OK, first print is underway! I'll post photos this afternoon if all goes well.

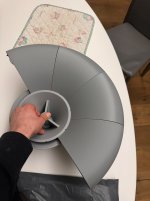

First print done without a hitch. Printed in Overture plain black PLA on a Flashforge Adventurer 5M, sliced in OrcaSlicer with mostly default settings but with an additional perimieter layer, using 15% triangle infill and tree supports. It took 4 hours 34 minutes. I used the tree supports because the way Orca laid out normal supports completely buried the phase shield and I was not sure I would have been able to remove the supports without breaking the spokes of the shield.

There is a little ripple in one spot (more noticeable in the photo than to the eye), some fuzz on the phase shield spokes, and the edge is rough where the tree supports attached, but I think it's quite serviceable. The idea to print on edge worked well, kudos to Joel for that.

It's going to take me a while to get to building cabinets for these. I'm afraid to look at the prce of decent sheet lumber these days!

Going to experiment with Fuzzy Skin! It might produce a more consistent textured surface -several settings available to produce various levels of fuzziness

Working on drawing desktop speakers with a waveguide and will experiment with a fuzzy surface

Working on drawing desktop speakers with a waveguide and will experiment with a fuzzy surface

I was directed to this thread from here regarding possibly matching a WO24P-4 / Paper with a SB26ADC-C000-4 and a Soma Sonus waveguide.

There seems to be many waveguide options available, but I'm completely clueless to which one suits this configuration best. I realise all information is probably buried in this 122-page thread somewhere...?

Could someone kindly point me to either the right product or a relevant post / site that doesn't require a Physics PhD for correct interpretation?

There seems to be many waveguide options available, but I'm completely clueless to which one suits this configuration best. I realise all information is probably buried in this 122-page thread somewhere...?

Could someone kindly point me to either the right product or a relevant post / site that doesn't require a Physics PhD for correct interpretation?

You will need the 8inch waveguide, I don't remember if it is circular or elliptical, but if you can chose, go with the elliptical in order to have closer distance between woofer and tweeter.

You can download it from somasonus website.

You can download it from somasonus website.

wondering how this filament will work. Iso alcohol smooth the surface

https://ca.polymaker.com/products/polysmooth?variant=44585343516990

https://ca.polymaker.com/products/polysmooth?variant=44585343516990

@Joel Wesseling

If you haven't tried yet, this is an example for the settings.

Green middle

0.2mm

Fuzzy skin Cura

Thickness 0.2mm

Density 10.0

The 2 others are 0.16mm slow print

If you haven't tried yet, this is an example for the settings.

Green middle

0.2mm

Fuzzy skin Cura

Thickness 0.2mm

Density 10.0

The 2 others are 0.16mm slow print

Never tried this one but I have a lot of filaments from Polymaker and for me the quality is good.wondering how this filament will work. Iso alcohol smooth the surface

https://ca.polymaker.com/products/polysmooth?variant=44585343516990

What happens if I cut waveguide for a woofer to be as close as possible to tweeter? Something like this:

If you want to try something like arendal, you should look at what hole size, what spacing of holes and what structure you want or should use. You will probably need to create some test versions and experiment with the percentage of open holes, etc. A very exciting idea in itself

I printed a pair with fuzzy skin - Point distance = 0.5mm

Thickness = 0.1mm

The layer lines are completely buried in the texture..

No supports except for build plate and printed horizontal.

Filament is Bambu Lab PLA Basic Jade White

Thickness = 0.1mm

The layer lines are completely buried in the texture..

No supports except for build plate and printed horizontal.

Filament is Bambu Lab PLA Basic Jade White

Attachments

0.4 mm nozzle?I printed a pair with fuzzy skin - Point distance = 0.5mm

Thickness = 0.1mm

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!