... No [BSP129 current source] trim needed for bias - it is pretty steady and consistent with source resistor(s) used to set it.

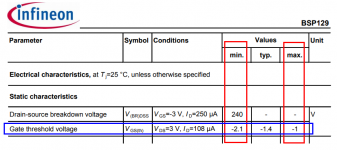

I'm surprised but, if you've measured it, you've measured it. Mfr datasheet below.

The SMD package means a greater inconvenience for builders if you ask them to measure GateThresholdVoltage and discard units outside the range (YourValue1 <= GateThresholdVoltage <= YourValue2). It's inconvenient because the SOT223 package is more difficult to connect to a low cost curve tracer, or to a homebrew Depletion NMOS measurement jig made from a scrap of Veroboard.

I found that a little smear of rubber cement {link} on the eraser of a #2 yellow pencil, makes a useful FET pick and place tool, which works for about 10 placements during GateThresholdVoltage testing. Then the stickum clogs up / wears out, and you throw it away. So buy a box of a dozen pencils and you're good to go.

_

Attachments

I found that a little smear of rubber cement {link} on the eraser of a #2 yellow pencil, makes a useful FET pick and place tool, which works for about 10 placements during GateThresholdVoltage testing. Then the stickum clogs up / wears out, and you throw it away. So buy a box of a dozen pencils and you're good to go.

Try beeswwax - infinite life.

A TH version will also be available, standby... DN2540 will be used for depletion mode and it is TO-220.

Attachments

Last edited:

I so appreciate efforts, and especially providing TH boards. Love the fact can be Amp front end or stand alone preamp...I intend to do both...cant have too many preamps in this house.

Russellc

Russellc

In preparation for testing the Melbourne DB, I took advantage of the 30% off sale on the M2X boardset. I will order a trial run of the Melbourne’s on both SMT and TH. Then order the missing items in the BOM. I generally have everything on hand except the TL431 and LM385’s. Perhaps need to get some more DZT5401 and BC560’s.

Consider using the same special zippety doo version of the TL431 used in the Austin daughter board. Its much better specification guarantees were not reflected in its price.

Consider using the same special zippety doo version of the TL431 used in the Austin daughter board. Its much better specification guarantees were not reflected in its price.

You mean the LM4040CIZ-10?

http://www.ti.com/lit/ds/symlink/lm4040-n.pdf

You mean the LM4040CIZ-10?

Uh, no

I mean the TL431 with 0.4% accuracy that was in a previous rev of the Austin board but not the final rev. Oops!

The LM4040 is very, very good if you can use one of the fixed voltage values they sell. If you need the 3 terminal version (LM4041) it's more expensive and there are fewer on the shelf, than the zippety good TL431s.

Wow, Melbourne continues to look awesome.

Count me in if you decide to make a group buy on boards.

All the boards for my M2x are complete, waiting on a piece of perf-board to make the power supply.

One of the things in the back of my mind is that I have 3-way speakers, and I wonder if I will find that different input stages will work better with the different drivers. I can find a way to spend $300.00 on a case, but I cringe on the idea if I end up building a second M2x for bi-amping (or even tri-amping) the speakers - I don't want to pony up for a second case.

I spent last Friday brainstorming with my son over heatsinks and chassis, we decided to try using a fan and build to around the Conrad heatsinks and a 7.4dB 120mm fan. I will just bolt the whole mess to a board for testing, and if it fails I lose ~$60.00, and if it works well as the math says it will, I can make the chassis from wood. I started ordering parts and discovered that Conrad is in Australia 🙁

I found something I expect will work on Ebay, and ordered all the parts to build a second power supply to run the fan and an Arduino based monitor for temperature, DC output, and power failure. There is a nice thread kicking around here about building one of these, my system will be much simpler and mostly if not entirely analogue.

Hopefully, I will have a nice pic of something unusual soon 🙂

-Josh

Count me in if you decide to make a group buy on boards.

All the boards for my M2x are complete, waiting on a piece of perf-board to make the power supply.

One of the things in the back of my mind is that I have 3-way speakers, and I wonder if I will find that different input stages will work better with the different drivers. I can find a way to spend $300.00 on a case, but I cringe on the idea if I end up building a second M2x for bi-amping (or even tri-amping) the speakers - I don't want to pony up for a second case.

I spent last Friday brainstorming with my son over heatsinks and chassis, we decided to try using a fan and build to around the Conrad heatsinks and a 7.4dB 120mm fan. I will just bolt the whole mess to a board for testing, and if it fails I lose ~$60.00, and if it works well as the math says it will, I can make the chassis from wood. I started ordering parts and discovered that Conrad is in Australia 🙁

I found something I expect will work on Ebay, and ordered all the parts to build a second power supply to run the fan and an Arduino based monitor for temperature, DC output, and power failure. There is a nice thread kicking around here about building one of these, my system will be much simpler and mostly if not entirely analogue.

Hopefully, I will have a nice pic of something unusual soon 🙂

-Josh

I spent last Friday brainstorming with my son over heatsinks and chassis, we decided to try using a fan and build to around the Conrad heatsinks and a 7.4dB 120mm fan. I will just bolt the whole mess to a board for testing, and if it fails I lose ~$60.00, and if it works well as the math says it will, I can make the chassis from wood. I started ordering parts and discovered that Conrad is in Australia 🙁

I found something I expect will work on Ebay, and ordered all the parts to build a second power supply to run the fan and an Arduino based monitor for temperature, DC output, and power failure. There is a nice thread kicking around here about building one of these, my system will be much simpler and mostly if not entirely analogue.

Hopefully, I will have a nice pic of something unusual soon 🙂

-Josh

You might want to see what we have been doing on the Alpha thread relative to heatsinks. Simply adding a PWM fan to a regular heatsink helps a lot. You can save yourself a ton of trouble by getting COTS $4 PWM fan controllers with variable speed, variable temp threshold settings, buzzer alarm and ability to drive up to 3 fans per controller.

We use surplus big Pentium heatsinks and an 80mm or 120mm PWM fan set to slowest speed. For the Alpha 55w amp, each MOSFET dissipates 100w, so needs a dedicated heatpipe CPU cooler and fan. But at slowest speed, it is silent and cools like no one's businees as MOSFET body is only 15C above ambient.

Here is Alpha BB with each fan and CPU cooler removing 100w:

The cost of the heatpipe spreader CPU cooler with 120mm PWM fan was $15 ea. (now seems to be going closer to $25ea). But cost, weight and size are well under what a passive 400w heatsink would be.

Here is an example of a $7 surplus Dell CPU cooler that I used to test out the Alpha. It has no problem cooling 75w from two MOSFETs here.

Here is an example of the PWM fan controller I use:

12v PWM PC CPU Fan Temperature Control Speed Controller Module High-temp Alarm | eBay

Count me in if you decide to make a group buy on boards.

I will start a separate GB thread once they are tested and verified to be in good working order. Will be blue with ENIG finish for a premium look and performance. I am ordering the test batch now.

@xrk971

Wow! Those are some awesome pics. I have felt for a while that our class A community is a bit behind the times in terms of cooling. There has been massive amounts of money spent in the last 20 years developing robust, efficient, and quiet cooling systems. I have no doubt the cheapest decent CPU heatsink/fan will outperform the massive heatsinks we use by a huge margin temperature wise.

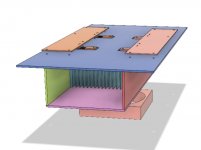

CPU heatsinks was definitely on our list of things we looked at. In the end, we opted for a more conventional heatsink in a tunnel with a fan. The image is an early version before I discovered the sinks would come up from Australia. The space between the fan and tunnel is filled with closed pore foam to isolate fan vibration.

The sink I found on Ebay is actually a 533mm heatsink extrusion offcut ($37.00 w/shipping!). I will cut it in half, and box it in with something cheap like masonite, rather than 3mm aluminum to save a few bucks and increase sturdyness. Tentatively, it looks like the whole system will fit in a chassis ~260mm wide, and as deep as it needs to be to keep the transformers far apart. ~$17.00 for the fan, ~$25.00 for the power supply, and I am in for <$80.00. The fan could probably be run off one of the power rails, but I feel better about isolating it. If it turns out I am going to build a second amp, then I have enough heatsink left over as well.

Wow! Those are some awesome pics. I have felt for a while that our class A community is a bit behind the times in terms of cooling. There has been massive amounts of money spent in the last 20 years developing robust, efficient, and quiet cooling systems. I have no doubt the cheapest decent CPU heatsink/fan will outperform the massive heatsinks we use by a huge margin temperature wise.

CPU heatsinks was definitely on our list of things we looked at. In the end, we opted for a more conventional heatsink in a tunnel with a fan. The image is an early version before I discovered the sinks would come up from Australia. The space between the fan and tunnel is filled with closed pore foam to isolate fan vibration.

The sink I found on Ebay is actually a 533mm heatsink extrusion offcut ($37.00 w/shipping!). I will cut it in half, and box it in with something cheap like masonite, rather than 3mm aluminum to save a few bucks and increase sturdyness. Tentatively, it looks like the whole system will fit in a chassis ~260mm wide, and as deep as it needs to be to keep the transformers far apart. ~$17.00 for the fan, ~$25.00 for the power supply, and I am in for <$80.00. The fan could probably be run off one of the power rails, but I feel better about isolating it. If it turns out I am going to build a second amp, then I have enough heatsink left over as well.

Attachments

Tunnel heatsinks are used in pro amps all the time. They usually are filled internally with fins and a fan is placed at inlet and exit. There’s little vibration if you are running slow speed.

Nelson Pass's article on the Class A "A40" amplifier, published in the 1980s, includes a tunnel heatsink with a fan blowing cool air through the tunnel. It's not a new idea.

Last edited:

@xrk971

Wow! Those are some awesome pics. I have felt for a while that our class A community is a bit behind the times in terms of cooling. There has been massive amounts of money spent in the last 20 years developing robust, efficient, and quiet cooling systems. I have no doubt the cheapest decent CPU heatsink/fan will outperform the massive heatsinks we use by a huge margin temperature wise.

Well Joshua, I don't think you can compare a CPU running at 3.5VDC to a Class A amp, let's say ACA at 24 VDC, 1.5A constantly.

If you were right all Pass Labs amps would be using CPU heatsinks instead of the massive chunks of aluminium.

The fact is no amount of money can defeat the laws of physics and we still need either huge lumps of metal or forced cooling to keep Class A temperatures sane.

IMHO massive hardware wins every time.

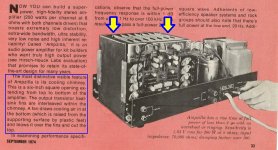

How could I forget James Bongiorno's AMPZILLA from 1974?? It made quite a splash and launched several companies including G.A.S. and Sumo.

Ampzilla had a tunnel heatsink plus fan, mounted vertically. Because the tunnel was rectangular, and vertical, they decided to call it a "chimney". Here is the first page of the circuit design article, in Popular Electronics magazine. I have added little arrows to the photograph, so you can quickly find the chimney.

_

Ampzilla had a tunnel heatsink plus fan, mounted vertically. Because the tunnel was rectangular, and vertical, they decided to call it a "chimney". Here is the first page of the circuit design article, in Popular Electronics magazine. I have added little arrows to the photograph, so you can quickly find the chimney.

_

Attachments

Pro Audio kW class amps have been doing tunnel cooled for ages. Look at how many MOSFETs they can slap onto these (on both sides):

This is a Behringer EP1500

An externally hosted image should be here but it was not working when we last tested it.

This is a Behringer EP1500

Well Joshua, I don't think you can compare a CPU running at 3.5VDC to a Class A amp, let's say ACA at 24 VDC, 1.5A constantly.

If you were right all Pass Labs amps would be using CPU heatsinks instead of the massive chunks of aluminium.

The fact is no amount of money can defeat the laws of physics and we still need either huge lumps of metal or forced cooling to keep Class A temperatures sane.

IMHO massive hardware wins every time.

You are right, my i7-5930k dissipates 140W (advertised) under nominal load using nothing more than a cheap heatpipe and fan. Nothing at all like the 36W dissipated running 24V at 1.5A. My CPU actually dissipates a fair bit more since I have it very OT'd. I used to run water cooling, until the pump died. Bought the cheap heat pipe to get me by and never bothered to take it off again.

I would also suggest that the reason that all Pass Labs amps do not run fans has more to do with his market than efficiency. PS Audio amps run fans after all...

Engineers make a living leveraging the laws of physics. Things like improvements to manufacturing and quality control of anodized surfaces greatly improves the ability of the sink to dissipate heat into the air. Computer modeling of laminar surfaces to optimize fan blades for flow and noise. Magnet manufacturing technology that makes BDC motors reliable and cheap. The list goes on.

So ya, you can't subvert the laws of physics, but if you are willing to spend the money, you can certainly put them to work for you.

Anyway, I had not meant to imply that I came up with tunnel cooling all on my own. Sorry if that was how it sounded. The design I ended up with has the fan blowing into the middle of the tunnel between the mosfets, and venting to each side. Unconventional, but probably not novel.

My intention was to design something that was inexpensive, has a very high chance of working with out tweaking, and does not require excessive amounts of time shoehorning it into a chassis of some kind. The upshot of a tunnel is that it is a module that can be essentially bolted to anything strong enough to support the weight. Big passive heat sinks on the other hand end up being part of the structure of the chassis and design becomes limited in order to maintain rigidity. Even having my own machine shop, the cost savings is not worth the effort of building my own aluminum chassis.

When you start playing with the math, you quickly realize that it only takes minimal airflow to get big results. Nice thing about living in the future is that you can go find online calculators to double check your work 🙂

Forced air convection is about 100x more efficient than passive natural convection radiators. Heat pipes are needed to remove and spread the extreme localized heat flux (120w over a few cm^2 is about what a large soldering iron is) at the die to a more manageable area with some fins that can then be cooled by fans. It is possible to use just heatpipes and very large passive radiators as some fanless PC cases have done.

This is simply because many people fear that fans are noisy, and big heatsinks OF A Class A amp look manly-man. If we designed Class A amps to be compact, low cost, and cool-running - they would look like computer server racks.

If you were right all Pass Labs amps would be using CPU heatsinks instead of the massive chunks of aluminium

This is simply because many people fear that fans are noisy, and big heatsinks OF A Class A amp look manly-man. If we designed Class A amps to be compact, low cost, and cool-running - they would look like computer server racks.

I have recently went through my drawers and from about 20 fans selected dozen of them that will run happily on half the volts and will be very quiet. I am sure everyone knows that.

Nelson likes it hot! 🙂

Nelson likes it hot! 🙂

You are right, my i7-5930k dissipates 140W (advertised) under nominal load using nothing more than a cheap heatpipe and fan. Nothing at all like the 36W dissipated running 24V at 1.5A. My CPU actually dissipates a fair bit more since I have it very OT'd. I used to run water cooling, until the pump died. Bought the cheap heat pipe to get me by and never bothered to take it off again.

I would also suggest that the reason that all Pass Labs amps do not run fans has more to do with his market than efficiency. PS Audio amps run fans after all...

Engineers make a living leveraging the laws of physics. Things like improvements to manufacturing and quality control of anodized surfaces greatly improves the ability of the sink to dissipate heat into the air. Computer modeling of laminar surfaces to optimize fan blades for flow and noise. Magnet manufacturing technology that makes BDC motors reliable and cheap. The list goes on.

So ya, you can't subvert the laws of physics, but if you are willing to spend the money, you can certainly put them to work for you.

Anyway, I had not meant to imply that I came up with tunnel cooling all on my own. Sorry if that was how it sounded. The design I ended up with has the fan blowing into the middle of the tunnel between the mosfets, and venting to each side. Unconventional, but probably not novel.

My intention was to design something that was inexpensive, has a very high chance of working with out tweaking, and does not require excessive amounts of time shoehorning it into a chassis of some kind. The upshot of a tunnel is that it is a module that can be essentially bolted to anything strong enough to support the weight. Big passive heat sinks on the other hand end up being part of the structure of the chassis and design becomes limited in order to maintain rigidity. Even having my own machine shop, the cost savings is not worth the effort of building my own aluminum chassis.

When you start playing with the math, you quickly realize that it only takes minimal airflow to get big results. Nice thing about living in the future is that you can go find online calculators to double check your work 🙂

Maybe I need to do more research.

However something is not right:

P = I x V

according to Anandtech the load voltage (core voltage) of this CPU is between 1.05 and 1.4 Volts

Intel Haswell-E Overclocking - The Intel Haswell-E CPU Review: Core i7-5960X, i7-5930K and i7-5820K Tested

so 140W = I x 1.4

therefore I = 140 / 1.4 = 100 Amps

Is that possible?

Maybe we are talking about different things here.

Something like PMPO vs RMS.

Also I am not arguing that forced cooling does not work, it does, but there are specific issues with it and one is reliability.

That is one of many reasons why Pass Labs amps employ monstrous heatsinks.

You have your valid reasons to go the path you have chosen.

I was just trying to point out that we cannot bend the law of physics no matter which way we try.

Best,

Stan

- Home

- Amplifiers

- Pass Labs

- The diyAudio First Watt M2x