I hope those ballbearings in the platter bearing are not worn or differing in diameter.

Try removing the plastic washer, but I don't see that it would cause a rotational problem.

Can you identify the "turntable brake" mentioned under "Controls" to check it is fully retracted when the platter is spinning?

I picture the brake as carrying a felt pad which contacts the platter to slow it down. Just another straw to clutch I'm afraid!

Try removing the plastic washer, but I don't see that it would cause a rotational problem.

Can you identify the "turntable brake" mentioned under "Controls" to check it is fully retracted when the platter is spinning?

I picture the brake as carrying a felt pad which contacts the platter to slow it down. Just another straw to clutch I'm afraid!

You may remember that the ball bearings were missing so I obtained a new set - 3/32" diameter - checked them with my micrometer.

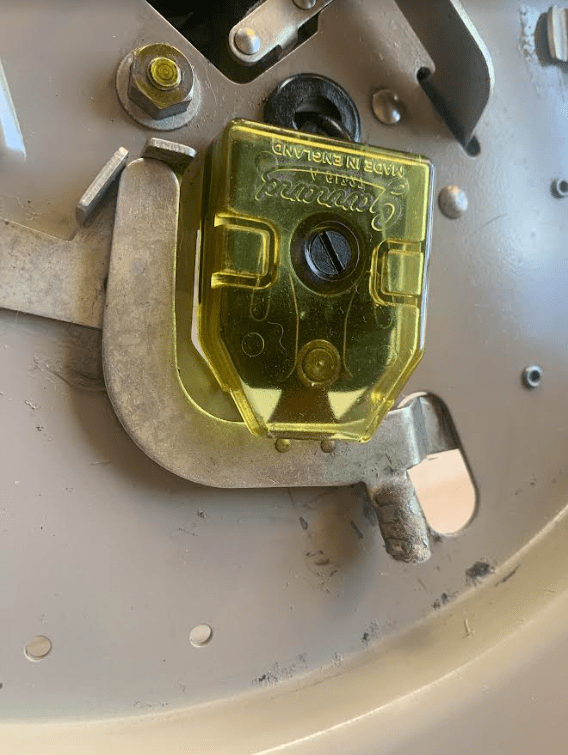

The picture below shows the brake position when the turntable is switched on - as you can see, it's fully retracted.

I'll try removing the plastic washer but do feel that I'm clutching at straws - this diagram from the other Service Sheet shows the plastic washer:-

The picture below shows the brake position when the turntable is switched on - as you can see, it's fully retracted.

I'll try removing the plastic washer but do feel that I'm clutching at straws - this diagram from the other Service Sheet shows the plastic washer:-

Attachments

Last edited:

Considerable effort has now been expended on disassembling and lubricating the motor, the cam assembly and the main bearing/spindle - the auto-changer is now back to working reasonably well. It still sticks sometimes but I now have no doubt it's the idler wheel rubber that is the issue. If you turn it on and run the platter on Manual for 5-10 minutes before trying the auto-changer this certainly helps matters - I'm assuming that the rubber is just warming up and softening enough to provide sufficient torque?

Two minor issues:-

1. The output from the push-pull stereo amp module has a slight balance issue and wondering where in the circuit this may be happening and how to fix it? I'm thinking cartridge, ECL82 valves or other components?

2. I have the usual loud 'pop' when the auto-changer turns off due to the contacts arcing. I intend to fit a suitable X2 capacitor to help fix this but wondered where is the best place - either across the mains tags on the on/off pot or across the switch under the platter?

Two minor issues:-

1. The output from the push-pull stereo amp module has a slight balance issue and wondering where in the circuit this may be happening and how to fix it? I'm thinking cartridge, ECL82 valves or other components?

2. I have the usual loud 'pop' when the auto-changer turns off due to the contacts arcing. I intend to fit a suitable X2 capacitor to help fix this but wondered where is the best place - either across the mains tags on the on/off pot or across the switch under the platter?

1. To eliminate the cartridge as the cause, try reversing the L/R channel connections at the cartridge.

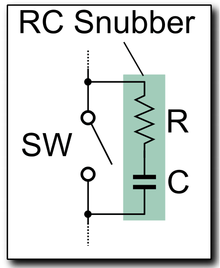

2. If you have access to the switch under the platter, then wire a high voltage 0.01 uF or 0.0047 uF capacitor across it.

2. If you have access to the switch under the platter, then wire a high voltage 0.01 uF or 0.0047 uF capacitor across it.

Adding a resistor in series with the capacitor is even more effective.

I've checked back on a previous post I made on the topic:

A widely used combination is 0.1uF + 100ohm. Go for 0.5 W rating on the resistor and 630 V rating on the capacitor.

I've checked back on a previous post I made on the topic:

A widely used combination is 0.1uF + 100ohm. Go for 0.5 W rating on the resistor and 630 V rating on the capacitor.

Attachments

Last edited:

Thanks Galu - pleased to see that you are still following and contributing to my Thread.

The under-platter switch is shown in my Post #123 above - where do you safely fit the cap and resistor?

The under-platter switch is shown in my Post #123 above - where do you safely fit the cap and resistor?

I'd be wary about opening up that switch just in case bits fly out - so caw canny!

Perhaps there's a failed suppression capacitor inside?

Provided there is sufficient slack, you could simply splice into the wires entering and leaving the switch.

Perhaps there's a failed suppression capacitor inside?

Provided there is sufficient slack, you could simply splice into the wires entering and leaving the switch.

You may remember that I successfully restored both the stereo amp module and the Garrard auto-changer in this PYE Stereo Black Box G63 - everything was working up to a point but there was still a slight problem with the Balance being skewed slightly on one channel. Through extensive probing and testing I narrowed this down to the ECC83 valve and managed to obtain a replacement.

So duly fitted the replacement valve which improved the Balance and everything was satisfactory ... BUT

I also had an 12AX7 valve which, being newer, I assumed would improve matters further? This was fitted but no sound was heard coming from the speakers? So as you would expect I put the ECC83 back in again but still no sound?

Any ideas as to what I may have done - the 12AX7 is a direct replacement for the ECC83 so It should have worked?

So duly fitted the replacement valve which improved the Balance and everything was satisfactory ... BUT

I also had an 12AX7 valve which, being newer, I assumed would improve matters further? This was fitted but no sound was heard coming from the speakers? So as you would expect I put the ECC83 back in again but still no sound?

Any ideas as to what I may have done - the 12AX7 is a direct replacement for the ECC83 so It should have worked?

It would appear that inserting the 12AX7 has upset something. The question is, what and why?

Is the amp completely dead, i.e., no hum through the loudspeakers?

Could there be a blown fuse?

Do the valve heater filaments light up?

Is an anode voltage present on the ECC83 (153 V on pins 1 and 6)?

Is the amp completely dead, i.e., no hum through the loudspeakers?

Could there be a blown fuse?

Do the valve heater filaments light up?

Is an anode voltage present on the ECC83 (153 V on pins 1 and 6)?

Thanks Galu - bit of an odd one as I seem to have no output from the pre-amp section? I’m still confused as to why this happened when just replacing an ECC83 with a 12AX7?

Won’t be able to do any checks or further testing until Friday,

Won’t be able to do any checks or further testing until Friday,

So, you can't answer any of my above questions at this time?

The only other thing I can suggest is to check that the insertion/withdrawal of the valve has not resulted in a broken connection at the valve base.

The only other thing I can suggest is to check that the insertion/withdrawal of the valve has not resulted in a broken connection at the valve base.

I think I may have a broken connection on the valve base - see attached picture.

On the assumption I’m counting correctly I think this is Pin 9 which on the ECC83 is hot (heater centre connection) which may explain why the valve wasn’t warming up!

On the assumption I’m counting correctly I think this is Pin 9 which on the ECC83 is hot (heater centre connection) which may explain why the valve wasn’t warming up!

I've now got an answer to my question of whether the heater lights up. 😉

Yer gonna need a new valve base. Will this adventure never end!

I've been cleaning up a manky old Garrard SP25 MKII I got cheaply as a source of spare parts for the well fettled one I use in my Man Shed.

I've got it operating OK and running to speed. However, the motor gets very hot, even though it is drawing the stipulated 0.7 A and its rotor is spinning freely.

I don't really need another working SP25, but it was fun renovating it. Replacement motors on ebay cost more than I paid for the entire deck so I won't be going down that route!

Yer gonna need a new valve base. Will this adventure never end!

I've been cleaning up a manky old Garrard SP25 MKII I got cheaply as a source of spare parts for the well fettled one I use in my Man Shed.

I've got it operating OK and running to speed. However, the motor gets very hot, even though it is drawing the stipulated 0.7 A and its rotor is spinning freely.

I don't really need another working SP25, but it was fun renovating it. Replacement motors on ebay cost more than I paid for the entire deck so I won't be going down that route!

I know about heaters which are wired in series or parallel but not sure about the centre tap?

Any implications for associated components if we have a fault here? Can I bodge it just to confirm that this is the problem??

Of course the B9A valve base is riveted just to make things more challenging - now where did I put my Dremel!

Any implications for associated components if we have a fault here? Can I bodge it just to confirm that this is the problem??

Of course the B9A valve base is riveted just to make things more challenging - now where did I put my Dremel!

The RH channel schematic shows only half of the heater filament connected to the heater supply, i.e., pins 4 and 9 used.

A dotted line shows pin 5 connected to pin 4 which would put the two halves of the winding in parallel.

Either way, the ECC83 would be configured for 6.3 V operation.

(By connecting the two heater halves in series the valve can be configured for 12.6 V operation, i.e., pin 9 not used.)

There should be no implication for associated components due to the disconnected heater.

Regarding bodging, I suppose you could insert a piece of copper wire into the broken socket in an attempt to make it grip the valve pin.

A dotted line shows pin 5 connected to pin 4 which would put the two halves of the winding in parallel.

Either way, the ECC83 would be configured for 6.3 V operation.

(By connecting the two heater halves in series the valve can be configured for 12.6 V operation, i.e., pin 9 not used.)

There should be no implication for associated components due to the disconnected heater.

Regarding bodging, I suppose you could insert a piece of copper wire into the broken socket in an attempt to make it grip the valve pin.

Thanks Galu for the helpful explanation.

I temporarily bodged a piece of copper wire into the Pin 9 valve socket and everything seemed to be working again! When I have time I’ll recheck all valve pin voltages and confirm again that the Balance issue is resolved by fitting the replacement ECC83.

Need to order up a new B9A valve base and do the job properly.

Hopefully the ‘adventure’ will end soon!

I temporarily bodged a piece of copper wire into the Pin 9 valve socket and everything seemed to be working again! When I have time I’ll recheck all valve pin voltages and confirm again that the Balance issue is resolved by fitting the replacement ECC83.

Need to order up a new B9A valve base and do the job properly.

Hopefully the ‘adventure’ will end soon!

Instead of replacing the valve base which would have been quite a challenge I managed to transpose an unused valve pin socket from the rectifier. Although this amp module has 6 x 9 pin valves i.e. 54 valve pin sockets, only two of those are unused!

Also swapped in a replacement ECC83 which improved the Balance issue but there is still a slight variance that can be ameliorated by the Balance control.

Also swapped in a replacement ECC83 which improved the Balance issue but there is still a slight variance that can be ameliorated by the Balance control.

- Home

- Amplifiers

- Tubes / Valves

- PYE Stereo Black Box G63