Hey Brandon! Good to hear from you!I'm using a 6" (6.78" with the driver flange) with the T25B and MW16TX, and it integrates really well. I'll do one for the T34B also. Since my goal is matching directivity and acoustic center for the intended woofers (nominal 6.5"), I don't design around the aesthetic aspect. You start giving up too much utility.

Any news on the speaker family with your waveguides?

Cheers!

Kind of slowed at the moment with school and work. I may take some vacation soon and build the final design and start working on a crossover.

Great! Life always gets in the middle of our hobby!Kind of slowed at the moment with school and work. I may take some vacation soon and build the final design and start working on a crossover.

Good luck and thanks for sharing your work!

You may consider doing something like what I did to get a true 6.5in from the elliptic waveguide. I changed the outer to a circle so that I could route easier and mate as close as possible to my midrange driver. iirc I took the 5in and set my outer to 5.25in, could have easily done 5in.Brandon. Is it possible to obtain real 6.5" Waveguide for Bliesma T34B? I've downloaded file "6.5x1.1 83 A T34 v2 stl.zip" but unfortunately it's 7.28" waveguide 🙁

Unfortunately I'm visualizer. And what's worse, speakers have to be accepted by my wife too because speakers will be installed in our sitting-room. I'm thinking about carving your "6.5x1.1 83 A T34 v2" waveguide directly in MDF. It looks good on visualization if driver flange is removed. But I don't know if carpenter will be able to do it on CNC machine using stl/step file. I have to ask him.

Nice. In which software have you modifed stl model?I changed the outer to a circle...

Hi jaakkopetteri,

The impact of doing this is shown in post #409 of the thread in the German forum (here the advantage of having no surrounding, i.e. the dome membrane close to the WG-throat and post #464 showing the impact of 'steps' from 1mm to 5mm when fitting a real world dome tweeter with a surrounding to the WG-throat.

Feel free to come back with questions, I'll be happy to check the old simulations if helpful. I might need some days to answer though.

Sorry for replyng that late. Fluid is right, i.e. I did theses simulations using ABEC and used conditions quite comparable to what fluid is suggesting for simulating with AKABAK:Here's the SB26 in an infinite baffle (no wg for simplicity), first with a source directly routed to a radiator linked to the BEM driver and then with a source-resistance-elecdyndriver-radiator model, the elec-dyn driver being grounded, enclosured and filled with SB26 T/S parameters. Comparing the results to those of Gaga here it seems like I should achieve something between my results 😅 Any ideas?

I definitely used acceleration to drive the diaphragm, i.e. no LEM-part. Only half the surround was driven (although with 100%) the outer half of the surround was not driven at all. I think Fluids method refines the model and I'd recommend to use it as suggested.

Dome Tweeter

The dome-tweeter is usually modeled with the front diaphragm only. The rear of the dome is regarded as part of the speaker and its effects are part of the TS-parameters (see also component Speaker).

So I would take out the enclosure and just fill in the Elec-Dyn Driver parts.

Simulating with constant acceleration is usually good enough when you are really looking at the directivity of the diaphragm and waveguide.

AKABAK defaults to constant velocity so it needs to be changed to have a falling not rising response.

This what I have been using to simulate Dome tweeters with constant acceleration.

Different amplification for the different parts and weight as Divide by jw.

I'd second that as well. From my simulations I learned, that very important topics during alignement of a dome to a waveguide are to (i) bring the throat close to the surrounding, (ii) check the width of the surrounding and add a short step with a height around the width of the surrounding.As far as I am concerned the important thing to simulate is, does the dome and surround shape work in the waveguide.

The impact of doing this is shown in post #409 of the thread in the German forum (here the advantage of having no surrounding, i.e. the dome membrane close to the WG-throat and post #464 showing the impact of 'steps' from 1mm to 5mm when fitting a real world dome tweeter with a surrounding to the WG-throat.

Feel free to come back with questions, I'll be happy to check the old simulations if helpful. I might need some days to answer though.

Was there a 6.5" round guide for the SB29RDAC?

What was the nicest response 6.5" round SB fabric combo?

What was the nicest response 6.5" round SB fabric combo?

I remember this has been asked before in this thread, but may I once again kindly ask for DXT stepped waveguide simulation and experiments? More practical information provided by member Gaga here:https://www.diyaudio.com/community/threads/dxt-wave-guide-dimensions.334739/

Hello fluid, Thanks. I am aware of those. Strickly speaking I would wish for a DXT printing file for the Vifa XT25 ringradiator.

Consider this a Dear Santa etc etc. thing..

Consider this a Dear Santa etc etc. thing..

I remember this has been asked before in this thread, but may I once again kindly ask for DXT stepped waveguide simulation and experiments? More practical information provided by member Gaga here:https://www.diyaudio.com/community/threads/dxt-wave-guide-dimensions.334739/

Is the drawing in that post accurate? I could try to make that and see how it measures. You probably won't have much luck simulating a fabric ring radiator, but I do have a Scanspeak ring radiator on hand to measure.

Was there a 6.5" round guide for the SB29RDAC?

What was the nicest response 6.5" round SB fabric combo?

I didn't have much luck with the SB29 early on, but should probably circle back to it. If I design something, I'll post the .stl and you can try it out.

I take it the drawing below is accurate, but do not have the exact opening size for the the XT at hand (some 32 mm??). If you could brew someting on the basis of the Scan Ringradiator diaphragm size , I 'd be very,very grateful Santa Brandon...

Attachments

Hi Boden,

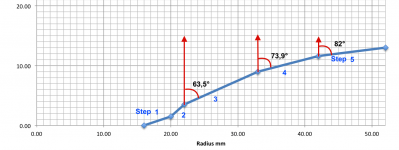

For your convenience the numbers used for the xls-figure:

D/2 = half diameter

H = height

Same numbers as applied for the xls figure you posted above with adjutsed x- and y- axis values.

Please note that the DXT waveguide has been optimized fot the applied dome tweeter (see impact of step 1 on the directivity here).

Using the Vifa XT25 ringradiator for the DXT-profile might change the directivity at high freququnecies. Might be seen by a respective simulation and adaptd accordingly. You'll be on the safe side if you use the dome tweeter used by seas (information available somewhere, just don't have it at hands actually).

Good luck and please post the results in case you proceed with the project....

For your convenience the numbers used for the xls-figure:

D/2 = half diameter

H = height

Same numbers as applied for the xls figure you posted above with adjutsed x- and y- axis values.

Please note that the DXT waveguide has been optimized fot the applied dome tweeter (see impact of step 1 on the directivity here).

Using the Vifa XT25 ringradiator for the DXT-profile might change the directivity at high freququnecies. Might be seen by a respective simulation and adaptd accordingly. You'll be on the safe side if you use the dome tweeter used by seas (information available somewhere, just don't have it at hands actually).

Good luck and please post the results in case you proceed with the project....

Update! I'll post results over the next few days as I progress. This post will be all SB Acoustics: SB26ADC, SB21SDC, and SB29SDAC. I also will have results for the CSS LD22, Dayton RST28 A & F, and SB19ST over the next few days.

I just tried to upload the RST28 STL file to JLCPCB and it thinks the WG is super tiny, any idea what I am doing wrong?

I just tried to upload the RST28 STL file to JLCPCB and it thinks the WG is super tiny, any idea what I am doing wrong?

When I open up one of the STL files in Ultimaker Cura I scale it up 2540% (25.4mm = 1 inch). However, I have not actually printed one, so I don't know if that is exactly what you need to do or not.

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!