FWIW, I don't tend to view/rely on snake oil sources and find such a suggestion offensive. However, I will admit that I should brush up on electronics....

Here's a slew of information on capacitor distortion, dielectrics, etc...

Cyril Bateman's Capacitor Sound articles | Linear Audio NL

Here's a slew of information on capacitor distortion, dielectrics, etc...

Cyril Bateman's Capacitor Sound articles | Linear Audio NL

... All three electrolytics produced significant distortions in these 0.3 volt tests. Almost five times larger with no bias, at least fifteen times larger with bias, than my PET assembly. I consider distortions from these 100 mF polar capacitors tested at 0.3volts, far exceed the sensible limit for use in the signal path of high quality audio.

Last edited:

Hi 12Bass,

On critical listening. I refuse to grade my own work. Others who do are use to me exposing them to equipment I have upgraded, equipment that has only been repaired and equipment in as-found condition (obviously working well). They never know what I'm going to hand them next. This keeps everyone honest. It does trip them up from time to time.

If you use an electrolytic capacitor in the signal path, you will suffer from Dielectric Absorption. Signal energy is trapped in the dielectric only to be released either never, or later at some point. This is practically the definition of distortion. Strapping smaller capacitors across this will not affect the DA problem in the least. So installing smaller capacitors with better dielectric material will not do anything to mitigate the damage done by the electrolytic capacitor. However, doing this for power supply bypass does work well, but that is because you are maintaining a low impedance up to very high frequencies. Here there are other factors that you are dealing with. It does not translate into signal coupling positions though.

Another issue would be capacitor distortion. This is a different problem and only occurs when you develop a voltage across a capacitor. This is probably what you were trying to improve on.

Physical reality. The PCB was designed to support a capacitor of a certain maximum size and lead diameter. Installing large capacitors can have a number of negative effects. The most obvious would be the support for the capacitor body is no longer borne by the PCB, but instead through the leads only, and therefore by the solder pads. These are not large enough on most PCBs to support the larger capacitor. Secondly, the hols often need to be drilled to a larger size to accommodate the larger leads found on larger capacitors. This directly reduces the amount of pad left to support the capacitor(s). The action of drilling the larger holes can weaken the bond between the pad and the substrate of the PCB. The larger capacitor may be positioned closer to a noise source, or it may radiate the signal running through it into more sensitive areas. The larger case is a larger antenna. In extreme cases, the capacitor can upset airflow used for cooling, or if adhesive was used, that can completely block air flow to some components.

That was a lot of information on capacitors. Most of it common sense. In addition to the above, there is another to watch. Certain capacitor types are designed to excel over different frequency ranges, but may be terrible for audio. I have seen ceramic capacitors pulled and the current darling capacitors installed. I've seen circuits that simply do not function anymore due to poor component choices that once did.

I once had a customer present a Luxman D-105u for warranty, and it was a new model, only a month old at the time. The complaint was that it wouldn't read CDs. Once it hit the bench, I discovered that every resistor had been replaced with metal film types, and the capacitors to the popular audio picks of the time. Further inspection revealed a tortured circuit board sporting lifted traces and missing pads. I closed it up, informed the distributor what was found, then called the customer with the news that not only had the terms of the warranty been violated, thereby releasing the distributor from any responsibility to repair the unit, the unit was not only too expensive to repair, but it would never be reliable after any repair attempt due to circuit board damage. At this point the upset customer indicated that his friend, a computer technician "who knew a lot about this stuff" had improved the unit, but that the equipment was junk because it needed cheap parts to work. Wow, right? He wanted to debate the issue, but I got him off the phone and had him come pick up the unit. No charge since I didn't want to have any more to do with him or his friend (who came along).

I have found some metal film resistors were inductive. It surprised the heck out of me.

-Chris

On critical listening. I refuse to grade my own work. Others who do are use to me exposing them to equipment I have upgraded, equipment that has only been repaired and equipment in as-found condition (obviously working well). They never know what I'm going to hand them next. This keeps everyone honest. It does trip them up from time to time.

If you use an electrolytic capacitor in the signal path, you will suffer from Dielectric Absorption. Signal energy is trapped in the dielectric only to be released either never, or later at some point. This is practically the definition of distortion. Strapping smaller capacitors across this will not affect the DA problem in the least. So installing smaller capacitors with better dielectric material will not do anything to mitigate the damage done by the electrolytic capacitor. However, doing this for power supply bypass does work well, but that is because you are maintaining a low impedance up to very high frequencies. Here there are other factors that you are dealing with. It does not translate into signal coupling positions though.

Another issue would be capacitor distortion. This is a different problem and only occurs when you develop a voltage across a capacitor. This is probably what you were trying to improve on.

Physical reality. The PCB was designed to support a capacitor of a certain maximum size and lead diameter. Installing large capacitors can have a number of negative effects. The most obvious would be the support for the capacitor body is no longer borne by the PCB, but instead through the leads only, and therefore by the solder pads. These are not large enough on most PCBs to support the larger capacitor. Secondly, the hols often need to be drilled to a larger size to accommodate the larger leads found on larger capacitors. This directly reduces the amount of pad left to support the capacitor(s). The action of drilling the larger holes can weaken the bond between the pad and the substrate of the PCB. The larger capacitor may be positioned closer to a noise source, or it may radiate the signal running through it into more sensitive areas. The larger case is a larger antenna. In extreme cases, the capacitor can upset airflow used for cooling, or if adhesive was used, that can completely block air flow to some components.

That was a lot of information on capacitors. Most of it common sense. In addition to the above, there is another to watch. Certain capacitor types are designed to excel over different frequency ranges, but may be terrible for audio. I have seen ceramic capacitors pulled and the current darling capacitors installed. I've seen circuits that simply do not function anymore due to poor component choices that once did.

I once had a customer present a Luxman D-105u for warranty, and it was a new model, only a month old at the time. The complaint was that it wouldn't read CDs. Once it hit the bench, I discovered that every resistor had been replaced with metal film types, and the capacitors to the popular audio picks of the time. Further inspection revealed a tortured circuit board sporting lifted traces and missing pads. I closed it up, informed the distributor what was found, then called the customer with the news that not only had the terms of the warranty been violated, thereby releasing the distributor from any responsibility to repair the unit, the unit was not only too expensive to repair, but it would never be reliable after any repair attempt due to circuit board damage. At this point the upset customer indicated that his friend, a computer technician "who knew a lot about this stuff" had improved the unit, but that the equipment was junk because it needed cheap parts to work. Wow, right? He wanted to debate the issue, but I got him off the phone and had him come pick up the unit. No charge since I didn't want to have any more to do with him or his friend (who came along).

I have found some metal film resistors were inductive. It surprised the heck out of me.

-Chris

Hi 12Bass,

Read that several times in the past along with several other articles and directly experimented myself a few times. You have to keep the circuit function of the capacitor in mind. Another hint: the impedance level in that circuit should be considered.

As I mentioned earlier, I am pretty sick and tired of seeing otherwise good equipment damaged or not worth repair due to "modifications" It seems that every time a post like yours is posted, I see at least a couple copy cats over the next few years. You would be surprised to see how many hack technicians specializing in "upgrades" can crank out. They make a lot of money doing this.

The last thing I was going to mention should be something to pay attention to. Many times a person would arrive at the shop with something they wanted modified. Most had problems that prevented them from working properly. Once repaired to spec and per the service manual, most of these people no longer saw the need to perform those "updates", and they couldn't believe they hadn't picked up on the poor sound quality. Most learned a valuable lesson about what they think they hear and what their ability to actually hear was. Professional musicians were included in that group, most who were paid members of an orchestra or ensemble who knew what the music sounded like.

That brings me to the next point. Short of a full rebuild, equipment should always be tested and brought to full operating potential with all faults corrected. You didn't do that. With a CD player, read errors create a BLER rate, and even a properly adjusted and operating CD player with a perfect CD will have an error rate that is non-zero. The big problem here is that the CD player is designed to hide this from us. The error correction can only fix so much, then the error concealer circuitry takes over and will make the data valid (not correct, I said valid), or it might mute the few bad words. You wouldn't notice this taking place even with a NOS setup. Speaking of NOS D/A conversion, if the drastic filters are not installed (and they won't be, trust me) you will feed 44.1 KHz into your audio equipment. This statement covers modifications to change an over sampled DAC to a NOS type DAC.

So the up-shoot of all this is simple. If there are problems with the CD player that cause data errors, the sound quality will be adversely affected. Basically it comes down to garbage in, garbage out. To properly, correctly repair a CD player, you need a lot of experience, the right equipment, the right test CDs (no, they cannot be copied) and whatever jigs or filters needed to set up the servos. A jitter meter wouldn't hurt either. If you are missing any of these things, the CD player is probably not properly set up. A very experienced technician might do a good job missing something, but that is a maybe. A layperson or semi-skilled technician has little chance of doing this successfully if they are missing any of the requirements listed above. Why is it that folks who are not very knowledgeable think that repairing something is easy? It might be easy for a skilled technician, but then it might not be either.

-Chris

Read that several times in the past along with several other articles and directly experimented myself a few times. You have to keep the circuit function of the capacitor in mind. Another hint: the impedance level in that circuit should be considered.

As I mentioned earlier, I am pretty sick and tired of seeing otherwise good equipment damaged or not worth repair due to "modifications" It seems that every time a post like yours is posted, I see at least a couple copy cats over the next few years. You would be surprised to see how many hack technicians specializing in "upgrades" can crank out. They make a lot of money doing this.

The last thing I was going to mention should be something to pay attention to. Many times a person would arrive at the shop with something they wanted modified. Most had problems that prevented them from working properly. Once repaired to spec and per the service manual, most of these people no longer saw the need to perform those "updates", and they couldn't believe they hadn't picked up on the poor sound quality. Most learned a valuable lesson about what they think they hear and what their ability to actually hear was. Professional musicians were included in that group, most who were paid members of an orchestra or ensemble who knew what the music sounded like.

That brings me to the next point. Short of a full rebuild, equipment should always be tested and brought to full operating potential with all faults corrected. You didn't do that. With a CD player, read errors create a BLER rate, and even a properly adjusted and operating CD player with a perfect CD will have an error rate that is non-zero. The big problem here is that the CD player is designed to hide this from us. The error correction can only fix so much, then the error concealer circuitry takes over and will make the data valid (not correct, I said valid), or it might mute the few bad words. You wouldn't notice this taking place even with a NOS setup. Speaking of NOS D/A conversion, if the drastic filters are not installed (and they won't be, trust me) you will feed 44.1 KHz into your audio equipment. This statement covers modifications to change an over sampled DAC to a NOS type DAC.

So the up-shoot of all this is simple. If there are problems with the CD player that cause data errors, the sound quality will be adversely affected. Basically it comes down to garbage in, garbage out. To properly, correctly repair a CD player, you need a lot of experience, the right equipment, the right test CDs (no, they cannot be copied) and whatever jigs or filters needed to set up the servos. A jitter meter wouldn't hurt either. If you are missing any of these things, the CD player is probably not properly set up. A very experienced technician might do a good job missing something, but that is a maybe. A layperson or semi-skilled technician has little chance of doing this successfully if they are missing any of the requirements listed above. Why is it that folks who are not very knowledgeable think that repairing something is easy? It might be easy for a skilled technician, but then it might not be either.

-Chris

Hi Chris,

A few clarifications:

There were no apparent issues with the X111ES CD transport before I started making modifications. It wasn't until later that it developed a problem reading toward the end of lengthy discs. A small amount of grease on the sled gears remedied this issue, and it now reads reliably and will not skip on most discs, even with moderate tapping on the case. At some point I would like to go through the CD block adjustment in the service manual, but decided that it is probably best left alone for now if reading reliably.

The 1000µF 16V caps easily replace the 47µF originals without requiring any drilling or encountering space issues. Modern electrolytics tend to be smaller. I can't provide a technical treatise on why the coupling capacitors change the sound so much, but they do. I did experience a larger electrolytic acting as an antenna in a power amp and ended up returning the original part.

In general, I try to keep reliability in mind when making modifications. By that, I mean that I am careful with component choice, soldering, and mounting, where the goal is to retain factory reliability. That said, I am a tinkerer by nature and have learned a few difficult lessons along the way.

From what I gather, NOS is a bad idea in principle (as the reconstruction filter is a necessary part of a digital sampling system in order to get a properly smoothed output waveform, remove aliasing, etc...) and not something I'm interested in pursuing, though I'd be curious to hear a NOS DAC to see if there's something to it.

A friend has an NAD 5300 which has a Disc Test function which displays the error rate and can give an idea of how many correctable and uncorrectable errors are encountered. Would be a cool feature to have for checking disc quality along with potential degradation of the optical reader.

See it in action here: YouTube

A few clarifications:

There were no apparent issues with the X111ES CD transport before I started making modifications. It wasn't until later that it developed a problem reading toward the end of lengthy discs. A small amount of grease on the sled gears remedied this issue, and it now reads reliably and will not skip on most discs, even with moderate tapping on the case. At some point I would like to go through the CD block adjustment in the service manual, but decided that it is probably best left alone for now if reading reliably.

The 1000µF 16V caps easily replace the 47µF originals without requiring any drilling or encountering space issues. Modern electrolytics tend to be smaller. I can't provide a technical treatise on why the coupling capacitors change the sound so much, but they do. I did experience a larger electrolytic acting as an antenna in a power amp and ended up returning the original part.

In general, I try to keep reliability in mind when making modifications. By that, I mean that I am careful with component choice, soldering, and mounting, where the goal is to retain factory reliability. That said, I am a tinkerer by nature and have learned a few difficult lessons along the way.

From what I gather, NOS is a bad idea in principle (as the reconstruction filter is a necessary part of a digital sampling system in order to get a properly smoothed output waveform, remove aliasing, etc...) and not something I'm interested in pursuing, though I'd be curious to hear a NOS DAC to see if there's something to it.

A friend has an NAD 5300 which has a Disc Test function which displays the error rate and can give an idea of how many correctable and uncorrectable errors are encountered. Would be a cool feature to have for checking disc quality along with potential degradation of the optical reader.

See it in action here: YouTube

I am aware of a large variety of cognitive and perceptual biases and, though I must admit that as a human I am susceptible, I do my best to recognize and mitigate their effects. That's why I spend hours critical listening and testing, making comparisons. More often than you seem to assume, I have found that my expectations were thwarted, that a particular modification or component substitution was a step backward. I refuse to allow myself to believe that any change I might make is automatically beneficial, because a great deal of experience has told me otherwise. If a given change sounds subjectively worse, I simply accept it, and step back, or try another approach.

The only way to remove expectation bias is fully blind testing (ie double-blind if other people are invoved, or machine-controlled random trials). Knowing the effect exists and trying to compensate for it does not work at all, go check out the McGurk effect to see just how easily the various other parts of the brain affect conscious acoustic perception in a _completely_ convincing way...

Once any kind of subtlety is involved audio perception is a minefield. I've managed to measure my sensitivity to various harmonics with computer generated tones - the harmonic is switched on several seconds after the start - the sudden appearance of a tone is a distinct event to perceive - but comparing two different clips one with and one without the harmonic is harder and feels more subjective. This relies on auditory memory which is a very specialized part of the brain which in most people only lasts about 7 seconds. Its hard enough measuring acoustic perception without adding memory into the mix - could you tell two shades of red apart by memory to any precision?

[ I reckon I can just detect a 200Hz 3rd harmonic at -57dB, when its switched on and off (on headphones), and -63dB for the 5th harmonic, seems to be the most sensitive frequency for this. If it weren't for IM products that suggests -80dB THD is plenty for my ears. ]

If you can engineer a comparison where the switch-over is instant without affecting volume, you have a much better chance of hearing real differences, but you still need randomized ABX or similar if the difference is really subtle -

Hi 12Bass,

No apparent issues. That is exactly what many customers have said when in fact there have been issues, enough to affect the sound quality, but not severe enough to cause mistracking.

Capacitors with low voltage ratings tend to have higher DA than units up to about 63 VDC. Try your tests again using 47 uF 63 VDC capacitors in the largest case size. Generally speaking, capacitors are of better quality today, but the orange capacitors with epoxy (or some hard coating) on the bottom often perform better than a new one in a smaller case.

Reliability is something to consider. I'm glad that that lesson has stuck with you.

NOS DACs are a terrible idea. Those who use them probably will not listen to anyone who hold a contrary viewpoint.

In the older CD players, there used to be exposed test points for the C1 and C2 error flags. We used to monitor them. However, the best looking eye pattern with the least amount of jitter would correspond with the lowest error rates. The same exact thing applied to DAT transports and any other serial data stream. Newer CD players hid these flags so they couldn't be monitored. Too bad, because they are instructive to watch.

I had modified a few CD players to have a buffered eye pattern output jack that would go to an oscilloscope. That way a recording studio could determine that a CD they just burned with the day's mixes was good or not.

The eye pattern is much like a blood test. You can determine a lot by observing one, but this comes with experience. When it comes to aligning your CD player, have a professional do it. Often we have to deviate a little from the manual, or even shim motors or slide rails in order to get the mechanical alignment right in the absence of mechanical adjustments. The very best transport I have ever seen was in the Nakamichi OMS-5 / 7 CD players. You could adjust the mechanical alignment bang-on. Then setting the servos up resulted in an eye pattern that looked like a picture. The quality of eye patterns has declined over the years to a point where I'm surprised that a CD player can play without serious audio issues.

-Chris

No apparent issues. That is exactly what many customers have said when in fact there have been issues, enough to affect the sound quality, but not severe enough to cause mistracking.

Capacitors with low voltage ratings tend to have higher DA than units up to about 63 VDC. Try your tests again using 47 uF 63 VDC capacitors in the largest case size. Generally speaking, capacitors are of better quality today, but the orange capacitors with epoxy (or some hard coating) on the bottom often perform better than a new one in a smaller case.

Reliability is something to consider. I'm glad that that lesson has stuck with you.

NOS DACs are a terrible idea. Those who use them probably will not listen to anyone who hold a contrary viewpoint.

In the older CD players, there used to be exposed test points for the C1 and C2 error flags. We used to monitor them. However, the best looking eye pattern with the least amount of jitter would correspond with the lowest error rates. The same exact thing applied to DAT transports and any other serial data stream. Newer CD players hid these flags so they couldn't be monitored. Too bad, because they are instructive to watch.

I had modified a few CD players to have a buffered eye pattern output jack that would go to an oscilloscope. That way a recording studio could determine that a CD they just burned with the day's mixes was good or not.

The eye pattern is much like a blood test. You can determine a lot by observing one, but this comes with experience. When it comes to aligning your CD player, have a professional do it. Often we have to deviate a little from the manual, or even shim motors or slide rails in order to get the mechanical alignment right in the absence of mechanical adjustments. The very best transport I have ever seen was in the Nakamichi OMS-5 / 7 CD players. You could adjust the mechanical alignment bang-on. Then setting the servos up resulted in an eye pattern that looked like a picture. The quality of eye patterns has declined over the years to a point where I'm surprised that a CD player can play without serious audio issues.

-Chris

A friend of mine is interested in setting up some ABX tests. We're thinking that listening for the effect of different types of coupling capacitors versus a piece of wire is a fairly straightforward way to begin and should be easily accomplished with a DPDT switch (for stereo). Comparing op amps would also be nice, but requires simultaneously switching many more connections.

Whilst I tend to be rather strict about epistemic issues, and am scientifically-minded, non-religious, etc... to a large degree I also think that when it comes to sound quality, the credo "if it sounds better, it is better" comes into play. I admit that I cannot be completely objective whilst listening and that psychoacoustics is pretty complex and murky terrain. That said, I still do my best to retain whatever objectivity that I can, and I often spend hours making comparisons, taking breaks, then coming back for 2nd and 3rd listening sessions, being as ruthlessly critical as I can. I never make modifications and simply assume that they will make an audible improvement because I know that it is often false.

The tested coupling capacitors are all Panasonic FR: 1000µF/16V and 220µF/50V. After repeated test sessions, the 1000µF caps sounded the best. The higher voltage rating of 220µF didn't seem to help... not that I considered the difference in dielectric properties at the time.

NOS is a bit of a curiosity for me, though I can't see why it would be better, though perhaps it might sound subjectively "warmer" if there's a roll-off near 20kHz. The thought of all that ultrasonic garbage going into the rest of the system is not appealing. Still, I'd be willing to listen to a NOS DAC, even though I think the idea is wrongheaded.

As for transport alignment/adjustment, that's an area I'm interested in pursuing at some point, and if/when I do, I'll be carefully reading the service manual and looking at the results on the oscilloscope. I'm very much a DIY person whenever possible and at this point it would be uneconomical to have a technician make such adjustments if I could even find a person who still works on old CD players. However, given that the transport is now reading reliably, that rabbit hole will have to wait.

Whilst I tend to be rather strict about epistemic issues, and am scientifically-minded, non-religious, etc... to a large degree I also think that when it comes to sound quality, the credo "if it sounds better, it is better" comes into play. I admit that I cannot be completely objective whilst listening and that psychoacoustics is pretty complex and murky terrain. That said, I still do my best to retain whatever objectivity that I can, and I often spend hours making comparisons, taking breaks, then coming back for 2nd and 3rd listening sessions, being as ruthlessly critical as I can. I never make modifications and simply assume that they will make an audible improvement because I know that it is often false.

Capacitors with low voltage ratings tend to have higher DA than units up to about 63 VDC. Try your tests again using 47 uF 63 VDC capacitors in the largest case size. Generally speaking, capacitors are of better quality today, but the orange capacitors with epoxy (or some hard coating) on the bottom often perform better than a new one in a smaller case.

NOS DACs are a terrible idea. Those who use them probably will not listen to anyone who hold a contrary viewpoint.

The tested coupling capacitors are all Panasonic FR: 1000µF/16V and 220µF/50V. After repeated test sessions, the 1000µF caps sounded the best. The higher voltage rating of 220µF didn't seem to help... not that I considered the difference in dielectric properties at the time.

NOS is a bit of a curiosity for me, though I can't see why it would be better, though perhaps it might sound subjectively "warmer" if there's a roll-off near 20kHz. The thought of all that ultrasonic garbage going into the rest of the system is not appealing. Still, I'd be willing to listen to a NOS DAC, even though I think the idea is wrongheaded.

As for transport alignment/adjustment, that's an area I'm interested in pursuing at some point, and if/when I do, I'll be carefully reading the service manual and looking at the results on the oscilloscope. I'm very much a DIY person whenever possible and at this point it would be uneconomical to have a technician make such adjustments if I could even find a person who still works on old CD players. However, given that the transport is now reading reliably, that rabbit hole will have to wait.

Last edited:

Hi 12Bass,

Say you find out there are serious issues with it. Wouldn't it be good to know before you sink anymore effort and $$$ into it making changes to a flawed piece of equipment?

There are reasons why there are people specialized at doing certain things. I don't do my own dental work, I don't repair my own car or furnace. There are people who will find things I don't even know about. Some of those things dangerous or costly if allowed to continue. By the same token, the stubborn DIY guy generally causes himself the highest service bills. The general order of people like this are : computer techs, engineers, TV service guys, DJs and DIY guys. None of these people know when to stop, put the tools down and take it to an expert. Even worse, when they think they have it fixed just because it functions. I've even had people who turn up the laser power (when it wasn't needed) because that can help a CD player work in the face of another problem. Lastly, why do these same people try to hide the truth if they finally do seek help? It costs more if I have to discover what they have done, and it puts me in a less charitable mood. I will generally give someone a break if they are straight up with me and I can see that they really are short of money (but who isn't?). If I'm lied to, I will generally close the unit up and never deal with them again. Life is too short to battle stupidity. Many other good technicians I know are the same way.

-Chris

How so? Given that you are so interested in sound quality, it's a real shame that your base instrument isn't looked after. This undermines your experiments. That, and you are kind of ripping yourself off by not looking after it. Your choice of course, but it would be nice to have reality step in every now and again.it would be uneconomical to have a technician make such adjustments

Say you find out there are serious issues with it. Wouldn't it be good to know before you sink anymore effort and $$$ into it making changes to a flawed piece of equipment?

Nothing could be further from the truth. That is a kind of sticking your head in the sand to avoid the truth. If it sounds better, and measures better, then it is better. I've found that people always prefer the lower distortion, lower noise equipment except a few who have married themselves to a certain piece or style of equipment. There are people who can't or won't see beyond those 2 watt record player on top systems with thin wood speakers that would drive most other folks out of the room. Those people are a lost cause because they refuse to consider anything else. Often it is due to economics.I also think that when it comes to sound quality, the credo "if it sounds better, it is better" comes into play.

There are reasons why there are people specialized at doing certain things. I don't do my own dental work, I don't repair my own car or furnace. There are people who will find things I don't even know about. Some of those things dangerous or costly if allowed to continue. By the same token, the stubborn DIY guy generally causes himself the highest service bills. The general order of people like this are : computer techs, engineers, TV service guys, DJs and DIY guys. None of these people know when to stop, put the tools down and take it to an expert. Even worse, when they think they have it fixed just because it functions. I've even had people who turn up the laser power (when it wasn't needed) because that can help a CD player work in the face of another problem. Lastly, why do these same people try to hide the truth if they finally do seek help? It costs more if I have to discover what they have done, and it puts me in a less charitable mood. I will generally give someone a break if they are straight up with me and I can see that they really are short of money (but who isn't?). If I'm lied to, I will generally close the unit up and never deal with them again. Life is too short to battle stupidity. Many other good technicians I know are the same way.

-Chris

Hi Mooly,

Do you agree that any CD transport that is functioning normally and reliably (after lubrication of the sled assembly) MUST have the optical block calibrated professionally, even though there are no obvious signs of skipping, abnormal pickup noise, glitches in audio, etc...? If so, that would imply that every single non-new laser optical pickup assembly in existence must therefore require such a professional optical block calibration, because performance absolutely cannot be guaranteed without it. Methinks, that would be seriously overstating the case....

Do you agree that any CD transport that is functioning normally and reliably (after lubrication of the sled assembly) MUST have the optical block calibrated professionally, even though there are no obvious signs of skipping, abnormal pickup noise, glitches in audio, etc...? If so, that would imply that every single non-new laser optical pickup assembly in existence must therefore require such a professional optical block calibration, because performance absolutely cannot be guaranteed without it. Methinks, that would be seriously overstating the case....

... Your choice of course, but it would be nice to have reality step in every now and again.

Frankly, the above is condescending and unprofessional. Very little of your input on this thread has been helpful or instructive, and much of it has been laced with personal attacks. I do not consider your responses to have been made in good faith. Thus, I have no interest in further dialog with you given the circumstances.

Hi 12Bass,

The response of someone who disagrees with another persons viewpoint. That's fine, but realize that everyone's posts are read by any number of other members, including lurkers and other folks who ride in via a search engine. I owe it to our members and any other folks reading to be honest and helpful.

I take it you strongly disagree with my belief that trained people can do a better job than untrained people who get their information from various sources on the 'net. Never mind that experience, tools and test CDs are required. I'm not making this stuff up, so how am I not being helpful?

One thing I would love to know is this. In what way is it "uneconomical to have a technician make such adjustments". Your exact words. I happen to know for a fact that having a technician look at your machine is the most economical thing you could possibly do. Either it needs some minor work, or it is working fine, or it is on its last legs (good to know but not always welcome news). If you go to a good technician you will have options and the truth.

Your inquiry to Mooly has been crafted in such a way that the answer can only be what you are looking for. Let me answer this in a conditional and truthful way.

Yes, any mechanism with enough hours of run time (play and pause time added together) that requires lubrication really does bear looking at. It may not require alignment (but I bet some things do on it), but the mechanical aspects will show wear and that may well affect the alignment of the beam. One item that really needs examination is the disc motor and the sleeve bearings. That bearing will wear to an oval or egg shape, and it will generate read errors if worn. If the CD is clamped by a pressure system, those surfaces will also have wear and generate errors as well. If it is magnetically chucked, then great. No wear in that system. The sled slide rail sleeve bearings will no longer fit properly. The slide area opposite the rail may be cracked as nylon injected onto metal tends to do.

One thing I mentioned earlier seems to have been missed. The CD software and CD servo system plus DSP have been designed to conceal problems. It isn't like a record player where problems show right up. A CD player often will work seemingly fine until one day it doesn't. Problems didn't suddenly occur. What happened was that performance deteriorated until such time the system couldn't hide the problems any more. However, the sound quality also deteriorated steadily, lagging the errors, but it was a qualitative thing. It doesn't work perfectly, then stop.

When do CD players need to be looked at? Right out of the box to be honest with you. The factory doesn't do any alignments. They put the pots into a standard position and if the CD player works, which it mostly does, out it goes. Sometimes the CD player doesn't work. We see those too. They are called D.O.A. for the complaint, or my favorite complaint, "N.F.G.". That is unhelpful of course. The remedies range from alignment to replacing a defective part or correcting solder connections. So new in the box means that no one has looked at it at all (except Revox and Studer who bench checked every single item before it was shipped to the dealer).

12Bass, if you feel I have not been helpful or instructive, that's too bad because I have been 100% truthful to you. Others will see this, and really that is all that matters to me. You're just one person who won't take good advice.

-Chris

The response of someone who disagrees with another persons viewpoint. That's fine, but realize that everyone's posts are read by any number of other members, including lurkers and other folks who ride in via a search engine. I owe it to our members and any other folks reading to be honest and helpful.

I take it you strongly disagree with my belief that trained people can do a better job than untrained people who get their information from various sources on the 'net. Never mind that experience, tools and test CDs are required. I'm not making this stuff up, so how am I not being helpful?

One thing I would love to know is this. In what way is it "uneconomical to have a technician make such adjustments". Your exact words. I happen to know for a fact that having a technician look at your machine is the most economical thing you could possibly do. Either it needs some minor work, or it is working fine, or it is on its last legs (good to know but not always welcome news). If you go to a good technician you will have options and the truth.

Your inquiry to Mooly has been crafted in such a way that the answer can only be what you are looking for. Let me answer this in a conditional and truthful way.

The rest of the post is a conclusion based on highly slanted information.Do you agree that any CD transport that is functioning normally and reliably (after lubrication of the sled assembly) MUST have the optical block calibrated professionally, even though there are no obvious signs of skipping, abnormal pickup noise, glitches in audio, etc...?

Yes, any mechanism with enough hours of run time (play and pause time added together) that requires lubrication really does bear looking at. It may not require alignment (but I bet some things do on it), but the mechanical aspects will show wear and that may well affect the alignment of the beam. One item that really needs examination is the disc motor and the sleeve bearings. That bearing will wear to an oval or egg shape, and it will generate read errors if worn. If the CD is clamped by a pressure system, those surfaces will also have wear and generate errors as well. If it is magnetically chucked, then great. No wear in that system. The sled slide rail sleeve bearings will no longer fit properly. The slide area opposite the rail may be cracked as nylon injected onto metal tends to do.

One thing I mentioned earlier seems to have been missed. The CD software and CD servo system plus DSP have been designed to conceal problems. It isn't like a record player where problems show right up. A CD player often will work seemingly fine until one day it doesn't. Problems didn't suddenly occur. What happened was that performance deteriorated until such time the system couldn't hide the problems any more. However, the sound quality also deteriorated steadily, lagging the errors, but it was a qualitative thing. It doesn't work perfectly, then stop.

When do CD players need to be looked at? Right out of the box to be honest with you. The factory doesn't do any alignments. They put the pots into a standard position and if the CD player works, which it mostly does, out it goes. Sometimes the CD player doesn't work. We see those too. They are called D.O.A. for the complaint, or my favorite complaint, "N.F.G.". That is unhelpful of course. The remedies range from alignment to replacing a defective part or correcting solder connections. So new in the box means that no one has looked at it at all (except Revox and Studer who bench checked every single item before it was shipped to the dealer).

12Bass, if you feel I have not been helpful or instructive, that's too bad because I have been 100% truthful to you. Others will see this, and really that is all that matters to me. You're just one person who won't take good advice.

Again, can you explain this to me?it would be uneconomical to have a technician make such adjustments

-Chris

Hi Mooly,

Do you agree that any CD transport that is functioning normally and reliably (after lubrication of the sled assembly) MUST have the optical block calibrated professionally, even though there are no obvious signs of skipping, abnormal pickup noise, glitches in audio, etc...? If so, that would imply that every single non-new laser optical pickup assembly in existence must therefore require such a professional optical block calibration, because performance absolutely cannot be guaranteed without it. Methinks, that would be seriously overstating the case....

You are missing what Chris is saying...

I could buy an off the shelf pickup and just swap it out into a player.

The player works and plays a disc all the way through... job done, how easy was that and the customers happy.

I wouldn't be happy though and probably so to the customer a little while down the line.

Lets say the new pickup gives 1 volt of RF and the players threshold for generating audible errors occurs when the decoder sees around 900mv. Not much leeway and a bad or imperfect disc may cause problems. A few months down the line contamination of the lens also comes into play reducing the level the decoder sees still further.

The customer complains citing that the discs play OK on other peoples gear.

If the tech had gone through a basic check and alignment he might have found that even simple adjustment to optimise the focus bias would have brought that 1 volt level up to say 1.5 volts.

Now look how much leeway there is for coping with less than perfect conditions after just one simple adjustment. Its way better than before.

Same goes for mechanical condition and it is actually important that the mechanics are right before attempting to perform electrical adjustments. Does the platter run true with no run-out? Is the lens to disc height correct (platter height) so that the lens suspension isn't being unduly stressed by having to be biased higher than it should. Also the servos are designed to work optimally with the lens suspension in the correct position.

Every little thing adds up... like tuning a car back in the day. Get it all right and it shows and pays off.

So the answer to your question is that a technician who takes pride in their work would attend to all these checks and adjustments both for their own satisfaction and that of the customer.

The guy on the forum who finds that swapping a £$10 KSS pickup fixes his previously non working player is chuffed to bits and happy in what he has done. He might not notice or even care that an odd burst of possibly audible audio degradation occurs when the error correction can't cope... he is just happy he fixed his player. Occasionally they might come back and ask for advice and then we can try and guide them into what to look at and what to do. It is then up to them if they want to pursue their quest further.

Chris will also understand and know what I mean when I say it is all 'hard won knowledge' found by years of doing this kind of work day in and day out. You find your own ways and ways and methods that go way beyond what the manuals tell you.

When it comes to debating parts swaps (opamps, caps etc) I tend to have my own views and not push those beyond an occasional 'this is what I use and why...' for the simple reason that you will never convince anyone otherwise. Everyone has their own ideas.

I think I've pondered long enough on this one now 🙂

Hi Mooly,

Thanks for the reply.

Could my X111ES benefit from a professional optical alignment? Possibly. Would such expensive service work significantly affect the sound? Doubtful, unless the transport is sufficiently out of adjustment that it is causing uncorrectable errors to occur. At present, there is nothing to suggest that is the case. I've listened very carefully, and the sound is pristine, nary a tick, pop, or whimper. I've encountered many a skipping CD player in my years, and I'm hearing nothing of the sort from my X111ES.

For some historical background, shortly after purchase I had to take my CDP-C435 in for warranty service due to a problem with the pickup oscillating. From what reading I've done since then, the focus gain may have been set too high, but I did not know that back in the 1990s. In any case, I recall that it required two trips to the "professionals" before the problem was repaired, and I'm not sure that they didn't just replace the KSS-240A and call it done. I recall not being impressed with their attention to detail, nor the time when I took my LG LDA-530 in for a reading problem with the optical drive, which turned out similarly, requiring a few weeks of back and forth before finally fixing the issue. Both sets of "trained professionals" failed to instill any confidence in paying for such work, at least at those particular repair shops.

If I actually knew someone local who was experienced, reliable, and qualified to make such adjustments, I might consider taking it in, depending upon the cost. However, I have already identified a real problem with the optical sled gears (a problem that actually impaired the function of the player) and lubrication seems to have completely eliminated the issue. Currently, there is nothing obviously anomalous in the behavior of the transport or CD player as a whole. Thus, it consider it more of a preventative measure sort of thing rather than any sort of necessary service. Nor do I think that the current status of the transport is acting as a significant impediment to the sound quality, though I may go through it with a scope at some point to check the EF balance & Focus Bias to see if they are up to spec.

Importantly, we're no longer talking about maintenance on a $400 CD player (or whatever the new price happened to be) here. In reality, my X111ES is a used, 29-year-old, $20, mass produced, CD player which I am enjoying modifying and listening to, and it does not seem reasonable to spend potentially hundreds of dollars for professional service on a player which currently exhibits no obvious faults, and that prospect makes even less sense when I have a copy of the service manual and an oscilloscope and can perform the basic adjustments myself, learning in the process (one of the basic principles behind DIY). Do I believe that I could match the results of an experienced CD player expert? No. But could I get it close enough such that the transport represents no significant barrier for the sound quality, yes, I think so, and perhaps even better than the factory default.

At this point, players using the same plastic Sony transport are fairly common and inexpensive. If at some point the X111ES's transport fails completely I would probably just swap in a part from a similar model. If the player were a Krell or Mark Levinson or other expensive esoteric brand, I might view things differently. But, in reality, the X111ES is an cheap, old, mass produced, Sony and as such does not warrant a great deal of further non-recoverable investment as far as I'm concerned.

The board has perhaps a few dollars worth of added capacitors along with some fairly expensive socketed op amps. If the player fails and becomes uneconomical to repair, I'll just remove the op amps and take a few dollars loss on the project and move on.

Whilst it is certainly true that I care very much about sound quality, this is not a rare, high end, piece of electronics we're talking about, i.e. something worthy of significant financial investment. Rather, it is more of a relic of a past era when optical media were still relevant, an era that is quickly fading as I type....

Thanks for the reply.

Could my X111ES benefit from a professional optical alignment? Possibly. Would such expensive service work significantly affect the sound? Doubtful, unless the transport is sufficiently out of adjustment that it is causing uncorrectable errors to occur. At present, there is nothing to suggest that is the case. I've listened very carefully, and the sound is pristine, nary a tick, pop, or whimper. I've encountered many a skipping CD player in my years, and I'm hearing nothing of the sort from my X111ES.

For some historical background, shortly after purchase I had to take my CDP-C435 in for warranty service due to a problem with the pickup oscillating. From what reading I've done since then, the focus gain may have been set too high, but I did not know that back in the 1990s. In any case, I recall that it required two trips to the "professionals" before the problem was repaired, and I'm not sure that they didn't just replace the KSS-240A and call it done. I recall not being impressed with their attention to detail, nor the time when I took my LG LDA-530 in for a reading problem with the optical drive, which turned out similarly, requiring a few weeks of back and forth before finally fixing the issue. Both sets of "trained professionals" failed to instill any confidence in paying for such work, at least at those particular repair shops.

If I actually knew someone local who was experienced, reliable, and qualified to make such adjustments, I might consider taking it in, depending upon the cost. However, I have already identified a real problem with the optical sled gears (a problem that actually impaired the function of the player) and lubrication seems to have completely eliminated the issue. Currently, there is nothing obviously anomalous in the behavior of the transport or CD player as a whole. Thus, it consider it more of a preventative measure sort of thing rather than any sort of necessary service. Nor do I think that the current status of the transport is acting as a significant impediment to the sound quality, though I may go through it with a scope at some point to check the EF balance & Focus Bias to see if they are up to spec.

Importantly, we're no longer talking about maintenance on a $400 CD player (or whatever the new price happened to be) here. In reality, my X111ES is a used, 29-year-old, $20, mass produced, CD player which I am enjoying modifying and listening to, and it does not seem reasonable to spend potentially hundreds of dollars for professional service on a player which currently exhibits no obvious faults, and that prospect makes even less sense when I have a copy of the service manual and an oscilloscope and can perform the basic adjustments myself, learning in the process (one of the basic principles behind DIY). Do I believe that I could match the results of an experienced CD player expert? No. But could I get it close enough such that the transport represents no significant barrier for the sound quality, yes, I think so, and perhaps even better than the factory default.

At this point, players using the same plastic Sony transport are fairly common and inexpensive. If at some point the X111ES's transport fails completely I would probably just swap in a part from a similar model. If the player were a Krell or Mark Levinson or other expensive esoteric brand, I might view things differently. But, in reality, the X111ES is an cheap, old, mass produced, Sony and as such does not warrant a great deal of further non-recoverable investment as far as I'm concerned.

The board has perhaps a few dollars worth of added capacitors along with some fairly expensive socketed op amps. If the player fails and becomes uneconomical to repair, I'll just remove the op amps and take a few dollars loss on the project and move on.

Whilst it is certainly true that I care very much about sound quality, this is not a rare, high end, piece of electronics we're talking about, i.e. something worthy of significant financial investment. Rather, it is more of a relic of a past era when optical media were still relevant, an era that is quickly fading as I type....

12Bass,

Just how much do you think a quick examination would cost in your case, possibly with some minor adjustments? It takes me 1/2 to 3/4 of an hour to take the unit apart, run some checks and possible adjustment and put back together. So the cost would run in the $30 to $45 range.

You can mentally devalue anything, including your car, to the point where you can argue the point that it isn't worth maintaining as you are here. But you also know that your player, working properly is substantially better than more expensive machines today. You simply can not buy in this current market a CD player that comes anywhere close to your current machine. I'm not trying to convince you to spend money, but to more accurately assess what you have.

Now, the other point you have raised is that you have not been successful in finding a good audio service technician. Most of those guys work from home these days. None work for stores in their location and stores heavily mark up repairs as a rule. Doubling the charge is common, 25% is the lowest mark up I have seen. Ask me how I know.

You shouldn't use the poor quality of service you have had as a determining factor for what your older machine is worth. The kind of guy you want is older (like me) and is very well respected along with the idea of being expensive. A more complete service job will at billing time be more than the low cost guys you have been using. But, that is the least expensive service you would have over time, and added to that, your equipment would perform better.

Your plans are just false economy.

I can't get over the lengths you will go to to improve the sound of your machine. You will do almost anything except provide the basic maintenance that the player needs and will directly affect the sound quality.

-Chris

Just how much do you think a quick examination would cost in your case, possibly with some minor adjustments? It takes me 1/2 to 3/4 of an hour to take the unit apart, run some checks and possible adjustment and put back together. So the cost would run in the $30 to $45 range.

You can mentally devalue anything, including your car, to the point where you can argue the point that it isn't worth maintaining as you are here. But you also know that your player, working properly is substantially better than more expensive machines today. You simply can not buy in this current market a CD player that comes anywhere close to your current machine. I'm not trying to convince you to spend money, but to more accurately assess what you have.

... that would be in similar condition, and also an unknown on top of that. One known fact would be that the host player would need an alignment due to the different head.If at some point the X111ES's transport fails completely I would probably just swap in a part from a similar model.

Cool! To where and for how much? Other used machines on average would be in similar condition to the one you just got rid of. How much time wasted looking for and making a deal for this "new to you" player? Your argument sounds great on the surface, but in practice, on average, is pretty silly.If the player fails and becomes uneconomical to repair, I'll just remove the op amps and take a few dollars loss on the project and move on.

Now, the other point you have raised is that you have not been successful in finding a good audio service technician. Most of those guys work from home these days. None work for stores in their location and stores heavily mark up repairs as a rule. Doubling the charge is common, 25% is the lowest mark up I have seen. Ask me how I know.

You shouldn't use the poor quality of service you have had as a determining factor for what your older machine is worth. The kind of guy you want is older (like me) and is very well respected along with the idea of being expensive. A more complete service job will at billing time be more than the low cost guys you have been using. But, that is the least expensive service you would have over time, and added to that, your equipment would perform better.

Your plans are just false economy.

I can't get over the lengths you will go to to improve the sound of your machine. You will do almost anything except provide the basic maintenance that the player needs and will directly affect the sound quality.

-Chris

As mentioned previously, I already have another high quality vintage CD player on hand, a Luxman DZ-112 with well-regarded PCM1701P R-2R DACs. I thought about modding it but then the X111ES came up and I prefer the Sony interface and ergonomics. The $25 DZ-112 (compete with remote and original box!) is prone to skipping if lightly bumped, so it likely requires optical block adjustment, if not a new laser. The drawer was stuck closed, so I purchased and installed a replacement belt for $3, bringing the total current investment to $28. Deals like this are not too difficult to find around here.

As for previous technicians, I did not use second rate repair shops. I took the CDP-C435 and LDA-530 to the specified factory authorized service centers, the "go to" repair shops in town, where the work was done under warranty. However, given the quality of service I received, I would be reluctant to pay out of my own pocket from those particular shops.

Part of my goal with such projects is to learn more about how these things work, so I will probably go through the DZ-112 service manual with my scope and see how far off things are and make adjustments if necessary. I've spent many hours reading about CD player technology in the past few months, looking though schematics, service manuals, reviews, technical reports, etc.... I'm more of a journey than the destination sort of person, though excellent sound quality is my ultimate goal. DIY if at all possible whilst meeting quality standards tends to be my MO.

As for previous technicians, I did not use second rate repair shops. I took the CDP-C435 and LDA-530 to the specified factory authorized service centers, the "go to" repair shops in town, where the work was done under warranty. However, given the quality of service I received, I would be reluctant to pay out of my own pocket from those particular shops.

Part of my goal with such projects is to learn more about how these things work, so I will probably go through the DZ-112 service manual with my scope and see how far off things are and make adjustments if necessary. I've spent many hours reading about CD player technology in the past few months, looking though schematics, service manuals, reviews, technical reports, etc.... I'm more of a journey than the destination sort of person, though excellent sound quality is my ultimate goal. DIY if at all possible whilst meeting quality standards tends to be my MO.

Last edited:

Hi 12Bass,

I'm sorry you ran into second rate shops. That was one reason I sold my shop. I was very tired of cleaning up after bad work. You know what is funny? I'm still doing that today, only the percentage of crap work I have to fix has more than tripled. However, there are some extremely good technicians out there. Most of the guys I know moved to home shops, and now most of those have retired. In the past, most technicians were both honest and good. I really miss those days.

My advice. Don't watch the dollar too closely or you may well miss some truly great machines. Also, seek out a great technician. I'm 60, so you don't have that much time given that I was one of the last techs to come up with both advantages (technology and apprenticing). That means the last of the really good technicians have or are going to retire soon. I am retired due to injury, but still work away at home here. There weren't very many technicians younger than I was that didn't throw in the towel and get a job in industry. I can tell you, the industry jobs are a lot easier, and pay a great deal more. That and you can leave your job at work every single night. Not so with audio service.

-Chris

I'm sorry you ran into second rate shops. That was one reason I sold my shop. I was very tired of cleaning up after bad work. You know what is funny? I'm still doing that today, only the percentage of crap work I have to fix has more than tripled. However, there are some extremely good technicians out there. Most of the guys I know moved to home shops, and now most of those have retired. In the past, most technicians were both honest and good. I really miss those days.

My advice. Don't watch the dollar too closely or you may well miss some truly great machines. Also, seek out a great technician. I'm 60, so you don't have that much time given that I was one of the last techs to come up with both advantages (technology and apprenticing). That means the last of the really good technicians have or are going to retire soon. I am retired due to injury, but still work away at home here. There weren't very many technicians younger than I was that didn't throw in the towel and get a job in industry. I can tell you, the industry jobs are a lot easier, and pay a great deal more. That and you can leave your job at work every single night. Not so with audio service.

-Chris

Hi Chris,

FWIW, I think things would have gone more smoothly if we were talking in person. It's very easy to misinterpret someone's text without all the necessary social cues.

Generally speaking, I get along very well with technician/repair types. I love learning how things work - have since I was very young - and sincerely appreciate people who tell it like it is, no bull...., as that's the way I like to be myself. I bought some DeoxIT from a retired local repair guy; we talked for a couple of hours. He's much like the type you described.

BTW, my crap work stays with me. You're safe! 😉

FWIW, I think things would have gone more smoothly if we were talking in person. It's very easy to misinterpret someone's text without all the necessary social cues.

Generally speaking, I get along very well with technician/repair types. I love learning how things work - have since I was very young - and sincerely appreciate people who tell it like it is, no bull...., as that's the way I like to be myself. I bought some DeoxIT from a retired local repair guy; we talked for a couple of hours. He's much like the type you described.

BTW, my crap work stays with me. You're safe! 😉

Hi 12Bass,

Yes, in person things would certainly have been smoother. We also don't have to worry about who else might be looking at everything we have said (I hope not anyway). I get along with most folks. You have to really work at it to get on my bad side.

You know what we had to go through in the early days of CD player instruction? We were taught the Reed-Solomon code and how it actually works. There went some time and brain cells I'll never get back! I know that later techs were not taught the very basics of how everything worked.

I know that Panasonic / Technics published some excellent manuals explaining how these things work. See if you can hunt down any of those publications. Most of the other seminars distributed photocopies of notes, nothing as nice as what Technics put out. As for Sony, in their early machines they made everything adjustable. There were more arcane procedures you had to follow. The old Sony CD players always frustrated me to no end. So much time wasted with things not done in other machines.

At the other end of the scale, the very best transport I have ever seen ever was teh one contained in the Nakamichi OMS-5/7. The mechanical adjustments took a while. You had to use solved to clean all the thread-lock off, then sand the sliding surfaces with 600 grit, then finish polishing with the other side of the wet/dry paper. However, once you did that you could align it absolutely perfectly. Then you did the electrical alignment. When you were done, it would track everything, even well out of Red Book standards. Of course, you had to modify the servo board too as it was originally designed to reject a CD if it was out of Red Book specification. That was a disaster of course! When you were done, a CD playing put an eye pattern on the scope that looked like an example of the perfect eye pattern. It didn't waves up and down, or back and forth. I bought an OMS-7 from a guy back then when my cost on the laser head was around $550. It still runs fantastically well. Its now time to tear it down, clean and relubricate it. I'll put in a different DAC section while I'm there. PCM-1702.

If you ever see a Denon DCD-S10 or DCD-3000, grab it! It uses a pair of PCM-1702 in push-pull per channel and a 20 bit digital filter. One of the nicest DAC sections I have heard. I bought a DCD-S10 and it still sits in my main system. I have upgraded everything in the way of audio equipment, so it can be done.

-Chris

Yes, in person things would certainly have been smoother. We also don't have to worry about who else might be looking at everything we have said (I hope not anyway). I get along with most folks. You have to really work at it to get on my bad side.

You know what we had to go through in the early days of CD player instruction? We were taught the Reed-Solomon code and how it actually works. There went some time and brain cells I'll never get back! I know that later techs were not taught the very basics of how everything worked.

I know that Panasonic / Technics published some excellent manuals explaining how these things work. See if you can hunt down any of those publications. Most of the other seminars distributed photocopies of notes, nothing as nice as what Technics put out. As for Sony, in their early machines they made everything adjustable. There were more arcane procedures you had to follow. The old Sony CD players always frustrated me to no end. So much time wasted with things not done in other machines.

At the other end of the scale, the very best transport I have ever seen ever was teh one contained in the Nakamichi OMS-5/7. The mechanical adjustments took a while. You had to use solved to clean all the thread-lock off, then sand the sliding surfaces with 600 grit, then finish polishing with the other side of the wet/dry paper. However, once you did that you could align it absolutely perfectly. Then you did the electrical alignment. When you were done, it would track everything, even well out of Red Book standards. Of course, you had to modify the servo board too as it was originally designed to reject a CD if it was out of Red Book specification. That was a disaster of course! When you were done, a CD playing put an eye pattern on the scope that looked like an example of the perfect eye pattern. It didn't waves up and down, or back and forth. I bought an OMS-7 from a guy back then when my cost on the laser head was around $550. It still runs fantastically well. Its now time to tear it down, clean and relubricate it. I'll put in a different DAC section while I'm there. PCM-1702.

If you ever see a Denon DCD-S10 or DCD-3000, grab it! It uses a pair of PCM-1702 in push-pull per channel and a 20 bit digital filter. One of the nicest DAC sections I have heard. I bought a DCD-S10 and it still sits in my main system. I have upgraded everything in the way of audio equipment, so it can be done.

-Chris

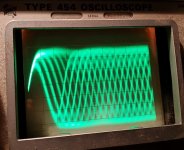

Here's the eye pattern from my X111ES. Scope set for 5mV/DIV with a 10x probe. Not sure if I'm measuring correctly, but it looks like ~0.3Vp-p, which seems low. It reliably reads CD-Rs burned with my Lite-On burner. The ground lead was connected to the chassis and a clean, good quality pressed CD was used for testing.

Comments/suggestions?

Comments/suggestions?

Attachments

Last edited:

That eye pattern looks normal (to me) but I expect the pk-pk amplitude should be around 1v or a little more. If it really was as low as 0.3v I very much doubt the player would be reading discs. The lowest amplitude I've ever seen from a Sony pick-up that was still reading well would be around 0.8v.

Are you sure it isn't set on 0.2v/div making the pk-pk amplitude about 1.2v?

Are you sure it isn't set on 0.2v/div making the pk-pk amplitude about 1.2v?

- Home

- Source & Line

- Digital Source

- Sony CDP790 and KSS240 Restoration Project