On every board I've had done at PCBWay, if there's no pad surrounding a hole they don't plate through. The only thing they are questioning in my boards is if a transistor mounting hole is outside the board edge. One annoying thing they do is convert assembly layers to silk screen.5) This one is strange 😕 , the 4 mounting holes are not shown in the "plated_through" layer or in the drill schedule but they are in the drill data, identified as using tool T10(3.17mm)

There is also no top/bottom soldermask around the holes which could be flagged as a violation. Usually one would make a mounting tooling hole un-plated since there is no connectivity and un-plated holes have higher tolerances. But for pcb fabs like pcbway they only offer plated holes (for the cheap process), so you are correct in making it plated. Some times they flag a plated through hole that has no annular ring, but pcbway has not done this for me.

Hi Valery,

Yeah I thought that R symbol would have some meaning, just need to know what it means. Nothing attached that I can see 🙂 No rush, have a nice Easter weekend

Happy eater eggs

P.S. Do you do the painted boiled eggs tradition? When my Dad was alive, he was Greek Orthodox, he would dye the boiled eggs, red and we would have a contest to smash each others egg ends against each others, to determine a winner, do you do this tradition?

Rick

Hi Rick, I am also 100% of Greek background and my 89 year old mom just made the

red Easter eggs today. The tradition is to crack the eggs against one another on Easter

day, and the person hitting says in Greek (or English I suppose) "Christ has risen", the

person holding the egg that was struck says "he has truly risen". My sons did not learn

to speak Greek but they do know these words in Greek as do most even mixed Greek

Americans. Here is a youtube video (their Greek is not so good):

https://www.youtube.com/watch?v=Wr93oljFRpo

The Spartans are known for their VERY tough warriors.

My Father's side were Greeks living in Turkey who fled in the early 1900s and settled in

New Haven CT where there are probably about 100 Greek families who also came from

Turkey around that time. My parents visited the village in the 1970s and found some

history from the time. We also have a family member in Greece who wrote a small

book about the memories from that village in Turkey.

Here is a bit about Asia Minor (Turkey) by a New Haven lady my age (our grandfathers

played cards together): Anatolia

Happy Easter Valery, and all who celebrate!

Last edited:

The tradition is to crack the eggs against one another on Easter day, and the person hitting says in Greek (or English I suppose) "Christ has risen", the person holding the egg that was struck says "he has truly risen".

Happy Easter Valery, and all who celebrate!

Hi Pete,

Russian tradition is exactly the same 😀

My younger daughter (10 yo) has already painted a few eggs 😛

Happy Easter!

Hello Vaizchenko

greetings just want to confirm some resitance values

33K or 43 K and 430k or 470 K can 3 pair mosfets be

used in output stage

warm regards

Andrew

Hi Andrew,

Depends on the rails you're going to use. What voltages do you have in mind?

3 pairs are fine, just one correction in this case - resistor value between the emitters of the drivers will be 620R (instead of 680R).

Cheers,

Valery

Hi Rick, I am also 100% of Greek background and my 89 year old mom just made the

red Easter eggs today. The tradition is to crack the eggs against one another on Easter

day, and the person hitting says in Greek (or English I suppose) "Christ has risen", the

person holding the egg that was struck says "he has truly risen". My sons did not learn

to speak Greek but they do know these words in Greek as do most even mixed Greek

Americans. Here is a youtube video (their Greek is not so good):

https://www.youtube.com/watch?v=Wr93oljFRpo

The Spartans are known for their VERY tough warriors.

My Father's side were Greeks living in Turkey who fled in the early 1900s and settled in

New Haven CT where there are probably about 100 Greek families who also came from

Turkey around that time. My parents visited the village in the 1970s and found some

history from the time. We also have a family member in Greece who wrote a small

book about the memories from that village in Turkey.

Here is a bit about Asia Minor (Turkey) by a New Haven lady my age (our grandfathers

played cards together): Anatolia

Happy Easter Valery, and all who celebrate!

Greek background everywhere in the diyaudio

Hi Valery,

Is there a reduction in THD if KSC1845 , KSA992 used in place of KSC3502 , KSA1851?

Is there a reduction in THD if KSC1845 , KSA992 used in place of KSC3502 , KSA1851?

Hi Valery,

Is there a reduction in THD if KSC1845 , KSA992 used in place of KSC3502 , KSA1851?

Hi,

Assuming 3502/1381 are expected to run at 5.5-6mA idle current (300-400mW dissipation), they will be slightly warm, requiring a small local heatsink for stable operation. TO-126 devices are much more suitable for this kind of operation. Also, they are used in common base mode here (no issue with hFE, although - E, F ratings are recommended). Plus, they are extremely fast (designed for wide-band video amplifiers, fT = 150MHz), which is very good for the purpose.

So, the answer is - no, 1845/992 will not give advantage in these positions.

Anyway - what is the reason of trying to reduce THD, being already at the level of 0.00006% or somewhere close to it? This is just a number, it's practically "immaterial" at this level.

Cheers,

Valery

Hot Air Soldering

A good article on the technique. Useful for those who are unfamiliar / unsure about SMD components in DIY projects 😉

Tools and Techniques for Hot Air Soldering Surface-Mount Components

A good article on the technique. Useful for those who are unfamiliar / unsure about SMD components in DIY projects 😉

Tools and Techniques for Hot Air Soldering Surface-Mount Components

The stencil paste method is the best method but it is really meant for a reflow oven. It will work okay with the hot air machine. It is faster than any other method and gets the correct amount of paste on the pads.

I used the paste smear/blob technique many years ago, as they show in the article, it is very difficult to apply the small amount required, esp for 0805 and smaller, so you end up having to use the solder wick to sop up the excess. I remember when we set up our lab at HP, we bought a few of those solder paste metering tools, we never even used them, because of what I said above. Also the paste has a shelf life, you make it last, it has to be refrigerated = PITA. Once it is refrigerated, you have to let it warm up to use it or it is to stiff to be used.

I have always hand solder smt at home, even some Q/DFN, the paste smear might be a bit better for Q/DFN, doing them by hand is a challenge.

To hand solder, you need a big eye magnifier, 15mil solder( I use glow-core) and a fine tip iron. To each there own I guess. I did buy a hot air machine from Sparkfun, it works similar to the Hakko we used to have in the labs. There is a mfg call Aoyue (SRA Soldering Home Page) that sells all the extra nozzles. Nozzle 1142 is the one I use most of the time. I usually use the hot air to remove smt ics, with liquid flux. To solder/remove 2 terminal passives, I use 2 irons fro removal, only need one and tweezers for placment, once you get the hang of it, it is a cinch and very quick. If you are going to hand solder smt, specify HASL lead solder finish on your pcb, it makes it so much easier, as there is already a very small amount of solder on the pads, all you need to do is just add a little bit more to complete the connection for a nice fillet.

I atatched a pic of a media player I design and built a few years back, it was all hand soldered as I describe above. It took a good part of a day to solder it up.

I used the paste smear/blob technique many years ago, as they show in the article, it is very difficult to apply the small amount required, esp for 0805 and smaller, so you end up having to use the solder wick to sop up the excess. I remember when we set up our lab at HP, we bought a few of those solder paste metering tools, we never even used them, because of what I said above. Also the paste has a shelf life, you make it last, it has to be refrigerated = PITA. Once it is refrigerated, you have to let it warm up to use it or it is to stiff to be used.

I have always hand solder smt at home, even some Q/DFN, the paste smear might be a bit better for Q/DFN, doing them by hand is a challenge.

To hand solder, you need a big eye magnifier, 15mil solder( I use glow-core) and a fine tip iron. To each there own I guess. I did buy a hot air machine from Sparkfun, it works similar to the Hakko we used to have in the labs. There is a mfg call Aoyue (SRA Soldering Home Page) that sells all the extra nozzles. Nozzle 1142 is the one I use most of the time. I usually use the hot air to remove smt ics, with liquid flux. To solder/remove 2 terminal passives, I use 2 irons fro removal, only need one and tweezers for placment, once you get the hang of it, it is a cinch and very quick. If you are going to hand solder smt, specify HASL lead solder finish on your pcb, it makes it so much easier, as there is already a very small amount of solder on the pads, all you need to do is just add a little bit more to complete the connection for a nice fillet.

I atatched a pic of a media player I design and built a few years back, it was all hand soldered as I describe above. It took a good part of a day to solder it up.

Attachments

Last edited:

I've found applying a layer of gel flux then applying a bit of solder paste with a syringe gives you about the perfect amount for hot air rework. It self aligns nicely as parts do in the oven too. I'm kicking around the idea of getting a cheap laser and burning out stencils. I've never tried one yet but they look easy to use.

gel flux sounds interesting, I have never used it before.

I do not think it is too expensive to get a stencil made although I have never done it.

pcbway makes stencil, ~$25USD for a 190x290mm = not too bad

Not sure how you would laser your own stencil, what drives the laser to the x,y position and creates the correct aperture? just the cost of the stainless steel would probably be more than $25.00

I do not think it is too expensive to get a stencil made although I have never done it.

pcbway makes stencil, ~$25USD for a 190x290mm = not too bad

Not sure how you would laser your own stencil, what drives the laser to the x,y position and creates the correct aperture? just the cost of the stainless steel would probably be more than $25.00

I atatched a pic of a media player I design and built a few years back, it was all hand soldered as I describe above. It took a good part of a day to solder it up.

Great layout job by the way 😉

There should be a way to convert the paste info to dfx and create a laser path. Worst case would be to print it, scan it into Corel draw and convert it that way. I've seen PCBWays service but have never tried it yet.

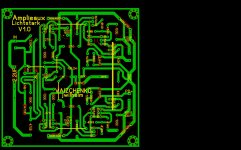

Thanks Valery, it worked first rev, one minor schematic error. It is 4 layers, here is the finished assembly up and running.

Maybe I should say what it is, it is media/radio player using Si4735C40(AM/FM/SW radio),atmega192a3(MCU),PCM2902B(USB CODEC),TPA3100D2(Class D amp), Rohm BU9458 (USB host/SDRAM CODEC),MAX9729(pre-amp/volume/channel_select/headphone amp),PCA8565(RTC), Bourns encoders,4x40 LCD

Maybe I should say what it is, it is media/radio player using Si4735C40(AM/FM/SW radio),atmega192a3(MCU),PCM2902B(USB CODEC),TPA3100D2(Class D amp), Rohm BU9458 (USB host/SDRAM CODEC),MAX9729(pre-amp/volume/channel_select/headphone amp),PCA8565(RTC), Bourns encoders,4x40 LCD

Attachments

Last edited:

I do not know Jeff how you will keep the required accuracy/registration, doing it that way 🙂 i say leave it to the experts, since they can do it so much cheaper, to me it is like trying to make your own pcb, not so easy.There should be a way to convert the paste info to dfx and create a laser path. Worst case would be to print it, scan it into Corel draw and convert it that way. I've seen PCBWays service but have never tried it yet.

Valery, Thanks for the information I am planning to run the VAS on +- 47 volt supply as I have little need for more then 100 watts per channel. The output rails are +- 40 volts.

Cheers

Cheers

Straight conversion shouldn't loose any accuracy. Scanning into draw and correcting the image size will be accurate within a couple thousandths. Should be fine for smearing solder.

- Home

- Amplifiers

- Solid State

- Revisiting some "old" ideas from 1970's - IPS, OPS