I need you to probe these again...

Check the schematic, they actually labeled these checks as test points.

You should be seeing +15volts on R401 and -15Volts on R402.

We may nee to revisit this check, once we get it out of protection.

Not a worry. I assumed the 16V4 and 17V1 were close enough. I was not sure if this was regulated to +- 15V or just floated with my mains (which runs at 120 steady).

For clarity - I broke out the measurements a bit cleaner for formatting. I had the black probe always on chassis ground and moved the red probe to the four points below for the new measurements.

R401 - Leg 1: 45V2

R401 - Leg 2: 17V2

R402 - Leg 1: (-)45V2

R402 - Leg 2: (-)16V4

Apologies once again. I'll try to do a better job being perfectly clear re: how I am measuring. Clearly my previous format did not work well. Again, with the black probe to ground and the red probe moving to two points:Okay, now we're getting someplace ...

Now lets check R417 ... you say it has 45 volts on one side and 0 on the other... The 45 volts is the bulk supply... the 0 volts is worrying.

R417 Leg 1 - 45V3

R417 Leg 2 - 45V3

The 0V was across the resistor. Previously we were looking for a voltage across it to see if the relay was getting voltage, so I checked it again just for good measure. Apologies.

So first step... check it again to verify your readings.

Double checked. Good news is that I am measuring consistently. I cleaned up the formatting for clarity.

D403: Leg1 (Cathode/Stripe side) to GND - 45V1 Leg 2 to ground ~7mV

So... nearly zero on one side... check. But 45 on the other... not so much.

Ok now we're getting someplace. This is wrong.

D403 should have either the relay voltage (assuming 12volts) across it when energized or 0 volts across it when not. You've just measured 45. That you read almost the same voltage on both sides of R417, which is in series, confirms the relay coil is not drawing current. There might be multiple reasons for this...

Step 1 ... recheck your reading. See if you get 45 and 0 volts every time,

Step 2 ... Double check your solder work from when you replaced that relay. If you probe the solder points gently with a small metal tool (a meter probe will do) and it pulls in and starts working... clean off the bad connection and resolder it.

Step 3 ... Closely examine the foil traces on the board around the relay. Make sure none are lifted or broken.

Step 4 ... If that doesn't get it... You're going to have to pull that relay out of the board and get a reading across the coil with the Ohms scale on your meter. It should read no more than a couple of hundred ohms. If it reads open... you've probably found your problem.

These relays almost universally have to pull in to connect the speakers. When you turn a normally working amp on, you get a few seconds delay while everything settles down then click the protection energizes the coil, pulls the relay and music starts. If that relay does not pull in...

Ok now we're getting someplace. This is wrong.

Let's check one other potential. We are dealing with a relay I already replaced. Did I choose an appropriate relay? I got one of these:

NTE Electronics R25–11d10–12

https://static6.arrow.com/aropdfconversion/3c229c5bd72e1b90e640b8130d885b6b2ed94314/r25.pdf

In the interim, I'll pull out the board and triple check everything.

You bought a -12 which is apparantly a 12 VDC relay coil.

Again resistance measurement (power off) across D403 will tell if you soldered relay right. 400-700 ohms (realy mvolts) not line to line, diode is conducting. Higher the other way, diode is not conducting, you see the relay coil. Infinity or ---- backwards across diode, relay is not soldered in or trace is broken.

Again resistance measurement (power off) across D403 will tell if you soldered relay right. 400-700 ohms (realy mvolts) not line to line, diode is conducting. Higher the other way, diode is not conducting, you see the relay coil. Infinity or ---- backwards across diode, relay is not soldered in or trace is broken.

Let's check one other potential. We are dealing with a relay I already replaced. Did I choose an appropriate relay? I got one of these:

NTE Electronics R25–11d10–12

https://static6.arrow.com/aropdfconversion/3c229c5bd72e1b90e640b8130d885b6b2ed94314/r25.pdf

In the interim, I'll pull out the board and triple check everything.

I can't really say unless I had the old one to compare to.

The coil on the one you linked is the two pins spaced further away from the rest.

@Indiajo -

You may be adding information, but I wasn't asking if I had the relay installed correctly, I was asking if I chose the correct / appropriate part in the first place.

Assuming I picked the right part, thank you. I Happened to be standing in front of it when your note came through. As you've seen with Douglas, I'm trying to be very clear re: how I'm taking measurements.

So. Here is what I've done.

Unplugged mains. Power switch off.

DMM set to Resistance:

1) Black probe on anode (stripe) leg red on other leg - 9.35kohms

2) Red on anode, black on other leg - 116kohms

DMM set to diode -

1) Black probe on anode (stripe) leg red on other leg - 0V58

2) Red on anode, black on other leg - begins ~1V57 and climbs steadily to ~2V21 and slows.

I appreciate what you're trying to convey, but it's a bit over my head. Trying to not only go by the rote, but pick up what you're putting down. Thanks!

You may be adding information, but I wasn't asking if I had the relay installed correctly, I was asking if I chose the correct / appropriate part in the first place.

Assuming I picked the right part, thank you. I Happened to be standing in front of it when your note came through. As you've seen with Douglas, I'm trying to be very clear re: how I'm taking measurements.

So. Here is what I've done.

Unplugged mains. Power switch off.

DMM set to Resistance:

1) Black probe on anode (stripe) leg red on other leg - 9.35kohms

2) Red on anode, black on other leg - 116kohms

DMM set to diode -

1) Black probe on anode (stripe) leg red on other leg - 0V58

2) Red on anode, black on other leg - begins ~1V57 and climbs steadily to ~2V21 and slows.

I appreciate what you're trying to convey, but it's a bit over my head. Trying to not only go by the rote, but pick up what you're putting down. Thanks!

Apologies once again. I'll try to do a better job being perfectly clear re: how I am measuring. Clearly my previous format did not work well. Again, with the black probe to ground and the red probe moving to two points:

R417 Leg 1 - 45V3

R417 Leg 2 - 45V3

The 0V was across the resistor. Previously we were looking for a voltage across it to see if the relay was getting voltage, so I checked it again just for good measure. Apologies.

A small point that experience will show you ... if you read both sides of a resistor (etc) it is a simple matter to deduce the rest. In this case you have the same voltage on both sides, therefore Ohm's law tells us there is no current through the resistor. If current was flowing we'd have two different voltages.

In this case no current through R417 which is in series with the relay coil, means no current through the relay coil. Then with almost the entire voltage appearing across a 12volt coil, we can pretty much deduce that the coil is the problem.

And FWIW .... connecting a 12volt relay on a 45 volt supply rail then using a resistor to drop the voltage is really crappy design.

Last edited:

I can't really say unless I had the old one to compare to.

The coil on the one you linked is the two pins spaced further away from the rest.

The original was a DW321-D12S. I can't seem to find a legit spec sheet for it. Odd.

Noted with thanks. On a new in box version of the "new" one, I get 278ohms pin to pin.

I'll yank out the one that's in there and give it a go.

Ok now we're getting someplace. This is wrong.

Step 1 ... recheck your reading. See if you get 45 and 0 volts every time,

Yep. Drat!

Step 2 ... Double check your solder work from when you replaced that relay. If you probe the solder points gently with a small metal tool (a meter probe will do) and it pulls in and starts working... clean off the bad connection and resolder it.

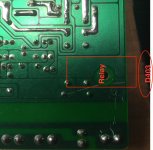

Wiggled it with a chopstick in circuit and powered up. No joy. Solder work looks good. Pic attached.

Step 3 ... Closely examine the foil traces on the board around the relay. Make sure none are lifted or broken.

Looking good. Same pic.

Step 4 ... If that doesn't get it... You're going to have to pull that relay out of the board and get a reading across the coil with the Ohms scale on your meter. It should read no more than a couple of hundred ohms. If it reads open... you've probably found your problem.

Stay tuned....

Edited to fix the formatting for quotes and add the pic. Also, the small scratch across the board seems to be from me dragging it across a standoff while removing.

Last edited:

Wiggled it with a chopstick in circuit and powered up. No joy. Solder work looks good. Pic attached.

About solder joints ...

When you solder something there is a risk that a little tunnel of flux is created between the component leg and the solder on the board foil. Essentially this will insulate the component from the board. This is your classic "cold solder joint". The reason we probe them with metal is that the tip of the probe (or a tiny screwdriver) will bridge the flux making the connection... telling us to solder more carefully next time.

They're easy enough to fix ... if you apply heat they will actually boil as the flux burns off.

For what it's worth... I've been at this over 30 years and I still make the occasional bad solder joint.

Last edited:

The original was a DW321-D12S. I can't seem to find a legit spec sheet for it. Odd.

Noted with thanks. On a new in box version of the "new" one, I get 278ohms pin to pin.

I'll yank out the one that's in there and give it a go.

Unfortunately reading resistance for a device in-circuit is often complicated by the reactions of other parts in the circuit. For example: an OHM scale reading of a resistor connected with a large capacitor will initially read as a dead short. Depending how big the capacitor is, it could be a matter of minutes before there is enough charge on the cap, that you can "see" the resistance.

The only way to know for sure is to fully isolate the part, which most often means taking it out or lifting one of it's legs.

While you have the relay out... grab a 9 volt battery and connect it across the coil the relay should pull in. When you release it should drop out. You will hear it clicking.

That makes perfect sense.

So, here are 3 data points.

Original relay I removed - 277 ohms (Apologies, I grabbed the old one)

New Relay never installed - 341 ohms

New Relay that I just removed from board - 368 ohms

So, here are 3 data points.

Original relay I removed - 277 ohms (Apologies, I grabbed the old one)

New Relay never installed - 341 ohms

New Relay that I just removed from board - 368 ohms

Okay, the old relay 277 ohms @ 12 v would be 43 ma.

43 ma through the 2 watt R417 680 ohms would be 1.2 Watt. Check. No money wasted. Designers try to run resistors no more than half power. You probably have the right relay coil voltage.

That low a resistance won't look different front and backwards on D403. Neither would 368 ohms.

While relay is out check D403 frontwards & backwards. Should be ---- backwards, 400 to 700 mv forwards on diode scale. These 1 amp diodes hardly ever fail at these low currents.

BTW the reason people replace protection relays is that usually the music won't flow through with dirty contacts. The old relay may be just fine, and maybe better than the NTE ones. Silver contacts would be premium for 75 w/ch amps. Generic relays are copper contacts, which oxidizes.

43 ma through the 2 watt R417 680 ohms would be 1.2 Watt. Check. No money wasted. Designers try to run resistors no more than half power. You probably have the right relay coil voltage.

That low a resistance won't look different front and backwards on D403. Neither would 368 ohms.

While relay is out check D403 frontwards & backwards. Should be ---- backwards, 400 to 700 mv forwards on diode scale. These 1 amp diodes hardly ever fail at these low currents.

BTW the reason people replace protection relays is that usually the music won't flow through with dirty contacts. The old relay may be just fine, and maybe better than the NTE ones. Silver contacts would be premium for 75 w/ch amps. Generic relays are copper contacts, which oxidizes.

Last edited:

While you have the relay out... grab a 9 volt battery and connect it across the coil the relay should pull in. When you release it should drop out. You will hear it clicking.

All 3 relays pull in with the 9V and drop out when released.

That makes perfect sense.

So, here are 3 data points.

Original relay I removed - 277 ohms (Apologies, I grabbed the old one)

New Relay never installed - 341 ohms

New Relay that I just removed from board - 368 ohms

Ok... that coil has continuity, you should not have seen the entire supply voltage across that coil.

Something else is going on... At this point I would suspect a cold solder joint, but it's hard to tell from your photo.

Ohms law says that we should be seeing...

680 ohms for R417 + 368 ohms for the coil ... so 45/ (680 + 368) == 45/1048 == ~43ma of current.

Thus R417 should have 680 X .043 == ~29.4 volts across it

So one leg should read the bulk supply and the other should read 45 - 29 == 16 volts.

thus D403 should read 16 volts on one leg and nearly 0 on the other.

If that circuit was not being triggered you would have bulk voltage everywhere in that chain.

This time when you put the relay back in, tin the pins first, then stay on the connections for a few seconds after applying solder, really cook them down.

Last edited:

All 3 relays pull in with the 9V and drop out when released.

So there's a chance you took out a good relay...

So there's a chance you took out a good relay...

It may be that way.

So. I put in another (fresh) new relay, jussssst in case I did something to the previous one during installation. To the best of my ability, I ensured proper, solid, strong solder joints.

New behavior (sort of). We have protection LEDs again, both red and green. Maybe that leans us toward a new direction. However, still no blue "power" LED. This is so weird! Even when I received the broken amp, the blue LED lit prior to the relay replacement.

I still get 45V on one side of D403.

I have to put things to rest for the evening. Tomorrow is a holiday, so I'll be tied up for the day.

Once again, I am thankful for all the help, and ideas. See you gentlemen on Friday.

The only other thing I can think of at the moment...

Might this be an actual fault of another kind... thermal? This amp does have thermal protection, and while I can physically see some thermistors on the heatsinks, I have no idea how to check if they're functioning properly in the circuit. It is tough for me to see between the board and the heatsink, but one thermistor (or whatever it is I'm staring at) sure looks different from the other.

Spit-balling. I truly have no idea.

Might this be an actual fault of another kind... thermal? This amp does have thermal protection, and while I can physically see some thermistors on the heatsinks, I have no idea how to check if they're functioning properly in the circuit. It is tough for me to see between the board and the heatsink, but one thermistor (or whatever it is I'm staring at) sure looks different from the other.

Spit-balling. I truly have no idea.

I still get 45V on one side of D403.

If the circuit is in protection you should have 45 volts on both sides of D403. This would indicate no current flow, telling us the protection chip is not pulling it in.

The relay and the protection lights both operate from Pin 6 of the TA7313 chip. That the protection lights are back on tells us that you now have continuity through the relay coil.

Follow the circuit ... From pin 6 of the TA7313 to the bottom of the relay coil... also to R423, Q402 and off to J8, pin 1, which leads to the display panel. In the display panel it goes from J8, to a couple of diodes that trigger the leds.

The bulk voltage on pin 6 of the chip is triggering Q402 to turn on the leds. So it seems a safe bet that is now fixed.

Next problem... WTF is causing protection faults?

For that we have to start looking at the inputs to the TA7313 chip itself. We;ll get into that in the next group of messages.

Last edited:

TA7317 Protection Chip

This is based on the TA7317 datasheet and schematics with marked voltages.

(Data sheet, such as it is, attached below)

The TA7317 protection chip is designed so that if everything is right, after a time delay, it pulls in a relay that connects amplifier outputs to speakers. It is intended to protect speakers by preventing DC offsets and turn on thumps from reaching them.

Power is on pin 9, ground is on pin 4 and pin 5 is connected to the chip's substrate.

Signals...

Power detect at pin 1

DC detect at pins 2 and 3

Relay driver at pin 6

Rapid turn off at pin 7

Turn on delay at pin 8

In operation...

pin 1 ... < 0.75 volts ... power detect

pin 2 ... >-1 <+1 volts ... DC detect

pin 3 ... >-1 <+1 volts ... DC detect

pin 4 ... 0 volts ... ground

pin 5 ... -0.8 volts ... chip substrate

pin 6 ... ~1.5 volts when on +Vbulk when off ... relay driver

pin 7 ... < 0.6 volts ... rapid turn off

pin 8 ... >+1.7 volts ... delay turn on cap.

pin 9 ... ~+3 volts .. chip power.

If pins 1, 2, 3, 7 and 8 are not biased correctly the relay will not energize.

At turn on or after a fault is cleared, Pin 8 is initially held to ground by a capacitor that is charged through a resistor. When the charge reaches approximately 1.6 volts, pin 6 will switch on, drawing current to energize the relay.

This is based on the TA7317 datasheet and schematics with marked voltages.

(Data sheet, such as it is, attached below)

The TA7317 protection chip is designed so that if everything is right, after a time delay, it pulls in a relay that connects amplifier outputs to speakers. It is intended to protect speakers by preventing DC offsets and turn on thumps from reaching them.

Power is on pin 9, ground is on pin 4 and pin 5 is connected to the chip's substrate.

Signals...

Power detect at pin 1

DC detect at pins 2 and 3

Relay driver at pin 6

Rapid turn off at pin 7

Turn on delay at pin 8

In operation...

pin 1 ... < 0.75 volts ... power detect

pin 2 ... >-1 <+1 volts ... DC detect

pin 3 ... >-1 <+1 volts ... DC detect

pin 4 ... 0 volts ... ground

pin 5 ... -0.8 volts ... chip substrate

pin 6 ... ~1.5 volts when on +Vbulk when off ... relay driver

pin 7 ... < 0.6 volts ... rapid turn off

pin 8 ... >+1.7 volts ... delay turn on cap.

pin 9 ... ~+3 volts .. chip power.

If pins 1, 2, 3, 7 and 8 are not biased correctly the relay will not energize.

At turn on or after a fault is cleared, Pin 8 is initially held to ground by a capacitor that is charged through a resistor. When the charge reaches approximately 1.6 volts, pin 6 will switch on, drawing current to energize the relay.

Attachments

Last edited:

- Home

- Amplifiers

- Solid State

- Repair of Alesis RA150