I fixed the switches and joined the pins. On my floppy the motor

only starts after I insert and remove something into the photo

interrupter. I see the same device on your board but as you say

every floppy is different. Is it possible to run the motor without

the logic board or is the main chip involved in the operation?

only starts after I insert and remove something into the photo

interrupter. I see the same device on your board but as you say

every floppy is different. Is it possible to run the motor without

the logic board or is the main chip involved in the operation?

hi guys

i now have some recordings MP3 of the floppy drive motor on a turntable so you can check the sound out

i dont think i can upload to DIY forum so....just email me if you want to hear it

also i have done a before and after recording of what differance an arm rewire makes if any1 wants to hear just email me

i have made some various pully sizes from plastic if any 1 needs some

best wishes

j7

audioorigami@gmail.com

i now have some recordings MP3 of the floppy drive motor on a turntable so you can check the sound out

i dont think i can upload to DIY forum so....just email me if you want to hear it

also i have done a before and after recording of what differance an arm rewire makes if any1 wants to hear just email me

i have made some various pully sizes from plastic if any 1 needs some

best wishes

j7

audioorigami@gmail.com

hi

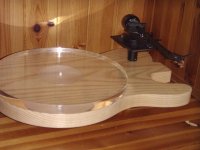

you have what i call the inverted type floppy ...with just the spindal sticking out ...this will make a fine motor for turntable

u need to use this end to mount a pully on ...u will need flaten the surface or pull of the existing pully ...to help mount your new 33/45rpm pully

you have what i call the inverted type floppy ...with just the spindal sticking out ...this will make a fine motor for turntable

u need to use this end to mount a pully on ...u will need flaten the surface or pull of the existing pully ...to help mount your new 33/45rpm pully

the long awaited part 3 is now ready

http://www.audioorigami.co.uk/FloppyProject/FloppyDIYMotor3.htm

thanks for your suport

best wishes j7

http://www.audioorigami.co.uk/FloppyProject/FloppyDIYMotor3.htm

thanks for your suport

best wishes j7

Attachments

that would be part 2.

http://www.audioorigami.co.uk/FloppyProject/FloppyDIYMotor2.htm

I found this 800ohm resistor inline to the motor controller…

(by jumpering each resistor with a 1000ohm resistor to see if any speed change was possible)

Each floppy will be different…so if you want to try varying the speed you will need spend a few minutes checking

😉

http://www.audioorigami.co.uk/FloppyProject/FloppyDIYMotor2.htm

I found this 800ohm resistor inline to the motor controller…

(by jumpering each resistor with a 1000ohm resistor to see if any speed change was possible)

Each floppy will be different…so if you want to try varying the speed you will need spend a few minutes checking

😉

hi

also raiseing the hieght of the magnet with a thin shim changes the speed....

finding what resistor changes the speed can be made easy by...

i wet my finger and put over the resistors to find out what resistor changes the speed fast

hope that helps

best wishes

j7

also raiseing the hieght of the magnet with a thin shim changes the speed....

finding what resistor changes the speed can be made easy by...

i wet my finger and put over the resistors to find out what resistor changes the speed fast

hope that helps

best wishes

j7

OK!

Thanks, I will try the finger trick 🙂 I am really anxious to get my DIY TT going 🙂 Audiorigami; do you have any pulleys that would be suitable for use with a linn lp12 subplatter? How much would it cost me? Thanks yet again!

Thanks, I will try the finger trick 🙂 I am really anxious to get my DIY TT going 🙂 Audiorigami; do you have any pulleys that would be suitable for use with a linn lp12 subplatter? How much would it cost me? Thanks yet again!

i wet my finger and put over the resistors to find out what resistor changes the speed fast

Clever.

postpunk

u can make tempory pullys from plastic easy with a electric drill....the final size will take a few attempts round about 16-18mm should be a good starting point

hope that helps

j7

u can make tempory pullys from plastic easy with a electric drill....the final size will take a few attempts round about 16-18mm should be a good starting point

hope that helps

j7

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- New EASY DIY brushless motor