Parallel - continuing with "current drive" concept

My God!

Please somebody stop me! 😀

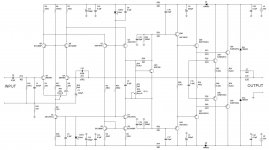

Following "Diagonal", here comes another relatively simple "current drive" design - I called it "Parallel".

Highly linear front-end, relatively low feedback loop gain (~35db), excellent stability margins, wide open loop bandwidth - hence low distortion distortion is almost constant within the audio frequency range (THD1 = 0.002%, THD20 = 0.003%).

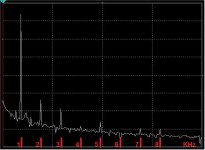

Pretty nice harmonics profile (attached) - mostly 2 and 3 are in place.

It can be adapted to variety of rail voltages and also can be used with MOSFET output stage. Not live-tested yet.

Cheers,

Valery

My God!

Please somebody stop me! 😀

Following "Diagonal", here comes another relatively simple "current drive" design - I called it "Parallel".

Highly linear front-end, relatively low feedback loop gain (~35db), excellent stability margins, wide open loop bandwidth - hence low distortion distortion is almost constant within the audio frequency range (THD1 = 0.002%, THD20 = 0.003%).

Pretty nice harmonics profile (attached) - mostly 2 and 3 are in place.

It can be adapted to variety of rail voltages and also can be used with MOSFET output stage. Not live-tested yet.

Cheers,

Valery

Attachments

Neat. That's a lot of transistors. 🙂

I have all but the MJE15033/32 drivers. Looks like a great neutral sounding setup. Very nice.

I have all but the MJE15033/32 drivers. Looks like a great neutral sounding setup. Very nice.

Yes, the full (not simplified) Diagonal front-end has got more transistors, than resistors 😀

This one - if you go for 1 pair of HexFETs - then you need only 2 drivers - you will have 4 transistors less immediately 😉

The layout can be very compact again.

This one - if you go for 1 pair of HexFETs - then you need only 2 drivers - you will have 4 transistors less immediately 😉

The layout can be very compact again.

That s reminiscent of an AD797, or a Luxman C02 preamp for a discrete version.

Luxman used this kind of topology ("parallel" current subtraction via common base cascade and current mirror at the bottom) with some variations in a number of amplifiers, but always having jFET-based LTP at the input. AD797 - never paid attention, but that's cool 😀

Yes of course,just a question.Cool, it has arrived! Now you have some work to do!😀

What are you using for smd solder?

Are you using solder paste or solder wire?

Last edited:

I've been using .015" solder wire lately. The paste is for reworking in an oven. Wash the boards with alcohol and apply a little liquid flux before starting. This really helps with SMD.

Ok!I've been using .015" solder wire lately. The paste is for reworking in an oven. Wash the boards with alcohol and apply a little liquid flux before starting. This really helps with SMD.

I'm looking for a suitable heat sink and i want your help.Please have a look here.Go through pages and help me choosing the right one.You've got some brand new stuff there! Very interesting to see the tests 😉

MAR electronics - ???????? - Standard Extruded Heatsinks 1

Last edited:

I'm using 12" x 6" HeatsinkUSA extrusions. With 48V rails they are hardly warming up.

SK501-200AL looks similar. 150mm versions should work.

SK501-200AL looks similar. 150mm versions should work.

Thanks,Jef i hope my supplier can import this from Germany.😕I'm using 12" x 6" HeatsinkUSA extrusions. With 48V rails they are hardly warming up.

SK501-200AL looks similar. 150mm versions should work.

Last edited:

Estimeted delivery time is 5-6 weeksThanks,Jef i hope my supplier can import this from Germany.😕

Cost for 2 pieces is 150€

Last edited:

Wow! That's $60/pair from HeatsinkUSA and takes a week for customs to finish admiring them here.

Wow! That's $60/pair from HeatsinkUSA and takes a week for customs to finish admiring them here.

Diy is a very expensive hobby here especialy if you haven't good friends.

Last edited:

Low cost heat sinks is the eternal enemy of DIYers. 🙁

If looks did not matter - a very low cost source of heatsinks are old aluminum cook pots. A 10in dia thick aluminum pot can probably serve as a good sink for a 250w class amp. Put some water in it and good for 2kW 😀

Other place to check are industrial building supplies where they make aluminum in scaffolding. Or aluminum extrusions for factory automation. They sell by the foot or meter. A 100mm square profile aluminum Bosch rail with channels for T nuts may also make a good sink.

Bosch Rexroth:

This profile is 25mm x 50mm x 1.82 meters long for about $40.

https://www.zoro.com/8020-framing-extrusion-t-slotted-10-series-1020-black-72/i/G6676871/

If looks did not matter - a very low cost source of heatsinks are old aluminum cook pots. A 10in dia thick aluminum pot can probably serve as a good sink for a 250w class amp. Put some water in it and good for 2kW 😀

Other place to check are industrial building supplies where they make aluminum in scaffolding. Or aluminum extrusions for factory automation. They sell by the foot or meter. A 100mm square profile aluminum Bosch rail with channels for T nuts may also make a good sink.

Bosch Rexroth:

An externally hosted image should be here but it was not working when we last tested it.

This profile is 25mm x 50mm x 1.82 meters long for about $40.

https://www.zoro.com/8020-framing-extrusion-t-slotted-10-series-1020-black-72/i/G6676871/

Last edited:

There are DIY options for heatsink that work very well. I have sheet metal equipment and milling machines so it's easy for me to have excellent results, but the same can be done with a table saw and a belt sander.

DIY Heatsink

DIY Heatsink

- Home

- Amplifiers

- Solid State

- Revisiting some "old" ideas from 1970's - IPS, OPS