lossy, that’s why the army used sand bags, stops bullets by dissipating their energy very efficiently

Good point, but will sand be effective for sound waves as well?

Has anyone here tried to talk throu a wall of sound bags?

Making a cabinet out of a naturally sound absorbing material (like foam core) or lining a box with melamine foam to prevent/reduce internal reflections makes a big difference. I had a case where I made the speakers out of foam core and they sounded great. As soon as anyone tried it in wood or BB ply, they all reported it sounded boxy or “cupped”. 4 cases reported this. I had one built in plywood and noticed same thing that wasn’t there in the foam core. It was finally solved by adding melamine foam on all surfaces in line of sight of the driver cone. The foam core cabinet did not have this problem despite minimal foam lining. In this respect, speakers made from hard (yet inert) materials like stone, concrete, hardwoods, glass, etc will tend to have the reflective boxy sound unless walls are treated to avoid reflections.

That is very interesting

It just reduces transmission from speaker chassis.But will this prevent sound transmission throu speaker box walls, i can not see it does? I guess there are different things here; resonances of box wall panels and sound transmission throu the box wall material

The sources of box sound are from; 1. reaction energy from the driver exciting the box, this particularly so at the boxes natural resonances, and, 2. the internal rear wave energy from the cone bouncing around in the box and re-exiting through the cone.

The former is addressed by choice of box material being low Q, and chipboard is better than MDF in this respect, but bracing and corner reinforcing with Scotia or isosceles triangle wood is very effective because this transfers energy from one panel to the others dissipating much. It also pushes up the resonant frequencies to a less objectionable range.

Damping the box with layers of absorbent also absorbs the secondary emission of energy from the box panels turning it into heat. It is usually of quite high mass, lead sheeting has been used, bitumen sheet is often commercially used, and I have used carpet underlay of the type which has reconstituted car tyre attached to a wool layer, and with considerable success.

The rear cone energy can best be absorbed by layers of suitable absorbent, long haired wool, BAF, and sponge, but loft insulation is unpleasant and unhealthy. If the whole internal volume is filled this will attenuate any bass reflex resonance, which may not be desirable, and should not be necessary in a correctly designed system. It is used however by manufacturers who attempt to match drivers and boxes which are not designed for each other.

I use BAF enclosed in Dacron envelopes so that I can change the amount at will, they fastened to the walls with Velcro.

I also damp the driver frames, paying particular attention to the area behind the cone which will potentially reflect directly through the cone.

The former is addressed by choice of box material being low Q, and chipboard is better than MDF in this respect, but bracing and corner reinforcing with Scotia or isosceles triangle wood is very effective because this transfers energy from one panel to the others dissipating much. It also pushes up the resonant frequencies to a less objectionable range.

Damping the box with layers of absorbent also absorbs the secondary emission of energy from the box panels turning it into heat. It is usually of quite high mass, lead sheeting has been used, bitumen sheet is often commercially used, and I have used carpet underlay of the type which has reconstituted car tyre attached to a wool layer, and with considerable success.

The rear cone energy can best be absorbed by layers of suitable absorbent, long haired wool, BAF, and sponge, but loft insulation is unpleasant and unhealthy. If the whole internal volume is filled this will attenuate any bass reflex resonance, which may not be desirable, and should not be necessary in a correctly designed system. It is used however by manufacturers who attempt to match drivers and boxes which are not designed for each other.

I use BAF enclosed in Dacron envelopes so that I can change the amount at will, they fastened to the walls with Velcro.

I also damp the driver frames, paying particular attention to the area behind the cone which will potentially reflect directly through the cone.

Attachments

This stops the whole speaker jumping around but creates a noisy cabinet due to both drivers hammering away on it.

I looked at running long bolts with spacers between the two drivers mounting holes. This stopped the drivers hammering on the cabinet but the frame of the driver was still driven and it pinched a significant amount of volume. When I simulated the vibration of the cabinet the long slender spacers were resonating within the passband. Perhaps it could have been made to work but it is not elegant.

The right way to do it (if practical) is to rigidly mount the drivers back to back perhaps with a short possibly vented cylinder between the magnets of the two drivers if it cannot be done directly. This keeps vibration out of the cabinet and the frame of the drivers while providing at worst a short stiff structure between the two driven magnets.

I'd say your ideas are excellent, since I incorporated them in my infinite baffle bass build. This is somewhat of an inverted concept verses the last picture I posted in this thread. In effect, the listener hears the back of the cone.

Attachments

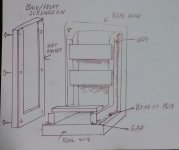

If you want a lossy box you could try this, based on the BBC Ls3/5a. The bead of PVA and gap provide a slightly soft joint and the difference between the real wood and MDF seem to give a very dead box. Having the front and back screwed on ( or held on by tension springs as I sometimes do ) also reduces sound transition. The ladder rungs attached to the MDF are baffles to help " defend " the sides from sound from the driver and to try and detract it as it bounces back. On my traffic light speakers I also added square steel bars to the front baffle to add weight and to stiffen it, quite a complicated speaker that one.

Member

Joined 2009

Paid Member

never mind transmitting sound through a big piece of solid wood - think about how much sound present inside the box is simply passing out through a very thin and un-braced cone !

True, however the cabinet has around 16 times the area to leak sound through ( and radiate from mechanical vibration transmitted from the driver ) than the driver cone, and the sound leaking through the cone has to bounce of something first. All three areas have to be addressed to reduce box sound.

Maybe not so important or driver dependent ? Look at #4: DTQWT TWEAKSI also damp the driver frames, paying particular attention to the area behind the cone which will potentially reflect directly through the cone.

The major manufacturers are paying great attention to the frame designs now, most are deep axially, but not circumferentially wide like that 70s basket I pictured earlier

True, however the cabinet has around 16 times the area to leak sound through ( and radiate from mechanical vibration transmitted from the driver ) than the driver cone

Indeed, it would be great to have a way of testing this, isolating the sound that leaks throu the box, maybe by mounting some anechoic cups over the drive units?

'I have thought about sticking a small speaker inside a bigger one to see what it sounds like'

Good idea! Even better to take a frequency response plot of the small speaker before and after. ...keeping the levels constant.

Good idea! Even better to take a frequency response plot of the small speaker before and after. ...keeping the levels constant.

Last edited:

Indeed, it would be great to have a way of testing this, isolating the sound that leaks throu the box, maybe by mounting some anechoic cups over the drive units?

I really doubt that much goes through the box from the air pressure inside.

I really doubt that much goes through the box from the air pressure inside.

I do believe more sounds then one might think is leaking throu cab the walls, and much likely to the point that it smears driver output.

I can imagine that this is most problematic in the lower range, maybe in the range where the woofer starts to roll of, with low sound levels on the outside while the levels is high inside the box?

I was fiddling with the crossover of my box in a box speakers last night ( it'll be several weeks before I can get the right chokes ), when you listen to a speaker with greatly reduced box noise it's a bit like the change going from ported enclosures to closed or aperiodic, you think where has the bass gone? - until it starts - and you smile. I was listening to Nirvana live in New York and the sound of the applause was totally different to what I'm used to, much, much sharper. Once I've got used to the sound ( or lack of it ) it'll be interesting to go back to six bits of wood and drivers to see if I could go back.

Making a box non resonant can be done, Arthur Khoubessarian of the Funk Firm said of my rebuild, (earlier pictures), that there was no box sound. Each had 53 braces in, but this is labour intensive, and perhaps proclusive in commercial situations.

My ADAMs have a sand filled cavity in the middle/top box.

My ADAMs have a sand filled cavity in the middle/top box.

- Home

- Loudspeakers

- Multi-Way

- What can I do against 'box sound' ?