I think it is Geddes who recommends multiple subs distributed around the room to even out the room modes and have better integration with the main speakers. Getting that low sound to match the main speakers and work with the room is not a simple problem.

If you go off center to a room corner or other undesirable spot , I agree.

In a well damped furnished room , there is a wide area of acceptable

listening. Higher levels , it comes down to port (and object) noise.

A sealed sub might need a "linkwitz sub transform" ... throw gobs

of equalized power at the higher fc sealed enclosure to "fake' the

>60hz content. This is a common OEM technique. 🙁

I like the port .... I can get a 500W 12" 25hz SPL with just 180W .

OS

I find most cheaper subs boomy and artificial sounding. Usually because the owner is overdriving an underpowered amp into them. This is why I'm building my own. I think the key to a good sub is mainly a good amplifier that doesn't run our of power supply. The Slew amp I put together makes my cheap ACI drivers sound great.

Car audio subs are supposed to be better these days, but I think they actually were better 20 years ago when we used free air drivers or large cabinets and a good AB amp. Back then we used to put together systems to sound good, not break windshields though.

JW , you should hear what a slew sounds like runing a properly aligned ported

sub with internal damping and thick material.

It will drop all objects to the floor way before you would even hear any port

noise (pumping air). Amazing how little cone movement can shake things.

No , I don't have it finished - ran the amp external w/DSP.

Boomy = an aftermarket "fits 12" driver" box. Not aligned to Qts/Vas/Fc of the particular driver.

OS

Last edited:

3 phase version is useful when pcb is suitable for thatI found 3 phase version, which can be +rail, -rail, and output/ground in sigle piece 🙂

Sajti

JW , you should hear what a slew sounds like runing a properly aligned ported

sub with internal damping and thick material.

It will drop all objects to the floor way before you would even hear any port

noise (pumping air). Amazing how little cone movement can shake things.

No , I don't have it finished - ran the amp external w/DSP.

OS

I was amazed how good mine sounded in that crappy plywood test box. I was also amazed how fast it blew that crappy box apart. My new cabinets are together butneed to be finished and heat sinks built yet.

3 phase version is useful when pcb is suitable for that

If you design your pcb for that version? 🙂

My another idea is to use the heatsink as a power supply rail 🙂

Sajti

Attachments

Nice idea! If you can find conductive thermal paste.If you design your pcb for that version? 🙂

My another idea is to use the heatsink as a power supply rail 🙂

Sajti

Last edited:

Nice idea! If you can find conductive thermal paste.

Like this?

WLPK 10, Thermal transfer compound and thermal interface film, Heatsinks f.cool, Fischer Elektronik

Sajti

I mean electrically conductive, as you say that the heatsinks are the power cables.

Do you mean that transistors plates seat on heatsink without thermal paste?

I mean electrically conductive, as you say that the heatsinks are the power cables.

Do you mean that transistors plates seat on heatsink without thermal paste?

There is paste under the transistors. Now I use common silicon paste. But as I've measured the resistance between the tab, and the heatsink, it's 0ohm.

Anyway the paste I mentioned, eletrically conductive, just check:

"dielectric strength not applicable, because conducting"

Sajti

At very low frequencies, i don't follow-you. You'll need bass traps to dump a little the room resonances.In a well damped furnished room , there is a wide area of acceptable listening.

The idea of Geddes is to multiply the sources to flatten the modes due to the location of the source. It looks like a good idea, and we don't care about group delay at those very low frequencies, but i never tested myself.

At very low frequencies, i don't follow-you. You'll need bass traps to dump a little the room resonances.

The idea of Geddes is to multiply the sources to flatten the modes due to the location of the source. It looks like a good idea, and we don't care about group delay at those very low frequencies, but i never tested myself.

I don't know , at average volume .... I have to "hunt" down a spot with

a noticeable higher or lower level. My listening room is quite asymmetrical ,

which could be to an advantage. 8 meter ceiling !

OS

Yes. I'm not surprised. (lucky for the 8 meters, man ;-)I have to "hunt" down a spot with a noticeable higher or lower level. My listening room is quite asymmetrical ,

which could be to an advantage. 8 meter ceiling !

In my previous house, the walls in thin plaster panels were resonating and acting like bass traps: no basses at all :-(

Happily, in my new home, solid walls, basses are back again. But i have to dump the room, pretty little, too much harshness in medium and treble.

There is paste under the transistors. Now I use common silicon paste. But as I've measured the resistance between the tab, and the heatsink, it's 0ohm.

Anyway the paste I mentioned, eletrically conductive, just check:

"dielectric strength not applicable, because conducting"

Sajti

I think you should use thermal paste with copper powder, for lower thermal resistance and better electrical conduction. What material you will use to isolate the heatsink from the chassis ground?

Or those conductive inks we use to repair PBs ? They are made of very thin silver and nicely fluid. But take care of not using aluminium Heat sink. Aluminium oxide itself instantly in contact with air, covering itself with "alumina" witch is a very good... isolator ;-)I think you should use thermal paste with copper powder, for lower thermal resistance and better electrical conduction.

I think you should use thermal paste with copper powder, for lower thermal resistance and better electrical conduction. What material you will use to isolate the heatsink from the chassis ground?

Copper and aluminum aren't a good mix when conducting electricity. Many houses have burned down from this.

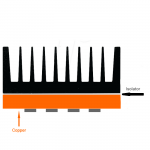

I would to that, using Nylon screews to fix the copper plate to the heat sink.

The copper base will allow to equalize further the temps between the power devices. The big surface of the isolator reduce its thermal resistance. You can mount the aluminium heat sing normally on the chassis, to earth. Of course, collectors need to be powered as habit by its pin in the same time by security.

The copper base will allow to equalize further the temps between the power devices. The big surface of the isolator reduce its thermal resistance. You can mount the aluminium heat sing normally on the chassis, to earth. Of course, collectors need to be powered as habit by its pin in the same time by security.

Attachments

I would to that, using Nylon screews to fix the copper plate to the heat sink.

The copper base will allow to equalize further the temps between the power devices. The big surface of the isolator reduce its thermal resistance. You can mount the aluminium heat sing normally on the chassis, to earth. Of course, collectors need to be powered as habit by its pin in the same time by security.

This actually looks like a good idea. Depending on your choice of output devices steel screws could be used too as TO 247 and MT-200 devices have insulated through holes. If everything was machined accurately shorting wouldn't be an issue.There wouldn't be that huge piece of live aluminum begging to have something fall on it and shorting out either.

Last edited:

Looking at the pictures just posted by carcass my question is does the transistor radiate equal heat on both sides of the package or is the internal die closer to the side we normally mount them on? If it is equal then those copper plates make a lot of sense for increasing the radiated surface ares to lower the die temperatures. I guess those little copper plates could end up being a secondary small finned heat sink.

I think you should use thermal paste with copper powder, for lower thermal resistance and better electrical conduction. What material you will use to isolate the heatsink from the chassis ground?

I will check them. Now I use common silicone based paste, but there is short circuit between the tab and the heatsink. The clip push the transistors with 65N.. It's impossible to insert them just with hand.

The heatsinks are mounted on the PCB, and the PCB is mounted to the chassis. The whole amplifier is upside down on the picture.

Sajti

- Home

- Amplifiers

- Solid State

- Slewmaster - CFA vs. VFA "Rumble"