Not a chance.

110dB@20Hz requires a 38.8mm one-way Xmax.

Similarly, the McCauley subwoofer linked above would also have excursion troubles.

Chris

right, only 24.3mm but way above the 14.5 listed.

Now the spectral content of music is way down below 33Hz, so you can put the gain up 5dB with very little chance to overdrive it.

Sorry for the late reply to post #211 page 22. I refer to the following thread for a discussion on this:Your maths is out.

If you double the cones, each must move half the amount, so that the same volume of air is being shifted.

With regards to the rest of it, you'd also double the radiating area of the cabinet, so any sound passing through the cabinet walls will also increase in level. Similarly, any sound bouncing around inside the cabinet and exiting via the cone will also increase.

No net gain or loss, I'm afraid.

I do think I covered the unwanted cabinet sound portion of this quite comprehensively in an earlier post: https://www.diyaudio.com/forums/multi-way/360015-box-sound-7.html#post6338825

Chris

wiring parallel or series sensitivity rules?

Specifically posts #7 and #13.

I perhaps should have mentioned mutual coupling in my original post.

Regarding surface area of the box. Since the drivers would usually be in the same box 1/6 of the surface is shared (2 sides out of 12 for 2 boxes) and the forces would cancel out, therefore we would get a moderate gain of 17% less radiating surface area compared with two boxes.

Also overall we would have twice the stuffing, so even if the power is only halved we would have more absorbency overall.

Last edited:

Are you sure it was down to air pressure? I have some U-frame subs which twisted severely until I sat them on sorbothane feet.

Whatever caused it it was in time with the bass.

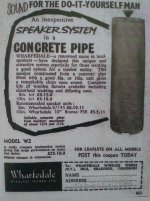

Is there a deflector cone magically floating above it? Ah, what they call a diffusing cone presumably

Yes, I'm not sure why they don't just stick the driver in upside down ( I've done this, twice with paper cones, both times they sounded awful, once with woven glass fibre cones - quite nice ). I think they had to control the standing wave with an internal baffle, once you get rid of box vibration it makes other distortions more clear. Perhaps one for the single man only ?

Least boxy sounding speaker award goes to my old pair of LS3/5A. Amazing imaging and they truly disappear, even more than my open baffles. Knuckle test tells the story. Indeed the box is important...

What if the back panel is taken off from a standard 2-way or 3-way speaker box? And, leave it some distance away from the wall?

I tried something similar, there was a pronounced resonance caused by the wave from the driver ( full range in this case ) exiting the open back, reflected as the opposite wave and going back into the box, I stuffed a bit of foam in and quite transformed the speakers, they sounded very natural after that, just lacking in bass. A more interesting experiment might be to cut the back of, then add a new one with a rubber gasket inbetween it and the box.

A more interesting experiment might be to cut the back of, then add a new one with a rubber gasket in between it and the box.

Can you explain this? I am a complete newbie on audio matters. 🙂

The BBCLs35a has the front ( and on some models the rear ) panels screwed on against rubber gaskets, because of this it has a very dead cabinet. Perhaps it would be as practical to glue rubber sheets and then mdf panels to the outside.

I did a box once where I did a home made lamination. I used MDF for the interior walls and used solid Oak (no voids, knots, etc.) for the exterior. This was probably as good as thick, solid concrete for dead quiet; no detectable flex or hint of "boxiness". The shape of the box was pentagonal and even the top and bottom panels were made to not be parallel. All internal bracing and stiffeners were also made to be non-parallel...about as non-boxy as I could do all by myself anyway...(not exactly B&W "matrix" stiff but oh so much easier than all of that would have been)

I have done some tests with smaller pieces of boards as mdf, particle, plywood and solid pine, it appears that a particle board glued to mdf board gives a very inert panel that is very good for speaker boxes, more inert that mdf glued to mdf or particle glued to particle board. I have also tried to glue boards together with silicone, it appears to be an advantage too but i need to run some more tests.

Summary: a loudspeaker box should not be build with a single sheet board, if you must it seems better to use particle board then mdf, much better is to mix two materials like mdf and particle board

Summary: a loudspeaker box should not be build with a single sheet board, if you must it seems better to use particle board then mdf, much better is to mix two materials like mdf and particle board

yep, a sandwich or laminate of two different materials makes sense. Maybe a rubber sheet between would improve it more? I know some have used two panels with sand in between with very good results as well.

i have been told many years ago from a very reliable source that the very best solution would be two sheets of plywood glued together with a damping glue, and bracings should be of solid wood only

it's a bit early in my tests but the above does not seem to be completely correct

it's a bit early in my tests but the above does not seem to be completely correct

Marine grade plywood would be the best. It has no voids so it is very solid 100%. Plywood is better than some people say because of the alternating grain patterns. The cheapest plywood however is to be avoided because of voids and other defects making it much less than ideal ( ie not uniform thickness or density).

I have done some tests with smaller pieces of boards as mdf, particle, plywood and solid pine, it appears that a particle board glued to mdf board gives a very inert panel that is very good for speaker boxes, more inert that mdf glued to mdf or particle glued to particle board.

What did you see that made you decide this? I've been thinking about trying particle board for my next CLD tests. Particle board for the inside box, and MDF for the outside box.

i am sorry to say that i might have come to the wrong conclusion, my test panels has changed character quite a bit, it appears that the white glue i used had not fully hardened when i runned the tests. now when the glue has hardened more the performance has gone worse for all panels, and the particle board glued to mdf seems no longer to be a good choice

sheets glued together with silicone seems to performa a lot better but it is best to wait a few more days if those characters changes too

sorry for that!

sheets glued together with silicone seems to performa a lot better but it is best to wait a few more days if those characters changes too

sorry for that!

I used a very good quality wood glue between my two panels. I then clamped them together. Then I also used enough wood screws to ensure a uniform binding force. I did use a trowel with spacings like one would use when cementing ceramic tiles. Perhaps the is the main difference here???

- Home

- Loudspeakers

- Multi-Way

- What can I do against 'box sound' ?