for a long time i had a wish to clone SonusFaber floorstand and i think Elsinore can take that shape, but i'd like to get opinions on this curved box by keeping same internal volume. is it a go or not?

i'll order the box to my friend with cnc service, built-in waveguide with green mdf which is claimed more durable. either original Elsinores box in red paint or curved like SF

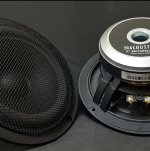

btw the NRX driver that i got has wire mesh cover, it is hard to remove it and i worry it will break if i force it. any issue on sound quality? aesthetically does not look good but take it or leave it

i'll order the box to my friend with cnc service, built-in waveguide with green mdf which is claimed more durable. either original Elsinores box in red paint or curved like SF

btw the NRX driver that i got has wire mesh cover, it is hard to remove it and i worry it will break if i force it. any issue on sound quality? aesthetically does not look good but take it or leave it

Attachments

I like the screens on the NRX drivers, but I've got grandchildren running around here like a pack of monkeys. Only a matter of time before one pokes a cone to see what happens.

It's still a poor-value proposition..

Spent enough time working through the Aluminum phase... Smaller speaker may be..

TY Scott, I pulled the trigger! Loved the way the darkened (carbonised)

boo looked!

Any advice on internal bracing material ? (Ply vs MDF) Normal wood expands and contracts as humidity levels change, plywood to a lesser degree. I would imagine MDF does as well. I wanted to find something that moves at the same rate as the boo so the corners are always tight and nothing gets spread apart from the inside... I also don't want any cracking in the boards from shrinkage...

Also, since the panels are 11.5-12" wide, Im gonna have to glue up some to have the width for the sides... I have a biscuit joiner, clamps etc, tight bond 3, but no edge joiner.... I know from past projects that if the edges are off of 90 even a hair, by the time you get around your box is no bueno...

Wondered if you have done this yet, how square was the boo and any other advise you may have from...

Are both sides of the boo panels as good looking as the images show?

Time to do some preliminary layouts on iron core inductors and get going on the x-over!

for a long time i had a wish to clone SonusFaber floorstand and i think Elsinore can take that shape, but i'd like to get opinions on this curved box by keeping same internal volume. is it a go or not?

Go for it!

Just make sure to keep the baffle dimensions, driver positions on the baffle, and box volume as specified in the Elsinore drawings.

Has anyone put a front facing port in the Elsinore ?

i will not only have to put my speakers close to the wall, the right one will be purty much in the corner... (I know.. but its the only house I have right now)

I under stand that front facing ports can help with situations like mine...

i will not only have to put my speakers close to the wall, the right one will be purty much in the corner... (I know.. but its the only house I have right now)

I under stand that front facing ports can help with situations like mine...

It should have a low stand anyway, consider putting casters on the stand to roll it out for critical listening.

Go for it!

Just make sure to keep the baffle dimensions, driver positions on the baffle, and box volume as specified in the Elsinore drawings.

sure i just ordered cutting template, overall 30mm width. this will cost me around 5 sheets of plywood for stereo build. 10cm extra base + another 10cm on top will be incorporated in my build because with original height, i'm short of around 10L internal volume

Has anyone put a front facing port in the Elsinore ?

i will not only have to put my speakers close to the wall, the right one will be purty much in the corner... (I know.. but its the only house I have right now)

I under stand that front facing ports can help with situations like mine...

I'll have to put my port on front baffle 😀

Attachments

I'll have to put my port on front baffle 😀

Think again! If you ask me, the midrange garbage coming out of the port(s) should not be directed towards your ears. I know that others have different opinions about this, so... up to you.

Go for it!

Just make sure to keep the baffle dimensions, driver positions on the baffle, and box volume as specified in the Elsinore drawings.

Particularly the width of the front panel, try not to make it too narrow and as close to 280mm wide as possible. It is about not shifting the tonal balance to much due to diffraction loss that affects the lower midrange (the transition from 2Pi to 4Pi). There are more than one kind of diffraction type involved, but basically keep things flush and not major change to the front of the speaker. How deep it is, that is not much of an issue.

If the baffle width ends up a lot narrower, I would suggest reducing L1 inductor to 3.5mH.

About the internal fill, line near the front panel and drivers (inside sides), and then the back of the enclosure near 50-60% fill, the material not too dense and not too close to the port. Keep the port at the rear and bottom, but I suspect you would so that anyway. Yes, there is no such thing as an entirely noiseless port.

Let us know, report your progress here, could be a unique pair of Elsinores coming up?

Cheers, Joe

Last edited:

with 5 sheet of laminated plywood which will cost me around $250, i just realised with the same money i can get hardwood like mahogany/soarwood for 1 meter cubic which should be enough for Elsinore and for sure it will look much better 🙂 so my reference design just changed.

this is what i'm expecting now

i'm still negotiating with my colleague about working cost with cnc, my basic plan with 5cm thick wood that he cut the template up to 2cm deep and i will continue finishing with hand router, then gluing and sanding.

or another option that he will do all that dirty work 😀 i just have to justify which one is better

with this design i will use bottom port

this is what i'm expecting now

i'm still negotiating with my colleague about working cost with cnc, my basic plan with 5cm thick wood that he cut the template up to 2cm deep and i will continue finishing with hand router, then gluing and sanding.

or another option that he will do all that dirty work 😀 i just have to justify which one is better

with this design i will use bottom port

Attachments

with 5 sheet of laminated plywood which will cost me around $250, i just realised with the same money i can get hardwood like mahogany/soarwood for 1 meter cubic which should be enough for Elsinore and for sure it will look much better 🙂 so my reference design just changed.

this is what i'm expecting now

This looks pretty! Can you tell more about this speaker? Is there maybe a thread about it somewhere?

This looks pretty! Can you tell more about this speaker? Is there maybe a thread about it somewhere?

you can enjoy the beauty picture here

Gracioso 2.0 – Acoustic preference

Mono and Stereo High-End Audio Magazine: Acoustic Preference Gracioso 2.0 LE/ST speakers NEW

for €12k i think that it's not overpriced compared to other commercial speaker considering it's beautiful hard wood material. even your wife would be pleased by it looks

..the same money i can get hardwood like mahogany/soarwood for 1 meter cubic which should be enough for Elsinore and for sure it will look much better 🙂 so my reference design just changed.

1. Make sure it's from a sustainable source.

2. Make sure it's kiln-dried with moisture content below 15%.

1. Make sure it's from a sustainable source.

2. Make sure it's kiln-dried with moisture content below 15%.

And learn how it's going to move, and in which direction, with moisture changes. Also realize that your finish won't stop the movement, it will only slow it down. That was the art of the great furniture makers .... they knew how it would move, and allowed for the movement. IMHO, solid wood is not the best choice.

Unless your environment is at a constant 6% year round, it's still going to expand and contract.

Not here to argue just stating I have built a lot of furniture in the Stickley manner and its all from quartersawn lumber it doesn't move the way traditional flat sawn does. Also 36% relative humidity equals 6% moisture content of raw unsealed wood. I have had no issues when I built in these dry months of winter .Seal all surfaces with multiple coats of shellac etc. Yes there are exceptions to all rules. cheers

Not wishing to argue, either. Quarter cut white oak is lovely stuff, and I also use it. You obviously know what you're doing, but not allowing for the movement of wood is a common issue with inexperienced woodworkers. I'm just raising the issue for those who may not be aware.

True it will pull and push itself apart if those provisions are not met and experience really pays off with some trial and errors. I had some till I researched the drying process and getting someone to quarter saw it for me. My Elsinores are the MK 3 version and weight 86 lbs each they sound fantastic . Thank you Joe for sharing this ...cheers

I agree about the quarter sawn timber being more stable.Of course all oak type timbers should be quarter sawn anyway.

I disagree about using kiln dried timber.Air dried from the same climate is much better.Especially if the kiln dried timber is over-dried and I would say anything below 11-12% is over dried.I would much rather use air dried 14%.

Things in very low humidity cold climate centrally heated climates might be different I suppose.I live in a mediterranean climate where timber will vary between 11-12% in summer and up to 16% in winter.

I have sold air dried jarrah furniture to Canadians who used it here before taking it to Canada and who have since brought it back again and it has not cracked or warped at all.All surfaces were sealed with 2 pack lacquer.

I disagree about using kiln dried timber.Air dried from the same climate is much better.Especially if the kiln dried timber is over-dried and I would say anything below 11-12% is over dried.I would much rather use air dried 14%.

Things in very low humidity cold climate centrally heated climates might be different I suppose.I live in a mediterranean climate where timber will vary between 11-12% in summer and up to 16% in winter.

I have sold air dried jarrah furniture to Canadians who used it here before taking it to Canada and who have since brought it back again and it has not cracked or warped at all.All surfaces were sealed with 2 pack lacquer.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread