Cool! Now add a battery and relay (and a charging circuit) and you can turn it into emergency lighting 🙂 An 18650 and a boost converter should power those LEDs for hours 🙂

https://www.instructables.com/12v-Automatic-Charger-Auto-Cut-OFF/

I made one from a 339 or 358, don't remember. Circuit off the internet.

Also put a change over relay, when the mains failed, the light came on.

Used the two poles available on the relay.

3 x 1W power LEDs, and 3 x 4V, 1.5 Ah batteries, so 12V, as factory emergency lights.

Automatic control of charge, and enough time to get people out when needed.

I made one from a 339 or 358, don't remember. Circuit off the internet.

Also put a change over relay, when the mains failed, the light came on.

Used the two poles available on the relay.

3 x 1W power LEDs, and 3 x 4V, 1.5 Ah batteries, so 12V, as factory emergency lights.

Automatic control of charge, and enough time to get people out when needed.

Lexicon PCM70 : Lucky for me simply recapping all electrolytics got the unit working!

That's a really good sounding unit! Last summer I repaired a Lexicon LXP-15 that I got for really cheap as it had very scratchy pots: 78 USD or so.

Looking inside, there were bad leaks at the PSU area. It was the Al. Electrolytics that leaked onto the board, eating up at traces. One diode was also bad. I repaired all the traces, changed the caps and put in a new diode and got it working again.

I have excellent digital effects in my Kurzweil K2500, they're in a separate module called KDFX, but I do like the LXP-15 too. Some people say the rack version, KSP8 is even better than Lexicon's better models, but the rack version has an SMPS whereas my synth has a Linear Regulated PSU.

I have a few mods planned for the LXP-15.

The unit I have already had some hardware mods by the manufacturer, preparing it for a firmware upgrade, so after getting a chip for around 20 CAD, I now have a LXP-15 II.

The old amp is now sweet as ever. Totally puts to shame the Parasound. Guess I did not mess it up. I was a Hafler 120 I converted to Exicons and Miller compensation, a few changes to physical layout and a few resistor changes to optimize IPS and VAS current.

I did spend a week beating my head into LTSpice and found I could eek a little lower distortion and stability margin, but don't think it is worth it. It benches .004% 1K @ 60W. ( Sims .00004 and I can get .00003 but that is with no reality of layout parasitics) Sim says another 5 degrees @ zero gain. Again, reality may not be that close anyway. It is almost tempting to get another to see how far it could be pushed. Dale mil spec resistors, degen the IPS current mirror, stiffer CCS and pi-filter on the rails for IPS and VAS.

I did spend a week beating my head into LTSpice and found I could eek a little lower distortion and stability margin, but don't think it is worth it. It benches .004% 1K @ 60W. ( Sims .00004 and I can get .00003 but that is with no reality of layout parasitics) Sim says another 5 degrees @ zero gain. Again, reality may not be that close anyway. It is almost tempting to get another to see how far it could be pushed. Dale mil spec resistors, degen the IPS current mirror, stiffer CCS and pi-filter on the rails for IPS and VAS.

unofficially, not sure if they would meet local 'code' as they are. But it and the circuit posted would certainly work!Cool! Now add a battery and relay (and a charging circuit) and you can turn it into emergency lighting 🙂 An 18650 and a boost converter should power those LEDs for hours 🙂

That is a pretty cool clock, though. 🙂 Does yours have the little thumbwheel feature to kick-start the synchro motor so it doesn't run backwards?

I always know I'm worklng on a really, really old Hammond organ when the boilerplate inside still reads Hammond Clock Company.

I always know I'm worklng on a really, really old Hammond organ when the boilerplate inside still reads Hammond Clock Company.

What model is that? Pictures?

I grew up with a Hammond M2 and now have an M3.

Speaking of synchro motors, a kid like me could get the M2 to run at a much slower speed if you did not hold the starter motor for long enough.

Made a better Halloween organ.

Too bad I can seem to do it with the M3.

I grew up with a Hammond M2 and now have an M3.

Speaking of synchro motors, a kid like me could get the M2 to run at a much slower speed if you did not hold the starter motor for long enough.

Made a better Halloween organ.

Too bad I can seem to do it with the M3.

Did that clock actually get sold, at that price?

You would think it was a rare item or something collectors are crazy about...

You would think it was a rare item or something collectors are crazy about...

Yes Jim, it's got the original kick-start synchronous motor and it runs perfectly.That is a pretty cool clock, though. 🙂 Does yours have the little thumbwheel feature to kick-start the synchro motor so it doesn't run backwards?

I always know I'm worklng on a really, really old Hammond organ when the boilerplate inside still reads Hammond Clock Company.

All brass gears too.

Well, let me tell you about the one I have.... it should rank as a prime collectors piece.Did that clock actually get sold, at that price?

You would think it was a rare item or something collectors are crazy about...

Back in October 31, 1994 , the city (Phila) demolished the old Sears Roebuck building here.... imploded it.

The next day, our shop counterman took a ride to visit the site, and in the rubble found that clock.

Apparently it was in one of the offices there, and miraculously survived the implosion.

The white translucent glass dial and it's outer glass cover still unbroken!

It even had its original 5 bulb back-light illumination intact, but the bulbs were burned out.

The counterman handed it to me, saying, "here's your early Christmas present"

I spent time on it, removing all the old black paint, polished the two end caps (at 3 and 9 o'clock).

Those decorative caps are made from heavy chrome castings, like auto bumpers of the era.

Primer, and 6 coats of gloss black paint and it looks fantastic for an 84 year old clock.

Overhauled the motor and lubed it, and replaced the rusted old bulb sockets - installed 10 white LED's with a small transformer and 78xx regulator, new wiring etc... it's got a sweet glow when lit up.

It hung all those years on the back wall of the shop, till we closed the shop in 2016, and I brought the old girl home for my workbench.

So 'this' particular Hammond clock has a neat history behind it. - and likely worth a bunch as a result.

Nevertheless, I won't sell it.

I did put a label on the back cover with the history and dated it though.

The story of Hammond goes like this....as far as I can tell.

They made clocks in the 1930's, before they made organs.

However, eventually, they began to face backruptcy - money issues.

Sears, in a business deal with Hammond, ordered a ton of these clocks for their factories and offices, saving Hammond from closing up, and then Hammond got into the organ business.

Here's a current ebay listing for one.. apparently they seem to go for high prices.

Attachments

My beloved Pure DRX-701ES DAB tuner had a little attention today. The caps in the PSU have been known to cause trouble and the two 470uF/25v reservoir caps were slightly bulged on top. The 2200uF 25v also got replaced. The board was already drilled out for leaded parts and so these are what I fitted, some quality Panasonic 35v replacements. Those odd looking do-dahs between the caps are marked on the board as PTH so presumably some surge limiting thermistors.

The opamp's which were generic something or others got swapped a few years back for LM833's (not the old LM833N but the TI upgrade which uses a quasi complementary NPN output stage). These are an under rated chip imo. The chip removal and soldering was all done by hand using a Philips soldering station and large bit.

I should have measured those curious looking things next to that particular LM833. Could be some kind of filter or coil. Seems to be one for each channel.

The opamp's which were generic something or others got swapped a few years back for LM833's (not the old LM833N but the TI upgrade which uses a quasi complementary NPN output stage). These are an under rated chip imo. The chip removal and soldering was all done by hand using a Philips soldering station and large bit.

I should have measured those curious looking things next to that particular LM833. Could be some kind of filter or coil. Seems to be one for each channel.

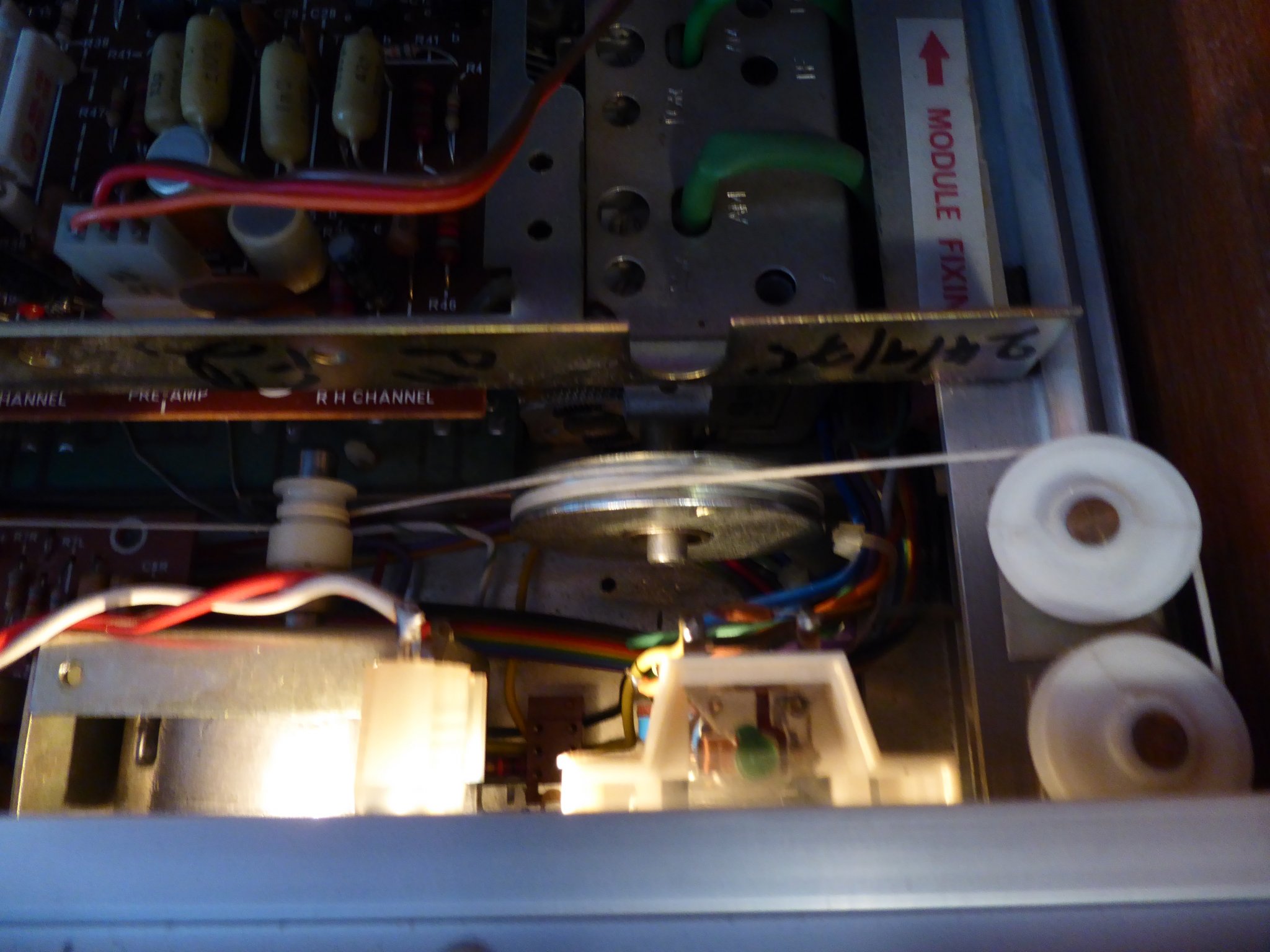

I s'ppose you could call it a repair, I've a Leak 2000 tuner/amp and the dial cord got detached somehow. I turned the tuning knob and found it wasn't working.

What I found when I removed the top of the cabbnet was a ball of cord up one end of the set.

I've a service manual which has a whole page devoted to the tuning cord and "how to replace it using the special tool." Which I didn't have.

It's impossible to get your fingers down here.

I managed to get it back on by making a tool from a piece of garden wire forming a loop at one end and using this to wind the cord back round the two spindles. At least the manual told me how many turns around each and in which direction, Then just a case of looping the cord around the four jockey wheels.

During the proceess I'd moved the tuning gang slightly. The "special tool" would have keept it in place. But it was easy enough to unhook one side of the pointer bracket and slide it about a centimetre to give a true reading. Whilst reading the manual I found out what the mute control was for when setting the AFC. I'd had this second-hand tuner/amp for fifteen years and had never before bothered to find out what it was for.

It must be near fifty years old now and still working. Though I recently bought another cheaply, as a spare. This one had started "motorboating." But they couldn't find anything wrong with it. It might have been a capacitor picking up something from some of my other stuff.

They don't make 'em like they used to.

What I found when I removed the top of the cabbnet was a ball of cord up one end of the set.

I've a service manual which has a whole page devoted to the tuning cord and "how to replace it using the special tool." Which I didn't have.

It's impossible to get your fingers down here.

I managed to get it back on by making a tool from a piece of garden wire forming a loop at one end and using this to wind the cord back round the two spindles. At least the manual told me how many turns around each and in which direction, Then just a case of looping the cord around the four jockey wheels.

During the proceess I'd moved the tuning gang slightly. The "special tool" would have keept it in place. But it was easy enough to unhook one side of the pointer bracket and slide it about a centimetre to give a true reading. Whilst reading the manual I found out what the mute control was for when setting the AFC. I'd had this second-hand tuner/amp for fifteen years and had never before bothered to find out what it was for.

It must be near fifty years old now and still working. Though I recently bought another cheaply, as a spare. This one had started "motorboating." But they couldn't find anything wrong with it. It might have been a capacitor picking up something from some of my other stuff.

They don't make 'em like they used to.

I've done many "dial cord" jobs over the years, they can be nerve racking sometimes, and cause me to spew choice vile language.I s'ppose you could call it a repair, I've a Leak 2000 tuner/amp and the dial cord got detached somehow. I turned the tuning knob and found it wasn't working.

What I found when I removed the top of the cabbnet was a ball of cord up one end of the set.

Some, without available stringing instructions - those you just need to sit and study how the cord is routed.

That Leak receiver would be an easy job for me.

And then there are those vintage tuner-preamps that have multiple cord drives, one for the tuning scale, and several others for indicators like bass-treble-balance like Zenith and RCA Victor did.

You turned the bass etc knob, and an illuminated "pointer" would glow through a small rotary dial and visually tell you the setting. - fancy stuff indeed.

But some of the worst re-stringing jobs were those German radio sets from the 1950's and 60's! - Blaupunkt, Grundig, Normandy, etc.

You had to deal with shiifting clutch assemblies, steel wire cords, and critical winding around tuner pulley assemblies.

Those...... caused a lot.... a lot, of cursing in the shop!

I learned to be a skilled contortionist with a filthy mouth.

That's quite a story! Thanks for sharing.Well, let me tell you about the one I have.... it should rank as a prime collectors piece.

Back in October 31, 1994 , the city (Phila) demolished the old Sears Roebuck building here.... imploded it.

The next day, our shop counterman took a ride to visit the site, and in the rubble found that clock.

Apparently it was in one of the offices there, and miraculously survived the implosion.

The white translucent glass dial and it's outer glass cover still unbroken!

It even had its original 5 bulb back-light illumination intact, but the bulbs were burned out.

The counterman handed it to me, saying, "here's your early Christmas present"

I spent time on it, removing all the old black paint, polished the two end caps (at 3 and 9 o'clock).

Those decorative caps are made from heavy chrome castings, like auto bumpers of the era.

Primer, and 6 coats of gloss black paint and it looks fantastic for an 84 year old clock.

Overhauled the motor and lubed it, and replaced the rusted old bulb sockets - installed 10 white LED's with a small transformer and 78xx regulator, new wiring etc... it's got a sweet glow when lit up.

It hung all those years on the back wall of the shop, till we closed the shop in 2016, and I brought the old girl home for my workbench.

So 'this' particular Hammond clock has a neat history behind it. - and likely worth a bunch as a result.

Nevertheless, I won't sell it.

I did put a label on the back cover with the history and dated it though.

The story of Hammond goes like this....as far as I can tell.

They made clocks in the 1930's, before they made organs.

However, eventually, they began to face backruptcy - money issues.

Sears, in a business deal with Hammond, ordered a ton of these clocks for their factories and offices, saving Hammond from closing up, and then Hammond got into the organ business.

Here's a current ebay listing for one.. apparently they seem to go for high prices.

Imagine no Jimmy Smith, Lonnie Smith, Keith Emerson, Larry Young, Booker T Jones, Gregg Allman, Brian Auger, Jimmy McGriff, Pigpen... They would all have been playing electric piano's! Or Wurlitzers - yuk! I cant imagine a music world without the 2nd / 3rd harmonic percussion sound.

Someone once told me a similar story about BMW; about to go bankrupt. But they had this little 250cc single cylinder MC, which sold enough to keep them in business and then become what they are today.

Don't forget the other half of that magical Hammond organ equation, the Leslie tone cabinet!

I will raise a glass this New Year's Eve to both Laurens Hammond and Don Leslie for bestowing that timeless sound upon us. I will then listen to ELP's Trilogy in surround sound! Happy New Year everybody!

I will raise a glass this New Year's Eve to both Laurens Hammond and Don Leslie for bestowing that timeless sound upon us. I will then listen to ELP's Trilogy in surround sound! Happy New Year everybody!

You know how folks are making PWM sine wave generators for their TT motors? I bet the same could be done for the sync motor in you M3. Then you could tune the keyboard to any pitch you wanted - within reason. I did it on a RTR tape deck one time using a small Korg synth and a power amp that could do 110 output. I wonder what half-speed percussion would sound like? Tong!What model is that? Pictures?

I grew up with a Hammond M2 and now have an M3.

Speaking of synchro motors, a kid like me could get the M2 to run at a much slower speed if you did not hold the starter motor for long enough.

Made a better Halloween organ.

Too bad I can seem to do it with the M3.

There were a couple of such things back in the day. I believe Hammond made a 110V oscillator accessory, mainly intended for converting organs between 50 & 60 Hz. A quick search reveals several different efforts at a Hammond motor transposer circuit, more than I expected. Interesting...

- Home

- Member Areas

- The Lounge

- What did you last repair?