I think it looks doable, the design is probably slightly stretchable without affecting looks.Nice looking design Onni. It's got a certain 1970's aesthetic and I mean that in a good sense. Very clean lines. A lot more WAF friendly than my rectangular box with a black baffle. I hope you can stuff all that into that little box. Those 8FE200's have a much larger bezel diameter than the smaller DC200's I used. I know I sure had a tough time fitting mine into a 46cm tall x 28cm wide x 33cm deep. This was using the Faital Pro LTH142 waveguide.

http://www.diyaudio.com/forums/multi-way/285030-bookshelf-multi-way-point-source-horn.html

The 8FE200 is only 4 mm larger outer diameter than the DC200 (209 vs 204 mm). The bezel looks large, but that's mainly due to the cone being unusually small for an 8" woofer. It's also 5 mm lower (total height) than the DC200 which should be positive 🙂

/Anton

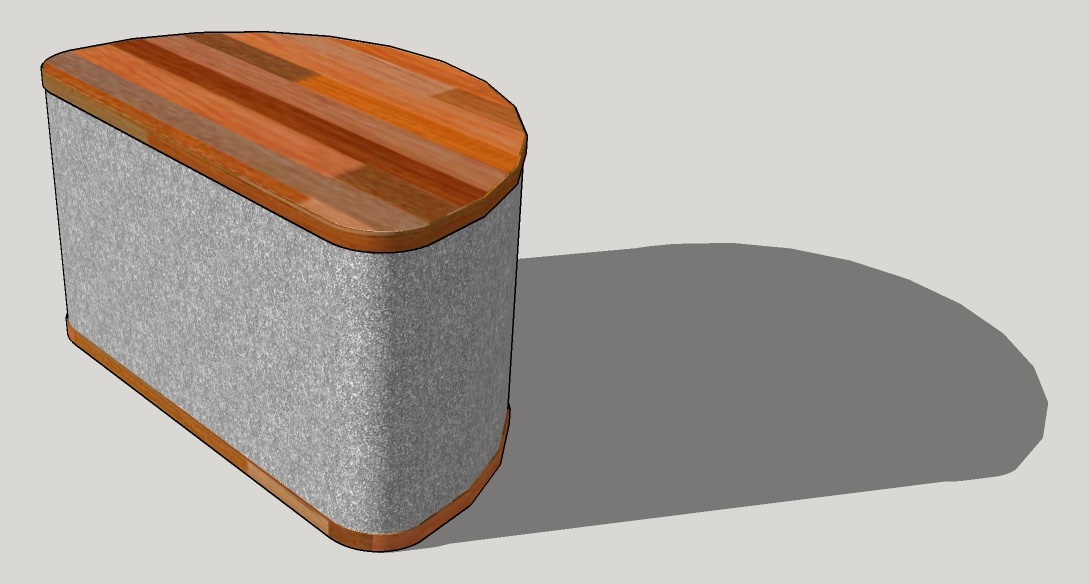

Played around a little in Sketchup. Outer dimensions are 50 x 28.2 x 30 cm and the waveguide mouth is thereby 40 x 25 cm.

/Anton

That is my all time favourite design for loudspeakers. I tried to make it work for my current build. The choice to either bend or stack plywood ruled it out... for now. Cudos on you for good design though.

Wow, thanks!That is my all time favourite design for loudspeakers. I tried to make it work for my current build. The choice to either bend or stack plywood ruled it out... for now. Cudos on you for good design though.

I'm guessing that it should be rather easy to bend thin (4 mm) plywood to a 25 cm radius. The ones I've found have 3 layers:

Which means that there is one stiff direction (two outer layers with grain in that direction) and one easily bendable (middle layer with grain in that direction). If I bend one at a time on 2-3 routed guides and only need finish that looks good when covered in fabric I should be fine. 4 layers for a total of 16 mm curved plywood is very stiff.

/Anton

you can get bendable (pre-kerfed) plywood and MDF which makes it easy

Bendy MDF Sheet - Rockler Woodworking Tools

Bendy MDF Sheet - Rockler Woodworking Tools

It wasn't the rear bend but the bend on the side I was concerned about. How to tie them into a 18mm front baffle.

Oh, I'm planning on using PVC pipe or possibly sonotube (2 layers glued together, added stiffeners).It wasn't the rear bend but the bend on the side I was concerned about. How to tie them into a 18mm front baffle.

/Anton

30 mm square legs

Tried adding the simplest possible legs, 30 mm squares. 45 mm long in front, 20 in back:

Looks decent for something so simple.

/Anton

Tried adding the simplest possible legs, 30 mm squares. 45 mm long in front, 20 in back:

Looks decent for something so simple.

/Anton

Attachments

From sweetspot:

/Anton

/Anton

Attachments

Last edited:

So aside from or including the layer of fabric, your wrap around is going to be flush with the top and bottom panels? So as to avoid diffraction? I'll be curious to see how you do this as I want to do this cabinet style quite badly.

Like I said my big problem was the roundover on the front baffle connecting to the thin plywood wrap around. My cabinets would be inside it so it would be totally cosmetic. But I still couldn't figure it out. Your idea of pvc pipe is interesting. I can't conceptualize just yet how that would work though.

I could have done it no problem if I didn't round over the edges of the front baffle. But that would be silly.

Like I said my big problem was the roundover on the front baffle connecting to the thin plywood wrap around. My cabinets would be inside it so it would be totally cosmetic. But I still couldn't figure it out. Your idea of pvc pipe is interesting. I can't conceptualize just yet how that would work though.

I could have done it no problem if I didn't round over the edges of the front baffle. But that would be silly.

An easy way to do those curved corners is shown here:

CABINET CORNERS

You can go so far as to get veneered plywood cylinders from them if you don't mind the cost

CABINET CORNERS

You can go so far as to get veneered plywood cylinders from them if you don't mind the cost

You might try soaking the plywood in water using wet towels for a day or two then bend it and screw into a curved form. The curved form could be the top and bottom. They don't have to be thick - just use CLD to damp resonances after they dry. Anthony Bisset built the Trynergy tractrix horns this way. More here:

http://www.diyaudio.com/forums/full...ll-range-tractrix-synergy-78.html#post4507708

http://www.diyaudio.com/forums/full...ll-range-tractrix-synergy-78.html#post4507708

Here's how it would look on my media console (290 x 40 x 50 cm, W x H x D):

Showed this to my SO and she was surprisingly positive! I think I could make these in a way that she would let them in to our living room 🙂

Raise the TV just a little and make three! 🙂

I'm going active though and see no difference in simming as an offset horn.

The OD option only simulates the two low-frequency offset drivers. The Multiple Entry Horn Wizard also takes the driver at the horn throat into account.

Attachments

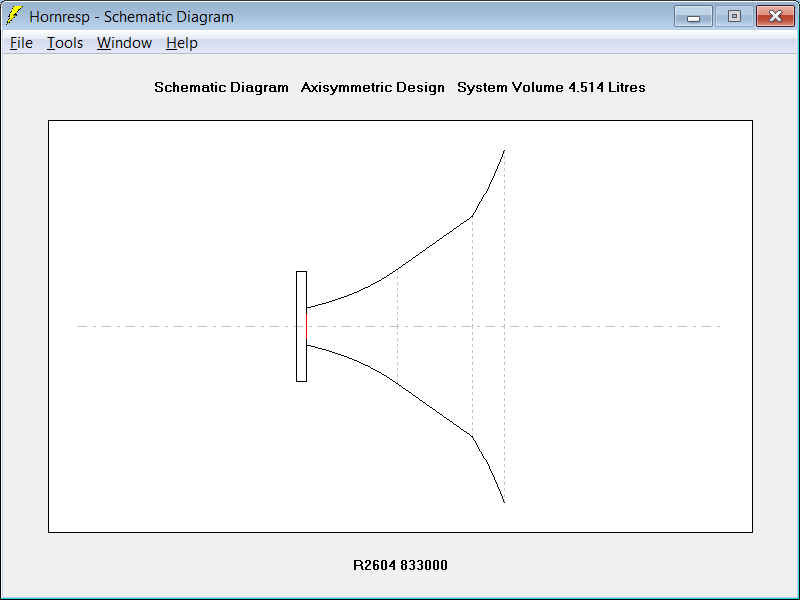

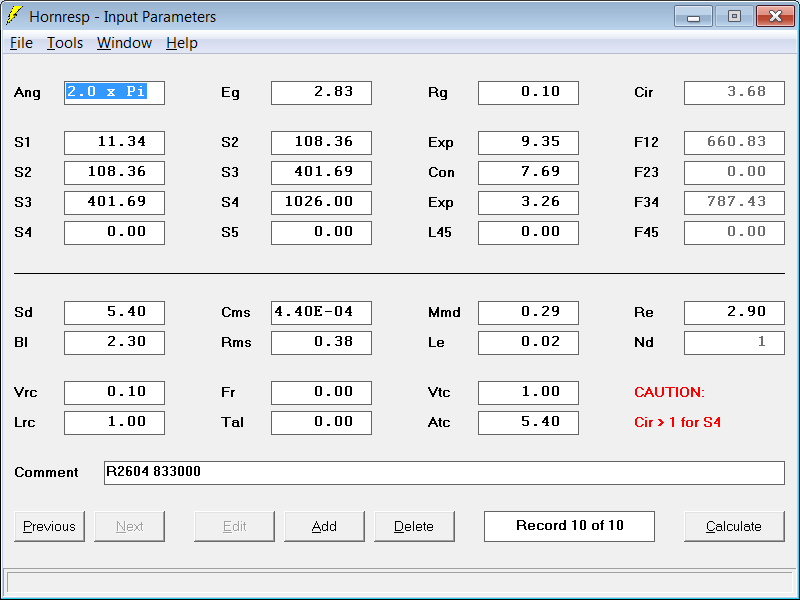

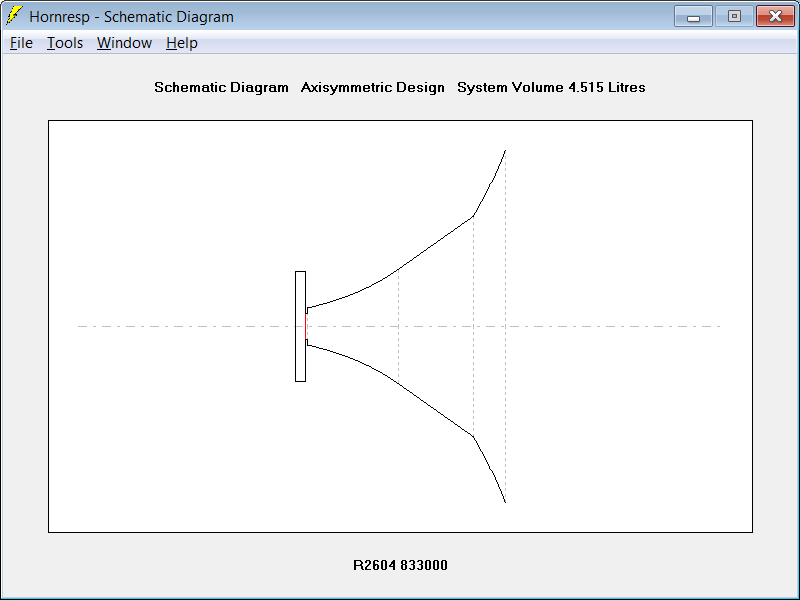

Alright, but how do I model this: R2604 833000?The OD option only simulates the two low-frequency offset drivers. The Multiple Entry Horn Wizard also takes the driver at the horn throat into account.

/Anton

Thanks!Great looking design Onni!

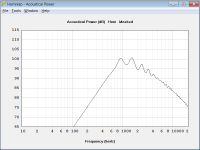

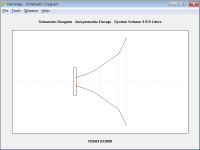

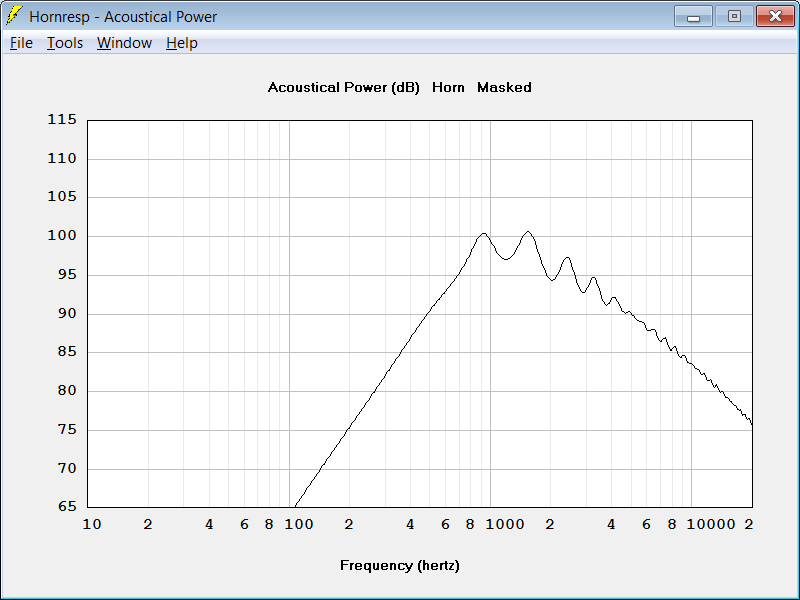

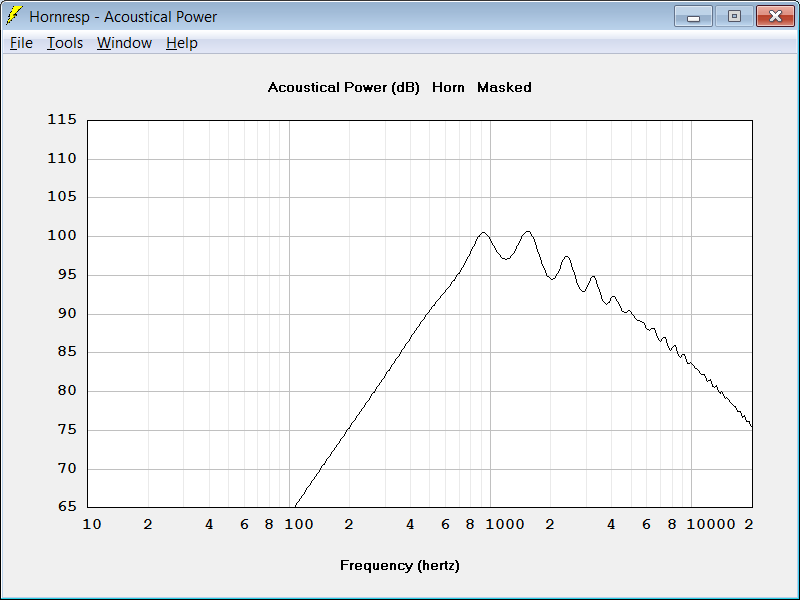

I tried modelling the R2604 in hornresp using the parameters from the data sheet. Please comment on how I've done!

The phase plug makes the schematic look a little weird as the Sd is smaller than the throat.

Displacement at 100 dB, 1 kHz is 0.19 mm which incidentally is just below Xmax (0.2 mm).

/Anton

Attachments

From sweetspot:

/Anton

I'd use spikes, not because of the audiophile attraction but because of the looks! Very 70's in a good way. 🙂

I'd use stacked construction on the outer shape though. With a Router and template it's easy. It's not like you're building arrays 😱 😉.

By the way, love what I see in the CSD, very promising.. got to love those ring radiators...

Last edited:

Spikes is a nice idea, brass should work. Maybe something like this:I'd use spikes, not because of the audiophile attraction but because of the looks! Very 70's in a good way. 🙂

I'd use stacked construction on the outer shape though. With a Router and template it's easy. It's not like you're building arrays 😱 😉.

By the way, love what I see in the CSD, very promising.. got to love those ring radiators...

Maybe only in the front and a soft one (or two) like this in the back:

Yeah, I have a router so that is indeed an idea. Building an array using stacked plywood would be crazy 😉

Good that I'm not alone in finding the CSD very promising 🙂

Comparison of 2.83 V into the proposed synergy and a model of the printed waveguide I've measured:

/Anton

Attachments

Last edited:

It has full TS parameters - you could model it assuming a pistonic diaphragm rather than as a ring radiator as an approximation. This horn would be easy to model in Akabak (and probably HR now that it has a synergy like multi-tap injection feature) - and certainly Comsol should be able to do it - does Comsol take driver TS parameters?

- Home

- Loudspeakers

- Multi-Way

- Synergy attempt without compression driver