I once designed and built a 80 watt valve push pull amplifier.

Powered it up and it played music ok.

Then the dreaded red plate on one of the valves.

Quick turn off and visual inspection found a missing grid stopper resistor.

Powered it up and it played music ok.

Then the dreaded red plate on one of the valves.

Quick turn off and visual inspection found a missing grid stopper resistor.

I fixed a hot air pencil today. It wasn't blowing any air, and there was a burnt resistor on a controller board yesterday when I opened it up. I couldn't find a schematic, so I slept on it & decided to put in an 800R 1W resistor to see what would happen. It powered up & the resistor didn't get hot, so I called it good.

Attachments

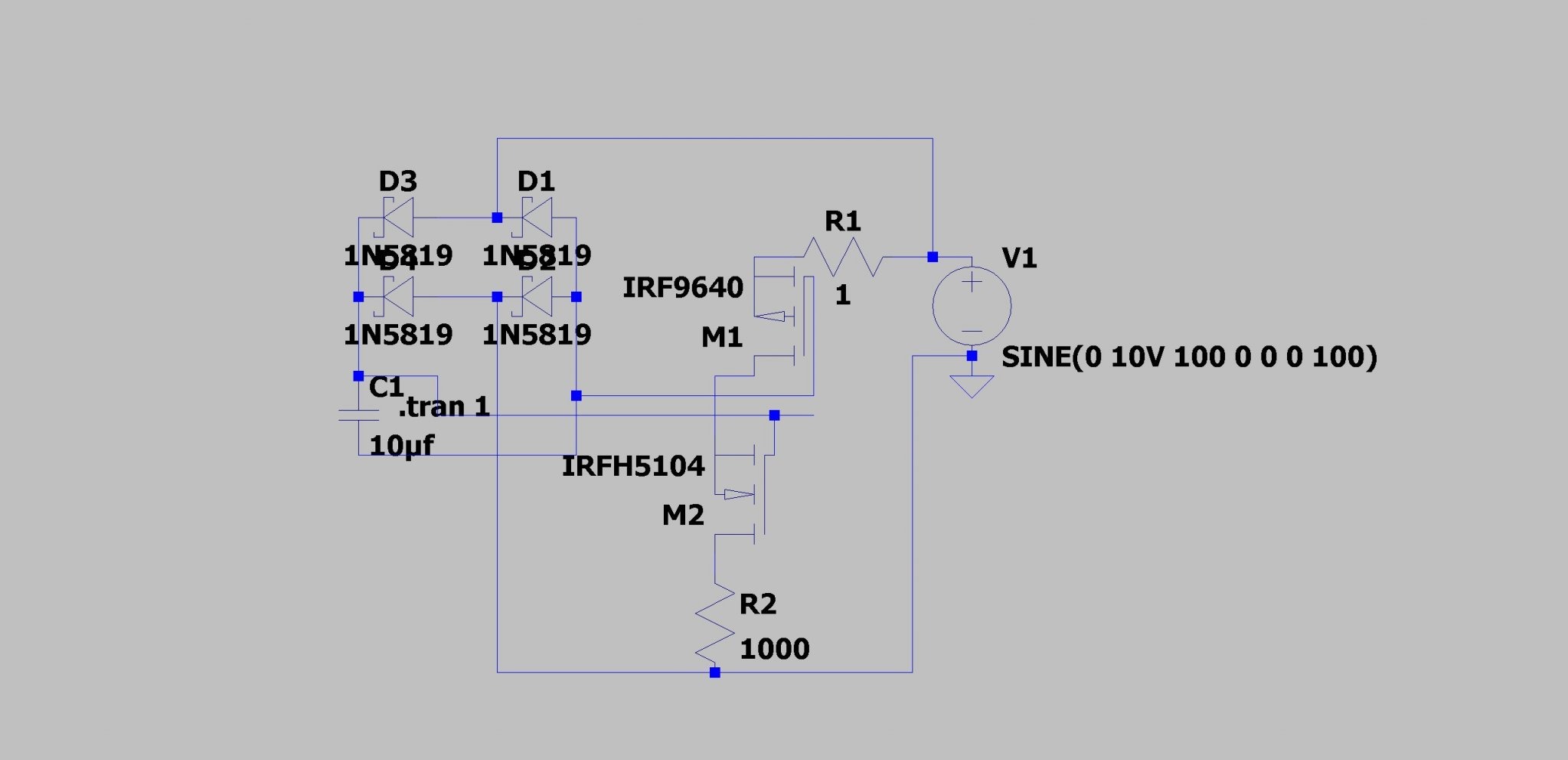

Been working on a DPDT mosfet relay.

It uses 8 mosfets to do the DPDT function.

Took a couple of goes to get it right.

I used wrong mosfet config for first attempt and got 5 volts out when it should have been 12 volts.

Got there in the end.

It uses 8 mosfets to do the DPDT function.

Took a couple of goes to get it right.

I used wrong mosfet config for first attempt and got 5 volts out when it should have been 12 volts.

Got there in the end.

Repaired a Pioneer PL-400 turntable. It had a bad chip controlling the speed. I was able to find a used part on Ebay.

I have found the switches to be more of a problem with the fast-on connectors. They break and then the switch goes intermittent.

I’ve seen cheap switches of every variety sit there and arc between the contacts. If the light is flickering or you hear a buzz coming from the switch itself, get rid of it.

They don't make gear like this anymore...

Hickok 'Cardomatic' Military Tube Tester in for repair.

Opened her up and went Wow!

TCD

Hickok 'Cardomatic' Military Tube Tester in for repair.

Opened her up and went Wow!

TCD

Attachments

Last edited:

When does the light bulb light up?Opened her up and went Wow!

Repaired my "Kala" uke company (same as famous for the uke basses) thin line nylon six string's output connector. Went to plug in the cord and the cheap plastic housing holding the contacts just pushed off the threaded barrel. Replace it with a Switchcraft - now it goes "ping!" when I unplug it.

The light is in series with a multi tap filament transformer, so it appears to be a form of current limiter.When does the light bulb light up?

This tester is pretty complex due to the 'cardomatic' punch card operation. There are almost 200 silver plated connection pins that are activated / not by the holes in punch cards.

All of the voltages for various filament / plate / grids etc are either transformer taps or switched resistors connected through the punch card switch matrix. That switching matrix

appears to be quite sensitive to mechanical setup and dirt etc which was one of the issues that had to be addressed.

It's a very cool piece of test gear - I'd love to own one.

PS The construction is 100% Aluminium for portability, the build quality is amazing. The transformers are all Al. cased and potted in (presumably) some form of Epoxy.

TCD

Interesting! So they knew about that, long before we started suggesting the "light bulb" method for checking if an unknown condition AC powered amplifier has a severe malfunction inside. Long before we were born, more like it...so it appears to be a form of current limiter.

Why is your (old-old) fusebox all Edison-thread sockets? Not just Edison's convenience. You can short-check with a lamp. Goes back well over a century.Long before we were born, more like it...

Oh! Wish I'd known that long ago! The main fusebox in my parents house was fuses up until 10 years ago, and I think some branch circuits still have fuses.Why is your (old-old) fusebox all Edison-thread sockets? Not just Edison's convenience. You can short-check with a lamp. Goes back well over a century.

Got my 2 wheel drive pickup un-stuck out of the mud at my construction site Thursday evening, almost a week after being abandoned there. Jacked the back end up, put it up on 2x12’s and laid a sheet of plywood between them. Drove it right out and back on the driveway.

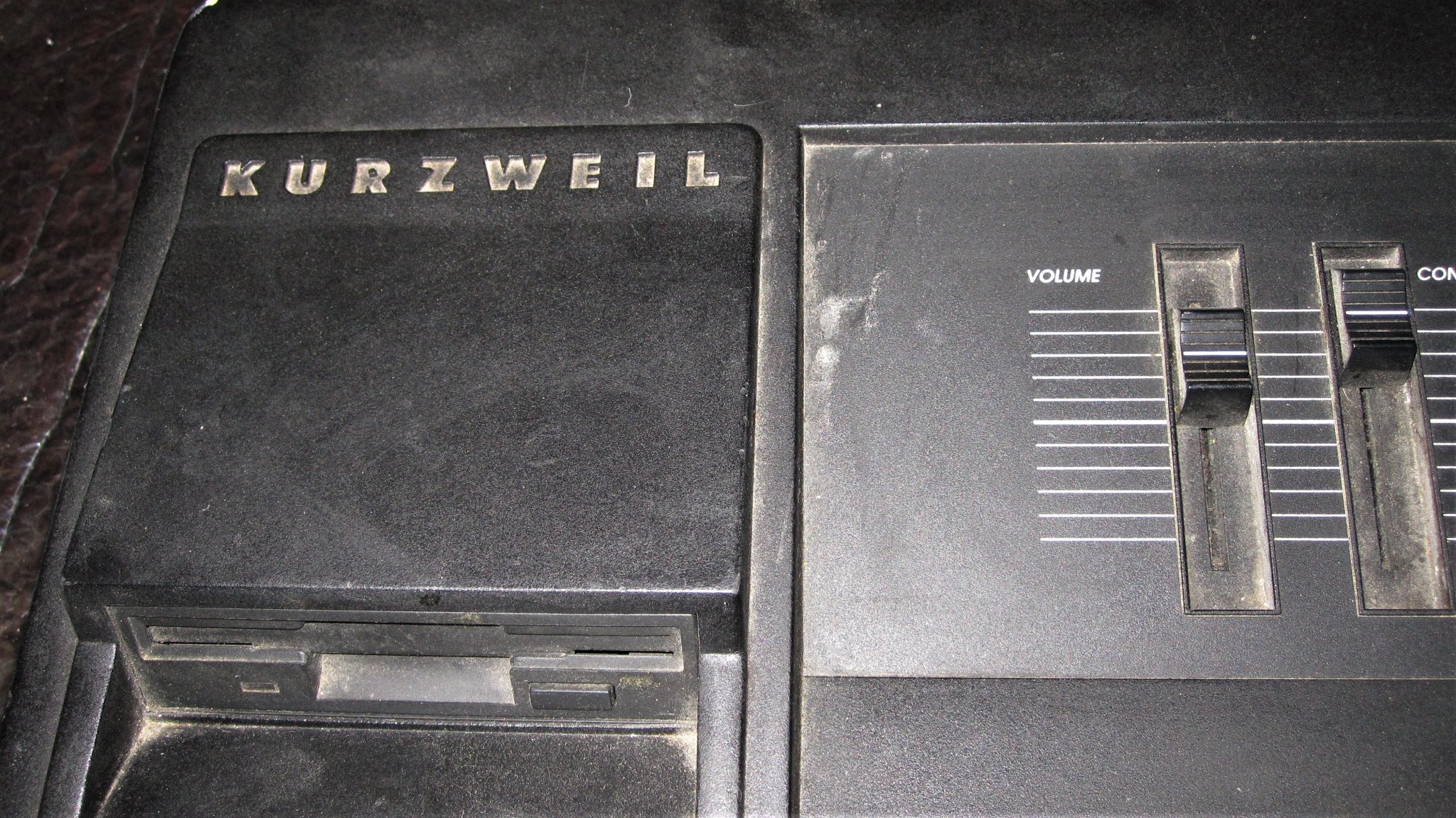

A very old, very battered Kurzweil K2000 v1.0, a rarity. This is a magnificent DSP-synth, extremely versatile, still holds its own 30 years after launch.

Common issue: LCD Backlight is dead. Other issues:

There may be a chip replacement to be done as there is noise if using the internal Digitech Effects. Direct outs are fine.

There may be additional chip replacements to upgrade the firmware: O.S. + Objects.

Common issue: LCD Backlight is dead. Other issues:

- someone left a batter inside the compartment, and it leaked, corroding the terminals

- bulging caps in PSU area

- broken key, easily replaced

- dust and grime - cleaned up

- stuck screw not enabling opening it up easily - caused HDD damage, so replaced HDD with a floppy emulator that takes USB

There may be a chip replacement to be done as there is noise if using the internal Digitech Effects. Direct outs are fine.

There may be additional chip replacements to upgrade the firmware: O.S. + Objects.

Speaking about digital pianos.

I have fixed today silent and too load keys in our Roland HP-3000s digital piano.

It basically needed cleaning the key contacts. The contact are traces on a pcb which get shortened by rubbery/silocon pads. Just like the some remote controls keys.

Each key has two contacts (2x2 pcb traces which get shortened by 2 pads - each pad shortens 2 traces). The piano measures time between closing these contacts and knows how fast the key travelled which tells it how hard a given note should be played.

It is tricky to remove the keys. I have made a key extraction tool out of an old shirt hanger.

Forcing the keys with a screwdriver (like in some youtube videos) was not a good idea with our model. Luckily I did not pursue that route for a long time.

I cleaner/rubbed the contacts with isopropyl alcohol, out it back together and the 30+ year old piano is fine again.

Not as good as the big acoustic Yamaha next to though... but I can't do anything about it.

I have fixed today silent and too load keys in our Roland HP-3000s digital piano.

It basically needed cleaning the key contacts. The contact are traces on a pcb which get shortened by rubbery/silocon pads. Just like the some remote controls keys.

Each key has two contacts (2x2 pcb traces which get shortened by 2 pads - each pad shortens 2 traces). The piano measures time between closing these contacts and knows how fast the key travelled which tells it how hard a given note should be played.

It is tricky to remove the keys. I have made a key extraction tool out of an old shirt hanger.

Forcing the keys with a screwdriver (like in some youtube videos) was not a good idea with our model. Luckily I did not pursue that route for a long time.

I cleaner/rubbed the contacts with isopropyl alcohol, out it back together and the 30+ year old piano is fine again.

Not as good as the big acoustic Yamaha next to though... but I can't do anything about it.

- Home

- Member Areas

- The Lounge

- What did you last repair?