I think my mistakes relate more to my outlook. I feel as if the hobby is one big ongoing project and nothing is ever entirely put to bed.

Here are some of mine:

1. I resisted buying a measurement mic

2. I resisted fully learning sim software

3. Paid too much attention to self proclaimed experts who offered pseudo science/snake oil theories.

I think number 3 was most hindering. Beware gatekeepers who always keep things slightly vague. Good gatekeepers are transparent, sharing and open minded.

However, in the last few years I've learnt to to sit with regret because if I was the same me in the same situation I would make the same decisions.

So, in short, you'll find your own journey and enjoy it your own way! 🙂

Here are some of mine:

1. I resisted buying a measurement mic

2. I resisted fully learning sim software

3. Paid too much attention to self proclaimed experts who offered pseudo science/snake oil theories.

I think number 3 was most hindering. Beware gatekeepers who always keep things slightly vague. Good gatekeepers are transparent, sharing and open minded.

However, in the last few years I've learnt to to sit with regret because if I was the same me in the same situation I would make the same decisions.

So, in short, you'll find your own journey and enjoy it your own way! 🙂

Oh yeah and once when I used order pre cut 18mm MDF as I didnt have a saw I hand sanded 25mm off a 200mm wide panel because I thought they'd cut it wrong. I was looking at the wrong panel.

Measure twice, buy a saw.

Measure twice, buy a saw.

Maybe it is my long history with maintaining an old boat, but I never, never, never use a power tool to fully drive a screw for furniture, cabinetry, speakers, or anything on my boat... All screws are always driven by hand, and always with the correct size pilot hole and counter sink. I also use a screw lubricant, such as wax, with dense hardwoods such as teak, maple, white oak, birch (including birch plywood). I will use a power driver when first installing a screw, but I stop once the screw is a few revolutions from tight. The final tightening is done by hand. I can feel when the screw is tight enough, and any further tightening is just damaging the wood threads. I always remove screws by hand, never with power. I have found I can remove and reinstall screws at least 20 times before the wood threads are worn out.

I don't use T-nuts or threaded inserts when installing drivers. I use wood screws installed as above. Maybe with MDF material, threaded inserts are unavoidable, but with quality plywood, drivers can be removed and reinstalled a dozen times at least without damaging the wood threads.

j.

I don't use T-nuts or threaded inserts when installing drivers. I use wood screws installed as above. Maybe with MDF material, threaded inserts are unavoidable, but with quality plywood, drivers can be removed and reinstalled a dozen times at least without damaging the wood threads.

j.

I built many ported woofer boxes but that created slow bass that could not accurately produce bass transients. That first cycle frequency response of your ported woofer system doesn't include any output from the port. So those low exponentially decaying plucked bass notes and drum beats get the first cycle of the transient crushed because the port hasn't had thee cycles to start ringing. Since each cycle is smaller than the last, you lost the real punch of those notes completely ( I know, you don't believe it. Go measure it yourself.) To avoid that, I build sealed boxes for the punch and accurate transient response,. But to get deep bass required huge sealed boxes and hard to find low resonance heavy cone woofers. Six cubic foot woofer boxes with matrix bracing are neat when you're single and young, but they are heavy and ugly. I finally read the Linkwitz web page and a few other books and figured out that there is a better way. Figure out how much bass you want, max SPL at the lowest frequency. From that you can figure out how much woofer displacement is required to get it. Displacement is all that matters. Displacement is cone area times Xmax. It's how much air the woofer can move. You will quickly find that the price of a woofer tracks linearly with the displacement. Buy a woofer with the required displacement and the lowest free air resonance you can find and put it in the smallest half cube shaped sealed box as appropriate. Now you find the F3 or 3 dB down cutoff of this box is too high to make deep bass? It's going to be 45 or 55 Hz. This does not matter at all. Design a Linkwitz transform at the preamp level to extend the closed box cut off to the lowest frequency you specified at the beginning. You're done. But but but everyone will say, you will bottom out that woofer. No, you bought the woofer with the required displacement to produce the bass you want at that low frequency. But but but that bass boost will use lots of power. Power is cheap and the woofer requires very little power to move to its Xmax at low frequencies. Every woofer I've ever used will hit Xmax at low frequencies long before it will hit it's power limit. Try it. It works. Perfect bass at the SPL and frequency extension you wanted. No slow ported bass, no huge 5 cubic foot boxes trying to get to a low sealed box resonance. You can put that Linwitz filter into JRiver or other streaming software, or equalizerAPO or a miniDSP or build it with a few op amps. There's no need to be stuck with the big boxes or port designs from 1965 anymore.

Last edited:

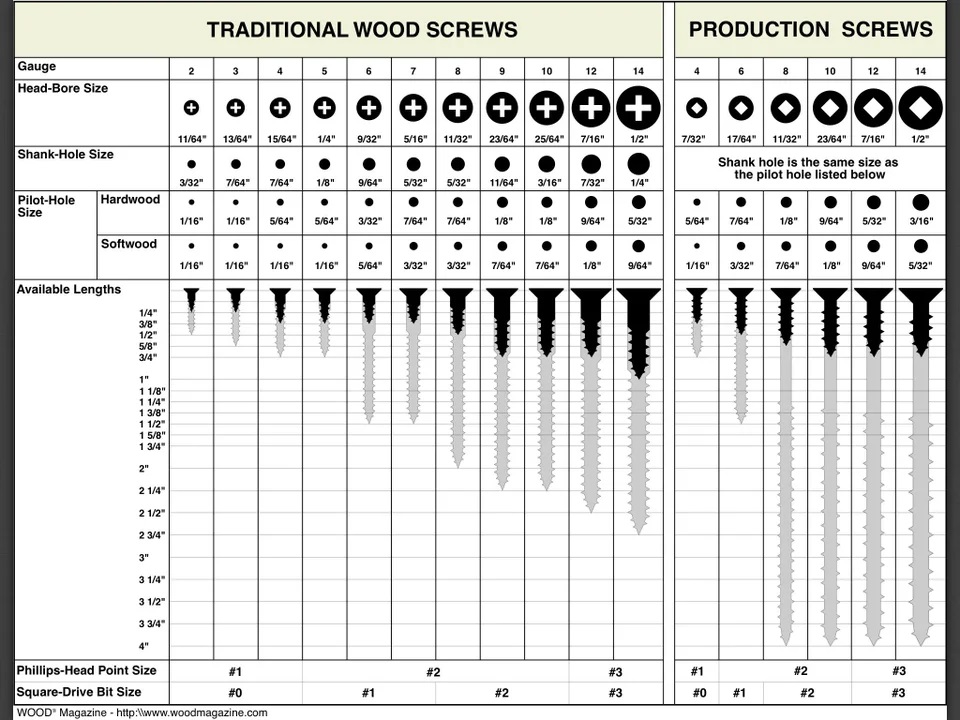

To support the "screwed properly" verses "just plain screwed" line of mistakes.

(Wood Magazine)

Also I try to put a little soap or paraffin on the threads but this might not be necessary.

Jeremy

(Wood Magazine)

Also I try to put a little soap or paraffin on the threads but this might not be necessary.

Jeremy

Hello! What advantage do you feel a QTC of ~0.9 in a sealed enclosure gives?too low Qtc with sealed enclosures usually doesn't sound good. Nowadays I feel around 0.9 sounds best

Qtc of around 0.9 just sounds great with most types of music and the low end is still tight enough to be accurate sounding, mainly with a smaller speaker placed further away from the walls and floor. That nice satisfying midbass punch is also there with a slightly higher Qtc.

I've built tons of sealed enclosure speakers with 0.7 or lower Qtc sealed alignments (acoustic suspension designs being my favorite), but with much larger drivers in appropriately designed enclosures. These by nature already sound "big" and life like, so they don't need the help of a higher Qtc alignment as long as you don't go too big - that hurts mechanical power handling.

Smaller sealed stand mounted style monitors or floor standers need a little more help in the low end acoustically if the drivers are further from any boundaries, even if you run them with subs. There's nothing more depressing than thin sounding speakers with little low end. Many people are hung up on having that perfect transient response on paper but 99% of them won't be happy with the bass (or even low midrange) of small monitor style speakers if the Qtc is less than 0.7 when they're placed on stands. I've come to the conclusion that 0.9 Qtc is the best compromise for good midbass, low end extension and decent transient response from all of the smaller speakers I've listened to, realizing the ones I found most pleasing, specifically in the midbass and lower midrange had a Qtc around 0.8 - 0.9. Otherwise I thought they sounded too thin and imbalanced, even if they had the help of subs. They were also harder to integrate with the subs and sound "together". That makes a ported design more "down to earth" sounding and functional if the speaker is being run without a sub, but its still far more difficult to build a good sounding smaller ported 2 way speaker than a great sounding sealed one (ie. port noise, resonances, midrange port wash, etc).

I've built tons of sealed enclosure speakers with 0.7 or lower Qtc sealed alignments (acoustic suspension designs being my favorite), but with much larger drivers in appropriately designed enclosures. These by nature already sound "big" and life like, so they don't need the help of a higher Qtc alignment as long as you don't go too big - that hurts mechanical power handling.

Smaller sealed stand mounted style monitors or floor standers need a little more help in the low end acoustically if the drivers are further from any boundaries, even if you run them with subs. There's nothing more depressing than thin sounding speakers with little low end. Many people are hung up on having that perfect transient response on paper but 99% of them won't be happy with the bass (or even low midrange) of small monitor style speakers if the Qtc is less than 0.7 when they're placed on stands. I've come to the conclusion that 0.9 Qtc is the best compromise for good midbass, low end extension and decent transient response from all of the smaller speakers I've listened to, realizing the ones I found most pleasing, specifically in the midbass and lower midrange had a Qtc around 0.8 - 0.9. Otherwise I thought they sounded too thin and imbalanced, even if they had the help of subs. They were also harder to integrate with the subs and sound "together". That makes a ported design more "down to earth" sounding and functional if the speaker is being run without a sub, but its still far more difficult to build a good sounding smaller ported 2 way speaker than a great sounding sealed one (ie. port noise, resonances, midrange port wash, etc).

Don't forget impedance in the circuit affects some on the Qtc, like amplifier output impedance and cabling, possible passive crossover components. If box Q is 0.9 then the system Q with electronics included is something higher. 😉

I factor all those other variables in most of the time if there's specific outboard gear influencing final Qtc. Amplifier damping is usually high enough to not change Qtc, unless dealing with tube output xformers. Cabling and inductor DCR usually ends up fairly low enough to not push it up significantly. I don't use cored inductors in the LP (or any part) of my crossovers if I can avoid them because how they affect the sound characteristics of the LF driver. The worst case scenario is maybe 0.5 ohms series resistance added to an 8 ohm LF driver (sometimes 4 ohms, which in theory cuts the series inductor value in half, including some of the DCR). With a very small driver and the resulting tons of BSC needed to flatten response, you can end up needing a laminated steel core inductor, usually netting you low 80s dB/2.83v efficiency... not the kind of speaker I like to build anyways. Once you're in the low 100s hz xover, it's more sensible and practical to go active xover, avoiding a huge series inductor, but the xover LP filter Q (with analog active xover) will affect Qtc depending on filter topology.Don't forget impedance in the circuit affects some on the Qtc, like amplifier output impedance and cabling, possible passive crossover components. If box Q is 0.9 then the system Q with electronics included is something higher. 😉

- Home

- Loudspeakers

- Multi-Way

- What Mistakes Did You Make As A Speaker Design Beginner?