2 X floppy motors

Fantastic idea.

I have a turntable that uses 2 AC motors. Would it be possible to replace them with 2 floppy motors.

I have avoided DC so far because, as I understand it, it is impossible to synchronise 2 of them them as well as the AC ones. Any thoughts? 🙂

Fantastic idea.

I have a turntable that uses 2 AC motors. Would it be possible to replace them with 2 floppy motors.

I have avoided DC so far because, as I understand it, it is impossible to synchronise 2 of them them as well as the AC ones. Any thoughts? 🙂

HI PIX

YES YOU ARE CORRECT ABOUT MORE POLES AFECTING THE SPEED

the floppy magnet allready has many poles...the dvd drive will be the same ...the magnet is manufacterd with the poles ready made so to speak

if u look on my web site ..on the about us page..you will see i built my own high speed motors and use the amount of magnets to vary the speed and ampage draw- as well as a varable speed controler

the control chip on the floppy already has a crystal to set the timing

i have spent a lot of time on brushless...the floppy is the beast thats been undiscoverd,

we should stick to 1 type if we want to move forward to other motors later on ...high speed motors make a lot of noise

HI Iain

yes i think 2 the same floppys will work no problem

YES YOU ARE CORRECT ABOUT MORE POLES AFECTING THE SPEED

the floppy magnet allready has many poles...the dvd drive will be the same ...the magnet is manufacterd with the poles ready made so to speak

if u look on my web site ..on the about us page..you will see i built my own high speed motors and use the amount of magnets to vary the speed and ampage draw- as well as a varable speed controler

the control chip on the floppy already has a crystal to set the timing

i have spent a lot of time on brushless...the floppy is the beast thats been undiscoverd,

we should stick to 1 type if we want to move forward to other motors later on ...high speed motors make a lot of noise

HI Iain

yes i think 2 the same floppys will work no problem

You could listen to it as it spins up and passes through 500 rpm. Maybe it would be quiet enough.

its a toruqe thing the high speed hard drive units are meant to spin fast...im not sure you would have a better "slow" unit(at least without rewireing them)...and u have the hasttle on building a controller....althoght it may well be better in the end

even the floppy hits extra noise i have found at differant RPMs with the vary speed pot in place

more details to follow on this weekend ....

best wishes

j7

even the floppy hits extra noise i have found at differant RPMs with the vary speed pot in place

more details to follow on this weekend ....

best wishes

j7

Is it even possible to just add a pot to controll speed? A google search indicates that it is not.

http://www.epanorama.net/circuits/diskstepper.html

http://www.epanorama.net/circuits/diskstepper.html

postpunk said:Is it even possible to just add a pot to controll speed? A google search indicates that it is not.

http://www.epanorama.net/circuits/diskstepper.html

It's not the stepper motor, but the three-phase drive motor for the floppy, which normally runs at 360 rpm. I've used these myself, but I only used the motor as a 3-phase synchronous motor by building a simple 3-phase oscillator and using three low-power drive amplifiers, one for each phase, driving the stator in a 'delta' configuration.

Ouroborus -

can you post, or send me any details about your oscillator and amplifier? I'm working on a project just like what you did.

can you post, or send me any details about your oscillator and amplifier? I'm working on a project just like what you did.

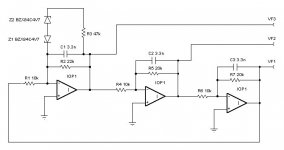

This is the type of 3-phase sine-wave oscillator I use. I've set the frequency to give 33rpm on my turntable, so you'll need to alter the value of the 10k resistors (and perhaps the capacitors) to get the correct frequency for you.

I run ordinary LF351 op-amps on +/6V, which also feeds the three power amps. Any low voltage audio power amps that will supply about 6V pk-pk at a current of 300mA or so will do.

If you dismantle the floppy drive, you'll find the rotor just pulls off. It's fairly easy to trace the three winding connections to the flexible ribbon. Simply connect the output of each amp to one of the stator wires. If the motor rotates the wrong way, swop over any two of the connections.

I run ordinary LF351 op-amps on +/6V, which also feeds the three power amps. Any low voltage audio power amps that will supply about 6V pk-pk at a current of 300mA or so will do.

If you dismantle the floppy drive, you'll find the rotor just pulls off. It's fairly easy to trace the three winding connections to the flexible ribbon. Simply connect the output of each amp to one of the stator wires. If the motor rotates the wrong way, swop over any two of the connections.

Attachments

Perfect, thanks. That's exactly what I need. I've already pulled my motor apart, traced the windings, etc.

okay part 2 of the Easy DIY floppy conversion should be uploaded shortly on my site tonight

www.audioorigami.co.uk

it shows the basic unit in a test bed...has two pulleys and or easy vary speed control

total time for the diy job from a basic of the shelf floppy is 1-3 hrs work depending on the model of floppy u use,...every floppy is different...so its best,if you can get a few of the same.

u can interchange pullys...compare/experiment etc

the pure 4volt cell phone battery and charger supply is the main concept in this simple design...i need some help to design a EASY battery charger cut-off circuit ...if any 1 has any information on a cheap and easy system please let us know

best wishes for now

j7

www.audioorigami.co.uk

it shows the basic unit in a test bed...has two pulleys and or easy vary speed control

total time for the diy job from a basic of the shelf floppy is 1-3 hrs work depending on the model of floppy u use,...every floppy is different...so its best,if you can get a few of the same.

u can interchange pullys...compare/experiment etc

the pure 4volt cell phone battery and charger supply is the main concept in this simple design...i need some help to design a EASY battery charger cut-off circuit ...if any 1 has any information on a cheap and easy system please let us know

best wishes for now

j7

Cell phone battery chargers in particular are very very easy. Especially if it's the battery from YOUR old phone...

Use the charger that came with the phone. Especially easy if your charger has a spot for charging a spare battery...slap it on the charger! 😀 This should be available for minimal cost from loads of sources if you can't get one from the manufacturer.

/edit:

I should have mentioned that these chargers may not be optimal for the type of battery in question... battery university says that most cell phone manufacturers will allow their batteries to be charged in a way that may shorten their life because people go through cell phones within a year or two, and battery longevity is not so much of a concern. Of course, replacement batteries are also to be had, so...

Use the charger that came with the phone. Especially easy if your charger has a spot for charging a spare battery...slap it on the charger! 😀 This should be available for minimal cost from loads of sources if you can't get one from the manufacturer.

/edit:

I should have mentioned that these chargers may not be optimal for the type of battery in question... battery university says that most cell phone manufacturers will allow their batteries to be charged in a way that may shorten their life because people go through cell phones within a year or two, and battery longevity is not so much of a concern. Of course, replacement batteries are also to be had, so...

Don't forget that if you have any small stepper motors with fairly coarse steps (say 10 degrees per step), then you can drive these as a synchronous motor with a two-phase (quadrature) pair of sine waves.

Most steppers seem to have fine steps of 1.8 degrees per step, and I've found that you can't get these to rotate fast enough to use as belt-drive turntable drive motors.

Most steppers seem to have fine steps of 1.8 degrees per step, and I've found that you can't get these to rotate fast enough to use as belt-drive turntable drive motors.

Anyone tried to use one on their turntable and report results?

Such motor should eliminate hum if battery powered.

Tom

Such motor should eliminate hum if battery powered.

Tom

i got 1 up and running in my test bed turntable ...sounds silent

i have been busy making little pullys...so hopefully ill have more spair time soon

will post more details in part 3 hopefully this weekend

i have been busy making little pullys...so hopefully ill have more spair time soon

will post more details in part 3 hopefully this weekend

yea a kit is no problem

what would be helpfull if people posted the inner pully and motor pully sizes...and i could work a little data base of models and floppy pully sizes..

i think proviosionally that the linn/thorns type units will be almost the same pulllys as standard

also with a couple of the same floppy units u can have different pullys mounted for 33 and 45 78 or 16 ...the whole magnet and pully just pull of...its fantastic

what would be helpfull if people posted the inner pully and motor pully sizes...and i could work a little data base of models and floppy pully sizes..

i think proviosionally that the linn/thorns type units will be almost the same pulllys as standard

also with a couple of the same floppy units u can have different pullys mounted for 33 and 45 78 or 16 ...the whole magnet and pully just pull of...its fantastic

There is a photo interrupter that needs a pulse to start the

motor, have you found a way to skip this step?

motor, have you found a way to skip this step?

eric

you just need to cheat 1 or 2 of the mechanical switches the floppy hits when you insert it

and join pin 12 to 11

and pins 16 to 15

its that simple...check the photos on my site

there is no photo interupter needed ..(i think you mean for the floppy heads to move?)

every motor is different so you need to open a few to pick the easy 1 to mod

best wishes

j7

you just need to cheat 1 or 2 of the mechanical switches the floppy hits when you insert it

and join pin 12 to 11

and pins 16 to 15

its that simple...check the photos on my site

there is no photo interupter needed ..(i think you mean for the floppy heads to move?)

every motor is different so you need to open a few to pick the easy 1 to mod

best wishes

j7

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- New EASY DIY brushless motor