Well, I found someplace I could purchase 2 Permali blocks measuring 400x500x20 in the US should those be the needed dimensions. Delivery 4-5 weeks, $1139 USD before cost of freight. How does that compare to what others have paid?

That's a lot more than what I paid for my 2 400x500x30mm blocks. IIRC it was about $500AU.

Maybe investigate Panzerholtz it's similar stuff. @donhughes111 might chime in and let you know where he bought his Pz from.

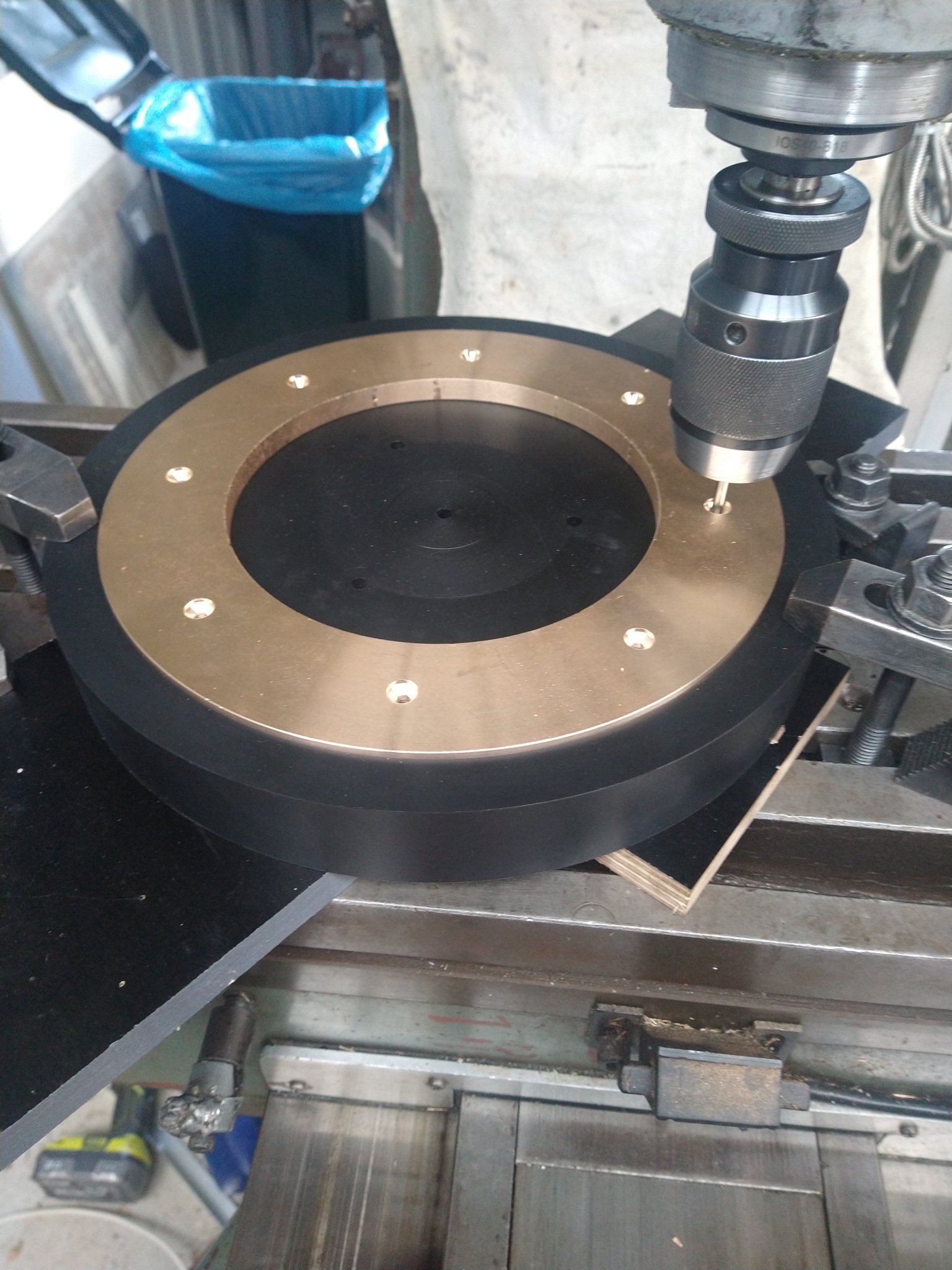

I also found the Permalli was not flat and needed the surfaces planed flat for a good glue joint. I did it on the milling machine with a 50mm carbide router bit, next time I'll get the supplier to do this. It could also be done with a router planer jig and a 50mm carbide router bit.

Maybe investigate Panzerholtz it's similar stuff. @donhughes111 might chime in and let you know where he bought his Pz from.

I also found the Permalli was not flat and needed the surfaces planed flat for a good glue joint. I did it on the milling machine with a 50mm carbide router bit, next time I'll get the supplier to do this. It could also be done with a router planer jig and a 50mm carbide router bit.

You don't have to use 400x500mm if you are remote mounting the motor. You can use any size that will suite your tonearm requirements. I used 400x500mm because I designed mine for 4 pivoting arms with the ability to mount a linear tracker.

I gave those numbers as an arbitrary starting point as I was not sure what they would have available in stock, as they are a piping company by trade. Glad to know there is someplace, but I’ve got a little time to sort out the specifics of my build and shop around to see if I can find a more reasonable price.

"That's a lot more than what I paid for my 2 400x500x30mm blocks. IIRC it was about $500AU."

That's crazy. $335USD. I wonder what the freight is to the US???

That's crazy. $335USD. I wonder what the freight is to the US???

Checked freight on 2x Permalli blocks and they are slightly over the maximum 20kg so would need to be shipped separately at about $300US each. It's not very often Australia is cheaper than the USA.

Thanks for checking on that. I asked if there was anything that I could to decrease cost, less customized with size etc, and they said there is too much loss of product for them to sell it at a similar cost to what you can do there in Australia, and suggested I buy the whole 4’x8’ board. Out of curiosity I’ve asked how much that would cost, maybe a group buy is an option.

One thing I forgot to mention was my Permalli is not exactly 400x500 it's slightly under so they could cut the panels from a single sheet. IIRC it's 400x490mm

So the engineer got back to me and a 4’x8’ board (1219x2438mm) sheet would cost $3-4k (not the most precise engineer!) Assuming $4k, and assuming a group order of 400x500x20mm boards was made (better to over compensate even if they could be 400x480 or something,) we could make 12 boards for 6 individuals and there would be some waste, would need to get it down in size to that ~480 to get 15 boards out of the whole sheet. Anywho, 6 plinths into $4k would be $667.

I don’t know if there would be enough interest from other US individuals here at that price point, or if the company would be willing to plane and cut that many pieces without adding extra fees, but thought I’d bring it to folks attention. The company is Piping Technology and Products, Inc. The engineer asked if I’d considered Micarta C as a cheaper option, not sure if that’s ever been mentioned or tried out by anyone but figured I’d bring it up.

One last thought, if the measurements suit your needs, there is a fellow on usaudiomart selling panzerholz 457x457x20 for $132.90 a board. I haven’t actually mapped out a plinth myself to see how tight that would be, but if it fits with a cantilever tonearm mount that’s certainly an attractive option for the price. https://www.usaudiomart.com/details/649922343-panzerholztankwood/

I don’t know if there would be enough interest from other US individuals here at that price point, or if the company would be willing to plane and cut that many pieces without adding extra fees, but thought I’d bring it to folks attention. The company is Piping Technology and Products, Inc. The engineer asked if I’d considered Micarta C as a cheaper option, not sure if that’s ever been mentioned or tried out by anyone but figured I’d bring it up.

One last thought, if the measurements suit your needs, there is a fellow on usaudiomart selling panzerholz 457x457x20 for $132.90 a board. I haven’t actually mapped out a plinth myself to see how tight that would be, but if it fits with a cantilever tonearm mount that’s certainly an attractive option for the price. https://www.usaudiomart.com/details/649922343-panzerholztankwood/

@FuzzyNightmares,

Just curious, how do you handle a group buy considering the weight and shipping cost of the product. This is not like shipping a few transistors.

Don

Just curious, how do you handle a group buy considering the weight and shipping cost of the product. This is not like shipping a few transistors.

Don

@donhughes111

Yeah the specifics would have to be worked out, and given the logistical challenges the company would likely have to be on board with making the cuts, packing/shipping, and providing individual invoices complete with shipping charges to each interested party. Due to the still high price that they put on the purchase of an entire 4’x8’ sheet I don’t believe it makes sense, particular once they factor in shipping, I’d imagine it would get to be very close to what it would cost to source these from Australia. Just wanted to share the information and bring it up as an option in case there were individuals wanting to try.

Personally, I’ve reached out and am awaiting reply from the individual selling the 457x457x20 mm panzer. I think for a single tonearm it should be adequate for my needs.

Yeah the specifics would have to be worked out, and given the logistical challenges the company would likely have to be on board with making the cuts, packing/shipping, and providing individual invoices complete with shipping charges to each interested party. Due to the still high price that they put on the purchase of an entire 4’x8’ sheet I don’t believe it makes sense, particular once they factor in shipping, I’d imagine it would get to be very close to what it would cost to source these from Australia. Just wanted to share the information and bring it up as an option in case there were individuals wanting to try.

Personally, I’ve reached out and am awaiting reply from the individual selling the 457x457x20 mm panzer. I think for a single tonearm it should be adequate for my needs.

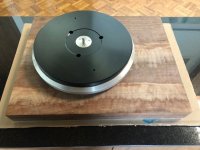

Making progress. I actually got my motor mount ring mounted on the Pz. A critical phase since the axis of the 2 Pz pieces and the motor mount ring had to be precisely co-liniar. A requirement to not stress the spindle axis. Now it gets to the tone arm install. I'll post separately on that. Pics attached.

Attachments

A question for the "noise" experts. Why have we not seen an Al-Pz-POM platter stack? Seems like it would ad another layer of noise reduction??? Especially with a decoupled spindle.

Don

Don

Don, You can cut a hole in the Pz for the arm mount. The other alternative is to mount the TA so the CL armboard hangs over the edge of the plinth to give access to install the cable in the bottom of the EPA-100.

My LP surface is 4" above the top of the plinth and I don't have room to install the cable in my EPA-100, 5" would give clearance.

I have seen a Pz platter for a Garrard 301. Pz is horrible to machine and blunts HSS/Co tools pretty quickly, so machining it flat enough for a platter would be challenging. POM works exceptionally well as the LP interface because it has similar Acoustic Impedance (AZ) to the LP so 98% of the vibration energy created by the stylus tracing the groove is transferred into the POM, with the LP clamped to the platter it makes the LP as thick as the POM.

POM also has higher density than Acrylic so it's ability to attenuate the energy wave is greater than Acrylic. @Bon platter use thicker POM 40mm and mine is 50mm both have a Gunmetal ring under the platter to lower COM and ensure the POM does not warp. The POM sits directly on the SP10 motor.

With the SP10 DD motor it's not necessary to increase MoI of the platter too much like is needed with a BD TT to maintain speed. Although from my testing the increased MoI of my platter alters the time constant of the Phase Locked Loop and smooths both Wow and Flutter but increases Drift slightly. Drift is very slow speed variation so the FM sidebands created by Drift are so close to the fundamental note that they are masked.

My LP surface is 4" above the top of the plinth and I don't have room to install the cable in my EPA-100, 5" would give clearance.

I have seen a Pz platter for a Garrard 301. Pz is horrible to machine and blunts HSS/Co tools pretty quickly, so machining it flat enough for a platter would be challenging. POM works exceptionally well as the LP interface because it has similar Acoustic Impedance (AZ) to the LP so 98% of the vibration energy created by the stylus tracing the groove is transferred into the POM, with the LP clamped to the platter it makes the LP as thick as the POM.

POM also has higher density than Acrylic so it's ability to attenuate the energy wave is greater than Acrylic. @Bon platter use thicker POM 40mm and mine is 50mm both have a Gunmetal ring under the platter to lower COM and ensure the POM does not warp. The POM sits directly on the SP10 motor.

With the SP10 DD motor it's not necessary to increase MoI of the platter too much like is needed with a BD TT to maintain speed. Although from my testing the increased MoI of my platter alters the time constant of the Phase Locked Loop and smooths both Wow and Flutter but increases Drift slightly. Drift is very slow speed variation so the FM sidebands created by Drift are so close to the fundamental note that they are masked.

Is there a drawing/instructions somewhere for how to machine the 20mm POM platter, modify the existing platter to attach the POM, and then, attach a decoupled spindle? Modifying the platter was something I did not necessarily want to get involved in but I guess if going through the effort of nude mounting in a custom plinth I might as well look at all options!I should mention Bon's POM platter is 40mm thick and I think there is no advantage to my 60mm POM platter that I could tell.

I also have a peripheral ring that I don't use now I have gone back to a reflex clamp because my Stanton CS-100 rubs on the ring. I pulled the motor apart after a few hundred hrs and there is virtually no wear on the thrust pad. I installed a new Torlon thrust pad and SI3N4 ball when I built the TT.

The minimum platter thickness to use a de-coupled spindle is 20mm POM on a stock platter. I have now made a few POM/stock platters for other SP10mk2 owners and all of them have reported an improvement in detail and a drop in noise.

With the few mods Bon and I have done to our mk2's they will hold their own against almost any TT out there. They are stunningly good.

With the SP10 DD motor it's not necessary to increase MoI of the platter too much like is needed with a BD TT to maintain speed. Although from my testing the increased MoI of my platter alters the time constant of the Phase Locked Loop and smooths both Wow and Flutter but increases Drift slightly. Drift is very slow speed variation so the FM sidebands created by Drift are so close to the fundamental note that they are masked.

The last data you shared showed the exact characteristic I and others have measured from increased MoI - slightly better flutter but worse wow. What changed, and will you post the new raw data?

@warrjon,

Is there a large cutout in the bottom of your POM platter to accommodate the motor and flange mount ring. (I presume). Also, did you stay with the 1" mount ring? Why?, when you are cutting into the POM material. What is the weight of the Platter in your last picture.

Thanks, trying to understand the reasoning behind your thinking.

R,

Don

Is there a large cutout in the bottom of your POM platter to accommodate the motor and flange mount ring. (I presume). Also, did you stay with the 1" mount ring? Why?, when you are cutting into the POM material. What is the weight of the Platter in your last picture.

Thanks, trying to understand the reasoning behind your thinking.

R,

Don

@donhughes111

The recess under the platter is the same as the OEM, the difference is the rest of the bottom of the platter is flat so it will not fit on a stock SP10 chassis as it'll foul on the chassis where the brake is.

My POM platter is about 8kg. I'm not specifically interested in mass. My goal was to manage the energy of the stylus tracking the groove. According to Shure research stylus is subject to g-force in the 1000's so there is considerable energy to manage, POM does a very good job. One thing you'll notice when you listen to the POM platter over the stock is the noticeable drop in LP surface noise.

The recess under the platter is the same as the OEM, the difference is the rest of the bottom of the platter is flat so it will not fit on a stock SP10 chassis as it'll foul on the chassis where the brake is.

My POM platter is about 8kg. I'm not specifically interested in mass. My goal was to manage the energy of the stylus tracking the groove. According to Shure research stylus is subject to g-force in the 1000's so there is considerable energy to manage, POM does a very good job. One thing you'll notice when you listen to the POM platter over the stock is the noticeable drop in LP surface noise.

I do have a dxf of the OEM/POM platter, which I use mainly for measurements, but I have no instructions. Do you have machining capability?Is there a drawing/instructions somewhere for how to machine the 20mm POM platter, modify the existing platter to attach the POM, and then, attach a decoupled spindle? Modifying the platter was something I did not necessarily want to get involved in but I guess if going through the effort of nude mounting in a custom plinth I might as well look at all options!

The POM is machined flat and bolted to the platter after the OEM rubber is removed. 2nd pic shows an early decoupled spindle and the 3rd pic is a recent platter the decoupled spindle is fixed to the POM so a reflex clamp can be used and the POM edge is chamfered at 50deg rather than stepped to prevent fluting.

The top of the platter also has threaded holes for lifting the platter as it's almost impossible to remove a platter from a chassis without them.

The prices shown from the Panzerholz Vendor are looking to be reasonably fair, the charge does not appear to have a excessive Mark Up. If this is a Long Term secure source for P'holz, is yet to be seen. Acting on a purchase as soon as reassurances are given might be the most advantageous approach.

A Importer of P'holz to the UK is now retired from their Business, my Import of P'holz Board, was the last small order to be supplied to the UK through this service. The Import Business Owner informed my that Delignit are declining small orders and their model is now looking to supply a fixed minimum quantity only.

The continued supply from this Vendor will possibly be dependant on how Delignit are will to support the orders being made. At present and through conversations with some who are P'holz Advocates, there does not seem to be any New Order P'holz, that is offered for a resale entering the UK, I am aware a limited amount of Old Import has been available.

I have stated this previously, the individual who originally promoted the idea of using P'holz in the forums, as a result of their measuring the properties of materials, suggested that 10mm thickness is enough to achieve the desired measurements that show the desired properties.

The Vendor in the Link, also has 25mm and other thicknesses, 25mm is the commonly seen thickness as a Plinth in the UK.

I know advocates of P'holz in the UK, who would potentially jump at the 40mm thickness, as they thought 32mm was noticeable as an improvement over 25mm, following their evaluations.

The inquiries being made to the Vendor, would be further beneficial, if the Product was made known to be B25 and a Cross Ply lamination, as it this Type that is the most commonly seen used for Plinth Designs.

A Importer of P'holz to the UK is now retired from their Business, my Import of P'holz Board, was the last small order to be supplied to the UK through this service. The Import Business Owner informed my that Delignit are declining small orders and their model is now looking to supply a fixed minimum quantity only.

The continued supply from this Vendor will possibly be dependant on how Delignit are will to support the orders being made. At present and through conversations with some who are P'holz Advocates, there does not seem to be any New Order P'holz, that is offered for a resale entering the UK, I am aware a limited amount of Old Import has been available.

I have stated this previously, the individual who originally promoted the idea of using P'holz in the forums, as a result of their measuring the properties of materials, suggested that 10mm thickness is enough to achieve the desired measurements that show the desired properties.

The Vendor in the Link, also has 25mm and other thicknesses, 25mm is the commonly seen thickness as a Plinth in the UK.

I know advocates of P'holz in the UK, who would potentially jump at the 40mm thickness, as they thought 32mm was noticeable as an improvement over 25mm, following their evaluations.

The inquiries being made to the Vendor, would be further beneficial, if the Product was made known to be B25 and a Cross Ply lamination, as it this Type that is the most commonly seen used for Plinth Designs.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread