I too use a slender ( steel, 1 inch dia 8" long ) spacer between two magnets with a threaded bar going through the whole lot ( ex coaxial drivers again ) , it took a while to realise where the " zing " was coming from......

Try Babybel cheese wax ( the red stuff ) between the magnets and the spacer. I have used some beside the magnet and basket ( the steel basket was flexing ) and it damped the vibration audibly. If you knead the wax it goes soft and tacky, I've used it between the magnet and rear of an enclosure before ( press the driver in so it squishes ). Works a treat.

Not really. Damping reduces the build up of resonances from the mechanical energy pumped into the cabinet and driver frames. If there is a lot of energy pumped in you will need lots of damping to keep it under reasonable control. A modest level of damping is always required since a driven undamped resonance will get louder and louder without limit. A need for high levels of damping though (e.g. you can clearly hear the effect of increasing damping) usually indicates high levels of mechanical energy being pumped into the cabinet. This happens when the driving forces (of fixed size one can do nothing about) push against a weak structure creating a large deflection/velocity and hence pumping a large amount of power (force*velocity in direction of force) into the structure.

What actually works a treat is not pumping large amounts of mechanical energy into the cabinet in the first place. This is what a high level of stiffness between the two magnets will achieve.

After it's been kneaded it goes hard; over the area of the back of a magnet, and at audible frequencies it's effectively solid.

How much do you loose because of the inteference of the two drivers (time delay of the rear driver) ?

After it's been kneaded it goes hard; over the area of the back of a magnet, and at audible frequencies it's effectively solid.

You'd be better off gluing them together.

I'm afraid it's a while since I've listened to them, but they sounded decent; they didn't sound like two speakers fighting each other. Glue is OK is you never want to take it apart, I don't have that confidence. I have now idea of the thermal expansion of the wax, don't blame me if it shrinks in cold weather and pulls the magnet off!

You might try some silicone RTV. It holds and dampens well but can be taken back apart if need be.

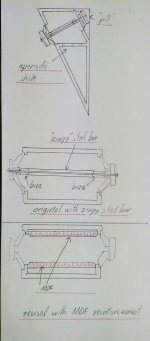

Barefoot uses a metal ring to bolt 2 magnets of the side woofers. Cabinet vibration is surprising low for small speaker.

How much do you loose because of the inteference of the two drivers (time delay of the rear driver) ?

If I understand what you are asking, there isn't a time delay because the pair of woofers are normally placed on the sides not the front and back (e.g. KEF blade). If they were placed front and back this wouldn't be a problem until the wavelength became short enough to become significant compared to the distance between the two drivers. A pair of subwoofer drivers are likely to be fine but it might become an issue for a pair of woofers.

Will a stiff driver mounting really change much? The very high spls inside a speaker box due to the small size can only be cured by killing energy, by very lossy box walls, or by increasing box size accordingly, or by adding correctly amount of acoustic damping inside the box?

Magnet to magnet? Yes.Will a stiff driver mounting really change much?

Member

Joined 2009

Paid Member

will sand filled box walls be lossy or just heavy?

lossy, that’s why the army used sand bags, stops bullets by dissipating their energy very efficiently

Last edited:

what do you think about lining speaker`s inside walls with cork to quell resonances ? I read it absorbs midrange and higher frequencies pretty well . Would it work for a bass cabinet if cork was thick enough ?

Member

Joined 2009

Paid Member

if you want to do it right, use constrained layer damping

Constrained layer damping - YouTube

A Big'un - the Audio Nirvana Super 15

Zu audio glues plastic honecomb panels to the inside of their boxes - you can buy this honeycomb plastic from boat building supply stores.

Constrained layer damping - YouTube

A Big'un - the Audio Nirvana Super 15

Zu audio glues plastic honecomb panels to the inside of their boxes - you can buy this honeycomb plastic from boat building supply stores.

Making a cabinet out of a naturally sound absorbing material (like foam core) or lining a box with melamine foam to prevent/reduce internal reflections makes a big difference. I had a case where I made the speakers out of foam core and they sounded great. As soon as anyone tried it in wood or BB ply, they all reported it sounded boxy or “cupped”. 4 cases reported this. I had one built in plywood and noticed same thing that wasn’t there in the foam core. It was finally solved by adding melamine foam on all surfaces in line of sight of the driver cone. The foam core cabinet did not have this problem despite minimal foam lining. In this respect, speakers made from hard (yet inert) materials like stone, concrete, hardwoods, glass, etc will tend to have the reflective boxy sound unless walls are treated to avoid reflections.

Magnet to magnet? Yes.

But will this prevent sound transmission throu speaker box walls, i can not see it does? I guess there are different things here; resonances of box wall panels and sound transmission throu the box wall material

- Home

- Loudspeakers

- Multi-Way

- What can I do against 'box sound' ?