secured to the front of the sink with the pins showing though on the inside for connecting to the PCB.

This would be my preferred method.

But someone gave me once the tip of the cable extension to avoid the use of a L bar.

This would be my preferred method.

But someone gave me once the tip of the cable extension to avoid the use of a L bar.

Please explain further how to do it, co'z L-bar is my only option to mount the PCB in the heatsink.....

Farley

Cable extension

You may need something like this to do that...

Regards,

Max.

Please explain further how to do it, co'z L-bar is my only option to mount the PCB in the heatsink.....

Farley

You may need something like this to do that...

Regards,

Max.

Attachments

Last edited:

yes, i know that kind of heatsink, but the PCB was design for either a flanged heatsink or L-bar as i have seen in some of GM pics.

Great. If Nagys didn't change the design in the last second before release to use the outdated, bulky and difficult to mount TO-3 case you wouldn't have this problem now. The added thermal resistance of every bar construction, be it an extra L-shaped or one-piece, requires a much bigger heatsink to use. Next time better use the superior TO-247 case which saves you all the difficult mounting and requires a heatsink of less than half the size plus you have the option to mount the pcb parallel to the heatsink saving a lot of space inside the amp. 😉 And no: The TO-3 doesn't sound any better than the same transistor inside a TO-247 package. There are very good reasons why the TO-3 package isn't used anymore. 😉

SCNR

I wish you success with this project. Honestly.

SCNR

I wish you success with this project. Honestly.

I do not know what happened to you with the TO3, but i believe you are exaggerating a little.the outdated, bulky and difficult to mount TO-3 case

Next time better use the superior TO-247 case .

The TO-3 package isn't used anymore. 😉

SCNR

I wish you success with this project. Honestly.

TO3 still exists in several rugged industrial designs (MIL, A&S, etc) and you can still buy TO3s fresh from factory,

I has a much better thermal dissipation that other "flat cases". So it is that some designs requires 3 pairs TO3 or 4 flat ones.

It has also the advantage to have available several kinds of nice sockets, where on-field easy repair is a desiderable option.

So, I am not saying that SOT 426 or 220 is not a space-saver and more indicated for new audio designs, but don't worry , metal cans will be around still for a while.

I hope you can still sleep well with that 😀😀😀 Honestly.

effebi

Effebi, yes, I'm exaggerating. 🙂 (Not only a bit. 😉 )

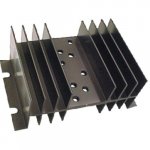

It's true the TO-3 package has better thermal resistance to the heatsink but the L-shaped bar totally spoils that advantage. A TO-247 package mounted directly to the heat sink without any bar in between will have lower thermal resistance. You can do this with TO-3 as well but need a special heat sink for this (shown above).

They might have their place in military applications. I just haven't seen them in recent industrial applications at all.

A socket for in field repair is nice indeed but sockets are always prone to fail - not for high reliability applications imo. At least I wouldn't trust them.

It's true the TO-3 package has better thermal resistance to the heatsink but the L-shaped bar totally spoils that advantage. A TO-247 package mounted directly to the heat sink without any bar in between will have lower thermal resistance. You can do this with TO-3 as well but need a special heat sink for this (shown above).

They might have their place in military applications. I just haven't seen them in recent industrial applications at all.

A socket for in field repair is nice indeed but sockets are always prone to fail - not for high reliability applications imo. At least I wouldn't trust them.

but the L-shaped bar

Not if the L-bracket is large enough.

(Hitachi MOSFETs are TO-3P package, not TO-247, btw)

I agree with you about the sockets in general. But for TO3 is a little bit special. TO3 was born to be socketed. Did you ever ask yoursef why those round, smoothed tips, stiff legs? Affordable sockets, rated as many amps a TO3 can do exist. Unfortunately good ones are so expensive and difficult to have nowadays that they are relegated to the professional use.Effebi, yes, I'm exaggerating. 🙂 (Not only a bit. 😉 )

A socket for in field repair is nice indeed but sockets are always prone to fail - not for high reliability applications imo. At least I wouldn't trust them.

bye

effebi

who still makes Lateral mosFETs to Hitachi specification in a To3 package?TO3 still exists in several rugged industrial designs (MIL, A&S, etc) and you can still buy TO3s fresh from factory,

Can you or I buy these To3 Laterals from that manufacturer?

Not if the L-bracket is large enough.

(Hitachi MOSFETs are TO-3P package, not TO-247, btw)

How large is large enough? There's a limit on thickness because the leads have finite length. The L-bracket not only needs to be thick enough it also must be absolutely flat, even and smooth where it contacts the heat sink.

I once planed a design with such a L-bracket and gave up because the results from calculations were so bad, a real high quality L-bracket not readily available and a custom precision machined one made of copper extremely expensive.

Those L-brackets are made by extrusion and this is not a very high precision manufacturing method. It doesn't matter for the space a TO-3 or TO-3P or TO-247 device occupies but it seriously matters for the area where a L-bracket is mounted to a heatsink. A thin bracket may flex and have enough contact but a thick one that is not exactly even might not flex so well and fit to the stiff but also not exactly even heat sink. A promising cure would be the heat sink that has the L-part built in. There's still some increased thermal resistance from the L-extention to the fins, but definitely much less than with the L-bracket.

IMO the TO-3 is a pain to mount and the thermal benefits lost so quickly.

But it even has some advantages mounting wise, namely the two screws that evenly apply pressure but this can be cured for the plastic packages easily.

It also has some other advantages and disadvantages that may or may not matter for DIY audio.

Every package has it's own set of problems. Pick your poison.

With a heatsink that is big enough the TO-3 with L-bracket will do fine. (The heatsinks Liliya uses are definitely more than adequate for this amp.)

@effebi: Interesting with the sockets, did not know this.

Btw:

This is not the first time this is discussed here. I found something more or less interesting to read:

http://www.diyaudio.com/forums/solid-state/38765-3-v-s-264-a.html

http://www.diyaudio.com/forums/solid-state/12349-3-247-a.html

who still makes Lateral mosFETs to Hitachi specification in a To3 package?

Can you or I buy these To3 Laterals from that manufacturer?

Some just arrived on my desk this week.

You can choose from buz series, ECF series, 2sj/2sk series (magnatec).

I have been led to believe these are made to Hitachi spec (could be wrong though)

Trace Elliot now use buz series in place of hitachi

Hello Liliya,

You are now so well advanced with the Goldmund amplifier, I am very curious about your listening experience.

We will greatly appreciate if you have finished the Goldmund clone, you create a new parts list to cover other builders to have also there benefit.

Because some of the parts are that difficult to get, would you create for us a new parts list with the components “that you have used”.

And mention where you get the difficult to get parts ordered.

What also is useful to create a simple PDF file with the things to lookout for if there are errors in the schema, and where should we measure.

Thanks, and keep us informed,

Rudy

You are now so well advanced with the Goldmund amplifier, I am very curious about your listening experience.

We will greatly appreciate if you have finished the Goldmund clone, you create a new parts list to cover other builders to have also there benefit.

Because some of the parts are that difficult to get, would you create for us a new parts list with the components “that you have used”.

And mention where you get the difficult to get parts ordered.

What also is useful to create a simple PDF file with the things to lookout for if there are errors in the schema, and where should we measure.

Thanks, and keep us informed,

Rudy

Some just arrived on my desk this week.

You can choose from buz series, ECF series, 2sj/2sk series (magnatec).

I have been led to believe these are made to Hitachi spec (could be wrong though)

Trace Elliot now use buz series in place of hitachi

And what about Semelab ALF08P16V/16K,are these ok?

best amps

The best amp i have used would be hh v 800,

Well built with fantastic outputs,

Anyone got any.

The best amp i have used would be hh v 800,

Well built with fantastic outputs,

Anyone got any.

BMW 850

On Friday was the job of Goldmund distracted by other tasks. Therefore, I did not reach my goals for that day. Now, in the weekend, it is my little daughter Kristine who gets my time and attention. Goldmund has to "rest".

I should like to make a digest of experience, any changes that I've done in relation to the original.

The changes are not many, and I have so far described some of them in # 1274.

When it comes to faults, I have not yet found other than what Alex points out in #1252.

But if the serious testing I will do together with Roar(with his measuring equipment, bought from Tandberg when they went down) reveals other errors, I will of course report on that.

Can any of you comments on this: Over the source resistors 0,22 ohm I have measured a 1,5mV drop. Roar says he wold like this measurement a lot higher.

In this case R23 is 1360 ohm.

More to come next week, also listening experience I hope.

Eivind Stillingen

On Friday was the job of Goldmund distracted by other tasks. Therefore, I did not reach my goals for that day. Now, in the weekend, it is my little daughter Kristine who gets my time and attention. Goldmund has to "rest".

I should like to make a digest of experience, any changes that I've done in relation to the original.

The changes are not many, and I have so far described some of them in # 1274.

When it comes to faults, I have not yet found other than what Alex points out in #1252.

But if the serious testing I will do together with Roar(with his measuring equipment, bought from Tandberg when they went down) reveals other errors, I will of course report on that.

Can any of you comments on this: Over the source resistors 0,22 ohm I have measured a 1,5mV drop. Roar says he wold like this measurement a lot higher.

In this case R23 is 1360 ohm.

More to come next week, also listening experience I hope.

Eivind Stillingen

Can any of you comments on this: Over the source resistors 0,22 ohm I have measured a 1,5mV drop. Roar says he wold like this measurement a lot higher.

In this case R23 is 1360 ohm.

Yes, Roar is right. You should measure a much higher voltage there. Are you sure R23 is 1360 Ohm? The schematic says it should be 330R. Bias is set by R20.

I would be aiming for 10mV over those 0.22Ohm source resistors as a bare minimum.

If it was me I would be using between 40mV and 70mV (ie between 180mA and 320mA per device). Hopefully you have nice big heatsinks.

If it was me I would be using between 40mV and 70mV (ie between 180mA and 320mA per device). Hopefully you have nice big heatsinks.

180 to 320 mA per device seems a bit too much to me. I vote for something between 50 and 100 mA.

But there must be a bias recommendation somewhere in the last 1000 posts. Is there someone who can remember or find it?

But there must be a bias recommendation somewhere in the last 1000 posts. Is there someone who can remember or find it?

- Home

- Amplifiers

- Solid State

- The Very Best Amplifier I Have Ever Heard!!!!