What kind of tape has been used that will release from the paper face of foam core, without tearing or removing the paper? Scotch tape seems to damage the face.

under product reviews for the 6.5 MCM 55-2970: "The Thiele-Small parameters are wrong" by MIAgeek on 1/6/2014

Value: Quality:

The actual Thiele-Small parameters are Fs=75.Hz, Vas= 6 liters, Qt= 1.12. See my review for the 55-2971 8" woofer

one MCM I've tried was good - a DVC woofer used in a Marshall Leach sub-sat system http://www.mcmelectronics.com/product/MCM-AUDIO-SELECT-55-1465-/55-1465

Value: Quality:

The actual Thiele-Small parameters are Fs=75.Hz, Vas= 6 liters, Qt= 1.12. See my review for the 55-2971 8" woofer

one MCM I've tried was good - a DVC woofer used in a Marshall Leach sub-sat system http://www.mcmelectronics.com/product/MCM-AUDIO-SELECT-55-1465-/55-1465

Last edited:

I wonder if that is an isolated unit or are they all like that? If this was the case the Qts is even higher than the PE units which are 0.95 and have a smaller magnet. Since the magnets on these units are bigger I would imagine the Qts is smaller given the driver looks very close except for the vented pole piece.

If fs is 75hz and Qts is 1.1 this could still work but bass will probably peak a little higher.

If fs is 75hz and Qts is 1.1 this could still work but bass will probably peak a little higher.

Eight Driver Nautaloss Sub with MCM 55-2970 and PE 299-609

I was curious to see what you can do if you super size this sub a little. Given that the drivers are so cheap at $6 ea x 8 is still under $50 or about what you would pay for a regular name brand 6.5 in driver like Peerless. If you put 8 drivers in a push-pull array (now at 4 ohms nominal) with a double-width Nautaloss cabinet (~13 in wide). Here is what you can get in terms of SPL and impulse response. I will have to go with what the manufacturer T/S parameters are given that they look like they were credibly measured with a plot and all.

http://www.mcmelectronics.com/content/ProductData/Spec%20Sheets/55-2970.pdf

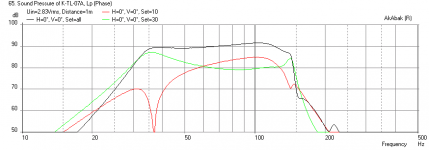

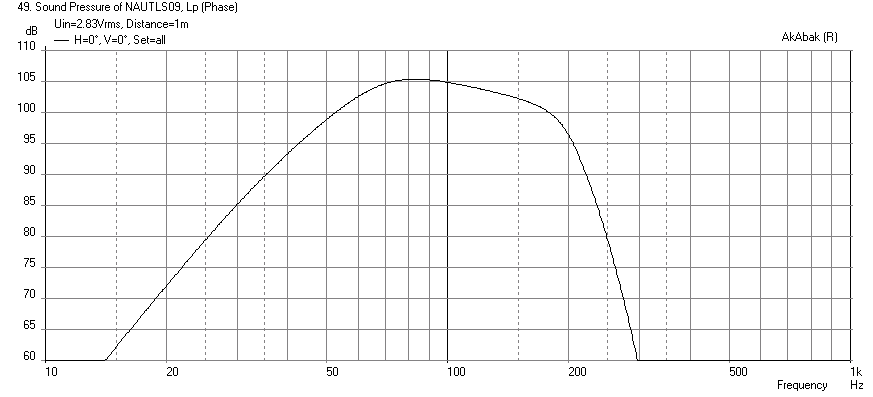

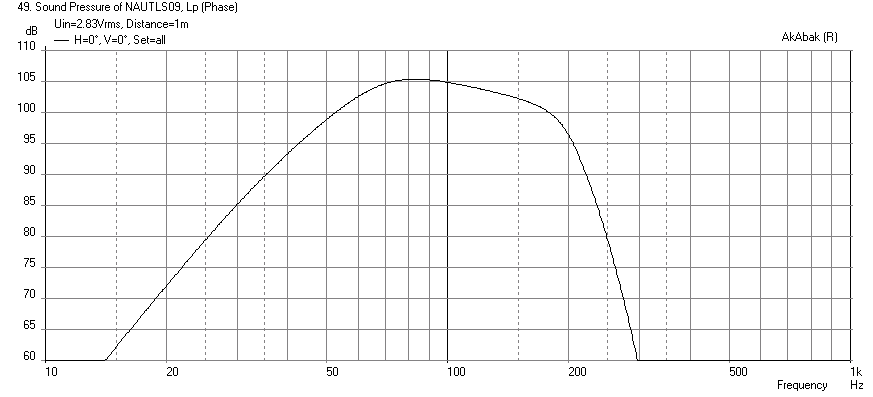

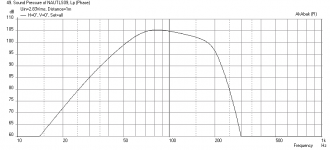

It is a pretty efficient setup when used with corner loading - 96 dB at 50 Hz and 103 dB at 120 Hz with 2.83 volts drive:

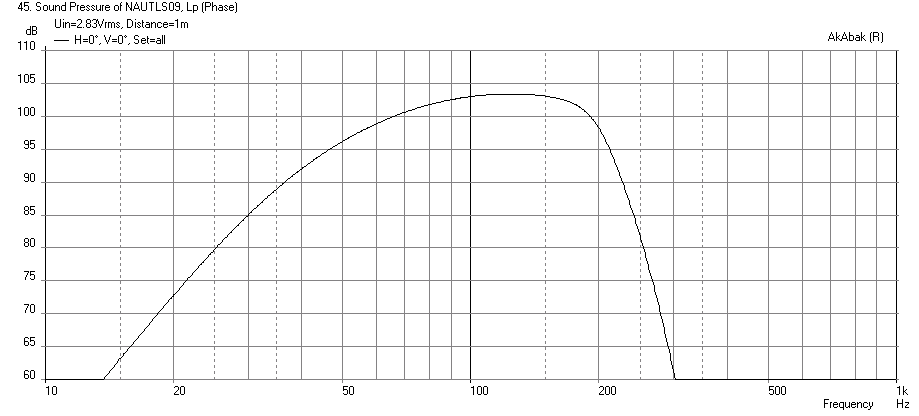

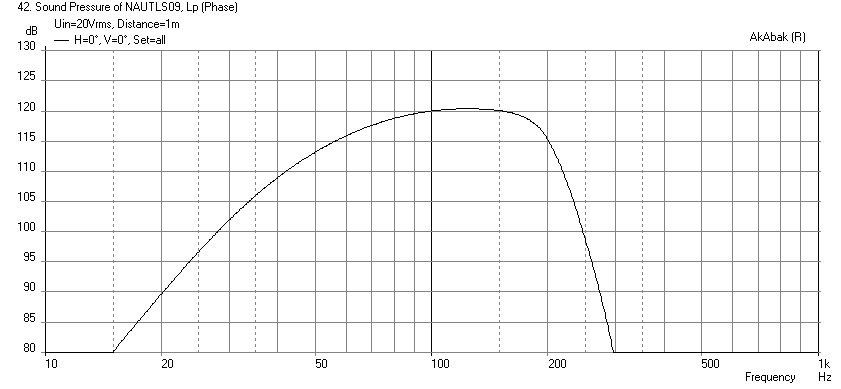

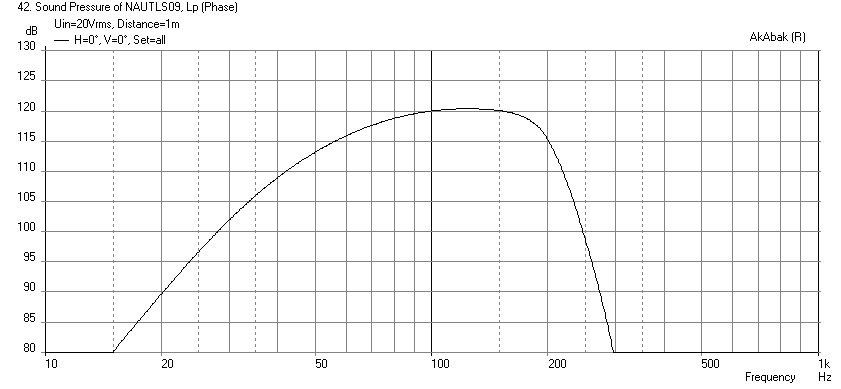

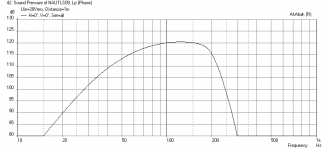

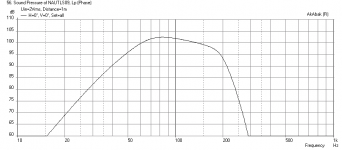

The xmax is stated as 3.5 mm, I am going to push the xmax by 1 mm (I have done this before with no harm done - and this will be the peak transient with normal operation at typically -20 dB below this) and we end up with a 20 volt rms max drive voltage for 100 watts total power (into 4 ohms nominal). Here is max SPL vs Frequency with 35 Hz high pass and 200 Hz low pass filters applied:

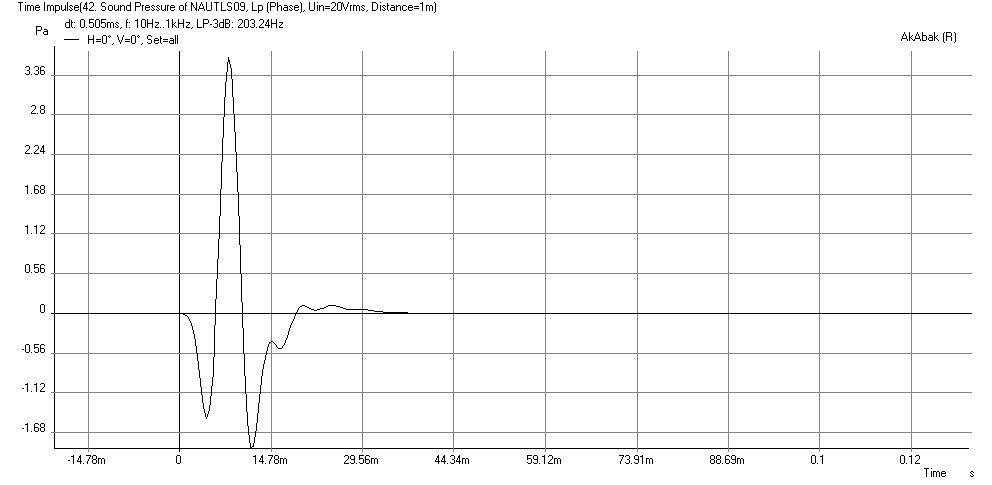

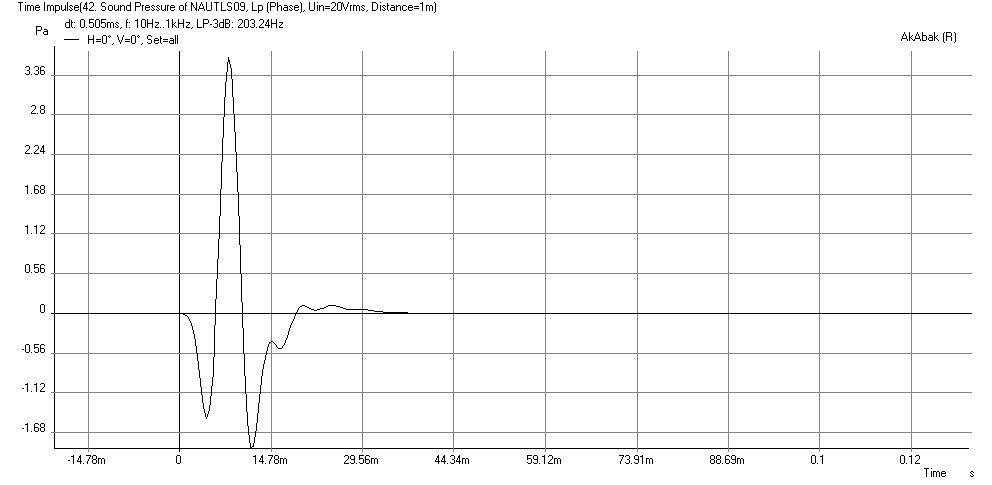

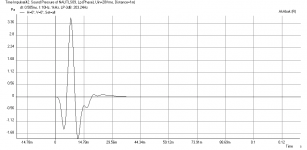

Here is the Impulse response if I switch the driver polarity (don't quite understand this one yet - as it introduces an 8 ms delay now but the spike is in the correct positive sense) and very clean:

So I think for $50 in drivers you can make a 120 dB capable sub that reaches about 65 Hz before EQ'ing with clean dynamics.

You will need a DSP processor to delay the HF mains by 8 ms to time-align this though.

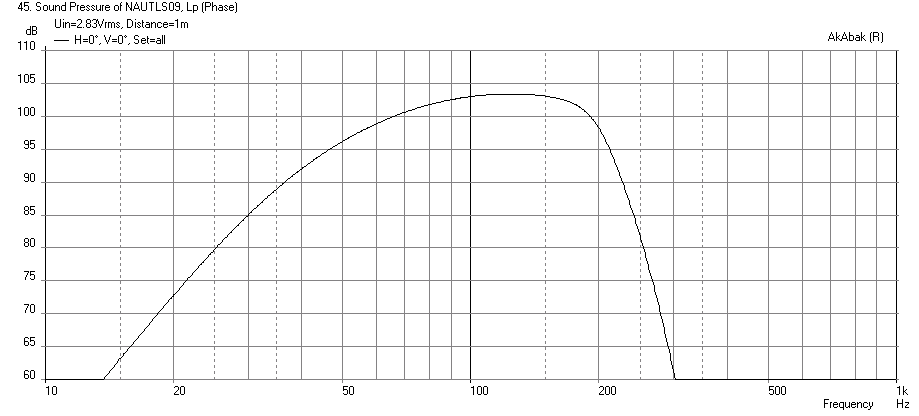

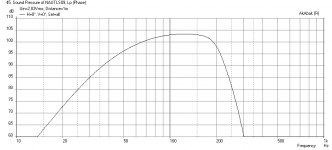

Well, I had to ask what happens with an 8 driver sub using the PE drivers? I think it has a deeper bass punch ( 99 dB at 50 Hz) due to the higher Qts:

To compare though, I have to set the driver voltage at 2 volts as the above sim is for a 2 ohm nominal load and I did not want to re-wire it for 4 ohms. The efficiencies end up being about the same at 96 dB at 50 hz. However, if you have a sub amp capable of 2 ohm drive (such as a TPA3116D2 class D set up for parallel bridge tied load (PBTL) at 100 watts and 2 ohms - this would be perfect.)

I was curious to see what you can do if you super size this sub a little. Given that the drivers are so cheap at $6 ea x 8 is still under $50 or about what you would pay for a regular name brand 6.5 in driver like Peerless. If you put 8 drivers in a push-pull array (now at 4 ohms nominal) with a double-width Nautaloss cabinet (~13 in wide). Here is what you can get in terms of SPL and impulse response. I will have to go with what the manufacturer T/S parameters are given that they look like they were credibly measured with a plot and all.

http://www.mcmelectronics.com/content/ProductData/Spec%20Sheets/55-2970.pdf

It is a pretty efficient setup when used with corner loading - 96 dB at 50 Hz and 103 dB at 120 Hz with 2.83 volts drive:

The xmax is stated as 3.5 mm, I am going to push the xmax by 1 mm (I have done this before with no harm done - and this will be the peak transient with normal operation at typically -20 dB below this) and we end up with a 20 volt rms max drive voltage for 100 watts total power (into 4 ohms nominal). Here is max SPL vs Frequency with 35 Hz high pass and 200 Hz low pass filters applied:

Here is the Impulse response if I switch the driver polarity (don't quite understand this one yet - as it introduces an 8 ms delay now but the spike is in the correct positive sense) and very clean:

So I think for $50 in drivers you can make a 120 dB capable sub that reaches about 65 Hz before EQ'ing with clean dynamics.

You will need a DSP processor to delay the HF mains by 8 ms to time-align this though.

Well, I had to ask what happens with an 8 driver sub using the PE drivers? I think it has a deeper bass punch ( 99 dB at 50 Hz) due to the higher Qts:

To compare though, I have to set the driver voltage at 2 volts as the above sim is for a 2 ohm nominal load and I did not want to re-wire it for 4 ohms. The efficiencies end up being about the same at 96 dB at 50 hz. However, if you have a sub amp capable of 2 ohm drive (such as a TPA3116D2 class D set up for parallel bridge tied load (PBTL) at 100 watts and 2 ohms - this would be perfect.)

Attachments

-

Nautaloss-Sub-Eight-Driver-MCM-55-2970-Max-SPL.png23.4 KB · Views: 872

Nautaloss-Sub-Eight-Driver-MCM-55-2970-Max-SPL.png23.4 KB · Views: 872 -

Nautaloss-Sub-Eight-Driver-MCM-55-2970-Impulse.png19.3 KB · Views: 878

Nautaloss-Sub-Eight-Driver-MCM-55-2970-Impulse.png19.3 KB · Views: 878 -

Nautaloss-Sub-Eight-Driver-MCM-55-2970-2.83Volt.png26 KB · Views: 877

Nautaloss-Sub-Eight-Driver-MCM-55-2970-2.83Volt.png26 KB · Views: 877 -

Nautaloss-Sub-Eight-Driver-PE-299-609-2.83Volt.png24.4 KB · Views: 865

Nautaloss-Sub-Eight-Driver-PE-299-609-2.83Volt.png24.4 KB · Views: 865 -

Nautaloss-Sub-Eight-Driver-PE-299-609-2.00Volt.png24.2 KB · Views: 854

Nautaloss-Sub-Eight-Driver-PE-299-609-2.00Volt.png24.2 KB · Views: 854

Last edited:

This is going way into the junk gear zone, but what about repurposing a car 6X9 speaker? I've got in front of me a pair of Kenwood KFC6960ie speakers. Came out of a car installation when my son still had Grannie's huge Buick (1st car, boring but totally functional and safe). these sounded pretty good on the back deck with that huge trunk. (big enough for several golf bags, a sub woofer, and a cooler, at once). The ratings for this such as I have, are:

4 ohms

peak power, 300 watts, rated power 75 watts,

magnet 330 g (11.6oz)

triaxial.

4 ohms

peak power, 300 watts, rated power 75 watts,

magnet 330 g (11.6oz)

triaxial.

This is going way into the junk gear zone, but what about repurposing a car 6X9 speaker? I've got in front of me a pair of Kenwood KFC6960ie speakers. Came out of a car installation when my son still had Grannie's huge Buick (1st car, boring but totally functional and safe). these sounded pretty good on the back deck with that huge trunk. (big enough for several golf bags, a sub woofer, and a cooler, at once). The ratings for this such as I have, are:

4 ohms

peak power, 300 watts, rated power 75 watts,

magnet 330 g (11.6oz)

triaxial.

It should work in a Nautaloss as it is high Qts. Just make one that can hold the 6x9 in place and make 3 ft long spiral and set rest of dimensions for convenience. Should sound good.

I do have some scrap, 1/4" and 1/8" thick fiberglass skin nomex honeycomb, as well as some smaller 2'x2' 1" thick aluminum skin, aluminum core honeycomb. I'm thinking these would work in a karlson made that way, since mostly (unless you have a cured top baffle) would would not have to kerf and curve any of the panels for a Karlson. Or even a Karlson Clam.

I think aerospace honeycomb panels are what speakers should be made of. They are stiff and lightweight. I surprised more people don't make speakers from it.

What about your Nautaloss. How is that coming?

Am I the only one who thinks that a 96 dB at 50 Hz efficient speaker for $50 in drivers is cool?

What about your Nautaloss. How is that coming?

Am I the only one who thinks that a 96 dB at 50 Hz efficient speaker for $50 in drivers is cool?

The Naut spirals are curing with weights on top. Gorilla on the internal edges and Elmer's PVA on the outside edges. I learned my lesson with the gorilla glue with the previous portions of the build. That stuff gets everywhere.

The Naut spirals are curing with weights on top. Gorilla on the internal edges and Elmer's PVA on the outside edges. I learned my lesson with the gorilla glue with the previous portions of the build. That stuff gets everywhere.

Looking forward to seeing the build. You are making Nautaloss II's right? What are you doing for the sub woofer?

X, when you first mentioned building the Nautaloss II I half expected you'd mount the Vifa's side by side. Listening to it with the enclosure placed on its side.

Gradually building more and more of them and stacking them until you get a floor to ceiling Nautaloss. Separately amped of coarse with one amp for each enclosure 😉.

Add EQ and subs and enjoy....

Gradually building more and more of them and stacking them until you get a floor to ceiling Nautaloss. Separately amped of coarse with one amp for each enclosure 😉.

Add EQ and subs and enjoy....

...i believe we do need some more "detailed" tech designs to recreate the _same_ speakers...

You mean a drawing of the Nautaloss II layout and dimensions? I can provide that but I will have to create it as I said before, I made it by sketching directly onto the side foam core board. I really don't think it is that critical as long as overall volume is approximately the same and TL length is about the same.

X, when you first mentioned building the Nautaloss II I half expected you'd mount the Vifa's side by side. Listening to it with the enclosure placed on its side.

Gradually building more and more of them and stacking them until you get a floor to ceiling Nautaloss. Separately amped of coarse with one amp for each enclosure 😉.

Add EQ and subs and enjoy....

I thought about this but alas, I don't think I will ever have 50 drivers or the time to make that many enclosures. I suppose one can build this over many years and patiently wait to have a completed system. 25 units stacked on its side is kind of cool. Additional bracing will be needed if the bottom units have to support the upper ones' weight. My current inventory of Vifa's is 18 drivers maybe not too far off? 🙂

I probably will build a sub. Right now there is a sub of sorts in my HT, of all things an Altec sub from one of their computer speakers. Mostly this sub is boomy instead of tight. It's sitting on the bottom shelf of the HT cabinet. Wondering if I can fit a small tapped horn, or TL-bandpass into this space, which is 16" deep x 35 1/2" wide x 7 1/2" high.Looking forward to seeing the build. You are making Nautaloss II's right? What are you doing for the sub woofer?

I probably will build a sub. Right now there is a sub of sorts in my HT, of all things an Altec sub from one of their computer speakers. Mostly this sub is boomy instead of tight. It's sitting on the bottom shelf of the HT cabinet. Wondering if I can fit a small tapped horn, or TL-bandpass into this space, which is 16" deep x 35 1/2" wide x 7 1/2" high.

If you take a Karlsonator and scale it to fit your space (34 in tall x 7 in wide cabinet on its side) and put a couple of 5.25 in drivers in it and remove the Karlson slot and use a simple rectangular opening that is 11 in tall, you can actually get a pretty nice tapped horn. Here is an example using dual Tang Band W5-704D's with a 37 Hz high pass and a 150 Hz low pass filter. It will reach 35 Hz. The trick is to find an 88 dB efficient driver with more than 3.3 mm xamx. They used to have a 5.5 mm xmax version but that sold out.

Attachments

Finally, I got one Naut finished and hooked up to the big Onkoyo, Playing a flac rendered recording of Cannonball Adderly Jazz.

Even though this build's quality was terrible, glue all over the place, and so on, the speaker sounds shockingly good. I may use this one as the center channel since it will be sitting in a cabinet5 and mostly won't be visible except for the front side. Will be building two more soon.

Even though this build's quality was terrible, glue all over the place, and so on, the speaker sounds shockingly good. I may use this one as the center channel since it will be sitting in a cabinet5 and mostly won't be visible except for the front side. Will be building two more soon.

Thoughts on how to improve the build:

PVA glue on all exposed edges.

Use a 5" wide tube to anchor the center,

Do an outside curve kerf on the internal tighter curved parts of the spiral, Seal kerfs with PVA glue,

Side panels out of 1/4" plywood (this is easy enough to cut.)

Front panel out of same plywood.

If I can find a shop to kerf it or buy pre-kerfed plywood make the spiral out of that. Or, I did see somewhere that someone made a cornu spiral out of small discrete flat pieces of wood.

Use the same type Vifa speakers.

PVA glue on all exposed edges.

Use a 5" wide tube to anchor the center,

Do an outside curve kerf on the internal tighter curved parts of the spiral, Seal kerfs with PVA glue,

Side panels out of 1/4" plywood (this is easy enough to cut.)

Front panel out of same plywood.

If I can find a shop to kerf it or buy pre-kerfed plywood make the spiral out of that. Or, I did see somewhere that someone made a cornu spiral out of small discrete flat pieces of wood.

Use the same type Vifa speakers.

Last edited:

the speaker sounds shockingly good.

Congrats!

Is this with the Altec PC subwoofer? Wait until you put a real sub that is clean next to it.

Good ideas for a wood build with side and front panels - all easy cuts. Not sure why you want to kerf the outside (convex) side of the foam core. Mine curved nicely with the scoring on the concave side and it leaves it smooth that way. Good idea on the tube - I thought of using a paper roll tube...

Any chance we can see photos of your ugly glue-covered baby? 🙂

Last edited:

- Home

- Loudspeakers

- Full Range

- The Nautaloss Ref Monitor