Hello Eucy,Thanks Christian... Very interesting... Did you ever get around to testing a dome??

Eucy

I think you mean an "Eucy's dome"? I remember I made tests some months ago but I have to say I don't remember exactly the results except at that time it didn't appear clearly as a solution. It was maybe with other materials, at least plywood. I should revisit my hard drive storage.

There is an other kind of dome which the "Steve's dome" where the central area is replaced by a stiffened material (tea bag) but it seems a full new area I don't want to go now.

Christian

This is certainly helpful in identifying the source! It seems to be related to changing boundary conditions at the exciter/plate interface.@EarthTonesElectronics

Hello Dave,

Here are measurements I prepared some time ago but I just did today. There might be interesting in the quest of the HF resonances.

I started from the situation of a DAEX25FHE glued on a 60x60cm (I know strange dimensions but it is before taking any decisions about how to size it) sheet of 9mm Depron (sort of XPS). This panel shows a huge peak at 12k (red curve)

As a countermeasure, I glued a 25mm thin aluminum disc at the exciter location (on the front side to avoid to remove the exciter).

Result the peak is still present but lower in frequency 8k and a loss of HF

View attachment 1471560 A bit disappointed because this countermeasure worked some months ago with an acrylic panel, I have removed the disc. The panel didn't return in its initial condition because while removing the alu disc, the glue removed also the skin of the Depron, the peak jumped to 9.5kHz

Then I applied the countermeasure recommended by Steve... a small piece of foam inserted in a maybe 2mm or less central hole. Magic! @spedge . Steve, I hope you'll be happy to see your advice applied!

View attachment 1471562

Here the original panel compared to the sponge countermeasure with the IR and a picture

View attachment 1471567

So I don't say there is no exciter breakup topic. Just to show what is the commonly encountered problem. There might be 2 topics in fact, the resonance of the central area occurring mainly with a light material and the voice coil breakup visible with a heavy material.

Christian

PS : all the measurements are gated at 5ms to reject the room.

PS2: I am wondering now what what would be the result thinning the central area... I remember Steve experimented it and I did so on my very first XPS panel. With the right profile, it could act as an acoustic black hole. Some constrained damping layer might be possible in addition...

Here are some simulations matching your experiments: blue line is basic exciter, orange line is with added mass at the exciter location (aluminum disc), yellow line is with the mass removed at the exciter location (e.g. cutting a hole in the panel). I don't think my model is complete yet, but I'm getting closer!

Good! I posted a follow up on the main thread : #14057 showing a test where the central areal was thinned and dampedThis is certainly helpful in identifying the source!

I have no experience with alu. Too heavy, too stiff. The heaviest material in my set is acrylic.It seems to be related to changing boundary conditions at the exciter/plate interface.

Here are some simulations matching your experiments: blue line is basic exciter, orange line is with added mass at the exciter location (aluminum disc), yellow line is with the mass removed at the exciter location (e.g. cutting a hole in the panel). I don't think my model is complete yet, but I'm getting closer!

On this topic of resonance in the 10kHz, the DIYer experiences are more from light panels like EPS. For them a very little mass or modification of the center change quickly the resonance.

My knowledge of your simulator is too low to fully understand "yellow line is with the mass removed at the exciter location (e.g. cutting a hole in the panel)" Making a hole removes mass yes but probably also decreases at the exciter ring the stiffness of the plate.

Some months ago, I made tests with a 2mm basswood ply. The goal was to find some countermeasure against the peak in the 3k range we see from the back of the panel. It was before understanding this peak is mainly due to the shape of the exciter. So as the supposed cause at this time was a resonance coming from the air trapped behind the panel in the voice coil area, I made tests with a hole of about the voice coil diameter in the panel. The measurements are below.

The upper blue curve is the panel without hole. This material doesn't suffer from an obvious peak.

Below green (highest peak) is with the hole. Pink is the same but with a kind of phase plug (a cylinder, in fact some pencil cap, In this case, the hole creates this huge 20k peak but the 3k peak from the rear side was not

For other materials like EPS, I have in mind that to remove the central disk of the plate stopped the HF extension. I am not sure to have evidence of that...

@EarthTonesElectronics

Dave, let me show you my on going tests and by that what I expect from the simulators.

@Veleric , should be interesting for you too.

After testing the central area effect on the HF, I decided to continue to what I have had in mind for weeks which is to see what is the effect of a skew edge (trapeze shape).

So I started from my 60x60cm sample

Then I resized it to a 30 top/42 bottom x 60 trapeze.

As the difference was not that important, I decided to test a 30x60... without paying attention it was a 1/2 ratio

An last I resized it to 24x60.

Below are the FR smoothed at 1/6 octave. The problem I want to point is visible but not that obvious. Do you see it?

Here are the spectrograms

Here are the spectrograms

60x60, not that bad

trapeze, it starts to be a bit long in the 500/600 Hz range

60x30. Horror! look at above 400 and 700Hz

60x30. Horror! look at above 400 and 700Hz

60x24, still some resonance but in the same magnitude as the trapeze

Up to that, I was in the idea to use the smoothness of the FR let say above 200Hz as a fitness indicator to classify the different designs. I don't have this figure for those measurements but it seems that the spectrogram view is much more sensitive.

All of that to say what I expect from a simulation is to be able to classify the designs in such a way. Of course it is not a big revelation to discard a 2:1 ratio. We have here "only" 4 variants. Where is the optimum, if there is one...

I add in my do list to test simulations of those panels. Not before next week.

Christian

Dave, let me show you my on going tests and by that what I expect from the simulators.

@Veleric , should be interesting for you too.

After testing the central area effect on the HF, I decided to continue to what I have had in mind for weeks which is to see what is the effect of a skew edge (trapeze shape).

So I started from my 60x60cm sample

Then I resized it to a 30 top/42 bottom x 60 trapeze.

As the difference was not that important, I decided to test a 30x60... without paying attention it was a 1/2 ratio

An last I resized it to 24x60.

Below are the FR smoothed at 1/6 octave. The problem I want to point is visible but not that obvious. Do you see it?

60x60, not that bad

trapeze, it starts to be a bit long in the 500/600 Hz range

60x24, still some resonance but in the same magnitude as the trapeze

Up to that, I was in the idea to use the smoothness of the FR let say above 200Hz as a fitness indicator to classify the different designs. I don't have this figure for those measurements but it seems that the spectrogram view is much more sensitive.

All of that to say what I expect from a simulation is to be able to classify the designs in such a way. Of course it is not a big revelation to discard a 2:1 ratio. We have here "only" 4 variants. Where is the optimum, if there is one...

I add in my do list to test simulations of those panels. Not before next week.

Christian

Christian

I assume these are free panels right? What are the suspension points? Are they EPS? And did you attempt to identify the elastic moduli?

Eric

I assume these are free panels right? What are the suspension points? Are they EPS? And did you attempt to identify the elastic moduli?

Eric

Christian,Of course it is not a big revelation to discard a 2:1 ratio.

No, it's not a big revelation. But it may still also possibly be misguided at the same time, at least in the case of a free panel. It's true that for a simply supported (and isotropic) panel, when the ratio of the side lengths is an integer multiple, there are more "coinciding" resonances than with non-integer ratio of side lengths. And it is reasonable to suggest that such overlapping resonances might result in more "ringing".

But I'm not so sure the same is true of a free panel (except for a 1:1 ratio!). As far as I can tell from my FEA models, there is nothing "special" about the resonances of free panels with side lengths with integer ratios. As an example, I just ran this model of a free panel with a 2:1 ratio. There's no coinciding resonances within the first 40 some frequencies. I suspect your FDM model will show similar results.

Eric

Yes they areChristian

I assume these are free panels right?

I use now one large ribbon of tape on the top part of the panel aligned on the exciter.What are the suspension points?

In the same test sequence, I removed the tape and made a measurement holding the exciter by the magnet. The FR was very similar to the one with the tape. So for now my conclusion is this tape method is very close to free edges conditions at least for the range above 150 to 200Hz.

It is not EPS, it is Depron which the brand name for sheets generally used for thermal isolation. It is an XPS made from a very thin foam. I am a bit surprised by the results which seem different from the XPS in thicker sheets (ie 20mm). The materials seem also different. In the article linked, it is written it is what is cardboard core.Are they EPS? And did you attempt to identify the elastic moduli?

Eric

Link to a wiki : Depron (FR), the article is in French.

I haven't measured the Young modulus for now.

The sheets are sold in 9mm or 6mm thick. This one is 9mm (measured 9.3mm). Density is 38.5kg/m³, so 0.35kg/m²

I have in my notes from some paper I found a 31kg/m³ XPS with E 20 to 40MPa and Poisson's coefficient 0.4 to 0.5. To be confirmed for Depron... Maybe I should make a tape test with a not too large sample to have the frequencies high enough.

With central tape : red, Hand held : blue

Central tape

Hand held

For sure your are right Eric... And what I wrote is wrong! It is not a simply supported panel. Thank you for the simulation.No, it's not a big revelation. But it may still also possibly be misguided at the same time, at least in the case of a free panel.

So a question comes... what is the cause of those resonances?

Maybe a side comment which is some weeks ago, I did about the same kind of tests with a 20mm thick sheet of EPS. I will try later fo find the measurements but it was the same global FR shape. Rather smooth (compare to other tests I made) and very suprising for me, with a low effect of the width on the bass roll off. The EPS sheet was cut from 80cm to 35cm with not that much change.

An other side comment is, for those light panel, it seems (to be confirmed) that adding the exciter with the effect of its spider stiffness pushes a resulting first mode above the second mode.

Christian,So a question comes... what is the cause of those resonances?

For me it is harder to explain why the other sizes don't have more obvious resonances.

Okay, XPS. In the English translation of the Wiki, I did not see any mention of cardboard.It is not EPS, it is Depron which the brand name for sheets generally used for thermal isolation. It is an XPS made from a very thin foam. I am a bit surprised by the results which seem different from the XPS in thicker sheets (ie 20mm). The materials seem also different. In the article linked, it is written it is what is cardboard core.

From the descriptions I found, it seems Depron is probably close to Owens Corning Foamular, the "pink" XPS foam common in US home improvement stores, except the pink foam is typically 14 mm thick (or more). That foam has a density around 40kg/m3 (so slightly higher than Depron). With tap testing I find a modulus of this Foamular to about 30 MPa in one direction and 60 MPa in the other, so your guess of 20-40 MPa for Depron is probably not far off. But don't be surprised if Depron is likewise anisotropic. Probably something like 30x40 cm would be ideal for tap testing, where the natural frequencies would start close to 50 Hz, so are easier to measure.

Did you see Bubbas leaf spring suspension? It could be another way to approach a "free-ish" suspension. Though I think it might be closer to free if he had made the support points to be the centers of the sides, instead of the corners.

Eric

Sorry, I made a mistake in the vocabulary.Okay, XPS. In the English translation of the Wiki, I did not see any mention of cardboard.

From the wiki link : Some plates for signage or any other graphic activity are coated with a smooth sheet such as “featherboard”.

I don't think "featherboard" is the right word. In French : carton plume or carton mousse. A few millimeter foam core with 2 paper skins. Popular in the art stores.

Interesting. The Depron has a shiny skin. It takes a porous aspect when sanded. It is the second material I tested starting with DML after a 20mm XPS (similar to the pink XPS). At that time I sanded it and apply PVA and I was very disappointed... no bass, no HF. Without sanding it, it might be interesting. The LF roll off is as expected and the HF extension not too bad. and in addition it is a light material.From the descriptions I found, it seems Depron is probably close to Owens Corning Foamular, the "pink" XPS foam common in US home improvement stores, except the pink foam is typically 14 mm thick (or more). That foam has a density around 40kg/m3 (so slightly higher than Depron). With tap testing I find a modulus of this Foamular to about 30 MPa in one direction and 60 MPa in the other, so your guess of 20-40 MPa for Depron is probably not far off. But don't be surprised if Depron is likewise anisotropic. Probably something like 30x40 cm would be ideal for tap testing, where the natural frequencies would start close to 50 Hz, so are easier to measure.

Yes I saw it. I am thinking to solutions with less additional mass to test the points at 10% (near the corners). From the very first simulation I ran with fixed points at mid edge, I am not convinced they are the best candidates for a free-isf panel. Maybe with some compliance or mass?Did you see Bubbas leaf spring suspension? It could be another way to approach a "free-ish" suspension. Though I think it might be closer to free if he had made the support points to be the centers of the sides, instead of the corners.

Christian

What was your evidence of that? Which modes are you considering to be "first" and "second"?An other side comment is, for those light panel, it seems (to be confirmed) that adding the exciter with the effect of its spider stiffness pushes a resulting first mode above the second mode.

Ah, I wondered if that was what they were referring to. We usually call that "posterboard". But your 9 mm Depron is without any paper skin, right?A few millimeter foam core with 2 paper skins. Popular in the art stores.

The shiny skin is common for XPS. It is normal during the extrusion process to blow cool air on the surface keep the surface from foaming as much and create a kind of skin.Interesting. The Depron has a shiny skin. It takes a porous aspect when sanded.

I guess the important question is this, what is actually the goal? To truly come as close as possible to a free panel (if so, why?), or perhaps to have something like a free panel, but better? What characteristic of the free panel is worth preserving? What not?Yes I saw it. I am thinking to solutions with less additional mass to test the points at 10% (near the corners). From the very first simulation I ran with fixed points at mid edge, I am not convinced they are the best candidates for a free-isf panel. Maybe with some compliance or mass?

Anything on the perimeter is likely to impact more modes, especially at the corners. But 10% inside might be far enough away to minimize that. What I found with foam at the midpoints of the sides was that the modes with the worst ringing seemed to be damped enough to stop much of the ringing. But likewise I am not convinced they are the best candidates. Just not the worst.

What I did like about Bubbas leaf springs is that they seem to provide some support for the mass of the panel (vertical stiffness) but with horizonal compliance. I don't know if the damping elements do any good or not. I do wonder though if the plastic "springs" also resonate, adding another problem area.

Eric

Eric

Didn't you mention that you had placed an aluminum disc at the exciter location to add mass and stiffness? That's what I did in my simulation - it was a thin acrylic panel with a small aluminum disc adding mass and stiffness at the exciter location.I have no experience with alu. Too heavy, too stiff. The heaviest material in my set is acrylic.

Yes I added a thin alu disc first on an acrylic panel some months ago and recently on the depron. When I said no experience with alu it is for a full alu plate which I understood maybe wrongly you use for tests.Didn't you mention that you had placed an aluminum disc at the exciter location to add mass and stiffness? That's what I did in my simulation - it was a thin acrylic panel with a small aluminum disc adding mass and stiffness at the exciter location.

This comes from the Python script. With the exciter model it is easy to modify the exciter mass and/or stiffness to come from an "ideal" exciter to a more real one. I will have deeper look next to that.What was your evidence of that? Which modes are you considering to be "first" and "second"?

Yes posterboard. My Depron is without paper.Ah, I wondered if that was what they were referring to. We usually call that "posterboard". But your 9 mm Depron is without any paper skin, right?

I see two possible axis. First is how the modes are spaced in the frequency range as already investigate for the simply supported plate. The second axis is the position of the anti-nodes on the plate which might play in the front and rear wave combination. On this second aspect we have for now few elements except that the simulation in a half space of a panel is too optimistic in the low to mid frequencies. The SPL we can measure in a room shows some bass roll off which is for an evidence of the dipole behavior, this is for long wavelength. When the wavelength in the mids come in the panel dimension, phase aspects should appear leading to additive and subtractive effect. A too regular location of nodes/antinodes might not help. Some chaos (remember one of the first article about DML) might be welcome.I guess the important question is this, what is actually the goal? To truly come as close as possible to a free panel (if so, why?), or perhaps to have something like a free panel, but better? What characteristic of the free panel is worth preserving? What not?

Hi Christian... I'd be interested in seeing your exciter model if you're agreeableThis comes from the Python script. With the exciter model it is easy to modify the exciter mass and/or stiffness to come from an "ideal" exciter to a more real one.

Eucy

For sure Eucy. No problemHi Christian... I'd be interested in seeing your exciter model if you're agreeable

I am preparing a new paper as a current status of the FDM for DML but it will need some days (weeks?) to post it. So here it is.

The diagram below is the electro-mechanical model I use.

Re, Le, BL, cms, rms, mmc are the exciter model while Zm is the panel.

Re is the DC resistance of the exciter

Le is the increase of the impedance on the electrical side due to the coil inductance, the eddy currents. I made the choice of the Wright model. It would be better to speak of a ZLe = kr * w^xr + j * ki * w^xi, w = 2*pi*f. This model is not physical in the way it doesn't come from the physics of the impedance increase. It is more a kind of heuristic that fit very well to the measurements.

H7 and H8 are the generator to model the Laplace force. In some papers (ie Dave's ones), it is modeled with a transformer. The key point is the voltage of H7 (right side) is the mechanical force = BL * i, BL force factor of the exciter, i the current through H8 (left side) and the voltage across H8 (left) is the electromagnetic voltage due to the speed of the coil which is in this model the current through H7 on the right. So fem = v/BL

Then come cms, the exciter compliance and mmc the mobile mass of the exciter which constant (frequency independent)

rms models the damping in the exciter (spider). rms is a variant of the Thorborg model with rms = rv * (1 + (2*pi*fv/w)^(nv+1)). The idea behind is to increase the damping below a certain frequency to model the visco-elastic behavior of the spider.

For a DAEX25FHE, I have currently:

- BL = 3.65Tm, Re = 4.35Ohm

- mmc = 1.25g, cms = 0.43mm/N

- rv = 0.041 Ns/m, fv = 190Hz, nv = 1

- kr = 0.0001, xr = 0.87, ki = 0.0007, xi = 0.8

Those values come from a curve fitting on impedance curves of real exciters with different added masses.

This remind me I started to update the exciter sheet based on the measurements from Eric, but it is not posted...

The key words to find papers on this topic are Wright, Thorborg, Novak

Christian

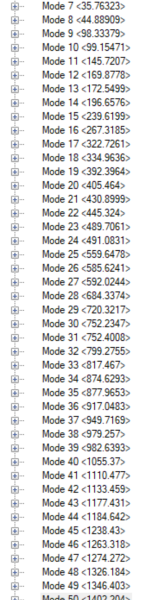

Here are some new velocity results using my updated exciter model with the coupling stiffness resonance that causes the peak in output at high frequencies.

My model seems to be about as complete as a non-FEM can get, so I'm planning to release a new PETTaLS version soon that includes these phenomena. I've measured these velocities for a number of exciter models and the basic structure seems to work well for all exciters.

Some design takeaways that might be helpful:

My model seems to be about as complete as a non-FEM can get, so I'm planning to release a new PETTaLS version soon that includes these phenomena. I've measured these velocities for a number of exciter models and the basic structure seems to work well for all exciters.

Some design takeaways that might be helpful:

- This is not a "drum mode" - I've also included the trapped air in my model, though. The specific driver above is completely vented, so there's no trapped air, and the coupling resonance effects are clearly visible.

- The coupling resonance is primarily a factor related to the exciter, not to the plate.

- The specific way that the coupling resonance affects the output depends on where it is relative to the nodes introduced by the coupler ring/disc shape. I'm hypothesizing that a way to mitigate this resonance is to cancel it out with ring shape nodes, which sometimes involves adding mass and sometimes involves subtracting mass, depending on the specific material. I don't have much evidence to support this right now, though, other than just playing around with numbers in the simulations and some of the measurements given in earlier posts.

- This resonance introduces a very sharp low-pass cutoff, and effectively defines the bandwidth of the exciter, regardless of the plate material.

Excellent Dave.This resonance introduces a very sharp low-pass cutoff, and effectively defines the bandwidth of the exciter, regardless of the plate material.

Have you identified the component of this coupling resonance? Something linked to the voice coil structure?

- Home

- Loudspeakers

- Full Range

- PETTaLS Flat Panel Speaker Simulation Software