Babowana said:Hi, all, again

I just launched out on house building

Choky might already say, ugly!

Talented freaks might feel no taste

Anyhow, cutting and gluing is going on

🙂

preliminary ugly!

Zen Mod said:preliminary ugly!

flg said:Very good Babowana😀 My favorite Holiday Hobby😀 Particularly nice heat sinks too😀

Thanks, I'm encouraged

kicking accelerator 😀

Babowana said:

The LED current value corrected

Babo.

Thanks for some test data of your BLUE LED

See this diagram ( LED turn-on Voltage ~2.6V ):

http://www.diyaudio.com/forums/attachment.php?s=&postid=1075032&stamp=1165471685

I might have use for this knowledge, some time.

Can of course be some variations of data for different brands Blue Led.

But some thing like 2.5-2.8V it may be.

christmas

lineup

Hi all

I did one thing that experts never recommend.

Let's see the attached picture. Do you see it?

Before I tell you what it is . . .

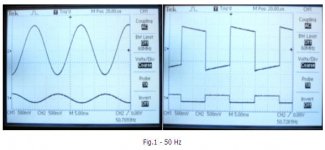

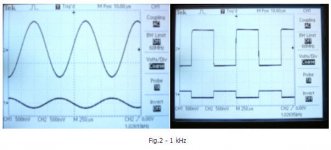

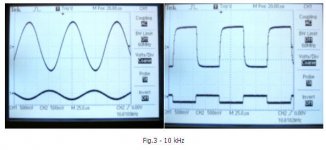

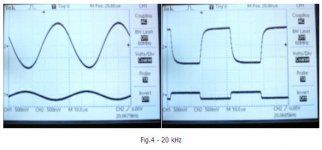

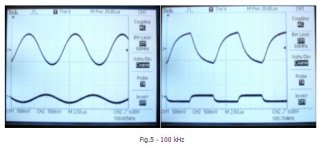

I had listening and oscilloscope tests.

From the tests, I can't detect any trouble, with luck . . .

The oscillopscope test results will follow (probably 6 posts) 🙂

I did one thing that experts never recommend.

Let's see the attached picture. Do you see it?

Before I tell you what it is . . .

I had listening and oscilloscope tests.

From the tests, I can't detect any trouble, with luck . . .

The oscillopscope test results will follow (probably 6 posts) 🙂

Attachments

Zen Mod said:are your ears pleased?

As I have ever said, yes.

During the tests, I see quite much of distortion.

2nd harmonics due to the unmatching complementary pair

of IRFP250N and IRFP9240.

Nevertheless, the sound is quite mine 🙂

Any special reason of asking?

Babowana said:I did one thing that experts never recommend.

You didn't get a proper carpenter to fit your floor? Those gaps between the planks are way too big. 😉

pinkmouse said:You didn't get a proper carpenter to fit your floor? Those gaps between the planks are way too big. 😉

Ha ha ha . . .

I gave up.

Quality control? Quality assurance?

I really have nothing to do about it

The gaps between the planks are still ok, but the gaps through the windows . . . My ZV5 helps some . . . 😀

PS. My place is a rental service apartment priced way overly.

Babowana said:

As I have ever said, yes.

During the tests, I see quite much of distortion.

2nd harmonics due to the unmatching complementary pair

of IRFP250N and IRFP9240.

Nevertheless, the sound is quite mine 🙂

Any special reason of asking?

I have no complains and I wouldn't tell you anything you doesn't know already-looking on those CRO pics.......

just one thing-why you didn't make that box as a tower,with htsnks on tower sides?

in that case wires can be shorter,and you can have one piece amp,instead of 3 piece jobie 😉

Zen Mod said:just one thing-why you didn't make that box as a tower,with htsnks on tower sides?

in that case wires can be shorter,and you can have one piece amp,instead of 3 piece jobie 😉

Thanks for the idea of the tower.

I agree with you that it would have been much better.

I will consider practicing it in the near future 😉

I started this ZV5 without any organized plan.

And, I had some problem in getting materials for boxes,

with language barrier here in this Great China.

So, I just bought the wood panels from Ikea,

cut them to the sizes, collected PSU components and

bolted them onto the panels.

I found the heat sink and ordered to cut it to the sizes of

estimated heat capacity, and bolted MOSFETs on them.

After all wire arrangement, tested the sound,

got wonderful sound, and wanted to finish this project,

completing the housing of the PSU body.

Now, I arrived to the current shape 🙂

If I try to force myself into finding one thing good with the three

pieces, it would be that the closed box can have low operating

temp of almost room temperature - longer life of elec capacitors.

Babowana said:

...................................

heatsinks left and right ,mounted on box (in the middle)

they have enough clearance from your nice wooden floor to have 'nuff air

terminals on the back

led on front

if you are not satisfied with this solution,you can always send hardware to me .......snks will be good used,box I can use for parts storage ..........

Attachments

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Papa! I want to have Zen V5.