Series of experiments did greatly improve the effectiveness of the way we achieved coupling.

What route did your journey take? 🙂

A solid coupling could be achieved by bolting or gluing the magnets together. It would be nice if the rims could be connected as well, it could make the task of connecting them to the box simpler too as theoretically they wouldn't transfer any mechanical vibration so it wouldn't have to be solid.

Boy, tha is sime history.

First became aware in the early 80s i guess. A series of thot experiments:

Recycle Woofer

Push-Push Dipole Concept

Bipolar RS 40-1394 ML-TQWT

toobz woofer

The last using woofers meant to have a lag bolt thru thru polepiece into the box which allowed for bolting the 2 together in a ridgid configuration. This is tricky for amateurs, so mstly , what i shall call, SE Push-Push. Trying the bolt holes together with ready rod, or some other way of tieing the driver bezels together.

Kef in their 104 Mkii tied the drivers together with rods and even more dramatic measures have been made.

It is possible to diy, i worked with a fellow in Scandinavia on an A7/Scan WAW and he devised a clever coupling that alowed him to tie the drivers tightly together and still removable.

This woofer went to somewhere in the US. An early example of more serious driver bracing.

This playe da role as well Mr J did a lot of measuring and work on these:

toobz woofer

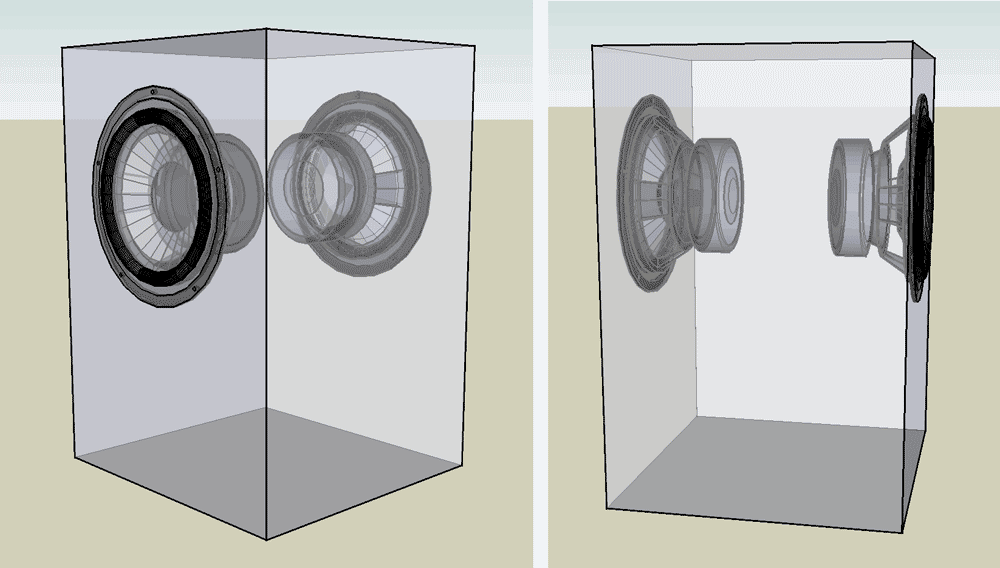

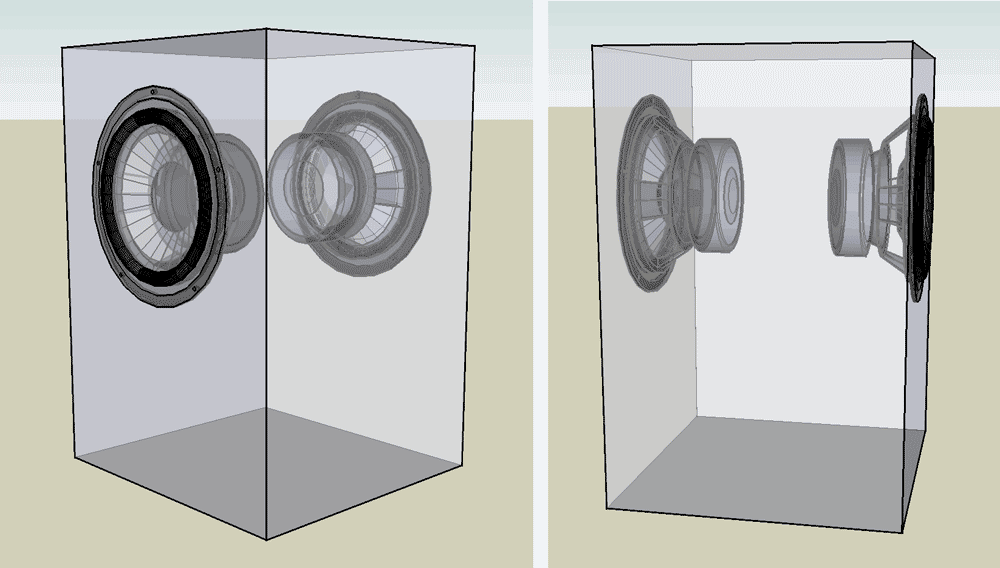

The first PP build i recall was sort of a large microTower with 2 5.25” + tweeters. My brother loves them. Just a hardwood “stick shoved between the 2 magnets (tricky to do). The compact width/depth of the box meant more than useua coupling between drivers due to just the box. Numerous other biPole FRs evolved th ecoupling mechanism, and we found the simple bracing as in that dual 10” subwoofer experiment. Purposely built with 15mm BB, one could pick up the box with 2 fingers in a driver cut-out, but it became a 2-man lift with woofers installed. I had to turn off the HF amp, and set the subs to some 10dB louder than it would ever be played. I could get teh top panel moving. A constrained layer of rock on top would sort that.

We built the smaller one at the end of the doc: http://www.planet10-hifi.com/downloads/SDX10-woofPlans-240418.pdf

More:

Simplified with no direct coupling:

Ouch-push-push-pull:

A practical coffee table:

microTowers

Ripple push-push mostly relies on the small “box” (can’t find the simple concept drawing.

http://www.p10hifi.net/planet10/forum/ripole-woofer-module.pdf

dave

First became aware in the early 80s i guess. A series of thot experiments:

Recycle Woofer

Push-Push Dipole Concept

Bipolar RS 40-1394 ML-TQWT

toobz woofer

The last using woofers meant to have a lag bolt thru thru polepiece into the box which allowed for bolting the 2 together in a ridgid configuration. This is tricky for amateurs, so mstly , what i shall call, SE Push-Push. Trying the bolt holes together with ready rod, or some other way of tieing the driver bezels together.

Kef in their 104 Mkii tied the drivers together with rods and even more dramatic measures have been made.

It is possible to diy, i worked with a fellow in Scandinavia on an A7/Scan WAW and he devised a clever coupling that alowed him to tie the drivers tightly together and still removable.

This woofer went to somewhere in the US. An early example of more serious driver bracing.

This playe da role as well Mr J did a lot of measuring and work on these:

toobz woofer

The first PP build i recall was sort of a large microTower with 2 5.25” + tweeters. My brother loves them. Just a hardwood “stick shoved between the 2 magnets (tricky to do). The compact width/depth of the box meant more than useua coupling between drivers due to just the box. Numerous other biPole FRs evolved th ecoupling mechanism, and we found the simple bracing as in that dual 10” subwoofer experiment. Purposely built with 15mm BB, one could pick up the box with 2 fingers in a driver cut-out, but it became a 2-man lift with woofers installed. I had to turn off the HF amp, and set the subs to some 10dB louder than it would ever be played. I could get teh top panel moving. A constrained layer of rock on top would sort that.

We built the smaller one at the end of the doc: http://www.planet10-hifi.com/downloads/SDX10-woofPlans-240418.pdf

More:

Simplified with no direct coupling:

Ouch-push-push-pull:

A practical coffee table:

microTowers

Ripple push-push mostly relies on the small “box” (can’t find the simple concept drawing.

http://www.p10hifi.net/planet10/forum/ripole-woofer-module.pdf

dave

The last using woofers meant to have a lag bolt thru thru polepiece into the box which allowed for bolting the 2 together in a ridgid configuration. This is tricky for amateurs, so mstly , what i shall call, SE Push-Push. Trying the bolt holes together with ready rod, or some other way of tieing the driver bezels together.

How is this push-push?

It can only be push-pull [or the dorky push-push/pull-pull moniker I saw somewhere] since the drivers are physically tied together:

Thank you Dave for taking the time to post all that, very interesting.

GM, the confusion never ends 😉🙂

GM, the confusion never ends 😉🙂

Keep in mind that I know little about driver motors, but is there any concern about placing a steel bolt into the magnet hole? Will it, or could it, affect the motor performance? Would it be better to use a non-ferrous bolt (aluminum or brass for example) ?

j.

j.

How is this push-push?

It can only be push-pull [or the dorky push-push/pull-pull moniker I saw somewhere] since the drivers are physically tied together:

You asked this before on my thread in subwoofer forum. The woofers are acoustically in phase...everything behind the woofer baffles represents the inside of the box. The diaphragms are not physically connected...I think thats what you thought last time you seen this pic lol

Last edited:

How is this push-push?

It is 2 drivers in phase in physical opposition. The rest is just bolting them together.

The woofer is somewhat unique in that it is designed to have a lag-bolt thru the polepiece.

PEARL PR-2 Woofer

It can only be push-pull [or the dorky push-push/pull-pull moniker

push-push/pull-pull is a pair of push-pull isobrail “modules” mounted push-push.

Somehow you are missing something Greg. These are clearly push-push.

dave

Keep in mind that I know little about driver motors, but is there any concern about placing a steel bolt into the magnet hole?

Yes, but the designer took that into consideration.

dave

I have occasionally toyed with the idea of a push-push transmission line for the woofers in a high efficiency multi-way speaker system.

You asked this before on my thread in subwoofer forum. The woofers are acoustically in phase...everything behind the woofer baffles represents the inside of the box. The diaphragms are not physically connected...I think thats what you thought last time you seen this pic lol

Oh well, apparently starting to 'circle the drain' to dementia.......and can't imagine me 'seeing' it any different then too.

Certainly looks like it with bipole layout plus there was ?? that marketed such a system, claiming all sorts of improved performance.

The woofer is somewhat unique in that it is designed to have a lag-bolt thru the polepiece.

Yes, a very poorly executed example. 🙁

Had the rod been terminated inside the magnets, not at the diaphragm to clearly show it a bipole and while I would presume it's in phase, it really should have been labeled as such.

I have occasionally toyed with the idea of a push-push transmission line for the woofers in a high efficiency multi-way speaker system.

BTW, when did we quit calling them bipole/bipolar?

...and can't imagine me 'seeing' it any different then too.

There are no dustcap on the woofers. Bolt goes thru the polepiece and does not conact the cones… it does sort of look like a rod connecting the cones — which would make it dipole (push-pull with a wasted box). A felt dustcap is stuck to the head of the bolt.

dave

Also. Push-push is usually referring to a woofer, a bipole a wider range loudspeaker where everything is not omniDirectional in nature.

dave

dave

Yes, that's more on point I think. I'd be more likely to call them bipoles when they have part or all of their range above the baffle step.

It can still be both.

It can still be both.

I was seduced by the push-push configuration right from the start.It is definitley not like an open baffle which would be a diplole. At low frequencies the push-push and the "normal" driver mounting behave alike.

The cancelling of the inertial forces is the main advantage of the design. I.e. less vibration that is fed into the floor (theoretically the vibration is even zero).

And if they are side-mounted narrow baffles with quite large drivers are possible.

I recently discovered that there is still a slight transmission of vibrations from the cabinet to the mid-high satellites that are just sitting on top.

I am wondering what would be the best way to uncouple them.

Another question for a project: would there be any point in mounting four woofers, one on each side of the cabinet?

- Home

- Loudspeakers

- Multi-Way

- Push Push Bass design