Cool. I love my tracksaw soooo much. It's improved my speaker building skill greatly, compared to a pretty decent table saw with sliding Incra miter.

Makita, with both the 55" and 118" rails.

I hated paying for the 118" rail, but when it's needed, it really helps. Can hold 1/2mm true or better, over 8ft cuts with it...even with bevels.

I figure you know this, but for maybe others considering a tracksaw.....

best setup I've learned, is to put a 4x8 piece of ply on a couple of sawhorses, then on the ply put a 4x8 sheet of sacrificial XPS foam for blade to cut down into. Makes a great table for easy precision cuts...

Thanks for the tips Mark. It was actually this thread that pushed me to order the track saw last week and I should be getting the 55" makita guide today.

I wanted to get one before just could not justify the expense. Now with this triangular/angled cuts, a tracksaw would be perfect and I can cut anywhere.

I think I'll just go straight 90 on my horizontal, no secondary flares flush to the walls... and do a bendy plywood/tractrix vertical secondary flare. You think this is a good idea?

I do think that's a good idea, and it's what i'd do if i build again.

Just not sure what you mean by "no secondary flares flush to the walls"

If I were doing straight wood flares, I'd use the angles and measurements the speadsheet gives.

If i were adding bendy board curved flares, I'd probably leave the mouth pieces unbeveled and square, to attach the bendy flares with square butts...

Just not sure what you mean by "no secondary flares flush to the walls"

If I were doing straight wood flares, I'd use the angles and measurements the speadsheet gives.

If i were adding bendy board curved flares, I'd probably leave the mouth pieces unbeveled and square, to attach the bendy flares with square butts...

I was thinking making the vertical panel butt against the sidewall and make the room's sidewall as the flare extension. It will be like a klipschorn, corner horn style

The horizontal panels can curl up/down. Sorry for the drawings, I'm just learning and on elementary level with fusion360 🙂

The horizontal panels can curl up/down. Sorry for the drawings, I'm just learning and on elementary level with fusion360 🙂

Attachments

Last edited:

I was thinking making the vertical panel butt against the sidewall and make the room's sidewall as the flare extension. It will be like a klipschorn, corner horn style

The horizontal panels can curl up/down. Sorry for the drawings, I'm just learning and on elementary level with fusion360 🙂

I see. Very creative ! 🙂

Mark, when you cut the panels with your tracksaw. Did you do straight cuts first, then a second pass with angled cuts? Or did you go straight to doing angled cuts?

Mark, when you cut the panels with your tracksaw. Did you do straight cuts first, then a second pass with angled cuts? Or did you go straight to doing angled cuts?

One cut..it's a big part of the joy 🙂

If you don't have clamps get these ..DEWALT Clamp For Tracksaw (DWS5026) - Track Saw Accessories - Amazon.com

Also, the dewalt n126162 dust collector fits right on...

I draw the lines/or marks on the baltic-birch with a 0.3mm pencil, and then just lay the rubber edge of the track right on the center of the line/mark.

It really just comes down to how close can I mark and then line up the track edge. That's why I use 0.3mm pencil, for fine marking.

Most often there's no need to caulk or sand.

I mean why do that fix it stuff, if you don't have to 😀

Ok that's great, wasn't sure I can get accurate angles, never used a tracksaw. I thought I'd have gaps and mess around with PL Construction glue to hide gaps 🙂

That dewalt clamp looks great, I ordered the makita clamps, but surprisingly my microjig clamps work with the rail too.

Do you mark the wood where the angles are with the protractor? Or just rely on the tracksaw angle indicator?

Can't wait to start cutting, thought I'd ask first, make sure I don't screw it up...

That dewalt clamp looks great, I ordered the makita clamps, but surprisingly my microjig clamps work with the rail too.

Do you mark the wood where the angles are with the protractor? Or just rely on the tracksaw angle indicator?

Can't wait to start cutting, thought I'd ask first, make sure I don't screw it up...

Attachments

Ok that's great, wasn't sure I can get accurate angles, never used a tracksaw. I thought I'd have gaps and mess around with PL Construction glue to hide gaps 🙂

That dewalt clamp looks great, I ordered the makita clamps, but surprisingly my microjig clamps work with the rail too.

Do you mark the wood where the angles are with the protractor? Or just rely on the tracksaw angle indicator?

Can't wait to start cutting, thought I'd ask first, make sure I don't screw it up...

Lol...i screw up so often i could make a youtube comedy vid😀

On arrival, I verified 0, 30, and 45 deg with a protractor, and since then just use the gauge on the saw (trying to eyeball the guage perpendicularly).

That has worked great, where synergy attempts merely screwed together are tight enough for good measurement work.

Come to think of it, my best sounding syn, the 60x40 heavy mofo, is still only screwed together.

Oh, occasionally make sure no sawdust gets caked under the 0 deg stops.

I didn't notice that had happened until cutting some 2" thick stock and could eyeball it a wee bit out of square.

LOL ok it's awesome that is tight enough to measure without gluing it in.

This track saw and Kreg pocket holes should make this fast and easy :fingers crossed:

This track saw and Kreg pocket holes should make this fast and easy :fingers crossed:

Awesome L-fence videos @nissep this would be perfect for smaller pieces/angles. I like the last video the best, it's small but still functional. I'll make one. Thanks for this

For large 40" 45 degree with large off cuts , tracksaws are perfect.

For large 40" 45 degree with large off cuts , tracksaws are perfect.

Don’t forget the shorter the piece that sticks out, the smaller the of cut can be.

To big of an of cut the likelihood of a kickback or jam it is between the regular fence and the blade

To big of an of cut the likelihood of a kickback or jam it is between the regular fence and the blade

I don't know how stiff the secondary flare needs to be. It does give me pause for concern though.

My previous 60x40 with same overall mouth size as this 90x60 syn7, that I built entirely out of wood, sounds a little tighter in the low mid/ upper bass range.

I think there are 3 or 4 plausible causes:

the tighter pattern, way stronger mid-low drivers (way stronger!), the port location differences, and then finally...

does the foamboard soften the sound...??? plain dunno..

Update:

I'm quoting one of my previous posts because it expressed concern for the sound of the low mid/ upper bass range, and whether the softness I was hearing might be due to the secondary epoxy/glass cloth foamboard flares.

In the hope stronger mid drivers would solve it, I just swapped a pair of Faitlal 10PR300's in for the 10FE200's.

WOW, what a difference.....sounds so much more like the heavy all-wood 60x40 (which had two kickass rcf mb12n405 in as mids).

Truly gripping sound again ....😀

In fairness to the 10FE200s, they were a whopping $34 a piece...and are a real bargain imo. But sometimes we get's whats we pays for, huh? 🙂

Always thought those FE's looked a little weak 😱

PR300's are popular in premium bass guitar cabs. Nice drivers.

PR300's are popular in premium bass guitar cabs. Nice drivers.

Always thought those FE's looked a little weak 😱

PR300's are popular in premium bass guitar cabs. Nice drivers.

Yep Ernie, I knew i was out on a limb with the FE's....

But i used them to get thru the proof-of-concept stage....which was...using lightweight 10"s on top and bottom, with mid ports in the center of the horn instead of corners....

I built the box to be able to take either the PR300 or 320, as a direct bolt in substitute if it all worked....which yay it has 🙂

If i were willing to add more weight, i'd probably move to the 10FH520.

It would add about 6 lb of driver weight, and maybe the same again for the larger horn it would take to mount them...but it would be a sweet and very powerful box...

ps...this is an edit...

it really is amazing how soft the FE's sound on direct comparison....lord how i love hi-fi PA !

ps...this is an edit...

it really is amazing how soft the FE's sound on direct comparison....lord how i love hi-fi PA !

I'm assuming your comparisons were done at higher spl's than most 😉

I'm assuming your comparisons were done at higher spl's than most 😉

That's part of what is so amazing about the swap....cause no, not really very high SPL at all.

Even at moderate listening levels, the PR300 is so much tighter than the FE200.

More than it should be really....I'm thinking maybe the 10:1 port compression ratio simply chokes down the FE200....???

But speaking of higher spl's....now i'm finding some resonance issues to fix with the removable flares...couldn't hear them till the PR300's dropped in..

Always something huh ?

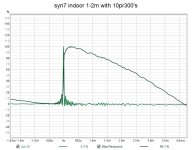

Here's today's indoor tuning with the PR300's in place, and a little deliberate VHF rolloff. Includes sub, so 4-way.

Attachments

- Home

- Loudspeakers

- Multi-Way

- synergy.....Take #7