably still considered a beginner despite dabbling on and off for 15 years or so 🙂 Early on, the biggest factor was being clueless with regard to the technical aspects of speaker design (e.g. T/S parameters, alignments), and just putting components together arbitrarily. I once made an enormous concrete horn sub with a car subwoofer because a friend said horn speakers sounded best - especially if made with concrete (it didn't).

Getting some basic measurement equipment and upskilling on the technical knowlege side has been one of the most helpful steps in the right direction.

Getting some basic measurement equipment and upskilling on the technical knowlege side has been one of the most helpful steps in the right direction.

Long time ago, when putting a pair of RS 12" in the carpeted hatch deckplate of my VW Scirocco, my hand slipped and went through the whole cone from the back side of one driver. Got out the rubber cement... Hurt, but not as bad - it was just a new Radio Shack speaker.Long time ago, when putting Lowthers on the open baffle, my hand slipped and I made a hole in the cone with screwdriver. Maan that hurt.

You know, I still remember that every time I go to mount a big driver - like my F15s and the 18 helpers.

Probably all of them! Purchased wrong part values so when I built and then took measurements it was a WTH moment. Drivers out of phase. Cut the wrong size woofer hole into the front baffles Cut port lengths wrong. Took a phone call in the middle of re-foaming drivers by the time I got back it had set so peel off start over! The best dropped a compression driver and the magnet broke free and shifted.

You get the idea!

Rob 🙂

You get the idea!

Rob 🙂

Cabinet resonances are bad. Use braces.

Or don't use cabinets at all.

I used to take my electrical interconnections for granted which I now don't consider a good practice.

Do you have a go to cable that you recommend? Most of my wires I bought from Mogami or Canare.

Bryguy, please note that I meant the crimps and solder joints (and not cables) when I said "electrical interconnections", maybe there's a better word for those things...

yes - i just added additional volume after realizing the miscalculation.Still fun 🙂

reduced baffle width for the tweeter was actually a quite good idea, although it was only driven by looks ...

baffle positioning is crucial!I have never heard of the baffle edge distance idea. Good to know!

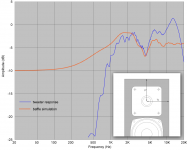

simulated diffraction effect done with jeff bagby's calculator:

Do we learn far more from mistakes, than successes ? On one of my first speakers, I made crude attempts at isolating vibration coming from the magnet, and tried it out in an unstuffed square box ( as it was a biscuit box it has a plastic liner, reducing sound transmission through the walls ), and it was eye opening how clear the boxy sound was, where as before the vibration and echoes had combined to form mush. In reducing one problem, it revealed another.

In retrospect, I'm glad that I made weird speakers, and many mistakes rather than making speakers to someone else's plans.

In retrospect, I'm glad that I made weird speakers, and many mistakes rather than making speakers to someone else's plans.

I used small lamp shades for enclosures in a 1970 Pontiac firebird my brother drove. It was just to see what could fit on the rear deck. They sat on a piece of board and the tweeter was just screwed to the board edge. They sounded so good (to us) and rocked all day. Looked like a pile of junk.

They stayed that way til he sold the car. The new buyer demanded to keep them. Made me realize there was a a lot more to speaker design than the stuff in the books of the time.

They stayed that way til he sold the car. The new buyer demanded to keep them. Made me realize there was a a lot more to speaker design than the stuff in the books of the time.

When you are starting out there are so many mistakes to make, how do you list them all?

For me the two most important mistakes that I "usually" don't make anymore are:

For me the two most important mistakes that I "usually" don't make anymore are:

- Thinking that speaker design is more important than room acoustics.

- Doing what I imagine (or want) to be right, instead of doing what actually works.

The biggest thing I've learnt over the years is that the crossover can make or break a speaker build. I also spent a lot of money on premium Hi Fi drivers early on in my projects only to find out that my ears prefer horns / pro type speakers later on. (big problem being not everybody gets a chance to listen to all types of speakers before starting the DIY hobby)

Other one is if it measures 'right' and sounds 'wrong' then something is probably amiss with the measurements 😀 (I ask my wife to listen and give opinions on whether she thinks something sounds right or wrong to double check myself)

I once had a trueRTA sweep that was very close to the harman curve at listening position, looked perfect. Listening to Pink Floyd it dawned on me that I could hardly hear the cymbals 😀 a couple of +dB adjustment on the tweeter level and bringing the midbass down a nudge and everything balanced out. Did another sweep and it almost looked the same but sounded very different.

Other one is if it measures 'right' and sounds 'wrong' then something is probably amiss with the measurements 😀 (I ask my wife to listen and give opinions on whether she thinks something sounds right or wrong to double check myself)

I once had a trueRTA sweep that was very close to the harman curve at listening position, looked perfect. Listening to Pink Floyd it dawned on me that I could hardly hear the cymbals 😀 a couple of +dB adjustment on the tweeter level and bringing the midbass down a nudge and everything balanced out. Did another sweep and it almost looked the same but sounded very different.

Omit the 'inter' prefix. 😉Bryguy, please note that I meant the crimps and solder joints (and not cables) when I said "electrical interconnections", maybe there's a better word for those things...

Not getting measurement capability soon enough - its most important use is in training your hearing, letting you know what you're actually listening to

"Electrical connections", that reads well, thank you !!Omit the 'inter' prefix. 😉

So, here's my question. Having completed your first speaker build of your own design, what mistakes did you find that you made? What aspects of your design left the most room for improvement?

Thanks all! I'm excited to hear your answers.

I like this question.

My first design had 2x Visaton W130S (5" midbass) and 1x Visaton FRS8M (3" full-range) per side.

When I was building, Visaton had a nice bit of software called Boxsim. It included the full catalogue of Visaton drivers, you enter baffle dimensions, design a passive crossover... Everything you might need.

So, I came up with a cabinet design which looked promising. The 5" midbass drivers were mounted on the sides with force cancellation, and I'd told Boxsim they were in a ported box of the right size. I think I aimed for a 40Hz port tuning. The passive crossover was pretty straightforward, and the graphs looked really promising.

The cabinets I built were tall and slim, and weren't acting as a ported box at all. More like an ML-TL (mass loaded transmission line) on account of their aspect ratio. The bass, then, wasn't working as intended.

Further, I found they sounded horrible when turned up. I thought it might be my amplifier running out of power (41Hz Amp6-basic, if anyone remembers those), so I tried something bigger. Still, the problem remained: the mid-high range turned shrill and screachy.

This was the problem that caused the speakers to be scrapped.

While Boxsim will tell you about the frequency response on- and off-axis, time-domain stuff etc etc, there's something it won't tell you: harmonic distortion. The pair of 5"s were still pretty comfortable when the 3" full-range unit was at the end of its tether, and that meant I couldn't turn them up to anywhere near the levels I wanted.

Since then, I've learned quite a lot. One of the things is that it's worth trying a few measurements at fairly high levels, to make sure nothing ends up unhappy. In all the speakers I've built since, the mid/high driver(s) have plenty of output on tap - it's the bass drivers which will (eventually) put a limit on things.

Chris

I made many mistakes. Maybe one of my bigger mistakes was that I thought the anechoic on-axis SPL response would tell me what a speaker sounds like.

It's kind of bizarre that a lot of companies and manufacturers still think that.I made many mistakes. Maybe one of my bigger mistakes was that I thought the anechoic on-axis SPL response would tell me what a speaker sounds like.

1) I was writing computer software to perform speaker system analysis for sealed and vented systems. I wanted to automate the system, so that once you entered the driver's TSPs, it would spit out the box volume to give a system Q of 0.707. I'm sure that the first driver I entered to test the routine was something from Radio Shack, which meant that it had almost no magnet on it. I was really surprised when the software spit out an enclosure with a negative volume!!!

2) In college, my roommate had a car with a largish sealed subwoofer in it, which had four 8" woofers in it. The bass was quite weak. I pulled one of the drivers out of it and spent 2 hours measuring the TSPs on it, then modeling a good enclosure for it. We had to reduce the enclose size somewhat with braces, add ports to it and line it with material to absorb reflections. It sounded better, but still wasn't very impressive.

A month later, he took it to a car stereo shop. They figured out in 60 seconds that two of the drivers were wired out of phase. From that day on, this is the first thing I check when listening to anything.

Mistakes I see most often.

1) The builder needs to decide before they start the project, if they are trying to build a system so that they can enjoy the results or are they trying to achieve some sort of perfection.

2) Spending far too much money on the most expensive drivers and fancy crossover parts, when they don't understand anything about acoustic and electrical measurements or hearing. They would be massively better off, reducing their driver budget by a factor of 10, purchasing 20 times as many crossover components, which are each 1/20 the cost of what they think they need, and spending $200 on several of the good books they can use to learn how to take measurements and software for system modeling.

2) In college, my roommate had a car with a largish sealed subwoofer in it, which had four 8" woofers in it. The bass was quite weak. I pulled one of the drivers out of it and spent 2 hours measuring the TSPs on it, then modeling a good enclosure for it. We had to reduce the enclose size somewhat with braces, add ports to it and line it with material to absorb reflections. It sounded better, but still wasn't very impressive.

A month later, he took it to a car stereo shop. They figured out in 60 seconds that two of the drivers were wired out of phase. From that day on, this is the first thing I check when listening to anything.

Mistakes I see most often.

1) The builder needs to decide before they start the project, if they are trying to build a system so that they can enjoy the results or are they trying to achieve some sort of perfection.

2) Spending far too much money on the most expensive drivers and fancy crossover parts, when they don't understand anything about acoustic and electrical measurements or hearing. They would be massively better off, reducing their driver budget by a factor of 10, purchasing 20 times as many crossover components, which are each 1/20 the cost of what they think they need, and spending $200 on several of the good books they can use to learn how to take measurements and software for system modeling.

- Home

- Loudspeakers

- Multi-Way

- What Mistakes Did You Make As A Speaker Design Beginner?