I agree with both of you entirely.... Never melted the solder even at ear splitting levels (after a beer ), but ofcourse in a home audio environment and not PA.

), but ofcourse in a home audio environment and not PA.

someone with more experience (in loud PA music and beers ) may be able to share experience.

I concede that I myself have used this (unmasked traces for power and spk) for APEX FX-100 3-pair PCB @+/-70VDC.

reg

Prasi

), but ofcourse in a home audio environment and not PA.

), but ofcourse in a home audio environment and not PA.someone with more experience (in loud PA music and beers ) may be able to share experience.

I concede that I myself have used this (unmasked traces for power and spk) for APEX FX-100 3-pair PCB @+/-70VDC.

reg

Prasi

does anyone know why he left the solder mask off some of the traces?

What purpose does that serve?

this trick is done on many boards, mostly smps boards, i see no issues with doing that, you can if you like....

these are amplifier boards.....i think that some softwares do this automatically...

Attachments

solder is applied to the traces to increase the current carrying ability of the main power traces. the layer of solder over the copper trace increases its thermal mass. by increasing the thermal mass, the traces heat up less and hot spots on the traces are reduced.

Hi X,

I take a liberty to explain what Hugh meant with regards to R10 🙂

R10 provides a bit of a local (nested) feedback from the VAS buffer to the mail feedbzck junction point.

Unsolder and lift one side of it and have a listen with no R10 in place.

Then solder it back and have a listen again.

Do you notice some difference? What option is better (with no R10 or with R10 in place)?

Cheers,

Valery

I simulated 100K resistor from collector VAS current to feedback node at my FX8 amplifier. THD was increase but H2 dominant. It tested by a friend of mine, he said the sound more warm and the vocal more forward. He like used 100K resistors 🙂

Perhaps there was a dual tion process of applying solder. First - chemical track across the surface, the second thermal - only at the locations of soldering parts.

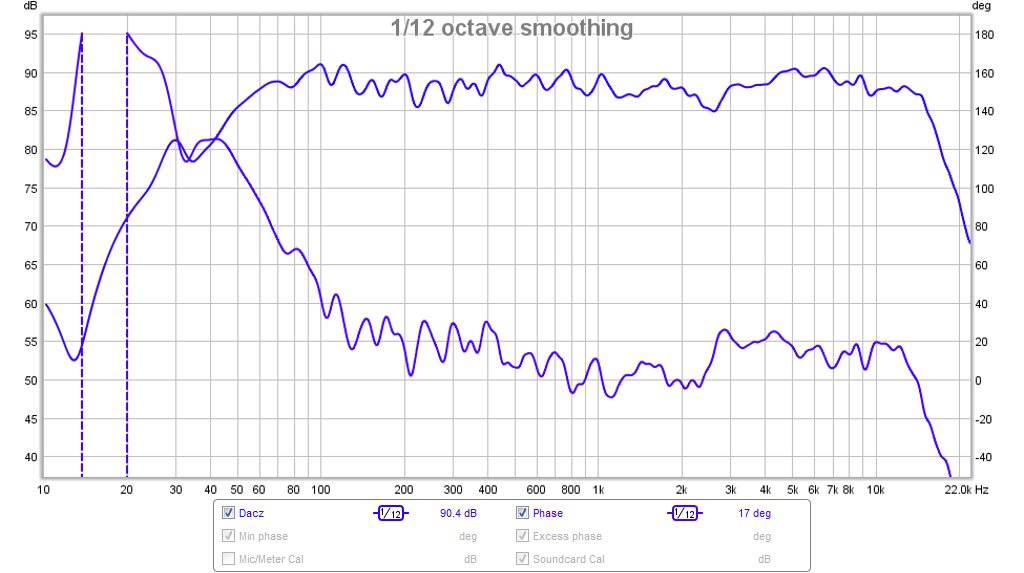

Longer term listening of DACZ

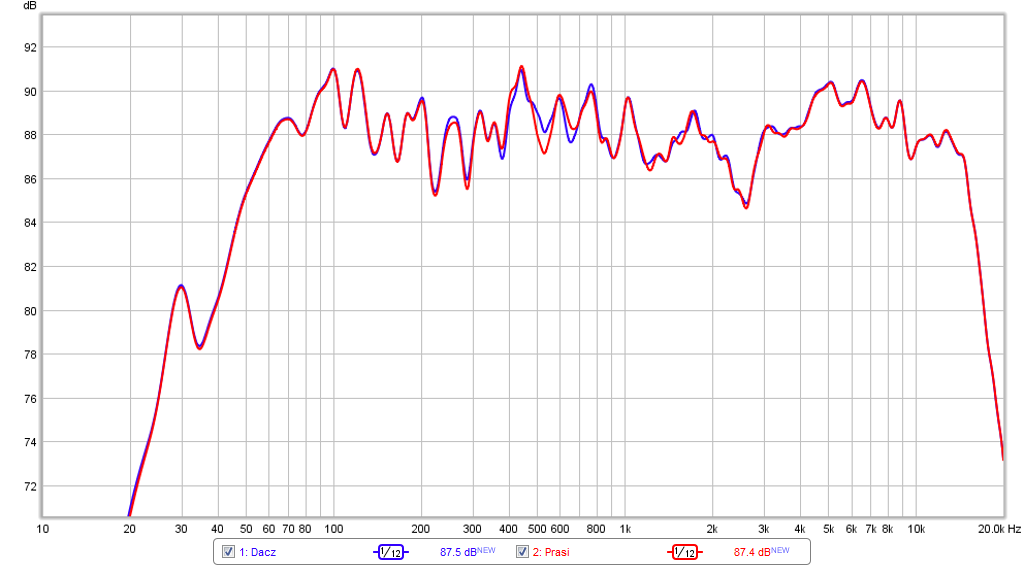

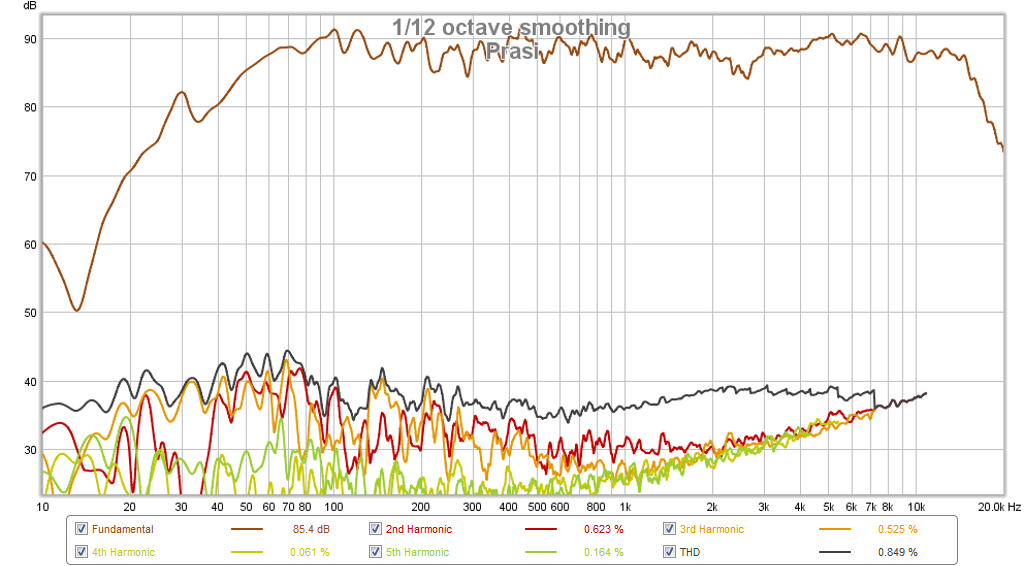

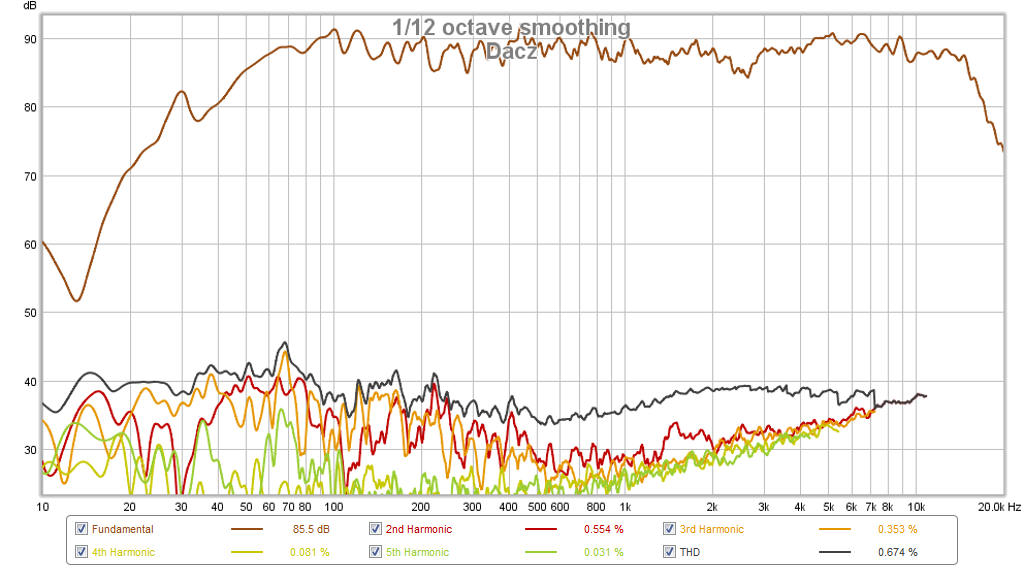

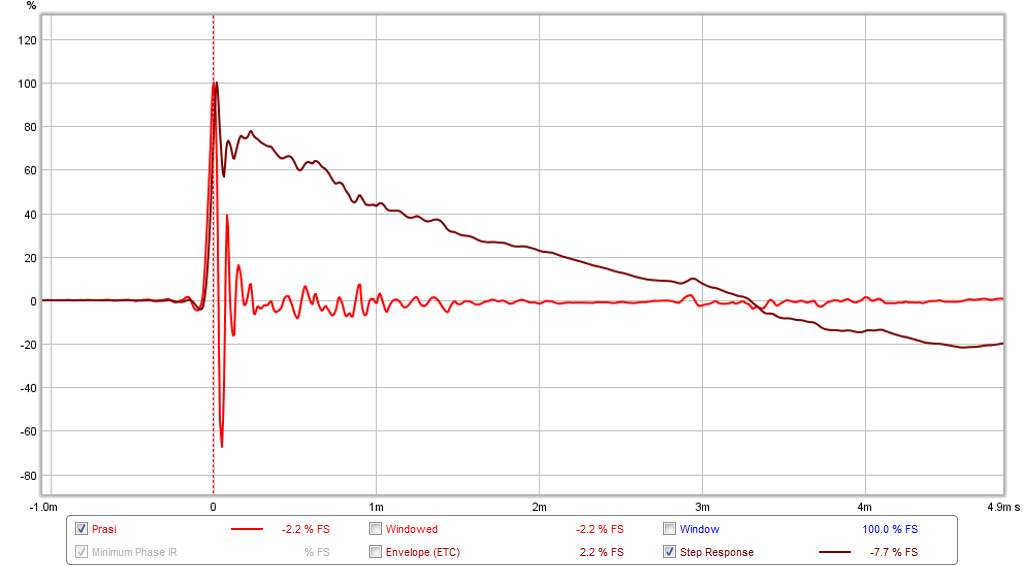

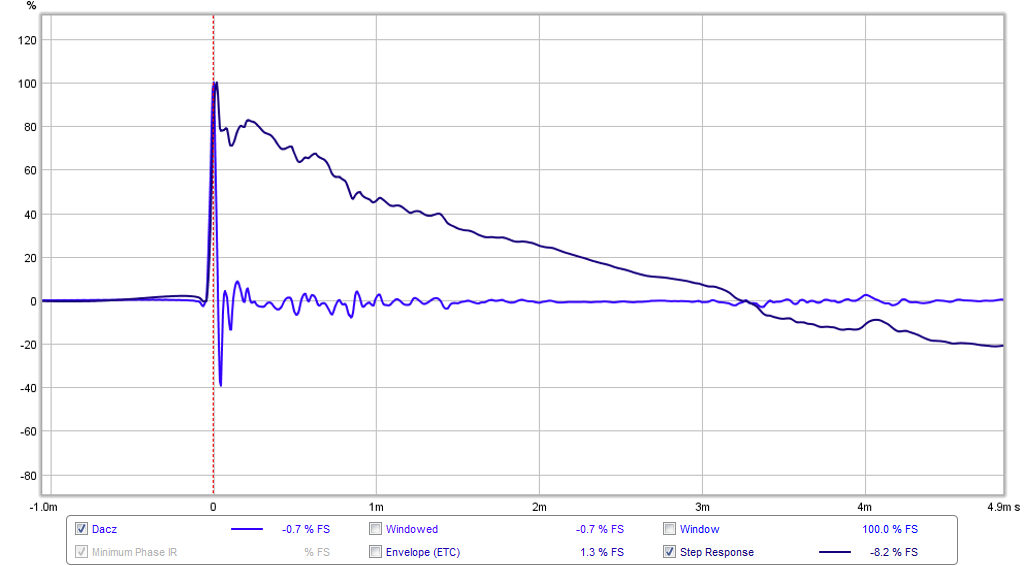

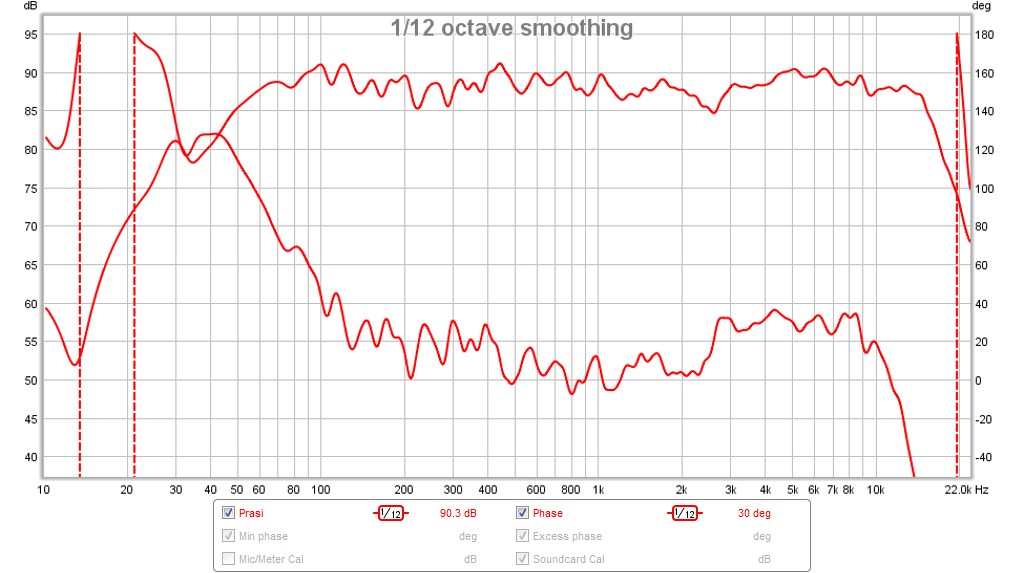

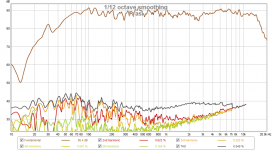

Now that I have put maybe 6 hours of listening on these new amps, I have to say they subjectively sound better than the last ones due to better quality components. I really like what I hear and the measurements bear this out. These are microphone measurements of the effect of the amp on a speaker (10F/RS225 FAST with transient perfect XO). There is lower measured harmonic distortion at the speaker in the bass response and at mids around 600Hz. The impulse/step response looks better with a more ideal step and less ringing. The measured phase also shows better linearity with a 15 deg difference at 6kHz. I listened before measuring so my subjective opinion was formed before seeing the data - it does sound a little better when listening to a lot of different tracks and genres. Now I labeled these amps Prasi and Dacz and that is not to say one layout is better than the other as my components were better on the Dacz and I think that makes a difference. I am using KSA1381 drivers/VAS vs MJE350's and using the Onsemi BJT vs the Toshiba 2SC5200. Also using film cap on C9 vs ceramic.

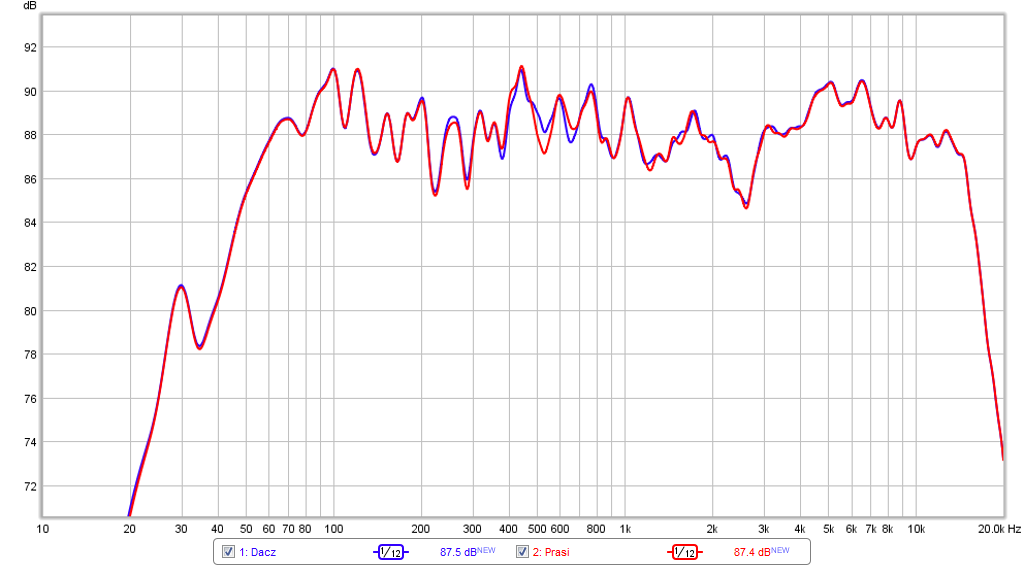

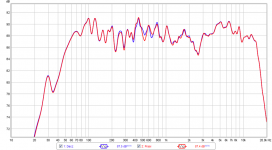

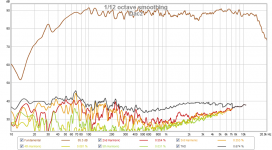

Here are the frequency measurements for both amps with same speaker/mic position and same PSU. Made within 15 minutes of each other (enough time to warm up and adjust for same bias). Measurements made at 50cm from speaker with third party calibrated UMIK-1, CS4398 DAC as the source. +/-36V power supply with 5mV ripple after CRCLC filter. The Dacz has a surprising small (+0.5dB) boost in the mid range from 400Hz to 800Hz. Otherwise they look pretty much identical:

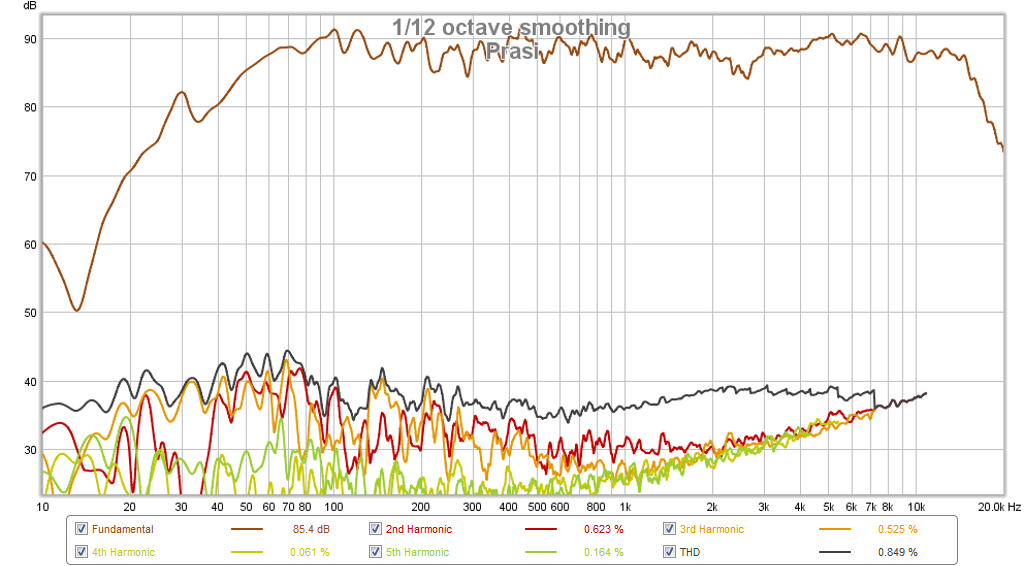

Here is the measured harmonic distortion on the Prasi (cursor at 50Hz):

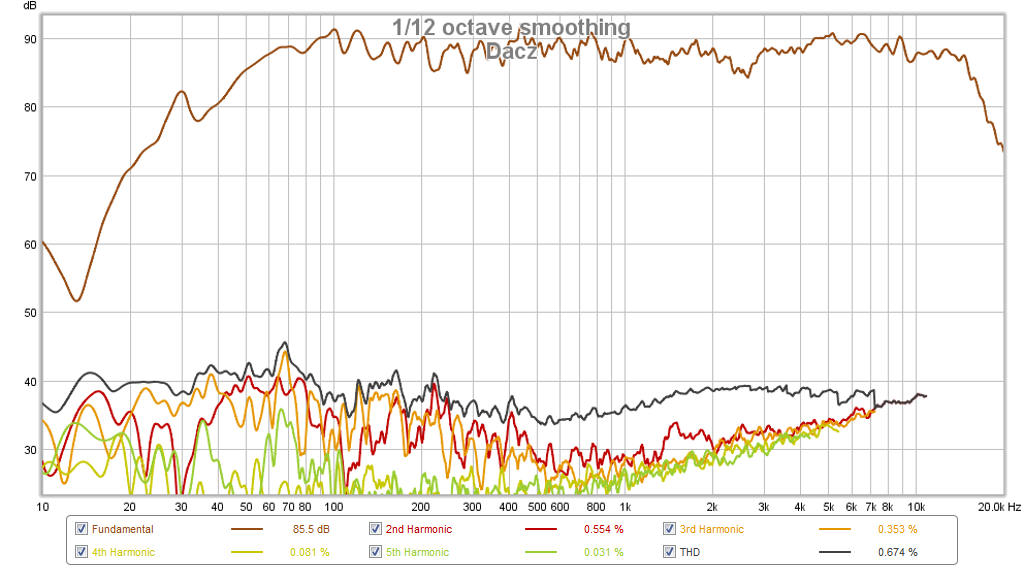

Here is the measured harmonic distortion on the Dacz, you can see that it is just a bit lower at 60Hz and somewhat lower in other sections (cursor at 50Hz):

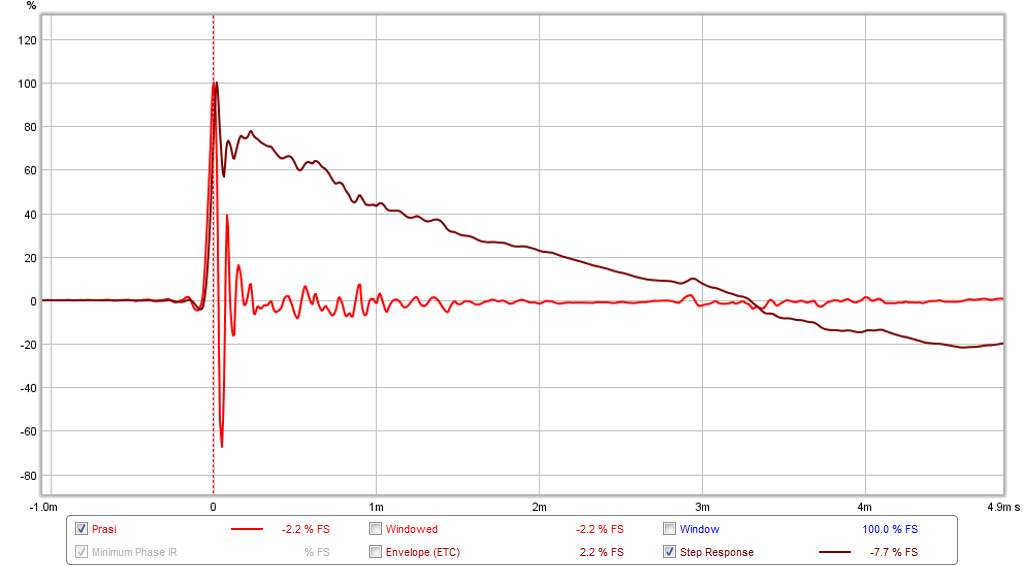

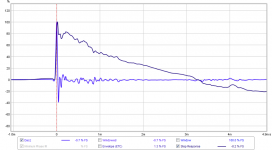

Here is the measured impulse and step response of the Prasi - a small amount of ringing or overshoot in the impulse:

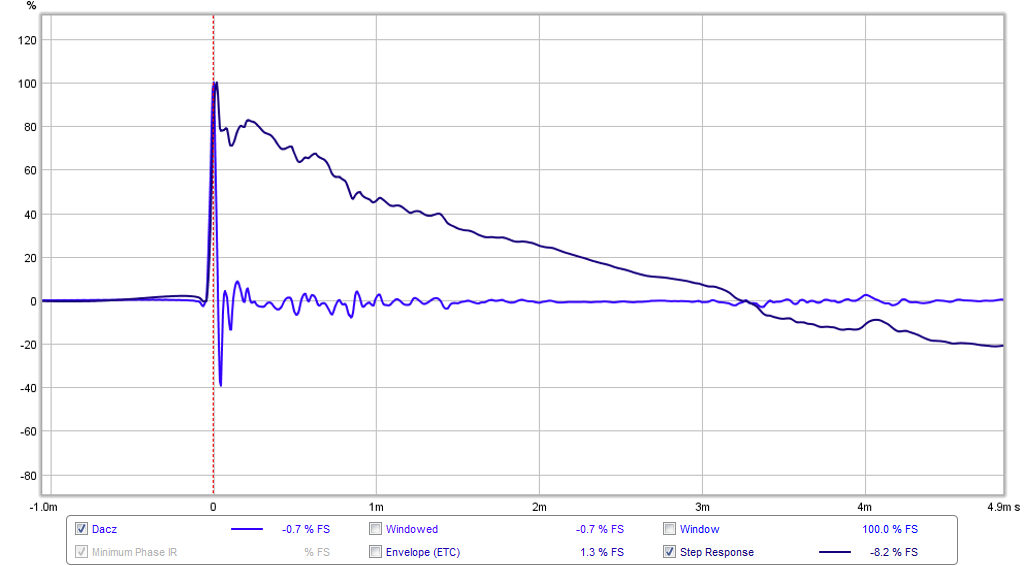

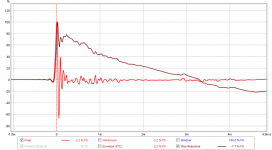

Here is the measured impulse and step response of the Dacz - a cleaner performance for sure and will sound more realistic with percussion:

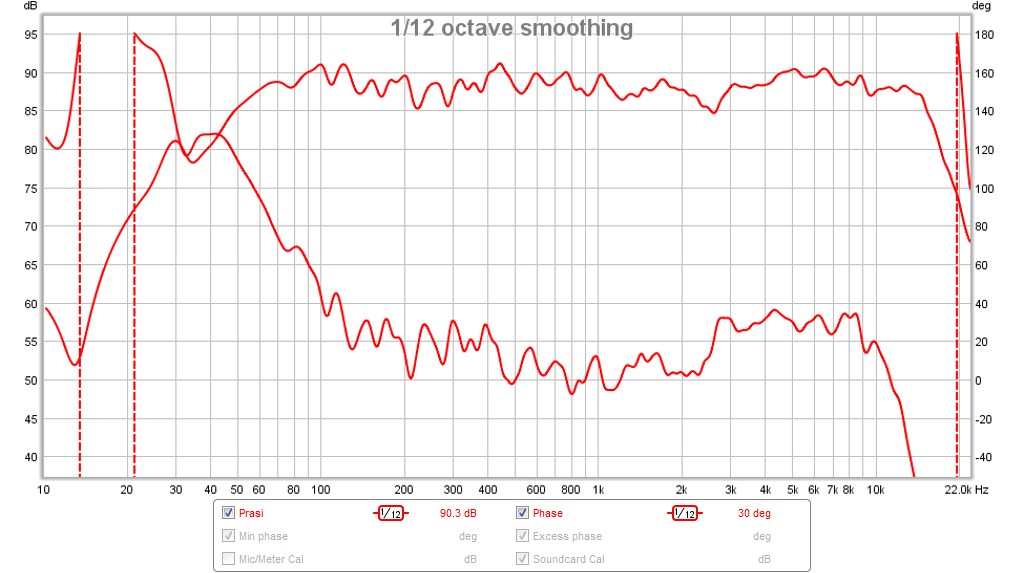

Here is the measured phase response for the Prasi:

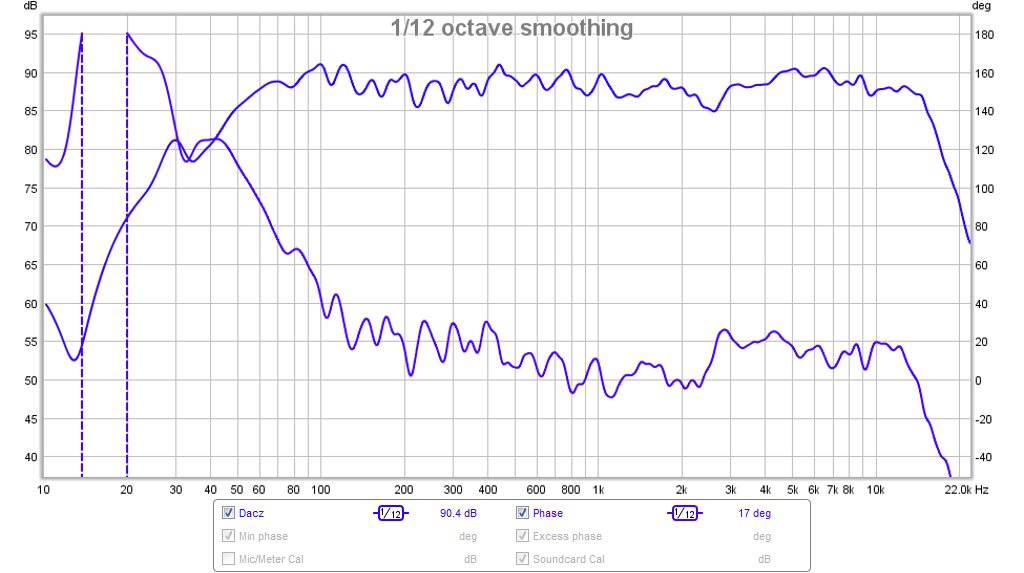

Here is the measured phase response for the Dacz - flatter in the higher treble range (3kHz to 15kHz):

Now that I have put maybe 6 hours of listening on these new amps, I have to say they subjectively sound better than the last ones due to better quality components. I really like what I hear and the measurements bear this out. These are microphone measurements of the effect of the amp on a speaker (10F/RS225 FAST with transient perfect XO). There is lower measured harmonic distortion at the speaker in the bass response and at mids around 600Hz. The impulse/step response looks better with a more ideal step and less ringing. The measured phase also shows better linearity with a 15 deg difference at 6kHz. I listened before measuring so my subjective opinion was formed before seeing the data - it does sound a little better when listening to a lot of different tracks and genres. Now I labeled these amps Prasi and Dacz and that is not to say one layout is better than the other as my components were better on the Dacz and I think that makes a difference. I am using KSA1381 drivers/VAS vs MJE350's and using the Onsemi BJT vs the Toshiba 2SC5200. Also using film cap on C9 vs ceramic.

Here are the frequency measurements for both amps with same speaker/mic position and same PSU. Made within 15 minutes of each other (enough time to warm up and adjust for same bias). Measurements made at 50cm from speaker with third party calibrated UMIK-1, CS4398 DAC as the source. +/-36V power supply with 5mV ripple after CRCLC filter. The Dacz has a surprising small (+0.5dB) boost in the mid range from 400Hz to 800Hz. Otherwise they look pretty much identical:

Here is the measured harmonic distortion on the Prasi (cursor at 50Hz):

Here is the measured harmonic distortion on the Dacz, you can see that it is just a bit lower at 60Hz and somewhat lower in other sections (cursor at 50Hz):

Here is the measured impulse and step response of the Prasi - a small amount of ringing or overshoot in the impulse:

Here is the measured impulse and step response of the Dacz - a cleaner performance for sure and will sound more realistic with percussion:

Here is the measured phase response for the Prasi:

Here is the measured phase response for the Dacz - flatter in the higher treble range (3kHz to 15kHz):

Attachments

-

Dacz-Quasi-Running.jpg129.3 KB · Views: 2,822

Dacz-Quasi-Running.jpg129.3 KB · Views: 2,822 -

Prasi-Dacz-Quasi-Compare-Phase-Dacz.png85.6 KB · Views: 1,198

Prasi-Dacz-Quasi-Compare-Phase-Dacz.png85.6 KB · Views: 1,198 -

Prasi-Dacz-Quasi-Compare-Phase-Prasi.png85 KB · Views: 1,201

Prasi-Dacz-Quasi-Compare-Phase-Prasi.png85 KB · Views: 1,201 -

Prasi-Dacz-Quasi-Compare-Impulse-Dacz.png53.5 KB · Views: 1,185

Prasi-Dacz-Quasi-Compare-Impulse-Dacz.png53.5 KB · Views: 1,185 -

Prasi-Dacz-Quasi-Compare-Impulse-Prasi.png55.9 KB · Views: 1,191

Prasi-Dacz-Quasi-Compare-Impulse-Prasi.png55.9 KB · Views: 1,191 -

Prasi-Dacz-Quasi-Compare-Freq.png73.4 KB · Views: 1,260

Prasi-Dacz-Quasi-Compare-Freq.png73.4 KB · Views: 1,260 -

Prasi-Dacz-Quasi-Compare-HD-Prasi.-50Hzpng.png156.1 KB · Views: 1,186

Prasi-Dacz-Quasi-Compare-HD-Prasi.-50Hzpng.png156.1 KB · Views: 1,186 -

Prasi-Dacz-Quasi-Compare-HD-Dacz-50Hz.png152.9 KB · Views: 1,199

Prasi-Dacz-Quasi-Compare-HD-Dacz-50Hz.png152.9 KB · Views: 1,199

Last edited:

hi xrk971.. nice through hole.. did you update the pads in sprint before sending to pcbway? if i could remember only Q3, Q4, Q6 and Q7 have through hole pads for easy soldering when fixed under the pcb. if the price is negligible, then it is a go for all through hole. nice and neat looking 😉

regards,

Dacz

regards,

Dacz

Attachments

hi xrk971.. nice through hole.. did you update the pads in sprint before sending to pcbway? if i could remember only Q3, Q4, Q6 and Q7 have through hole pads for easy soldering when fixed under the pcb. if the price is negligible, then it is a go for all through hole. nice and neat looking 😉

regards,

Dacz

Thanks, Dacz - I agree, they turned out rather nicely thanks to a great layout! A pretty amp to look at and beautiful to listen to. I used the older Gerbers without the drilled holes for the Q's - and it was me who discovered that the holes were missing - so too late to use revised Gerbers. It wasn't hard to drill my own so not a big deal.

Hello xrk971Since there is already a 0.33R source/collector resistor in place, I doubt you need thicker traces to reduce the ohmic drop across that 1in travel of copper trace. The resistive drop there is much smaller than 0.33R.

2oz copper PCBs (under 100mm Sq) cost substantially more (more than 2x) than 1oz. If you are building for home use and fun and trying to keep costs down - doesn't make sense. If you expect a lot of reworking, it makes repairs easier from standpoint of durability from pad peel off. But with good design making pads bigger around parts that need exchangingos often enough. Transistors for example should have bigger oversized pads.

For pcb 10cm x 10cm (1oz) manufacturer that provides exactly the same price as PCBWay but it seems to 2oz tracks the price is much cheaper.

FirstPCB - the Best Valuable Prototype & Batch PCB Production

🙂

I'm running a batch of 10 PCBs with 2oz copper. I'll sell the extras for those interested. 20$ stereo set (2PCBs) shipped. 3x stereo sets available. Please PM me only, do not want to pollute this thread.

Got one boxed up for real. Putting the case and ancillary parts together takes longer then building the amp. Soft start and speaker protection is the 21st century protection set. Works great. Tomorrow the second should be done and we can have a listen on the big system.

Attachments

Now that I have put maybe 6 hours of listening on these new amps, I have to say they subjectively sound better than the last ones due to better quality components. I really like what I hear and the measurements bear this out. These are microphone measurements of the effect of the amp on a speaker (10F/RS225 FAST with transient perfect XO). There is lower measured harmonic distortion at the speaker in the bass response and at mids around 600Hz. The impulse/step response looks better with a more ideal step and less ringing. The measured phase also shows better linearity with a 15 deg difference at 6kHz. I listened before measuring so my subjective opinion was formed before seeing the data - it does sound a little better when listening to a lot of different tracks and genres. Now I labeled these amps Prasi and Dacz and that is not to say one layout is better than the other as my components were better on the Dacz and I think that makes a difference. I am using KSA1381 drivers/VAS vs MJE350's and using the Onsemi BJT vs the Toshiba 2SC5200. Also using film cap on C9 vs ceramic.

I hope this finally convinces you that component quality and type does matter in amps😀.

reg

prasi

I hope this finally convinces you that component quality and type does matter in amps😀.

reg

prasi

I don't think I ever said I don't believe in component quality having an effect on performance of amp. That's different than wanting to use lower cost parts that are of good quality relative to more expensive parts. I think film caps in the right places makes a difference. But I am not so convinced a CBB is not going to sound as good as Wima. Or is US made $0.69 Dale resistor going to sound better than a $0.05 Chinese made metal thin film resistor?

I don't think I ever said I don't believe in component quality having an effect on performance of amp. That's different than wanting to use lower cost parts that are of good quality relative to more expensive parts. I think film caps in the right places makes a difference. But I am not so convinced a CBB is not going to sound as good as Wima. Or is US made $0.69 Dale resistor going to sound better than a $0.05 Chinese made metal thin film resistor?

did i ever say anything about using high cost components?

All I said was quality and type of parts (the designer intended). If you are convinced with quality of your components, good for you.

You gotta be real careful, X, many of the Yankee parts like Dale are being made increasingly in China....... and Fairchild moved all it's operation to China years ago, and now bought recently by IRF.

You build very nice amps, and Dacz, Prasi, Thiago, Farjon and Phunk have all done very nice pcb layouts... 😎

BTW, I have found that if you use a IRF140 as the upper nmos on this amp and you are using a snubber, you can improve the sonic performance markedly if you decrease the stopper to 120R from the present 220R.

Ciao,

Hugh

You build very nice amps, and Dacz, Prasi, Thiago, Farjon and Phunk have all done very nice pcb layouts... 😎

BTW, I have found that if you use a IRF140 as the upper nmos on this amp and you are using a snubber, you can improve the sonic performance markedly if you decrease the stopper to 120R from the present 220R.

Ciao,

Hugh

You have a good point Hugh and I am aware of the fact that for example, Vishay IRFP240's are made in China. The ones I get from China for $0.67 look as perform the same as the $2.05 ones from Digikey (which says they originated from China). I wasn't sure about the Dale "sausage link" resistors that seem to be so en vogue with builders. Material and whether or not they are inductive is probably probably a bigger impact on sound.

Thanks for tip on first gen IRFP140. Does it sound better than 240?

Thanks for tip on first gen IRFP140. Does it sound better than 240?

X,

My bad, I actually meant the IRF240/9240.

I think the Chinese parts are steadily improving in quality as western manufacturers repair to North Asia to exploit the lower costs. However, a lower limit will be reached soon, and some of these factories will move to even cheaper countries like Burma, Bangladesh, even Vietnam. Much of the cheaper clothing we buy in Oz are actually made in Bangladesh. It seems to me that China will have to do something about its ratio of debt to GDP - presently 220%. I can't see how this can be swept under the carpet. But for the next ten years I'm sure almost all electronic parts and built products will come from China.

Hugh

My bad, I actually meant the IRF240/9240.

I think the Chinese parts are steadily improving in quality as western manufacturers repair to North Asia to exploit the lower costs. However, a lower limit will be reached soon, and some of these factories will move to even cheaper countries like Burma, Bangladesh, even Vietnam. Much of the cheaper clothing we buy in Oz are actually made in Bangladesh. It seems to me that China will have to do something about its ratio of debt to GDP - presently 220%. I can't see how this can be swept under the carpet. But for the next ten years I'm sure almost all electronic parts and built products will come from China.

Hugh

If plopping in a $0.02 120R gate stopper resistor will markedly improve the sound, that is about as much bang for the buck as anyone could hope for. 🙂

I will try it.

I think Vietnam already makes some fine optical lenses for cameras, great shoes and clothing, and wood furniture even. I may have even seen a laptop cone from Vietnam.

I will try it.

I think Vietnam already makes some fine optical lenses for cameras, great shoes and clothing, and wood furniture even. I may have even seen a laptop cone from Vietnam.

Hi Hugh (after a long time 😱 ), the Chinese plants of OEM's do produce nice quality parts conforming to the specs laid down by OEMs. Its the dubious sellers, selling very cheap parts on Aliexpress or some such sites, that one has to be careful of. e.g 2SK1058 with Toshiba printed on it, a tiny 470uF with 10000uF Rubycon/ nichicon printed or caps that blow (grossly over-rated voltage, Terry had some caps that blew) or a power transistor printed 2sc2922 with an imitation die. some such things that a diyer needs to be aware of, so that he doesn't get cheated.You gotta be real careful, X, many of the Yankee parts like Dale are being made increasingly in China....... and Fairchild moved all it's operation to China years ago, and now bought recently by IRF.

You build very nice amps, and Dacz, Prasi, Thiago, Farjon and Phunk have all done very nice pcb layouts... 😎

Ciao,

Hugh

I hope we will soon see the new Qaksa!

regards

Prasi

Last edited:

- Home

- Amplifiers

- Solid State

- Very simple quasi complimentary MOSFET amplifier

![IMG_8001[1].JPG](/community/data/attachments/534/534338-971787eee7907e8d986d63251fa2f12c.jpg?hash=lxeH7ueQfo)