I often take dead things apart to see how they worked, or why they didn't, hence my disassembly of a large GM AC compressor a long time ago.

Your Denso unit looks exactly like the compressor that was on my 1984 Dodge turbo motor. I never had a dead one to take apart......just changed several clutches, replaced a leaking hose, and evacuate / recharge the system. Back then you could buy R-12 at Walmart.

Like brake cylinders......leave the fine detail stuff that can kill you to the experts. Engine cylinders for normal applications can be done at home. High horsepower stuff is also best done by someone with a boring / honing machine and a torque plate made for your specific engine block.

Your Denso unit looks exactly like the compressor that was on my 1984 Dodge turbo motor. I never had a dead one to take apart......just changed several clutches, replaced a leaking hose, and evacuate / recharge the system. Back then you could buy R-12 at Walmart.

Like brake cylinders......leave the fine detail stuff that can kill you to the experts. Engine cylinders for normal applications can be done at home. High horsepower stuff is also best done by someone with a boring / honing machine and a torque plate made for your specific engine block.

440's... turbo bikes. OK. We have something in common here. All cars can be upped in power easily -- to a point. Then it gets hard. Right now I am driving a Caddi CTS-V with stock 640 HP etc. A few of the usual things for any car are planned; Freer flowing inlet and exhaust. There's always some hidden power doing that. Larger K&N air filter. Long tube headers and freer flowing cat. converter. larger diam pipes. Easy extra power. Maybe a slight retune on the fuel map. Could do 700HP on the street with no troubles.

Later, if I feel this isn't enough -- I can change the supercharger pully drive ratio and spin it faster..... the in and out changes will already allow for the extra flow.

The best plugs I have used on this and other high HP cars are the plasma generating plugs. yes, you can hear and feel the difference..... runs so smooth and stronger pulling.

THx-RNMarsh

I'd go all in.

But it not my money / car / licence.

I think I found the misfire problem that I was having with my 3VZ-FE.

There are two small hoses both the same size, one vacuum and one hot water, one going into the top of the intake manifold and one going underneath the intake manifold into the heater pipe which runs the entire length of the block to the other side where the water pump is.

I think I might've accidentally switched the two around and the engine was sucking water into the intake manifold for a short while when I took it for a test drive about 6 months ago or more. Hence the misfire.

Easy enough to mess up... Hopefully it won't have a bent conrod, engines with blown head gaskets don't get bent conrods.. so it should be fine and dandy.

Anyway the problem has been corrected now:

1) I've replaced all of the hoses with brand new hose of same type, vacuum hose for vacuum hose, fuel hose for fuel hose, water hose for water hose.

2) Replaced the starter motor.

3) Cleaned the area around the motor and gearbox with a wire brush.

4) Lubricated nuts and bolts with anti-seize and/or engine oil (Engine oil used for steel bolts, aluminium anti seize compound for aluminium bolts).

5) Replaced the spark plugs, leads, dizzy cap, rotor button.

6) Sealed up the distributor cap with RTV to prevent water getting into it.

7) Replaced all rubber hoses.

8) Replaced most of the split loom that covers the wiring.

9) Done the big 3 wiring upgrade with heavily protected 35mmSQ wiring.

10) Rebuilt the A/C Compressor.

11) Cleaned out the Alternator (Probably going to replace it soon anyway, it has a LOT of miles on it)

12) Replaced the tappet cover gaskets and intake manifold gaskets.

13) Blocked up the EGR valve (At least I think I did? I can't quite remember its so long ago now)

14) Installed a bitchin' car audio system (haven't finished yet, still yet have to install 6x RCA cables from the front to the back AND wire up the amplifier and I still haven't yet done the speaker install on the passengers front side door.)

15) Sound deadened the drivers side door and the rear parcel shelf and underneath the rear seats.

16) Replaced the fuel injectors, fuel filter.

17) Replaced the thermostat, sealed the water pipe in RTV (Its setting tonight)

And many other things. And many things still need to be done.

I've done a lot. and this week I get to start it up again for the first time in ages. It would be a shame if I've done any permanent damage to the engine but it just might give me an excuse to do an engine rebuild...

I will post some more up to date pictures, hopefully tomorrow I'll take some more photos, but for now you can enjoy the pictures that I took of the starter motor and ignition leads after they were installed and yes that is 35mmSQ cable going to the brand new starter motor, I hope it doesn't break anything when I start it. I will be turning the engine over by hand first then cranking the engine over without the fuel pump running to ensure oil gets into the oil passages before I start it up for real.

There are two small hoses both the same size, one vacuum and one hot water, one going into the top of the intake manifold and one going underneath the intake manifold into the heater pipe which runs the entire length of the block to the other side where the water pump is.

I think I might've accidentally switched the two around and the engine was sucking water into the intake manifold for a short while when I took it for a test drive about 6 months ago or more. Hence the misfire.

Easy enough to mess up... Hopefully it won't have a bent conrod, engines with blown head gaskets don't get bent conrods.. so it should be fine and dandy.

Anyway the problem has been corrected now:

1) I've replaced all of the hoses with brand new hose of same type, vacuum hose for vacuum hose, fuel hose for fuel hose, water hose for water hose.

2) Replaced the starter motor.

3) Cleaned the area around the motor and gearbox with a wire brush.

4) Lubricated nuts and bolts with anti-seize and/or engine oil (Engine oil used for steel bolts, aluminium anti seize compound for aluminium bolts).

5) Replaced the spark plugs, leads, dizzy cap, rotor button.

6) Sealed up the distributor cap with RTV to prevent water getting into it.

7) Replaced all rubber hoses.

8) Replaced most of the split loom that covers the wiring.

9) Done the big 3 wiring upgrade with heavily protected 35mmSQ wiring.

10) Rebuilt the A/C Compressor.

11) Cleaned out the Alternator (Probably going to replace it soon anyway, it has a LOT of miles on it)

12) Replaced the tappet cover gaskets and intake manifold gaskets.

13) Blocked up the EGR valve (At least I think I did? I can't quite remember its so long ago now)

14) Installed a bitchin' car audio system (haven't finished yet, still yet have to install 6x RCA cables from the front to the back AND wire up the amplifier and I still haven't yet done the speaker install on the passengers front side door.)

15) Sound deadened the drivers side door and the rear parcel shelf and underneath the rear seats.

16) Replaced the fuel injectors, fuel filter.

17) Replaced the thermostat, sealed the water pipe in RTV (Its setting tonight)

And many other things. And many things still need to be done.

I've done a lot. and this week I get to start it up again for the first time in ages. It would be a shame if I've done any permanent damage to the engine but it just might give me an excuse to do an engine rebuild...

I will post some more up to date pictures, hopefully tomorrow I'll take some more photos, but for now you can enjoy the pictures that I took of the starter motor and ignition leads after they were installed and yes that is 35mmSQ cable going to the brand new starter motor, I hope it doesn't break anything when I start it. I will be turning the engine over by hand first then cranking the engine over without the fuel pump running to ensure oil gets into the oil passages before I start it up for real.

Attachments

Last edited:

Namely:many things still need to be done

1) Replace the remaining rubber hoses in the engine bay namely fuel return line + replace the fuel filler cap to improve fuel economy.

2) Install the new charcoal canister thermostatically controlled valve that I'm waiting to arrive from the USA. The old one was too cracked and broken to be used. (90925-05068) BVSV EVAP switch. TOYOTA LEXUS 88-96 PORTED VACUUM SWITCH 90925-05068 BVSV EVAP EGR SWITCH SENSOR | eBay

3) Replace the fuel pump for good measure/reliability's sake.

4) Replace the split loom going to the front bank oxygen sensor.

5) Replace the fuel regulator for good measure/reliability's sake.

6) Fabricate and get my brother to install a sheet steel crash guard underneath the engine bay to prevent against damage from tree branches and logs and stones and rocks/boulders.

7) pay someone to install new raised springs and shock absorbers, then pay Pedders to go nuts on the steering and suspension bushings, and replace the sway bar with a stiffer one.

8) pay someone to install huge 17 inch mud tyres (I'm thinking of going with Ford AU steel wheels, they are cheap and readily available).

9) pay someone to install a huge aluminium bullbar and offroad lights (If I can manage to score a bullbar that is)

10) Install a large HAM+CB radio antenna array for HF/2m/70cm + Australian 477MHz UHF CB.

Of course I'm currently negotiating for someone to give me a part time job at the moment as a mechanics helper so somehow I will manage to fit all of this in into 2019. None of this will be happening soon except for steps 1-4, everything else is on the 2019-2020 agenda. My back has proven itself that it can do at least some kind of work on cars so heres hoping that I will be able to obtain some kind of paid employment out of it, it might end up being volunteer work for the time being though and it might be only 10 hours per week until I can prove to myself and my emploer that I can start working more hours per week. What I need is an understanding employer and I might have found one (a family friend).

Getting Centerlink to play ball with me is another challenge entirely which may be massive. They still haven't called me back. They say on their website that people on disability can work up to 30 hours per week but I want it in writing...

The ultimate goal is that I can no longer be a financial burden on the state and the people who pay taxes. That I can improve my wellbeing and self esteem and that I can get out of the house more often with a job.

The pension isn't much to live off of. The ultimate goal then is to be able to rent my own house. If I fail in this mission then it means that I will have to spend the rest of my life (when my mother passes away and we have to sell the house) living in housing commission amongst the drunks and drug abusers. Which amounts to at least 35+ years of living in torment and hell.

And I don't like that idea.

Here is hoping that lady luck is on my side.

Last edited:

An engine with a water jacket to cylinder leak can fill a cylinder with water once the coolant is hot and under pressure, but most noticeably when you have stopped the engine for a while. If you try to start it again the compression lockup will be obvious, like tapping a piston down on to a steel bench.Hopefully it won't have a bent conrod, engines with blown head gaskets don't get bent conrods..

If it concerns you, pour a little oil directly on and around the valves, and in through the spark plug holes.to ensure oil gets into the oil passages before I start it up for real.

An engine with a water jacket to cylinder leak can fill a cylinder with water once the coolant is hot and under pressure, but most noticeably when you have stopped the engine for a while. If you try to start it again the compression lockup will be obvious, like tapping a piston down on to a steel bench.

Thanks!

6 months ago before I started disassembling things I ran the engine for 5 mins in the car port trying to find the source of the problem so I had some time to find out the cause and see what it was doing and it never sounded to me like it was a metal on metal sound, it sounded purely like a misfire. Possibly the water snuffing out the flame.

But when I went for a test drive (to fill it up with gas) down to the petrol station earlier that day it did conk out just down the street on the way back home (possibly water heating up and pushing its way into the intake manifold, or it being sucked in), or it locked up with water maybe... who knows. I did restart it and it sounded like a loud misfire the way back home and sounded like it was only running on 2 cylinders, so maybe the computer detected that there was a knock condition and it cut off the fuel to the injectors.

When I finally shut the engine down 6 months (or so) ago I did a thorough inspection. What would happen is that it would sound exactly like an intermittent misfire that would happen for a period of time and go away for a long period of time and I diagnosed it down to the Number 5 injector (rear cylinder bank) as being faulty. That injector sounded different to all of the others and that is a sure fire sign of a bad injector.

Before ordering the injectors I put a test light on the ECU and it had a strong signal, it cut power to a 10 watt globe anyway...

But I now suspect that it may have been water leaking into the intake manifold and where the intake hose is plumbed into is where number 5 and 6 cylinder intake valves are located. Anyway I did remove the spark plugs and I did notice a small amount of water residue on the piston in number 5 cylinder (front cylinder bank), no other cylinders were wet like this.

I assumed at the time that the injector was bad and that it was stuck open, hence the white smoke from the exhaust, but I now suspect that it was water leaking into the intake manifold. So mystery solved!

So when I start the engine up again sometime this week NONE of the original symptoms will be there and the engine will purr like a kitten.

The fact that it was an intermittent fault and it would sound perfectly fine for up to a minute with no loud sounds tells me that there isn't any permanent damage done to the engine and it sounded like that before I shut it down.

But who knows for sure...

A precautionary tale.

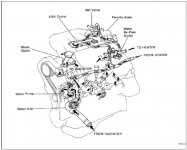

In the image below with that hose returning from the EGR cooler mounted underneath the intake manifold/throttle body, that paticular hose may have been crossed over with a vacuum hose that goes to the same IAC valve and the intake manifold which is in the same area.

Silly design.

Attachments

Last edited:

Anyway I did remove the spark plugs and I did notice a small amount of water residue on the piston in number 5 cylinder (front cylinder bank), no other cylinders were wet like this.

Correction, Number 6 cylinder (front cylinder bank), I used a borescope camera.

Cylinders are arranged thusly:

Drivers seat = D

Passengers seat = P

RRR

D P

135

246

FFF

FFF = Front of car

RRR = Rear of car

Note this car is australian so the drivers seat is on the right hand side.

Last edited:

Does the coolant smell of exhaust by chance?

If not it doesn’t have any solid bearing on whether the gasket is bad or not, the water can go into the cylinder while the exhaust gasses don’t pass into the water jackets, and visa versa.

Can you borrow a compression tester ?

It sounds from witnessing the water in the cylinder that you are in for a head gasket replacement, but it is always good to have more than one indicator.

I had a Tercel that would consume a head gasket annually, got to be very annoying.

If not it doesn’t have any solid bearing on whether the gasket is bad or not, the water can go into the cylinder while the exhaust gasses don’t pass into the water jackets, and visa versa.

Can you borrow a compression tester ?

It sounds from witnessing the water in the cylinder that you are in for a head gasket replacement, but it is always good to have more than one indicator.

I had a Tercel that would consume a head gasket annually, got to be very annoying.

Use! assembly lube on all the crank and valve train bearing surfaces AND Pack the oil pump with Vaseline.

That will assure that the pump self primes and the assly lube will lube the important bits until oil under pressure gets to them.

Pouring oil over the Valve train is more useful than over your Feet.... but not by much 😉

That will assure that the pump self primes and the assly lube will lube the important bits until oil under pressure gets to them.

Pouring oil over the Valve train is more useful than over your Feet.... but not by much 😉

If antifreeze got into the oil make sure that the oil and filter are changed, and then change them again within a few hours of run time.

I bought a dead Dodge Omni for $100. The car had overheated and blew the head gasket. I changed the gasket, and changed the oil due to the milky look caused by water.

I proceeded to treat the car just like a $100 car often pegging the tach by flooring it around corners in the rain. One day there was a whack under the hood, follower by a severe engine miss and a backfire through the carb under attempts to rev in neutral. Autopsy revealed that an intake lobe on the cam had worn so bad that the follower had come off it's hydraulic pedestal. A $10 junkyard camshaft fixed the car.

I had a friend that was a metalurgy expert analyze the cam. He told me that all the lobes were worn, some worse than others and it was caused by the antifreeze causing the lubricating oil film to shear off the cam creating a metal to metal contact. He advised me to change the followers, but I never did.

I tried for over a year to blow that car up, but it wouldn't die. It even survived my leaf blower supercharger experiment that set most of the stuff under the hood on fire. I wound up giving the car to a relative.

I bought a dead Dodge Omni for $100. The car had overheated and blew the head gasket. I changed the gasket, and changed the oil due to the milky look caused by water.

I proceeded to treat the car just like a $100 car often pegging the tach by flooring it around corners in the rain. One day there was a whack under the hood, follower by a severe engine miss and a backfire through the carb under attempts to rev in neutral. Autopsy revealed that an intake lobe on the cam had worn so bad that the follower had come off it's hydraulic pedestal. A $10 junkyard camshaft fixed the car.

I had a friend that was a metalurgy expert analyze the cam. He told me that all the lobes were worn, some worse than others and it was caused by the antifreeze causing the lubricating oil film to shear off the cam creating a metal to metal contact. He advised me to change the followers, but I never did.

I tried for over a year to blow that car up, but it wouldn't die. It even survived my leaf blower supercharger experiment that set most of the stuff under the hood on fire. I wound up giving the car to a relative.

I was more on the suddenness of it than the noise, it can be relatively quiet. It will be thoroughly but temporarily seized. If you keep trying the starter, or pushing the car in gear etc, you may find that over a couple of minutes you can slowly force the water back through whence it cam. Best is to release the spark plug and stand back as you start it.it never sounded to me like it was a metal on metal sound,

Maybe, or upsetting the plug, but moreso than..it sounded purely like a misfire. Possibly the water snuffing out the flame.

Knocking is generally reduced when water is introduced to the cylinder. Besides, the knock sensor circuit typically retards the spark so the most gas expansion happens when the piston isn't so tight against the top.maybe the computer detected that there was a knock condition and it cut off the fuel to the injectors.

mmm. I'm reassembling it now and filling up the transmission cooler channels with oil and the engine block with oil and the hydraulic fan with transmission fluid.

Hopefully I will be able to stab it sometime this afternoon/within the next hour or so.

Hopefully I will be able to stab it sometime this afternoon/within the next hour or so.

okay what did we learn today.

Either keep your starter battery charged.

Or

Don't trust Bosch.

Either one is preventing it from starting. The battery is sitting at 12.00v and I've got it on charge overnight.

Shame really, it was a really expensive Supercharge Gold Plus battery.... it is a few years old now though.

I remember fully charging it before I disconnected it from the car... it may have a problem if it can't hold a charge over 5 months.

But I'm betting that its a faulty starter motor. the starter motor relay won't even engage. I've checked the circuit going to the relay on the starter motor with an indicator light and it IS getting power so I'm thinking that the starter motor is fubar.

I couldn't even get a single crank out of it and no sound, zilch, came out of the starter motor. So I'm thinking we have a faulty starter motor.

I'm not 100% sure that its the battery, the interior lights didn't dim when I turned the key which means that the starter isn't even drawing current from the battery.

Tomorrow I'll hit the relay with a hammer and see if that fixes it.

Either keep your starter battery charged.

Or

Don't trust Bosch.

Either one is preventing it from starting. The battery is sitting at 12.00v and I've got it on charge overnight.

Shame really, it was a really expensive Supercharge Gold Plus battery.... it is a few years old now though.

I remember fully charging it before I disconnected it from the car... it may have a problem if it can't hold a charge over 5 months.

But I'm betting that its a faulty starter motor. the starter motor relay won't even engage. I've checked the circuit going to the relay on the starter motor with an indicator light and it IS getting power so I'm thinking that the starter motor is fubar.

I couldn't even get a single crank out of it and no sound, zilch, came out of the starter motor. So I'm thinking we have a faulty starter motor.

I'm not 100% sure that its the battery, the interior lights didn't dim when I turned the key which means that the starter isn't even drawing current from the battery.

Tomorrow I'll hit the relay with a hammer and see if that fixes it.

Last edited:

Yesterday It was very hot and humid with zero wind. I sweat soaked two pairs of shorts while mowing the lawn, and it was 9 to 11 AM. I then drove my 10 year old Honda on several short errands without issue, returning it to the driveway about 5 PM.

This morning early, I planned on going to the gym, but my car, or more specifically the 6 year old Walmart battery had other plans. The battery had been warning me by cranking very slowly on cold days last winter, and refusing to start on a -12 F (-24 C) day the previous winter. There was no issue on the 90 to 97 F (32 to 36 C) degree days we had in July, nor yesterday at 94 F, but this morning at 72 F (22C) it gave up the ghost. A half hour charge at 6 amps raised the 10 volts to 11.5 and allowed for a short burst of headlights before they faded out.

I ripped out the dead battery and went off to Walmart. The exact same battery that cost me $79 6 years ago was now $119. I put it in the car, and tested the voltage, 12.7 volts. Starting the car yields 13.9 volts, so the alternator is indeed alternating.

Bosch starters were the preferred unit on the old 2.2 L Dodge / Chrylser turbo engines because they handled the heat better than the Japanese or American starters. They also had brushes that could be replaced without taking the starter apart.

A long period of non use can cause some sort of non conductive film to develop on the brushes. Usually spinning the armature by hand or with a screwdriver (if possible) will clear it. The old GM (Holden) starters used a copper disk in the solenoid. A green corrosion would grow on the disk making them inoperative. Disassembly and a wire brush was the fix. I don't know how your starter is built, but no current is likely a corroded part somewhere.

This morning early, I planned on going to the gym, but my car, or more specifically the 6 year old Walmart battery had other plans. The battery had been warning me by cranking very slowly on cold days last winter, and refusing to start on a -12 F (-24 C) day the previous winter. There was no issue on the 90 to 97 F (32 to 36 C) degree days we had in July, nor yesterday at 94 F, but this morning at 72 F (22C) it gave up the ghost. A half hour charge at 6 amps raised the 10 volts to 11.5 and allowed for a short burst of headlights before they faded out.

I ripped out the dead battery and went off to Walmart. The exact same battery that cost me $79 6 years ago was now $119. I put it in the car, and tested the voltage, 12.7 volts. Starting the car yields 13.9 volts, so the alternator is indeed alternating.

Bosch starters were the preferred unit on the old 2.2 L Dodge / Chrylser turbo engines because they handled the heat better than the Japanese or American starters. They also had brushes that could be replaced without taking the starter apart.

A long period of non use can cause some sort of non conductive film to develop on the brushes. Usually spinning the armature by hand or with a screwdriver (if possible) will clear it. The old GM (Holden) starters used a copper disk in the solenoid. A green corrosion would grow on the disk making them inoperative. Disassembly and a wire brush was the fix. I don't know how your starter is built, but no current is likely a corroded part somewhere.

Its a brand new Bosch starter tubelab... If it came pre-corroded when I bought it then that doesn't bode well for the rest of its service life.

There shouldn't be anything wrong with it at all. I even have the test slip right in front of me.

Unless maybe the corrosion is somewhere else. Possibly on the 35mmsq cable that I didn't cover in corrosion inhibitor on either the transmission housing or the body of the car.

There was a bit of corrosion around the crimp of the lugs on the negative leads but I didn't think it was going to be an issue in starting the car. I think I'll go down there this morning and see whats up with an ohm meter.

I'll probably clean them all anyway and seal them up with RTV silicone just for good measure.

But that doesn't explain why the voltage didn't collapse (lights didn't dim) when I put power to the starter motor's solenoid. So if it isn't the wiring that I installed then its gotta be the solenoid in the starter as you say.

There shouldn't be anything wrong with it at all. I even have the test slip right in front of me.

Unless maybe the corrosion is somewhere else. Possibly on the 35mmsq cable that I didn't cover in corrosion inhibitor on either the transmission housing or the body of the car.

There was a bit of corrosion around the crimp of the lugs on the negative leads but I didn't think it was going to be an issue in starting the car. I think I'll go down there this morning and see whats up with an ohm meter.

I'll probably clean them all anyway and seal them up with RTV silicone just for good measure.

But that doesn't explain why the voltage didn't collapse (lights didn't dim) when I put power to the starter motor's solenoid. So if it isn't the wiring that I installed then its gotta be the solenoid in the starter as you say.

Last edited:

Hokay... What did we learn today.

That cars can be worthless pieces of **** not worth the time of day.

And that water pumps can die in the *** spontaneously and start leaking like a sieve. And that the misfire is still there. It will crank over and run but it will misfire like its missing a few cylinders. The engine shakes violently. Possibly the ignition coil or the fuel pump but if its the fuel pump I would expect it to work at least a little bit.

if its not those two things then it COULD be a faulty AFM = Air Flow Meter.

I started it up and the misfire is still there and the water pump is leaking like a sieve, it wasn't before when I mothballed the car.

And no this engine doesn't have a crank angle sensor.

I found something rather interesting though, when I was doing a current draw test the reading was 480mA, extremely high. I will have to do a current draw test with the bonnet closed to trick the security system into thinking that the car is secure before I can be sure that its not just the ECU pulling that amount of current.

Once I get this water pump problem sorted I might have to break out a light globe and try to get some codes from the ECU, see what that thinks is the problem.

I'm thinking now that it might be a timing belt related issue. Which is a BIG job on this engine. Maybe the teeth on the belt have come off.

Unfortunatley I have run out of time and patience, registration is due within a month.

It might be time for me to call in some help with this timing belt issue. Which could end up costing $800, mostly in labor.

That cars can be worthless pieces of **** not worth the time of day.

And that water pumps can die in the *** spontaneously and start leaking like a sieve. And that the misfire is still there. It will crank over and run but it will misfire like its missing a few cylinders. The engine shakes violently. Possibly the ignition coil or the fuel pump but if its the fuel pump I would expect it to work at least a little bit.

if its not those two things then it COULD be a faulty AFM = Air Flow Meter.

I started it up and the misfire is still there and the water pump is leaking like a sieve, it wasn't before when I mothballed the car.

And no this engine doesn't have a crank angle sensor.

I found something rather interesting though, when I was doing a current draw test the reading was 480mA, extremely high. I will have to do a current draw test with the bonnet closed to trick the security system into thinking that the car is secure before I can be sure that its not just the ECU pulling that amount of current.

Once I get this water pump problem sorted I might have to break out a light globe and try to get some codes from the ECU, see what that thinks is the problem.

I'm thinking now that it might be a timing belt related issue. Which is a BIG job on this engine. Maybe the teeth on the belt have come off.

Unfortunatley I have run out of time and patience, registration is due within a month.

It might be time for me to call in some help with this timing belt issue. Which could end up costing $800, mostly in labor.

Last edited:

And just think all of this started 5 months ago when I replaced a simple battery lead and moved an O2 sensor a few cm to the right.

Then again I did gun it a bit that day but it was perfectly fine on the drive back home and the temperature was always normal.

I'm thinking that I've broke off some teeth on the timing belt. Hence the reason why it will run fine for a few mins and then act up like crazy.

This is my second japanese car that I've broke by the way. But Ford Falcons always want to kill me.

Then again I did gun it a bit that day but it was perfectly fine on the drive back home and the temperature was always normal.

I'm thinking that I've broke off some teeth on the timing belt. Hence the reason why it will run fine for a few mins and then act up like crazy.

This is my second japanese car that I've broke by the way. But Ford Falcons always want to kill me.

Last edited:

I doubt that you have a bad timing belt. I have never seen one lose a single tooth. They tend to strip off in bunches. I did manage to stretch one once, by messing up a shift at 7000 RPM. The engine started running badly and got worse with every mile and died after about two miles.

There are two kinds of engine designs, clearance engines where the valves don't hit the pistons if the timing chain or belt breaks, and interference engines where they kiss each other.......the kiss of death!

My turbo Dodge was a clearance engine, so nothing in the engine got broken, but the transaxle wound up with a broken bearing and a bent mainshaft.

If a timing belt jumped a tooth on a clearance engine the engine would run poorly if at all. It would not come and go. Timing belts do not lose position then go pack to normal. It takes considerable energy to turn the camshaft against the valve spring force, so the shaft tends to stop turning quickly if the belt slips, and this tends to rip lots of teeth off the belt. I changed the timing belt once a year as normal maintenance when I used to race.

A vacuum leak or water in a cylinder or two could cause an engine misfire. The fuel pump would not cause one or two cylinders to drop out. The fuel injectors need a certain pressure to work, if it isn't there, the car won't run. When the car is misfiring, smell the exhaust. A cylinder that has fuel injected, but not ignited well smell like gasoline. A water leak into the intake system will create a sweet smell from the antifreeze.

I had a Ford Mustang that would spontaneously drop one or two cylinders. No trouble codes would show on a scanner. It was usually the same cylinder, or two, but they were not on the same coil. It was a "wasted spark" distributorless ignition system which uses 3 coils for 6 cylinders. This meant that a dead coil or coil driver would take out two cylinders. Sometimes one, two or even three cylinders would go out, but not in pairs, so it had to be fuel.

Before I figured it out I read in a magazine about a similar weird issue in a Corvette, and GM recommended trying a new battery. OK, my battery was the original Ford battery, and it was 5 years old. A voltmeter test revealed that the car was only making 12.something volts at 2000 RPM, so I tried a new battery. It never happened again.

There are two kinds of engine designs, clearance engines where the valves don't hit the pistons if the timing chain or belt breaks, and interference engines where they kiss each other.......the kiss of death!

My turbo Dodge was a clearance engine, so nothing in the engine got broken, but the transaxle wound up with a broken bearing and a bent mainshaft.

If a timing belt jumped a tooth on a clearance engine the engine would run poorly if at all. It would not come and go. Timing belts do not lose position then go pack to normal. It takes considerable energy to turn the camshaft against the valve spring force, so the shaft tends to stop turning quickly if the belt slips, and this tends to rip lots of teeth off the belt. I changed the timing belt once a year as normal maintenance when I used to race.

A vacuum leak or water in a cylinder or two could cause an engine misfire. The fuel pump would not cause one or two cylinders to drop out. The fuel injectors need a certain pressure to work, if it isn't there, the car won't run. When the car is misfiring, smell the exhaust. A cylinder that has fuel injected, but not ignited well smell like gasoline. A water leak into the intake system will create a sweet smell from the antifreeze.

I had a Ford Mustang that would spontaneously drop one or two cylinders. No trouble codes would show on a scanner. It was usually the same cylinder, or two, but they were not on the same coil. It was a "wasted spark" distributorless ignition system which uses 3 coils for 6 cylinders. This meant that a dead coil or coil driver would take out two cylinders. Sometimes one, two or even three cylinders would go out, but not in pairs, so it had to be fuel.

Before I figured it out I read in a magazine about a similar weird issue in a Corvette, and GM recommended trying a new battery. OK, my battery was the original Ford battery, and it was 5 years old. A voltmeter test revealed that the car was only making 12.something volts at 2000 RPM, so I tried a new battery. It never happened again.

It takes considerable energy to turn the camshaft against the valve spring force, so the shaft tends to stop turning quickly if the belt slips, and this tends to rip lots of teeth off the belt.

Maybe then the water pump bearings have gone and the timing belt is losing tension. That I would believe. Because guess what, the water pump is driven by the timing belt!

And there is water leaking out around where the water pump is but its covered by a plastic timing belt cover so I cannot see properly for sure, and this cover is a pain in the *** to get off.

I'll have to pop open the timing cover and take a look.

Last edited:

I pulled the timing cover off to get a good look at a few things and I think one of the timing bearings (or the power steering pump, it is a bit low on oil, I'm filling it up at the moment.) is making that noise, anyway it went away after a few minutes of running the engine. I had a good look at the whole area with a HID spotlight. As you say tubelab its not the timing belt, everything is tight in there despite the squirrelly bearing coming from somewhere. I placed a listening stick onto the water pump, power steering pump and timing belt bearings and I couldn't narrow it down but that doesn't mean its not bad. I think its a timing bearing anyway.

No water leak from the water pump at all. The water pump is tight as a drum.

The "miss" isn't a miss at all. The tailpipe is flooded with fuel. She is running very rich. I'm suspecting at this point a bad fuel pressure regulator but I'm going to watch a few youtube videos to confirm my suspicions before I call it certain. They are $100-$200 for this car and my nextdoor neighbour has told me that on Toyota's the Fuel pressure regulator goes bad all the time.

Its either that or one of the two O2 sensors could've gone bad after I brushed up against it. Which makes a LOT of sense when you consider that the problems started when I touched the cables surrounding the O2 sensor when I was busy installing the big 3 cables, I touched the cable going to the knock sensors and I initially suspected the knock sensors but I'm suspecting the front bank O2 sensor now.

I also suspected the AFM but I don't think its that anymore, it could be, I'll go down and spray it liberally with electrical contact cleaner tomorrow.

I don't suspect a head gasket at this point as I wasn't losing any water before I mothballed the car. Also the exhaust doesn't smell sweet. It wreaks of fuel. It WAS smelling sweet before but I think I crossed a water hose onto the intake manifold as I stated before. But now the sweet smelling exhaust has gone, replaced only by fuel.

No water leak from the water pump at all. The water pump is tight as a drum.

The "miss" isn't a miss at all. The tailpipe is flooded with fuel. She is running very rich. I'm suspecting at this point a bad fuel pressure regulator but I'm going to watch a few youtube videos to confirm my suspicions before I call it certain. They are $100-$200 for this car and my nextdoor neighbour has told me that on Toyota's the Fuel pressure regulator goes bad all the time.

Its either that or one of the two O2 sensors could've gone bad after I brushed up against it. Which makes a LOT of sense when you consider that the problems started when I touched the cables surrounding the O2 sensor when I was busy installing the big 3 cables, I touched the cable going to the knock sensors and I initially suspected the knock sensors but I'm suspecting the front bank O2 sensor now.

I also suspected the AFM but I don't think its that anymore, it could be, I'll go down and spray it liberally with electrical contact cleaner tomorrow.

I don't suspect a head gasket at this point as I wasn't losing any water before I mothballed the car. Also the exhaust doesn't smell sweet. It wreaks of fuel. It WAS smelling sweet before but I think I crossed a water hose onto the intake manifold as I stated before. But now the sweet smelling exhaust has gone, replaced only by fuel.

Last edited:

- Home

- Member Areas

- The Lounge

- The car thread