Hi Jon,

My experience is, that the ideal value of the cap across the feadback resistor depends in a high amount to the specific output transformer.

Did you connect the wires on the transformer in the same way they were before after experimenting. Reversing will result in positive feedback and thus to oscillation.

My experience is, that the ideal value of the cap across the feadback resistor depends in a high amount to the specific output transformer.

Did you connect the wires on the transformer in the same way they were before after experimenting. Reversing will result in positive feedback and thus to oscillation.

I didn't remove any wiring to install the feedback caps - just soldered them in from below the board. I've attached a picture of the amp with caps installed. Given that I've been running without the caps for a year or so, I wouldn't have thought I could have the phase wrong.

Attachments

Your picture appears to show R104 & R204 installed next to your feedback caps. If they've been installed the previous year and it ran, your phasing is not reversed. And simply adding the feedback caps would not have changed that.

Yes, they are installed. In fact, I recall having to swap the phasing when I first built the amp.

In that case, any ideas what else could cause oscillation?

In that case, any ideas what else could cause oscillation?

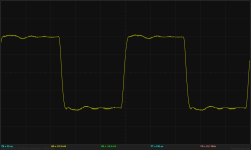

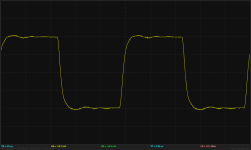

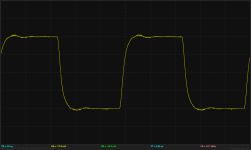

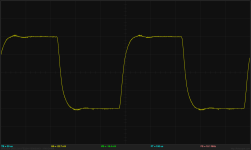

Here are my scope traces from testing with a variety of cap values (none, 270pF, 390pF, and 500pF.) The input is a 10KHz square wave. The traces show 200mv divisions.

Attachments

Hi,

I'm ordering parts for a SPP build. Looking thru this thread I see some people have ordered an Edco CXPP25-MS-8K/23%. While others have ordered the CXPP25-MS-7.6K.

I'm going to use EL84 tubes. What are the advantages to each?

thanks, Jacques

I'm ordering parts for a SPP build. Looking thru this thread I see some people have ordered an Edco CXPP25-MS-8K/23%. While others have ordered the CXPP25-MS-7.6K.

I'm going to use EL84 tubes. What are the advantages to each?

thanks, Jacques

I went with CXPP25-MS-8K/23% because it has the 23% screen tap to run the amp in ultralinear mode.

PCB ordered. This will be interesting to see how it drives my DIY open baffles. Now, for some reading.

What tubes and OPT's are you going to use?

whoops: I see you are going with big Hammond's. Looking forward to see your outcome!

Win W5JAG

whoops: I see you are going with big Hammond's. Looking forward to see your outcome!

Win W5JAG

That's real fast shipping! Thanks George. Now if I can find testing procedures all on one page. a few projects to finish and I'll get right on this SPP.

Nice - those look like the gold plated PCBs that George got last time he had them made. Enjoy!

I ran out of SPP boards so I ordered another batch.......They are shiny gold too! Now that I have some extras I may hack one up to see what some non standard tubes will do in it.

It will be a winter project though, I have too many outdoor projects that must be completed before cold comes. We had a new house built at a budget price, but some of the "temporary" things furnished by the builder "for the buyers convenience" like front steps have already come apart.

It will be a winter project though, I have too many outdoor projects that must be completed before cold comes. We had a new house built at a budget price, but some of the "temporary" things furnished by the builder "for the buyers convenience" like front steps have already come apart.

George,

Sorry to hear about the flimsy parts that your builder put in. Hope you can get them fixed.

Sorry to hear about the flimsy parts that your builder put in. Hope you can get them fixed.

..... but some of the "temporary" things furnished by the builder "for the buyers convenience" like front steps have already come apart.

Contractors never cease to amaze me, in a not very good way.

If you need steps in a hurry, try a mobile ( manufactured ) home supply place - they usually have prefabs in a variety of dimensions .....

Win W5JAG

Sorry to hear about the flimsy parts that your builder put in.....Contractors never cease to amaze me, in a not very good way.

Maybe I didn't explain things correctly. We knew what we were getting. The front and rear steps, entire basement including the stairs, garage and the stairs leading from the house to the garage were all "unfinished" with minimal temporary fixtures intended by the builder for "contractors use." There was no driveway, lot clearance, prep and drainage either. We had been spending our summers here for several years clearing the lot and doing a lot of the dirty work ourselves.

This was all agreed upon in advance. We spent our budget on the house itself, planning to use the funds recovered from selling the house we were living in at the time of construction to have local contractors, friends and relatives in the business do the work.

The problems started when my daughter, her husband and 4 kids decided to move here from Seattle to live in that house until they got settled. That was almost 3 years ago. They are still in that house, we are paying their bills and the house is worth a lot less now than it was 3 years ago. The husband is working 2 jobs, but can't keep up with the expenses of 4 kids, which will increase as they get older.

After a 41 year engineering career at Motorola, I took a buyout and left south Florida. Motorola reneged on it's retiree health care plan and I have spent over 25K on health care so far this year, compounding the financial issues.

All of this has left the "basement lab" far from finished, and minimal funds to complete the tasks left undone, so I have become the chief builder, plumber, and electrician here, and maintenance man at the other house.

I have several cool projects lined up for winter, all of which need some outdoor table saw (among other things) time, including a 1 Kilowatt tube amp. I already have the necessary parts for these projects, I just need to some other things done first.

If you need steps in a hurry, try a mobile ( manufactured ) home supply place - they usually have prefabs in a variety of dimensions

I used the frame from the front stairway of a mobile home that is on the lot for the steps that are there now. I covered them with some wood that I got out of the dumpster where the contractor threw the scraps during the house build. They were cutoffs from the floor joists which didn't fare well during the past 2 winters. We plan to recover them with deck material and Sherri wants that fancy plastic stuff. We must also craft some hand rails before someone slips off the stairs on icy days.

The old mobile home is now an 800 Sq Ft storage building which looks funny with a front door 3 feet in the air and no stairs.

Now that I have some extras I may hack one up to see what some non standard tubes will do in it.

Somewhere, in a box full of stuff near me, is a pair of completely built and tested SPP boards. Each were wired for mono PPP EL84's making over 50 watts each. They were going into a cube shaped box with a clear Lexan face. It never got finished when I left Florida and the wood shop class where I did most of my wood work.

If I find them I have a bunch of cheap tubes to try that will require some W5JAG style board hacking. I'm thinking an aluminum L bracket for the odd tube sockets rather than a hole in the board though.

- Home

- More Vendors...

- Tubelab

- Tubelab Simple P-P