I agree on using good quality plywood I used Baltic Birch on my 4 DIY Klipsch WMW bass bin's on the horn section of the cabinet and Red Oak for the outsides.Hi Pabesco,

I've not used the 18LW2400's but I do not think you will be disappointed, and they should do nicely for a "smaller" system. There are two routes you can go on wood IMO, one being quality plywood, and the other being something cheap like OSB. The middle ground of particleboard, MDF, and regular construction ply you should avoid altogether.

Quality plywood is or can be tough to find and really expensive, especially on an island. 13 ply Baltic Birch B/BB grade is generally considered the good stuff, but what makes it good is that there are no voids and the quality of the inner ply's is nearly as good as the outer surface you see. Baltic Birch is totally made of birch, not just birch veneer for outer skins.

BB ply:

An externally hosted image should be here but it was not working when we last tested it.

The difference:

Both examples appear to be of good quality, but I would prefer not to buy the one on the left. Fewer ply's give a tendency to to warp and the thin outer veneers are easy to damage.

This is what you want to avoid:

An externally hosted image should be here but it was not working when we last tested it.

The gaps due to voids or splices can make air leaks or rattle 😡

There is some stuff called Auraco Ply that I tried on some monitors:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

It's OK if available, not great but serviceable. It's one of those that tends to warp, but it is generally void free.

If you are inexperienced in woodworking get help, you don't need fancy tools but you do need to be able to make clean straight accurate cuts.

No scoops

Attachments

Thats MWM Bass Bins I need new glasses😕I agree on using good quality plywood I used Baltic Birch on my 4 DIY Klipsch WMW bass bin's on the horn section of the cabinet and Red Oak for the outsides.

Dan the inner part of the bin is Baltic Birch sorry not sure what you mean by MDO?Nice work, is that BB MDO ply? I've never seen that before...

I've never seen MDO with a BB core...

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

The Red Oak plywood has about 10 plysAn externally hosted image should be here but it was not working when we last tested it.

Yes not cheap it was about $120 a sheet it's twice as heavy as regular shop grade birch plywood.Lets try again...

Your monkey needs a new prescription Dan.

😕 You off your meds again Chimpchenko?

Your pics is plywood with Kraft paper overlay.

Used tons of the stuff when I worked at a museum many moons ago.

What our Klipsch buddy posted is not the same stuff.

His is simply Oak veneered baltic birch.

Unobtainium unless you know where to get it.

Used tons of the stuff when I worked at a museum many moons ago.

What our Klipsch buddy posted is not the same stuff.

His is simply Oak veneered baltic birch.

Unobtainium unless you know where to get it.

Can anyone tell me if I should insulate the TH18 cabinet. I'm completing the first one today but don't remember reading anything about insulating or damping. I would really like to know before putting on the last side panel.

Thanks guys

Thanks guys

Just do the large braces, no corner reflectors unless you are doing handle cutouts milled into the exterior panels. Then just use that one reflector on the back / top

No stuffing necessary, how high do you want to run these?

Martin wanted to originally run these to 180hz, but that's not really recommended.

Which version are you constructing? Cone corrected or non?

No stuffing necessary, how high do you want to run these?

Martin wanted to originally run these to 180hz, but that's not really recommended.

Which version are you constructing? Cone corrected or non?

i am using the original design with the internal reflectors without cone correction as recomended.

there are four 45 degrees cutouts that go to the top of the cab and this is what i used. i will try to post the pics i took. would i be able to just copy and paste pics to this forum or would i have to do something else?

there are four 45 degrees cutouts that go to the top of the cab and this is what i used. i will try to post the pics i took. would i be able to just copy and paste pics to this forum or would i have to do something else?

hi Pabesco

Go to reply and look near the bottom of the text box and open Go Advanced and scroll down and you will see manage attachments,select the files you want and upload them, after your finished hit submit ,it iwill take you back to your post,Simple as pie,lol.

😀

NS

Go to reply and look near the bottom of the text box and open Go Advanced and scroll down and you will see manage attachments,select the files you want and upload them, after your finished hit submit ,it iwill take you back to your post,Simple as pie,lol.

😀

NS

Hello everyone,

Seems like it has been a while since anyone has posted to this forum...

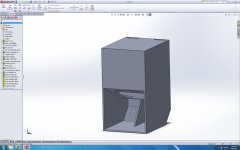

I am about to begin a build of 4 of these (mkII version) and as such I have drawn up the sub in CAD (SolidWorks).

Unfortunately my solidworks skills are not yet to the point that I can take my 3d model and make a cut sheet from it, as such I humbly ask for someone who is better at cad than I am's assistance in this matter.

So if you are interested in taking a decent solidworks file of the mkII sub and making a cut sheet from it please PM me and I will send you a copy of my file to play with.

Thank you all for your help,

-Sam Feine

Seems like it has been a while since anyone has posted to this forum...

I am about to begin a build of 4 of these (mkII version) and as such I have drawn up the sub in CAD (SolidWorks).

Unfortunately my solidworks skills are not yet to the point that I can take my 3d model and make a cut sheet from it, as such I humbly ask for someone who is better at cad than I am's assistance in this matter.

So if you are interested in taking a decent solidworks file of the mkII sub and making a cut sheet from it please PM me and I will send you a copy of my file to play with.

Thank you all for your help,

-Sam Feine

Attachments

The difficulty with producing a cut list is that you have made the entire cabinet as one component. It would be easier if you had modelled the speaker as an assembly. The separate panels then can be laid out in a separate assembly to see how they can be nested to suit whatever timber panel sizes you have available.

You could still achieve this with what you have by adding the TH18 model to a new assembly, and then adding individual panel parts overlaying what you have already modelled. Make the parts associative to the base model and they should update if the base model is modified. The individual parts can then be laid out to produce the cut list.

Hopefully that makes sense🙂

Regards Martin (Xoc1)

You could still achieve this with what you have by adding the TH18 model to a new assembly, and then adding individual panel parts overlaying what you have already modelled. Make the parts associative to the base model and they should update if the base model is modified. The individual parts can then be laid out to produce the cut list.

Hopefully that makes sense🙂

Regards Martin (Xoc1)

Hi Martin,

I think that I understand what you are saying, in essence I will have to model each panel of wood individually then using the original model as a guide "assemble" them in an assembly. What I don't understand is how making them associative to the original model would allow for the panel models to change when the original model is changed.

I will give that a try, it will take a little while to model each panel but in the end your right that will make it very easy to lay out flat in a cut sheet.

One other question, I can't seem to figure out how to model the throat correction in Hornresp (or if that is even possible) any tips?

I think that I understand what you are saying, in essence I will have to model each panel of wood individually then using the original model as a guide "assemble" them in an assembly. What I don't understand is how making them associative to the original model would allow for the panel models to change when the original model is changed.

I will give that a try, it will take a little while to model each panel but in the end your right that will make it very easy to lay out flat in a cut sheet.

One other question, I can't seem to figure out how to model the throat correction in Hornresp (or if that is even possible) any tips?

final specs and questions

hi to all, thanks so much for the information given. i built two of the th18s from the original design as suggested. i have 18sound 2400s loaded in them and they sound great but i have a few questions

1. is there something i need to connect to the speaker before the amp such as a filter or cross over? i notice a clicking sound whenever i add more power to the speaker and need to know what to do

2. i will build two more and load with bnc speakers, i will use more bracing and need a final design with cut sheet if not too much trouble. i have read and read and dont know which is the final design

3. after building the new ones should i fill all voids with foam or this is not needed?

4. i noticed some of the builders used plywood, can this build be done with ferolla or good one side ply?

5. i am using a behringer inuke 6000dsp for these two and have no idea how to set this amp for these drivers, i am learning as i go and any help would be greatly appreciated

6.i have a qsc 2450, would i be able to use this amp to power these subs as i was reading? or is this way too little power for these drivers?

thanks in advance for any help with the answers

7. what tops are suggested to build to go with these th18s?

hi to all, thanks so much for the information given. i built two of the th18s from the original design as suggested. i have 18sound 2400s loaded in them and they sound great but i have a few questions

1. is there something i need to connect to the speaker before the amp such as a filter or cross over? i notice a clicking sound whenever i add more power to the speaker and need to know what to do

2. i will build two more and load with bnc speakers, i will use more bracing and need a final design with cut sheet if not too much trouble. i have read and read and dont know which is the final design

3. after building the new ones should i fill all voids with foam or this is not needed?

4. i noticed some of the builders used plywood, can this build be done with ferolla or good one side ply?

5. i am using a behringer inuke 6000dsp for these two and have no idea how to set this amp for these drivers, i am learning as i go and any help would be greatly appreciated

6.i have a qsc 2450, would i be able to use this amp to power these subs as i was reading? or is this way too little power for these drivers?

thanks in advance for any help with the answers

7. what tops are suggested to build to go with these th18s?

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)