best to bolt them to bottom plate

proper and simplest way to keep them cold

thermal goop and split washer, must

proper and simplest way to keep them cold

thermal goop and split washer, must

Kinda tough to do that….but there is a hole….hummmmm

Attachments

Last edited:

The inline leaded rectifiers can work in the upright position with a little help..

I have these in my Aleph J; they do run pretty warm, about 55° by the Papa scale.

ZM is still correct; the baseplate of a chassis makes a good heatsink for the brick style rectifiers.

I have these in my Aleph J; they do run pretty warm, about 55° by the Papa scale.

ZM is still correct; the baseplate of a chassis makes a good heatsink for the brick style rectifiers.

Attachments

TA, what’s the specs on that baby? The one I’m looking at is 600v, 35a. Will bolt to bottom plate. Thanks

ZM bitten too many times, to even consider using small plasticky drek in any amp drawing 1A5+ per channel and having ooomph caps

35A is smallest bridge ever going in any of my amps

35A is smallest bridge ever going in any of my amps

Glass Passivation (melting glass) is applied at 800degrees I think. Should be pretty good. Guess I’ll find out.

I prefer more something like this...

https://www.mouser.de/ProductDetail...=sGAEpiMZZMvplms98TlKY6I1zmttAFjhDacDtzkuvZk=

Cheers

Dirk

https://www.mouser.de/ProductDetail...=sGAEpiMZZMvplms98TlKY6I1zmttAFjhDacDtzkuvZk=

Cheers

Dirk

The GBPC series rectifiers use spade terminals, not screw. I only use these for ground lift circuits.

Here is a different series of high current (60A) rectifiers that can be used with larger amps. Screw terminals, chassis floorplate mount, and still fairly low Vf.

Here is a different series of high current (60A) rectifiers that can be used with larger amps. Screw terminals, chassis floorplate mount, and still fairly low Vf.

Attachments

Thanks for memory spark. That’s the one I’ve used before. Just couldn’t find it. Spendy little buggers. They sure make excellent terminations.

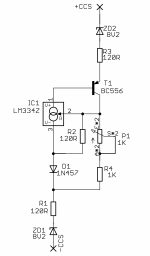

you know your way around CCS Daughterboards?And so it begins….thanks to Mr. ZM.

I mean,there is only left for you to solder LM334, BC556 and trimpot, all being in bag with pcbs

and then, be sure to solder them with copper studs at least 5mm elevated from main pcbs

just a reminder ( for me, as first) - this is R.3 thread, while you have lastlast blingy - (42)

posted also in original (42) thread, post #109 https://www.diyaudio.com/community/...o-sissysit-42-as-a-cradle.387767/post-7256125 , note added in opening thread post

Attachments

Last edited:

Holy cow……I just read. Learning the ways of the mighty ZM is taxing & exciting all at once but nevertheless I remain diligent. I have so much to learn….”I’ll be Bock”.. 🍻

You must really enjoy the SHI@ out of it as your approaching 50,000 messages!!!

I for one am very glad their folks like you out there.

I for one am very glad their folks like you out there.

- Home

- Amplifiers

- Pass Labs

- SissySIT R.3