I think the LA6510 is an opamp.

When I looked at the data sheet I had pins 33 and 31 as focus related and 10 ? and 5 as tracking.

Don't be scared of trying any adjustments as long as you can set them back where they were. Mark the presets with a dab of ink on the white and blue parts so you can line them up exactly if needed. Do one at a time and make a note of what each is.

I've told you what to expect for each function 🙂

When I looked at the data sheet I had pins 33 and 31 as focus related and 10 ? and 5 as tracking.

Don't be scared of trying any adjustments as long as you can set them back where they were. Mark the presets with a dab of ink on the white and blue parts so you can line them up exactly if needed. Do one at a time and make a note of what each is.

I've told you what to expect for each function 🙂

Thanks for all kind support Mooly, yes you are right LA9200 pin 10 goes to opam LA6510 pin 6 (Tracking) pot p104 100K is between two ICs can be this pot? LA9200 pin 5 goes to p103 20K and after goes to GND I think isn't this pot to adjust tracking?

Last edited:

Sled position at disc start is difficult because there is nothing to measure physically. Make sure any microswitches are undamaged and the "leaves" straight and not bent.

I think it's OK see pic

I would look to fixing the skipping first because that may well be connected to the not reading TOC and should be easier to fix.

Do the sled check first and then repeat it using the same CD (use a long disc) and keep a note of where in the disc the problem occurs.

Attachments

It's not that sort of fault really. That won't tell you anything.

From what you say (looking back to the start), the not reading TOC could be mechanical. The pickup has to be in the correct position and if it's out a little bit then that can cause issues. It usually depends on the physical position of a limit switch to tell the servo when its at the end.

Also the spindle motor (platter motor) could be temperamental. Unofficial fixes are disconnecting the spindle motor and applying 9 volts for a few seconds to spin and clean up the commutator.

And skipping through a track could be sled related. Does it skip at the same point on the disc if its left to play ?

You must do the test of measuring DC volts across the motor when playing to make sure the sled isn't sticking. If the voltage is around 0.2 volts say (and it is low normally) and then it suddenly goes 0.3, 0.4, 0.5 and so on and then jumps and the voltage falls back to normal that is because the sled was sticking.

I have two motors: spindle motor & laser picup motor, wich one?

All these have to be confirmed before going to deep looking for an electronic issue.

A lot of things have to come together and work correctly in a CD player and all must be checked.

The microswitch looks OK. It probably has a plastic spiggot to locate it. You can always come back to this area but concentrate on getting it to play a disc through perfectly first.

Its the sled motor (the motor that drives the gears) that you measure the voltage across. I would solder two wires so that you can connect the DVM up and then sit back and watch as it plays through a disc.

If there is old grease (hardened or dirty) on the sled or gears then I would always strip down and a clean and relubricate.

You won't have this but I always use a special plastics grease that is for plastic/metal surfaces in any combination.

Its the sled motor (the motor that drives the gears) that you measure the voltage across. I would solder two wires so that you can connect the DVM up and then sit back and watch as it plays through a disc.

If there is old grease (hardened or dirty) on the sled or gears then I would always strip down and a clean and relubricate.

You won't have this but I always use a special plastics grease that is for plastic/metal surfaces in any combination.

How do you say "spiggot"?

I don't see any old grease on the sled or gears see pics.

I have silicon based oil, can I use it?

Laser pickup is new max. have surely 200 or 300 hours.

I don't see any old grease on the sled or gears see pics.

I have silicon based oil, can I use it?

Laser pickup is new max. have surely 200 or 300 hours.

Attachments

Changing setting in pot p104 don't change nothing in the eye pattern.

Changing setting in pot p107 don't change nothing in the eye pattern.

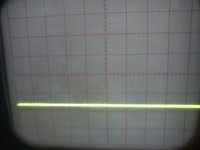

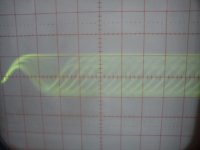

Changing setting in pot p105 change the eye pattern to an straight line in the scope but can adjust for a better one eye pattern.

Changing setting in pot p107 don't change nothing in the eye pattern.

Changing setting in pot p105 change the eye pattern to an straight line in the scope but can adjust for a better one eye pattern.

Last edited:

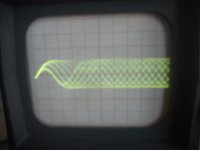

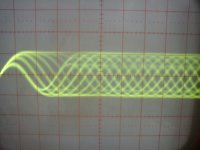

Changing setting in pot p101 can change the eye pattern attached two pics one with adjust for best eye pattern that I left, other pic shows a straight line with wrong setting doing the player finish to play and CD transport display showo 0 track , 0 min and 0 sec that's with setting in a max direction, the other pic shows setting max in the opposite direction (not focused eye pattern).

Attachments

Has altering the presets P101 and P105 improved on the quality of the eye pattern compared to what it was before ?

Silicon oils and grease are safe as long as viscosity is OK so silicon oil is good for the sled runners.

Spigot... a locating peg 🙂

Silicon oils and grease are safe as long as viscosity is OK so silicon oil is good for the sled runners.

Spigot... a locating peg 🙂

Really not.

OK I will use silicon oil for the sled runners.

Thanks now I understand what's spigot.

OK I will use silicon oil for the sled runners.

Thanks now I understand what's spigot.

So next step really is to monitor the DC voltage across the sled motor as I mentioned before. That's a really good guide as to whether there is a mechanical problem.

So next step really is to monitor the DC voltage across the sled motor as I mentioned before. That's a really good guide as to whether there is a mechanical problem.

This can be fix also the TOC issue?

This can be fix also the TOC issue?

It is all part of gathering all the information that hopefully leads to finding the problem.

It may or may not be related to the TOC issue.

When you fix a fault and then look back you usually find all the evidence was there all along.

Now I don't get sound but player seems OK I see in the display how is playing, measured Hex Inverter 74HC4049 and reference voltages aren't OK pin 1 & 12 are OK +5VDC but pins 4 & 6 only shows 2,25VDC instead 5,2VDC & 5,1VDC respectively, possible is gone😡

- Home

- Source & Line

- Digital Source

- Test CD for CD player adjustment