I have also played around with different tensions on the clutch (there is a metal tongue which you can bend in order to vary the pressure of the clutch) with no usable result.

An update from me - Mouser messed up delivery from Texas and I only received caps today, will try and fit and test before I leave for 2 weeks this weekend, just to see if it’s fixed the problem.

But…while digging the 204 out of storage, I found another completely stock one I bought a few years back and forgot about 🙂 I made a note on masking tape on top of it that it played for a 15 minute test without issue.

Ultimately I’d sell the stock one for €100 if you’re interested @eschenborn - but first I’d want to test it for longer, and transfer Crystal out of it so I can compare it to the external clock on my other 204. So probably not available until end of February, mid-March

But…while digging the 204 out of storage, I found another completely stock one I bought a few years back and forgot about 🙂 I made a note on masking tape on top of it that it played for a 15 minute test without issue.

Ultimately I’d sell the stock one for €100 if you’re interested @eschenborn - but first I’d want to test it for longer, and transfer Crystal out of it so I can compare it to the external clock on my other 204. So probably not available until end of February, mid-March

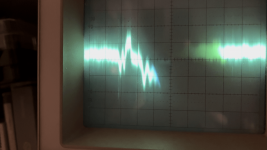

That looks essentially OK, the ripple is low. What we look for are sudden noisy random bursts of ripple indicating a worn or dirty commutator.

(the scope ground should just go to the main 0 volt line. Post #217, the motor is shown as going to ground. Connecting to the minus rail might short the rail out if the player and scope are both mains grounded)

(the scope ground should just go to the main 0 volt line. Post #217, the motor is shown as going to ground. Connecting to the minus rail might short the rail out if the player and scope are both mains grounded)

This is what I got with the scope ground probe attached to player ground, see in my dropbox: https://www.dropbox.com/s/73bjba7srvx2yb9/IMG_1910.MOV?dl=0

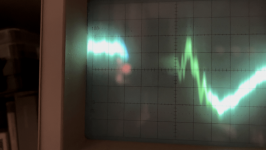

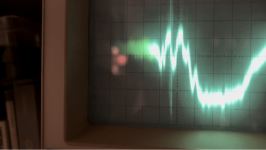

If you look at the little video, you might even audibly notice the player skip. When it does, the scope shows these patterns:

If you look at the little video, you might even audibly notice the player skip. When it does, the scope shows these patterns:

Attachments

I honestly don't know. Was it pushed or did it jump 😉 in other words was that cause or was it caused by...

I still think if this was platter/turntable/motor related you would see it do this losing lock while it was paused. Its difficult. We've not had a definitive breakthrough yet on this 🙁

I still think if this was platter/turntable/motor related you would see it do this losing lock while it was paused. Its difficult. We've not had a definitive breakthrough yet on this 🙁

Thanks, Mooly. Yes. I agree (with my quite limited expertise on interpreting the scope pictures). I admit to have run out of ideas. And of time to invest in this particular unit. My strategy is to wait for an affordable donor unit which does not suffer from the same symptoms and then swap components in order to narrow down the problem.

Like you I'd really like to know what is the cause of this, makes me feel bad to leave things in the dark (apart from not using this player anymore). But mentally I have gotten to the place where I am ready to give up on this for the time being.

The scenario for the above is that the drive starts to "tick" or "twitter" audibly (as if trying to make more effort to hold the track), then glitches with a louder "tick"/"twitter", wich is visible as the spikes shown on the photos.

I am not sure that if the arm lost track first this would show at all in the spindle motor's behavior, as the spindle drive should be fairly autonomous and, so to speak, just pull through, regardless of the arm skipping. But maybe electrically it is not organized like this.

Thanks again @Mooly for your patience and perseverance!

Like you I'd really like to know what is the cause of this, makes me feel bad to leave things in the dark (apart from not using this player anymore). But mentally I have gotten to the place where I am ready to give up on this for the time being.

The scenario for the above is that the drive starts to "tick" or "twitter" audibly (as if trying to make more effort to hold the track), then glitches with a louder "tick"/"twitter", wich is visible as the spikes shown on the photos.

I am not sure that if the arm lost track first this would show at all in the spindle motor's behavior, as the spindle drive should be fairly autonomous and, so to speak, just pull through, regardless of the arm skipping. But maybe electrically it is not organized like this.

Thanks again @Mooly for your patience and perseverance!

I think you have gone very far in the search, perhaps much more than ordinary mortals would have done, you can be proud of yourself and I agree with you on the fact of finding another cd organ donor player to validate or invalidate this or that part.

Really enjoyed reading this thread, hope it has a happy ending.

Really enjoyed reading this thread, hope it has a happy ending.

I look in my archives if I have a machine that could correspond to your search.

That alone suggests (and we've been here before 🙂) that the arm is sticking as it tracks across the disc.The scenario for the above is that the drive starts to "tick" or "twitter" audibly (as if trying to make more effort to hold the track), then glitches with a louder "tick"/"twitter", wich is visible as the spikes shown on the photos.

It would be good to pin it down to a module/PCB or the mech as a first thing.

Don't give up on it but I do agree if you can come up with another unit to do some swaps with then that would be ideal.

Thank you so much! It is a nice way to speak of your collection of your players as your "archive". I will apply this terminology next time a friend mocks me about stacks of old hifi stuff 🙂 And thanks from my heart for your kind offer to search this archive for possible donor organs.I look in my archives if I have a machine that could correspond to your search.

I admit that speaking about a donor means to accept at least one casualty, which really goes against the grain for me, in trying to re-animate as many of these old machines as possible. But the CDM-0 motor (without knowing if it's the culprit) indeed IS a sealed throwaway item (even though it may last very long before becoming exhausted).

Yes, it does. I agree.That alone suggests (and we've been here before 🙂) that the arm is sticking as it tracks across the disc.

It would be good to pin it down to a module/PCB or the mech as a first thing.

Don't give up on it but I do agree if you can come up with another unit to do some swaps with then that would be ideal.

I did lubricate the arm though (and after I did it played a whole night without a single skip, only to completely stutter the next morning).

The arm moves easily, the flexprint is ok and not in the way, so I don't really see mechanical obstacles.

But it could be an electronic glitch that makes the arm skip... back to square 1. So indeed trying different modules gives a chance of ruling out suspects, probably the only chance.

I have this mostly untouched CD-104 with CDM-1 that I could use as a temporary donor, but as it works well I am actually a bit afraid to swap CDMs. I'd also need to swap the tray PCB, as all cables somehow need to fit into their plugs... will be messy and a source of mistakes. So I'd prefer to use a 204 for this.

At the moment I am using a CD-350 as a substitute, still with TDA1540, which I do prefer over its predeccesor TDA1541. Personal taste 🙂 I assume if you love vintage stuff than always the oldest incarnation of something is the most romantically promising.

PS: I lubricated the swing arm spindle from above and below, pulling it out half way. If it comes out whole, it needs to be reassembled and pushed back, with all the little washers at specific places in the right order... which is a trap I'd fall into... and then I'd need to do the horrible Philips "transparent CD-thing with a straight line on it" to realign... so I don't pull it out.

(I remember when I "repaired" the gear box in the rear wheel hub of my first decent bike when I was 12 or so... out came a lot of cogs. After reassembling I had the equal number still left outside...)

(I remember when I "repaired" the gear box in the rear wheel hub of my first decent bike when I was 12 or so... out came a lot of cogs. After reassembling I had the equal number still left outside...)

I really like the way this has become a scientific endeavor for the community's sake. I'll track that down some way or another! And then I'll write that CDM-0/1 checklist for problem finding!That alone suggests (and we've been here before 🙂) that the arm is sticking as it tracks across the disc.

It would be good to pin it down to a module/PCB or the mech as a first thing.

Don't give up on it but I do agree if you can come up with another unit to do some swaps with then that would be ideal.

I only hope the cause of all this will not be something completely stupid caused by myself 🙂

(Mooly might remember a certain not replaced sand filled fuse in a SONY amp that did not release the protection relay)

(Mooly might remember a certain not replaced sand filled fuse in a SONY amp that did not release the protection relay)

That is where it gets frustrating, where you actually do something that seems to correct the problem... except it doesn't fully. You start wondering whether it is connected or not.I did lubricate the arm though (and after I did it played a whole night without a single skip, only to completely stutter the next morning).

The arm moves easily, the flexprint is ok and not in the way, so I don't really see mechanical obstacles.

The arm moves easily in the 'macro' world but does it begin to seize at the microscopic movement it sees when playing.

That reminds me of something a motor engineer told me years ago about thermostats in a car. I said it opens correctly in hot water at the correct temperature and he reckoned that proved nothing and went on to say that in actual use the 'stat' never opened like that and merely 'hovered' on its seat, open by just a tiny tiny amount. Literally hovering between closed and open by little more than the thickness of a bit of paper.

and then I'd need to do the horrible Philips "transparent CD-thing with a straight line on it" to realign... so I don't pull it out.

Nah, when it comes down to it 'just busk it' as we used to say. Philips are nutz in their alignment procedures.

Take lots of pictures and lots of notes. Everything you do write down in numbered sequence.with all the little washers at specific places in the right order... which is a trap I'd fall into

- Home

- Source & Line

- Digital Source

- Phillips CD 204 skipping 3 years after rebuild