Not with an English threaded bottom bracket. And those old one piece cranks went through bearings like water - it would get wallowed out inside a week climbing hills of any consequence. As it is I get 6 months out of a BB - and that’s using it well past it’s sell by date. Good thing the BBs are only about $40 for a Dura-Ace.

I take it you're not using sealed bearings then?

They even make a cartridge for older frames...

https://www.walmart.ca/en/ip/FSA-BB-6000-MegaExo-Cartridge-Sealed-BB-English/PRD2PVT3W6H7ZU9

They even make a cartridge for older frames...

https://www.walmart.ca/en/ip/FSA-BB-6000-MegaExo-Cartridge-Sealed-BB-English/PRD2PVT3W6H7ZU9

You just get correspondingly more time out of ceramic bearings. The dollar per run hour ends up being exactly the same, with the added complication of the extra corrosion from leaving it in longer. When you pull it every 6 months it never gets a chance to weld itself to the frame.

I've been running the same sealed Mid BB on my bike that it came with in 2005. OTOH, BMX tend to stand up to hard use...

They press in like on a car...

They press in like on a car...

The seals are the reason for longevity, they protect the metal from moisture, and possibly salty moisture from roads covered with salt in winter.

Use good quality seals the next time you do maintenance...

Use them at both sides of the shaft., where it comes out of the frame.

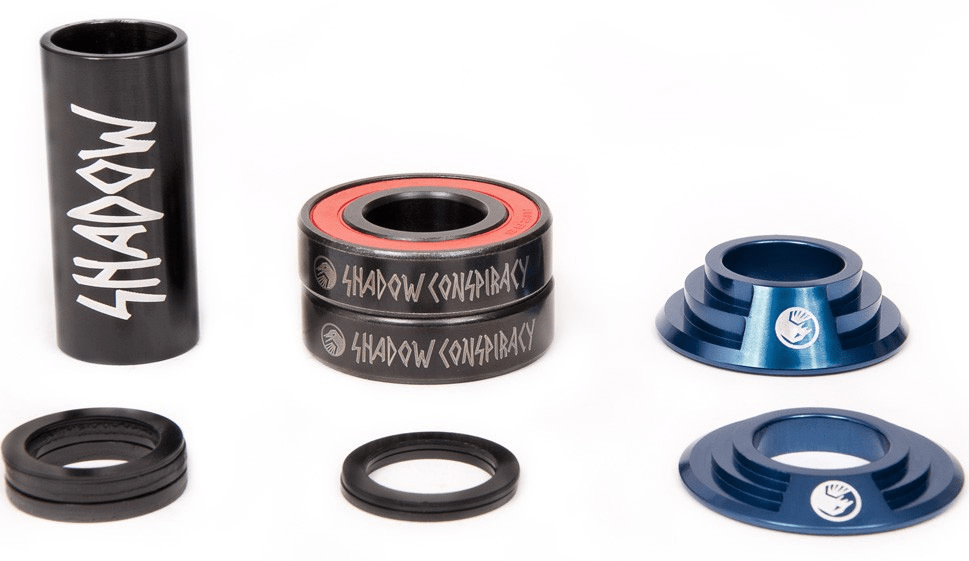

And try to put FAG, SKF, Timken or NTN bearings, or those from a reputed supplier. Use the 2 rubber seal type as in above photo.

Like capacitors, bearings also come in different quality types, from superlative to scrap.

Use good quality seals the next time you do maintenance...

Use them at both sides of the shaft., where it comes out of the frame.

And try to put FAG, SKF, Timken or NTN bearings, or those from a reputed supplier. Use the 2 rubber seal type as in above photo.

Like capacitors, bearings also come in different quality types, from superlative to scrap.

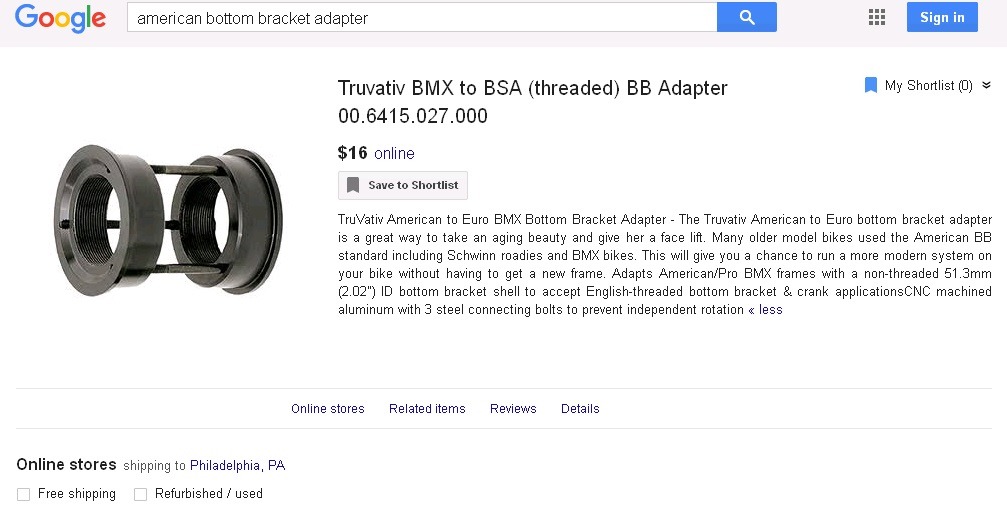

I had to switch out the American BB on my Murray bike in order to change the pedal arangement.

I got this, works great, easy to install, and can use the european cranks.

I got this, works great, easy to install, and can use the european cranks.

Repurposed an old Nokia phone charger to power daughter's crappy battery powered Christmas tree lights.

A set of 4 AAs wouldn't even last an evening. She was surprised when I turned up for Christmas Dinner with a soldering iron.

A set of 4 AAs wouldn't even last an evening. She was surprised when I turned up for Christmas Dinner with a soldering iron.

Fixed the inlaw’s robo cleaner. Twice - once for the charger cable damage due to puppy mawling and the second time the battery pack connect pin seems to have popped out of the connector block. All working now.

Robo cleaners are for the LAZY crowd.Fixed the inlaw’s robo cleaner. Twice - once for the charger cable damage due to puppy mawling and the second time the battery pack connect pin seems to have popped out of the connector block. All working now.

I'm Old School and staying there.

I repaired a Christmas LED candela -- put the battery contactor in white vinegar for a few minutes. Only one of the six had been damaged.

I dug out an amp I built a year ago to find it was still complete - just missing the tubes. I thought I had junked it for the parts.

So I put in 4 6P36S tubes, turned it on, and blew the four screen resistors... I then realized I built it for 6P45S, not 6P36S! Oops!

New resistors, sockets rewired, and bias lowered to 80mA and all seems well.

So I put in 4 6P36S tubes, turned it on, and blew the four screen resistors... I then realized I built it for 6P45S, not 6P36S! Oops!

New resistors, sockets rewired, and bias lowered to 80mA and all seems well.

I attempted to replace the lamp in my 2012 Hotpoint oven. Due to (surprise!) heat in the oven the Edison base had become somewhat oxidized, so when I twisted, the bulb envelop came out, but not the base. In the process of prying out the base with a needlenose, I shorted out one of the dangling wires inside the base. This caused a ginormous spark. I their genius wisdom, the GE engineers decided we don't really need a fuse anywhere in the range so when the short occurred, the oven controller PCB traces became the fuse, and they plated both trace side PCBs with and odd solder, Cu metal plate. This plating is impossible to remove, even if I repaired the traces. Luckily, I found a replacement controller on ebay for $50 - otherwise whole thing would go to the landfill. --- For want of a bulb. Never buy a GE anything. Let's hope their jet engines are better than this crap. BTW, I also have a 1956 Westinghouse range that still works perfectly.

I would have pulled the fuse/turned off the breaker. I'm used to getting out the old base with a potato and I like it when the power is off for that 🙂

Hindsight is the clearest! Shoulda woulda ...I would have pulled the fuse/turned off the breaker. I'm used to getting out the old base with a potato and I like it when the power is off for that 🙂

Alas...... COMMON SENSE is in short supply these days.Think anything should be unplugged before sticking tools and fingers inside it.

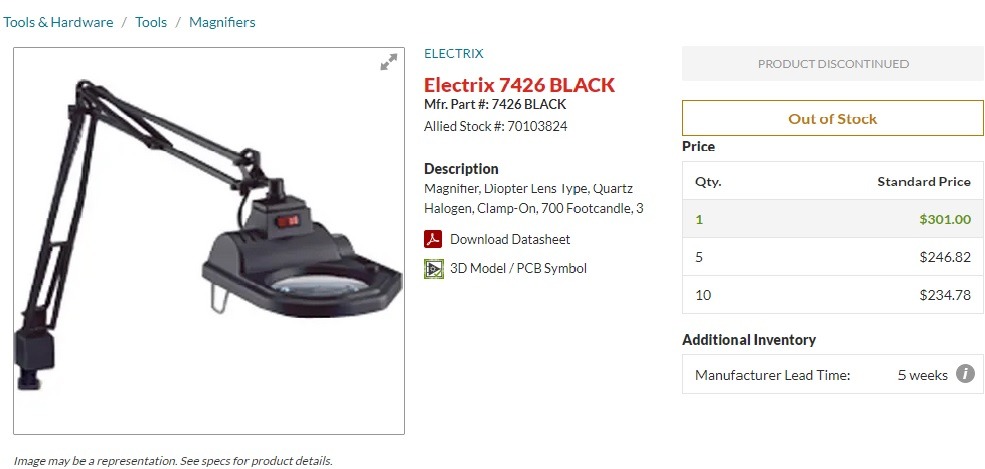

Well, the latest thing on ON THE BENCH today is my over-the-bench swing-arm lamp/magnifier.

I've had it ever since at the shop, and now use it over my basement workbench.

Industrial design Electrix model 7426. (West Haven CT.)

The lamp uses a DC bayonet halogen 100w bulb - they cost $17 each to replace.

The fixture itself is expensive, I'd bet no one on here has one on their bench.

But for the price, it has its design issues.

So, after 2 bulbs overheated and died, I decided to.... OMG!..... Modify the damn thing.

For a standard 100w screw in bulb. (much cheaper)

There is enough room "under the hood" so why not?

Now it puts out the same amount of light, and uses the common lamp bulbs - and I'm happy.

I've had it ever since at the shop, and now use it over my basement workbench.

Industrial design Electrix model 7426. (West Haven CT.)

The lamp uses a DC bayonet halogen 100w bulb - they cost $17 each to replace.

The fixture itself is expensive, I'd bet no one on here has one on their bench.

But for the price, it has its design issues.

So, after 2 bulbs overheated and died, I decided to.... OMG!..... Modify the damn thing.

For a standard 100w screw in bulb. (much cheaper)

There is enough room "under the hood" so why not?

Now it puts out the same amount of light, and uses the common lamp bulbs - and I'm happy.

Last edited:

I've seen someone use a 36" wire cutter to cut through a LIVE 240VAC wire.

Fortunately he was holding the insulated handles.

I tried to scare the heck out of him so he wouldn't do that again.

He may have gone into business instead of engineering, no great loss.

Fortunately he was holding the insulated handles.

I tried to scare the heck out of him so he wouldn't do that again.

He may have gone into business instead of engineering, no great loss.

- Home

- Member Areas

- The Lounge

- What did you last repair?