4. You could go either 1 or 2W. Those flameproofs of mine are 2W.

You won't use as much current with a MOSFET output stage

Thanks Os , on point 4, I should r114/115 be 10 ohm's, not 4.7 ?

You won't use as much current with a MOSFET output stage

Thanks Os , on point 4, I should r114/115 be 10 ohm's, not 4.7 ?

Last edited:

Gooday all,

I just want to make sure. Any input stage developed with the slewmaster can be used when using the new version fet output stage. Is this correct ?

I just want to make sure. Any input stage developed with the slewmaster can be used when using the new version fet output stage. Is this correct ?

Yes ,this is correct.Gooday all,

I just want to make sure. Any input stage developed with the slewmaster can be used when using the new version fet output stage. Is this correct ?

Yesterday i started work on Evans PCB´s. It is little bit difficult to do it without BOM and silk screen... No caps voltage... is it there something more, than schematic only? Anyone finished? 😀

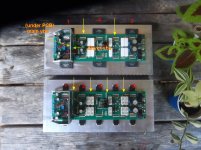

mine are done and tested with 1 pair.

ALL caps are 100v except maybe the 1 uf Vbe cap (35-100V).

It will work with a huge range for the big electro's.

I've measured almost no ripple at load with as little as 47u for the multiplier caps.

The OPS's don't have many different parts. Even as I am making a book ,

The PCB itself will have the values on the next round of boards.

Don't worry , this is the final slew EF3 - it will have a long support period.

(like winXP).

PS - I ordered 2 new extrusions , taps and drills for mine ... am waiting

to fire up the whole thing. Still4given , I think ... has them fully done ?

OS

I´d like to order some parts today... I am not decided, how much output pairs I will use... Mouser have NJW on stock...or any other "better" choice ? 😀

I´d like to order some parts today... I am not decided, how much output pairs I will use... Mouser have NJW on stock...or any other "better" choice ? 😀

If you want ultimate power handling go for these.

2SA1295 - ALLEGRO SANKEN - TRANSISTOR,BJT,PNP,230V V(BR)CEO,17A I(C),SIP | Newark element14

2SC3264 - ALLEGRO SANKEN - TRANSISTOR, BJT, NPN, 230VCEO,17A, SIP (MT-200) | Newark element14

I´d like to order some parts today... I am not decided, how much output pairs I will use... Mouser have NJW on stock...or any other "better" choice ? 😀

My 5 pair njw's = 200W/8R amp.

MJL's or IRFP's (Vfets) = 250+W amp

Sanken MT-200's = 400W amp

Roughly. quite a range ... huh !

Truly a "builder choice" project !

OS

so.... Now I have no idea, which output trans I will use... 😀 anyway, If I use lets say two/three output pairs, is it enough to use for VAS Toshibas 2sa/2sc ?

This is my question also.so.... Now I have no idea, which output trans I will use... 😀 anyway, If I use lets say two/three output pairs, is it enough to use for VAS Toshibas 2sa/2sc ?

Is it enough,these(2sa,2sc) for 3 pairs MT 200?

Last edited:

This is my question also.

Is it enough,these(2sa,2sc) for 3 pairs MT 200?

+1

This is my question also.

Is it enough,these(2sa,2sc) for 3 pairs MT 200?

Most likely the 1A+ SOA of the toshiba's can run even 3 pair

Sanken MT100 -200. Sankens have more current gain than the ON's.

Best to use the big fat mt-100's for 5 pair NJW/MJL.

680 runs 2 pair mt-100 with the toshibas with a 220R driver Re.

We have a larger heatsink on the slew (HK has NONE !)

OS

680 runs 2 pair mt-100 with the toshibas with a 220R driver ReMost likely the 1A+ SOA of the toshiba's can run even 3 pair

Sanken MT100 -200. Sankens have more current gain than the ON's.

Best to use the big fat mt-100's for 5 pair NJW/MJL.

680 runs 2 pair mt-100 with the toshibas with a 220R driver Re.

We have a larger heatsink on the slew (HK has NONE !)

OS

Do you mean a commercial amplifier uses 2 pairs mt-100 as output with 2sa-2sc as driver?

Re, you mean R113=220R?

Last edited:

680 runs 2 pair mt-100 with the toshibas with a 220R driver Re

Do you mean a commercial amplifier uses 2 pairs mt-100 as output with 2sa-2sc as driver?

Re, you mean R113=220R?

Yes , R113 ... and yes (below- 680) - Slewmaster's "Daddy".

OS

Attachments

Edit. I see you mean Harman Kardon HK680680 runs 2 pair mt-100 with the toshibas with a 220R driver Re

Do you mean a commercial amplifier uses 2 pairs mt-100 as output with 2sa-2sc as driver?

Re, you mean R113=220R?

Wow Jeff, these are good prices. Those Mt-200 from my local Element 14 cost 27 dollars each!!!!. Talking about being ripped off and being too far away from every one.If you want ultimate power handling go for these.

2SA1295 - ALLEGRO SANKEN - TRANSISTOR,BJT,PNP,230V V(BR)CEO,17A I(C),SIP | Newark element14

2SC3264 - ALLEGRO SANKEN - TRANSISTOR, BJT, NPN, 230VCEO,17A, SIP (MT-200) | Newark element14

Quan

optimum 250W slewmasters ...

3 pair mt-200 or 5 pair NJW spread out optimally over

a .4C/W extrusion.

5 pair "arcwelder" (MT-200) , I would recommend double

the extrusion (.2C/W 300mm X 300mm).

Either way , a calculated and tested 40C idle , <50C heavy use

can be expected. Extrusions should be within 1C - end to end.

OS

3 pair mt-200 or 5 pair NJW spread out optimally over

a .4C/W extrusion.

5 pair "arcwelder" (MT-200) , I would recommend double

the extrusion (.2C/W 300mm X 300mm).

Either way , a calculated and tested 40C idle , <50C heavy use

can be expected. Extrusions should be within 1C - end to end.

OS

Attachments

Hi Os, what about the sankens 2SD2390/SB1560 ?. I got about 4 pairs on each board pulled from an old HK receiver. Can i use mje 15032/15033 with them?

Quan

Quan

Hi Os, what about the sankens 2SD2390/SB1560 ?. I got about 4 pairs on each board pulled from an old HK receiver. Can i use mje 15032/15033 with them?

Quan

Yes, but you won't have as powerful an amp. 2SD2390/SB1560

are 150V / 100w devices. Lower rails + 150W amp (4-5 pairs).

Also , MJE's would be ideal for those little sankens !

oS

- Home

- Amplifiers

- Solid State

- SlewMaster Builds