My first thought was to print an inner shell aswell however it would consume a bunch of filament and it would also take quite som time to print the 4 inner shells that would go with my 4 outer shells so my idea now is to just print a top part for each outer shell and then fill each side with epoxy one at a time and just let gravity level it off for me, seems the cheapest and easiest option right now. Another thought i hade was to maybe carve out an inner mass out of styrofoam or whatever you call it , the stuff they use when shipping stuff - hopefully cheap, and then just carve it out when done if the epoxy sticks to it

edit: Would just like to also add, since you are worried about delamination which i guess you mena the pla shell not sticking to the Epoxy, according to my brother who actually did his chemical engineering masters degree thesis in a related area (they were researching different polymers) epoxy and PLA do form chemical crosslinks so it should stick on the molecular level, ypu could increase this bonding by controlling the temperature when it's setting in precise ways but that seems a bit overkill for this application, delamination shouldn't be a problem though in theory i guess

edit: Would just like to also add, since you are worried about delamination which i guess you mena the pla shell not sticking to the Epoxy, according to my brother who actually did his chemical engineering masters degree thesis in a related area (they were researching different polymers) epoxy and PLA do form chemical crosslinks so it should stick on the molecular level, ypu could increase this bonding by controlling the temperature when it's setting in precise ways but that seems a bit overkill for this application, delamination shouldn't be a problem though in theory i guess

Last edited:

Hello! Did you get chance to measure it?I have it printed, just haven't had time with school and work.

Which printer do you get?Well... I ended up ordering the biggest 3d printer I could find for a reasonable price ...

Looks pretty good! I have a Creality with about 30x30x40cm which is fine for the moment but to print a complete front baffle that 10cm more would be great!

Have you stopped this project?This is my current testing with VituixCad for my 2 way using Hypex FA122, B&C 8NDL51 and SB26ADC in 8" waveguide. Not perfect but getting there. Crossover 1.2khz LR 4th, the SB is one robust tweeter. I'm really enjoying listening in mono, its going to be strange going back to stereo once both are built.

Yes, parts for sale in the marketplace. I bought a set of Genelec 8350's instead.... not very DIY of me!

Impressive work! I'm very thankful for your effort for non-professionals to use your modeling.

Following your thread, I think you have made a circular version of sb26adc waveguide but didn't posted it(only image of it). What I can find on your website is only ellipse versions.

I do know that ellipse versions have higher potential especially on the vertical dispersion, but still if it doesn't bother you much, would it be possible that you post your pre-designed circular version as well?

Specifically I hope I could get the 5" no ps version, but anything would be just fine.

For days I tried to do it by myself, but for a dumb like me modeling through mathmatics is extreamly challenging.. 🙁

Thanks

Following your thread, I think you have made a circular version of sb26adc waveguide but didn't posted it(only image of it). What I can find on your website is only ellipse versions.

I do know that ellipse versions have higher potential especially on the vertical dispersion, but still if it doesn't bother you much, would it be possible that you post your pre-designed circular version as well?

Specifically I hope I could get the 5" no ps version, but anything would be just fine.

For days I tried to do it by myself, but for a dumb like me modeling through mathmatics is extreamly challenging.. 🙁

Thanks

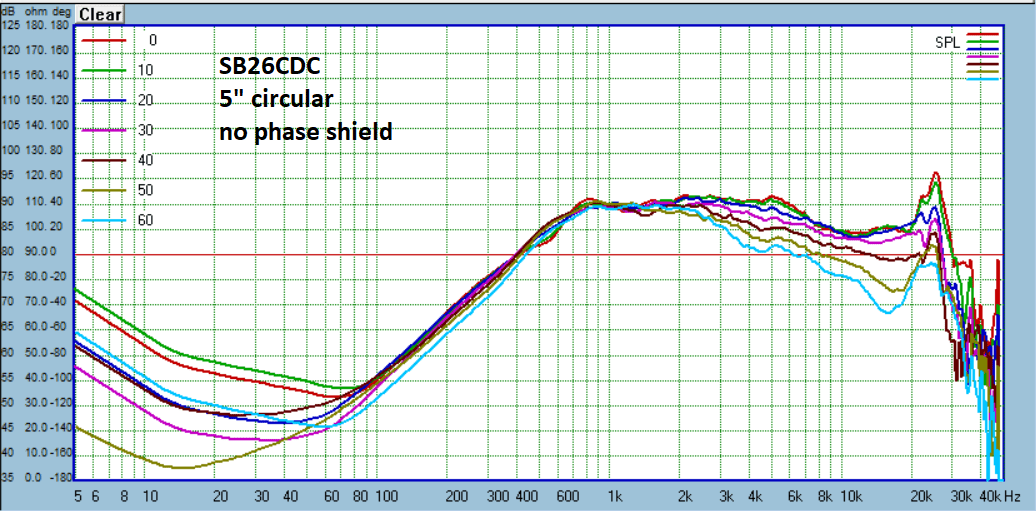

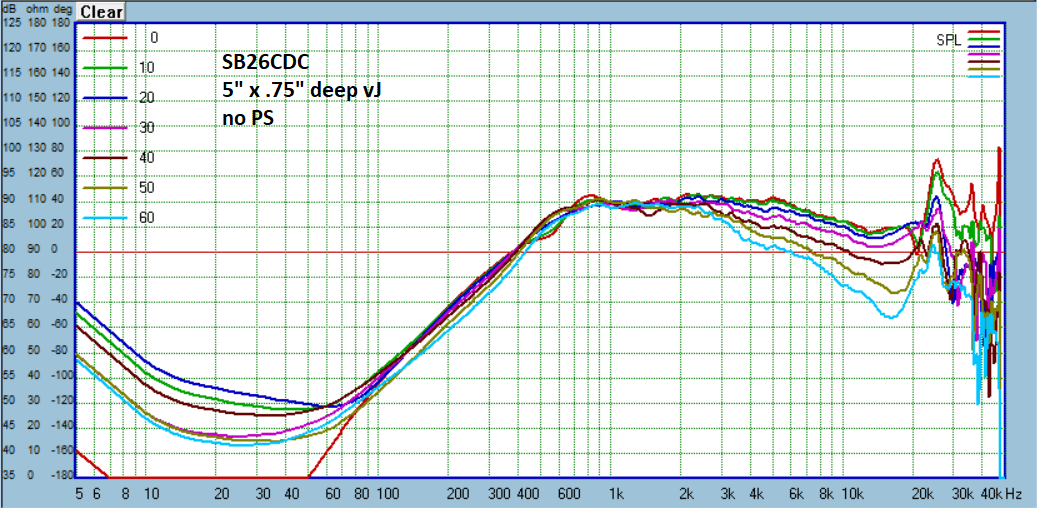

Here is the 5" circular guide. the contour is the same as the elliptical in its horizontal axis, so just a round version of the elliptical.

I'm no expert, but I would imagine the air impedance loading would be much different in a circular waveguide, compared to an oval waveguide with the save X-axis profile.That's interesting - I would have expected a more even radiation in all directions of a circular version vs. oval but not a worse frequency response?

And THANK YOU for your great work and contribution to the DIY world!

Yes, exactly. Works well for such simple prototyping and bigger models. But I'm just a beginner in printing - I'm sure with some tuning you could get significant better results as I am.

I would look at the new Creality K1 Max if you really need a bigger printer. I'm really really tempted to buy the K1 to replace one of my Ender 3 Pros.

K1 Max is the printer I would have liked to buy 2 years ago - looks great! But not bigger ...

CR-M4 would allow to print complete smaller front baffles before doing proper CNC from wood.

CR-M4 would allow to print complete smaller front baffles before doing proper CNC from wood.

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!