Open baffle is a speaker without a back - i.e. open.

.............

What if, I close the bass reflex vent (situated in front) and install passive radiator in the back? Would the box become more boomy, without the boxy sound? I am asking questions, before doing anything. 🙂

A speaker rated as 4ohms will often have a measured dc resistance of around 3ohms.Looking at that drawing in the link, what if one take a standard loudspeaker box and cut off about 2/3 cabinet from the back, would it become an open baffle speaker?

Another question, bit off topic, how to make a 3Ohm 2-way speaker box to a 4Ohm one? I haven't opened it yet.

Sorry, i have not read all the replies.

Are you asking because you do not have the room / space for open baffle drivers, i found OB they do need to be well away from walls to get that spacious kind of audio, low colouration, so big rooms are necessary.

I have got good results from using the visaton B200 driver, and cutting a hole in the wall behind, so that the Visaton B200 uses the room behind, which is the kitchen as the " Enclosure " so-to-speak and it works really well, very impressed, open sound and my smallish living is not dominated by big ugly boxes lying around especially as i have a 7.1 set up.

Are you asking because you do not have the room / space for open baffle drivers, i found OB they do need to be well away from walls to get that spacious kind of audio, low colouration, so big rooms are necessary.

I have got good results from using the visaton B200 driver, and cutting a hole in the wall behind, so that the Visaton B200 uses the room behind, which is the kitchen as the " Enclosure " so-to-speak and it works really well, very impressed, open sound and my smallish living is not dominated by big ugly boxes lying around especially as i have a 7.1 set up.

Last edited:

Got an idea for (largish) multiway speaker main enclosure, that shouldn't be too difficult to build and could potentially enable some experiments with quarter wave attenuators for standing waves inside the enclosure.

Here is the idea three layers XPS sheet sandwitched between ply or mdf, use some appropriate glue for some CLD effect. Nothing new yet but one could make some cutouts to the inner layer of ply and a leave a cavity into the XPS foam, fill in some wool. Similar thing to what this thread is about but for the woofer: 3D Printed Metamaterials , Yamaha NS-5000 has something like this implemented but using some kind of resonators "inside" the box. It could be benefitial to dampen out some of the worst standing waves in the enclosure I think. A prototype shouldn't be too hard. Leave one wall adjustable by using some screws instead of glue, measure and adjust the cavity within that wall. I've got all the materials at hand so might try it sometime near future unless someone shoots this down as not possible/practical. I haven't done any math yet, just popped into my mind.

Let me know what you think?🙂

Here is the idea three layers XPS sheet sandwitched between ply or mdf, use some appropriate glue for some CLD effect. Nothing new yet but one could make some cutouts to the inner layer of ply and a leave a cavity into the XPS foam, fill in some wool. Similar thing to what this thread is about but for the woofer: 3D Printed Metamaterials , Yamaha NS-5000 has something like this implemented but using some kind of resonators "inside" the box. It could be benefitial to dampen out some of the worst standing waves in the enclosure I think. A prototype shouldn't be too hard. Leave one wall adjustable by using some screws instead of glue, measure and adjust the cavity within that wall. I've got all the materials at hand so might try it sometime near future unless someone shoots this down as not possible/practical. I haven't done any math yet, just popped into my mind.

Let me know what you think?🙂

Last edited:

oh, there is bad typing straight from the start, can't edit so. Not three layers XPS but the whole wall construct is three layers total. Not sure if XPS is familiar name for others? I mean the construction insulation board, closed cell foam. Easy to cut, cheapish, stiff, various thicknesses available.

Hi Tmuikku,

I've been contempling something similar but from different reason initially ( need a material i can 'shape' the inside of the box with hot knife).

I wonder a few things about a cld built like that: wich kind of adhesive to use and if a dedicated layer of sorbothane could be of any benefits?

I suppose it could works very well for a dedicated mid cab.

Maybe Xrk have done such experiment with XPS/multiply or mdf construction.

I've been contempling something similar but from different reason initially ( need a material i can 'shape' the inside of the box with hot knife).

I wonder a few things about a cld built like that: wich kind of adhesive to use and if a dedicated layer of sorbothane could be of any benefits?

I suppose it could works very well for a dedicated mid cab.

Maybe Xrk have done such experiment with XPS/multiply or mdf construction.

I did an XPS foam CLD build here: Box Construction Methods | somasonus. It's better than a typical box, but other methods were at least as good while being much easier to build. I used Loctite PL300 adhesive.

I'm going to do harmonic distortion testing soon to see if there is any benefit to the various methods that I didn't measure already.

Instead of sorbothane, you might consider 3M VHB tape. I have some now and just built a cabinet using it for the CLD braces. You could also build the box itself with it, but I'm going to measure to the braces first to see if I want to do that.

I'm going to do harmonic distortion testing soon to see if there is any benefit to the various methods that I didn't measure already.

Instead of sorbothane, you might consider 3M VHB tape. I have some now and just built a cabinet using it for the CLD braces. You could also build the box itself with it, but I'm going to measure to the braces first to see if I want to do that.

It appears as though the foam is not the better damped, given the choice of nidacore or polyurethane.

Do you have that data overlayed (one panel, each material one chart)?

Do you have that data overlayed (one panel, each material one chart)?

No, no new measurement request at this time, and yes I can still see what I need as it is presented, thanks.

I don't need to remeasure anything, I just process the IR again, so whatever you want to see I can do.

Jeah augerpro has done measurements for the CLD part, but the possibilty of cavity is interesting.A cavity could function as resonator to dampen standing wave(s) that have long wave lenght, longer than stuffing can handle. Maybe CLD is enough, but if enclosure has dimension approaching one meter the lowest modes inside are pretty low in frequency.

You should find that a cabinet dimension that is long enough to support a long wavelength is also long enough for the damping material.

That is true AllenB. Some people prefer less stuffing for closed boxes and sometimes ported boxes can't have enough stuffing without killing the port functioning so maybe this could be an option? But why KEF used the metamaterial to kill tweeter back wave where little amount of wool should work as well?😀 marketing maybe. If it really sounds better with the use of resonators instead of dampening material in high frequencies it should work for lows as well. Can't kill all the woofer pass band since 30 resonators (KEF) would fill the whole room 😀 I thought maybe one could fit only a few resonators to help with the worst offenders at the same time while doing the CLD thingy.

Last edited:

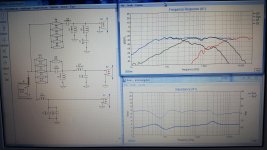

This is my first open baffle design, recently finished.

Drive units are Alpha15a, Seas U18 and Mundorf AMT. Measuring the responses on a prototype baffle was tricky and took a few attempts, likewise for the three way crossover design but the end result was worth it.

My own take on the subject of this thread is now...get rid of the box if you can. This has ended my search for a Quad ESL63 replacement.

Drive units are Alpha15a, Seas U18 and Mundorf AMT. Measuring the responses on a prototype baffle was tricky and took a few attempts, likewise for the three way crossover design but the end result was worth it.

My own take on the subject of this thread is now...get rid of the box if you can. This has ended my search for a Quad ESL63 replacement.

Attachments

Last edited:

Here is the rear. I shall fit an acoustically transparent cover.

Also attached are the Xover, F.R. and Impedance.

Also attached are the Xover, F.R. and Impedance.

Attachments

Last edited:

Since building some Linkwitz Phoenix dipole speakers, I have never been happy with 'box' speakers.

I've also owned ESL63s and currently have some Martin Logan hybrid electrostatics which are superb. In between time I had some Yamaha NS-f51 & Q Acoustics 3050i floor standers, neither of which I liked so they were reduced to home theatre duties.

Once you have listened to some open back/dipole speakers you won't be listening to a box speaker if given a choice......

I've also owned ESL63s and currently have some Martin Logan hybrid electrostatics which are superb. In between time I had some Yamaha NS-f51 & Q Acoustics 3050i floor standers, neither of which I liked so they were reduced to home theatre duties.

Once you have listened to some open back/dipole speakers you won't be listening to a box speaker if given a choice......

...it helps when its the right way up🙂

Thank-you for your additional pictures !

say, if I am to understand this *simulation* correctly, this is what the program predicts it will measure like?

If so, how about some actual acoustic measurements to see if theory meets reality ?

- Home

- Loudspeakers

- Multi-Way

- What can I do against 'box sound' ?