ok, modern low dynamic stuff heard from radio can be mixed with what ever.

But yeah, cool speakers. no interest to copy those

manninen : what is your message? do you want to be unkind?

Hello guys

Love the builds here. I have a Dayton audio speaker tester for the T/S specs

What is a low / high t/s specs do I need to look for in a mid/low ,full range driver for OB build and is there a crossover software for making a crossover for these. I’d like to try my best to stay away from a electronic crossover so I don’t have to use a lot of amps

Thanks

Love the builds here. I have a Dayton audio speaker tester for the T/S specs

What is a low / high t/s specs do I need to look for in a mid/low ,full range driver for OB build and is there a crossover software for making a crossover for these. I’d like to try my best to stay away from a electronic crossover so I don’t have to use a lot of amps

Thanks

With about 6 non-resilient cables, (“piano wire?”) I think you could suspend a woofer or cluster of woofers from the ceiling without fore and aft, or pendulum movement. In that case the weight of the driver would actually help.

You don't want that. Probably you mean the things you see at the concerts, which are not related to the art of home audio reproduction

With about 6 non-resilient cables, (“piano wire?”) I think you could suspend a woofer or cluster of woofers from the ceiling without fore and aft, or pendulum movement. In that case the weight of the driver would actually help.

There is no mechanical engeneer here ?

This oscillatory system is a lot easyer to calculate than T&S alignement.

I didn't see a thread documenting your build. Did you start one? I'm especially interested in knowing how the EVA foam is cut and formed and where to source blocks large enough for an 18" woofer.

Hi WBS,

I didn´t start a thread yet, as interest seemed to be a little low. I can still do it - I have a few photos of the building process as well (and I hope that I haven´t got to do it again anytime soon...). Some changes have been done as well actually - I quitted the rear tweeter finally and have changed the filter a few times, now being back to a near standard 12/18dB parallel filter at 300Hz.

Getting the EVA took some time - I had a nice offer from Taiwan, but would have needed to order a whole container of the stuff... in the end, it turned out not that easy to get 100kg/m³ EVA in black in 1000x1000x40mm sheets, but finally I got them from Intec Foams in the UK. The sheets are then glued together with black epoxy.

Routing and sanding took a little while...

All the best

Mattes

Hi WBS,

I didn´t start a thread yet, as interest seemed to be a little low. I can still do it - I have a few photos of the building process as well (and I hope that I haven´t got to do it again anytime soon...). Some changes have been done as well actually - I quitted the rear tweeter finally and have changed the filter a few times, now being back to a near standard 12/18dB parallel filter at 300Hz.

Getting the EVA took some time - I had a nice offer from Taiwan, but would have needed to order a whole container of the stuff... in the end, it turned out not that easy to get 100kg/m³ EVA in black in 1000x1000x40mm sheets, but finally I got them from Intec Foams in the UK. The sheets are then glued together with black epoxy.

Routing and sanding took a little while...

All the best

Mattes

Hallo Mattes,

I'm interested too. You have invented an unique construction method that well deserves documentation.

I'm interested too. You have invented an unique construction method that well deserves documentation.

Dear Mattes,

just a question: what makes you think wire mounting is better than mounting the driver by the magnet? Just curious to learn the underlying line of thinking here.

Eelco

just a question: what makes you think wire mounting is better than mounting the driver by the magnet? Just curious to learn the underlying line of thinking here.

Eelco

I have a controversial dubt, Does is a Gallery thread? Or right now is a discussion one as every thread in this forum?

I open this thread looking for pictures. I know there are plenty of choices for interchange information that could be relevant for the questioners.

Best Regards

I open this thread looking for pictures. I know there are plenty of choices for interchange information that could be relevant for the questioners.

Best Regards

Last edited:

I have a controversial dubt, Does is a Gallery thread? Or right now is a discussion one as every thread in this forum?

I open this thread looking for pictures. I know there are plenty of choices for interchange information that could be relevant for the questioners.

Best Regards

Dady, I agree. I admit I've gone overboard asking too many detailed of Mattes' project. A separate thread for his build would be best. 😱

No friend, that's happen all the time, We get excited about topics that normally we can never talk to our wives and it is natural that we do not realize.Dady, I agree. I admit I've gone overboard asking too many detailed of Mattes' project. A separate thread for his build would be best. 😱

The best for you

Dear All,

OK, in order not to congest the gallery anymore, I´ll start a thread with my speakers soon. Just let me please hint on several free swinging discussions here in the forum; from where I got the idea, which is certainly not new. Michael has offered a physical explanation as well in his pages, to be found here

Beautiful Swingin' Speaker

but sadly several pictures seemed to have gone.

This and several other threads have been my inspiration, and again I have to thank everybody here for the input.

All the best

Mattes

OK, in order not to congest the gallery anymore, I´ll start a thread with my speakers soon. Just let me please hint on several free swinging discussions here in the forum; from where I got the idea, which is certainly not new. Michael has offered a physical explanation as well in his pages, to be found here

Beautiful Swingin' Speaker

but sadly several pictures seemed to have gone.

This and several other threads have been my inspiration, and again I have to thank everybody here for the input.

All the best

Mattes

I believe in mounting drivers by their magnet, such that the baffle isn’t also a mounting surface ... greatly reduces vibration effects.

So far I have magnet mounted my tangband fullrange, it’s baffle no longer vibrates with the fullrange. Will be doing woofers next.

Can you describe exactly how you did this please? And how do you make it airtight where the driver meets the front baffle if it’s not attached to it?

In the case of a woofer it helps if the motor has a tapered hole as the AE Dipole-18 has (M10). Then you have to design some kind of support to bolt the woofer to it. With a light driver you can suspend it from the motor, with a heavy woofer I would recommend to rest the driver in the support, decoupling it with hard rubber or similar (I will use 2mm thick cork-rubber) and then fix it with a bolt.

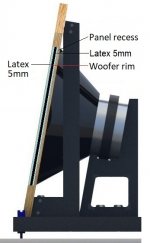

As per the basket, air tight is relative, you cannot press the rim of the woofer too much, otherwise you will lose the effect of float it. I recommend natural latex foam, placed behind and in the front of the rim. Then you can avoid air short-circuit with a metal front ring (see for instance Daniel Hertz speakers).

It is important the support of the woofer has some front-to-back adjustment so you can position the rim of the woofer in the exact plane you need.

I made my support by CNC in solid aluminum. Using wood or other materials is possible but not so safe. The support of the woofer must be anchored to a solid platform, this is paramount. Mine weights 150kg.

I attach a rendered sequence how to prepare the front panel to hide and seal woofer rim.

Regards,

Claudio.

As per the basket, air tight is relative, you cannot press the rim of the woofer too much, otherwise you will lose the effect of float it. I recommend natural latex foam, placed behind and in the front of the rim. Then you can avoid air short-circuit with a metal front ring (see for instance Daniel Hertz speakers).

It is important the support of the woofer has some front-to-back adjustment so you can position the rim of the woofer in the exact plane you need.

I made my support by CNC in solid aluminum. Using wood or other materials is possible but not so safe. The support of the woofer must be anchored to a solid platform, this is paramount. Mine weights 150kg.

I attach a rendered sequence how to prepare the front panel to hide and seal woofer rim.

Regards,

Claudio.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Ultimate Open Baffle Gallery