Probably not if it's teak or mahogany. I also wonder about the mass vs cart problem, though shure carts can be fitted with stiffer styli. Anything using God's carbon fibre (wood) is ok by me (retired carpenter)

Nice turntable by the way.

Nice turntable by the way.

Last edited:

I like so many aspects of your design. I assume the heavier weight of this arm is compatible with the shures compliance?

Love the look of the raw wood, perhaps clear low sheen varnish? Yeah I found the headshell a nuisance to start with, but I'm sure you'll find a way to make it work. Overall look is very pleasing to the eye.

The Shure M44-7 is only a 'learner' cartridge, being used for testing. I will eventually use a Denon 103 or a Decca London Super Gold.

The arm tube and headshell assembly weighs 25.33 grams. The end of the headshell needs to be trimmed by a couple of centimetres, so that will most likely reduce the weight by 3 to 4 grams.

Finally begun my tonearm. Have no photos yet. Using materials on hand, I am attempting to copy the SAEC 8000 ST headshell and using the same arm geometry.

What weight should I aim for on my headshell minus the Cart and Screws? I am going to try with a Sumiko Pearl or something similar as I have many carts from my Technics and Kenwood tables.

There is so much information on this thread now... its amazing. Thanks all.

What weight should I aim for on my headshell minus the Cart and Screws? I am going to try with a Sumiko Pearl or something similar as I have many carts from my Technics and Kenwood tables.

There is so much information on this thread now... its amazing. Thanks all.

What weight should I aim for on my headshell minus the Cart and Screws? I am going to try with a Sumiko Pearl or something similar as I have many carts from my Technics and Kenwood tables.

How those photos coming Mortron?

Sorry I have no answer for you on the head shell weight, I just followed Stews recommendation to leave 3" past the pivot for my counter weight adjustment.

Anyone done anything like this ?

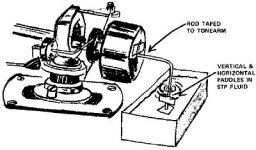

Tonearm Damping Article By Bob Graham The BAS Speaker Volume 3 No. 4, January 1995

Not sure I can see the need myself, my arm tracks warped records beautifully!

Attachments

How those photos coming Mortron?

Sorry I have no answer for you on the head shell weight, I just followed Stews recommendation to leave 3" past the pivot for my counter weight adjustment.

Anyone done anything like this ?

Tonearm Damping Article By Bob Graham The BAS Speaker Volume 3 No. 4, January 1995

Not sure I can see the need myself, my arm tracks warped records beautifully!

Had a bit of a health setback and getting a small scale has also put a slow on the project.

Once i know the weight i am considering will work, i will be able to put it all together. I want to see if i will benefit from drilling anything out to save weight etc. I am most nervous my headshell idea will fail. Mounting my pivot cup will be the next major hurdle... a dowel inside would be great but want to be able to fish the female part out to reuse should i need to. I was considering something inside the arm tube to make it solid, then threading into that a screw from the top of the arm with a female bearing on the end that would sit inside the arm. I know....pictures :lol:

So far i have just used materials on hand or given to me... so its likely a $2.19 cost could be a realistic ballpark.

For anyone considering this arm, as time passes, you will come into materials that you can use and one day, you can just start turning all them bits into something exciting.

The Wand

The Wand.. I wonder where the inspiration for this came from

Design Build Listen, home of The Wand Tonearm and DIY Hi Fi components 😱

The Wand.. I wonder where the inspiration for this came from

Design Build Listen, home of The Wand Tonearm and DIY Hi Fi components 😱

and on a Dual idler to boot!

jls,

looks great. I'm sure it sounds great, but cannot compare to it as I use aluminum arrow shafts exclusively.

I've pondered the need for a diy-able tonearm lift for some time. The simplest would be a wooden disc screwed to an upright. It must be mounted off-centre with a machine screw and nut. The disc will need a rod long enough to reach the arm at the end of a record.

jls,

looks great. I'm sure it sounds great, but cannot compare to it as I use aluminum arrow shafts exclusively.

I've pondered the need for a diy-able tonearm lift for some time. The simplest would be a wooden disc screwed to an upright. It must be mounted off-centre with a machine screw and nut. The disc will need a rod long enough to reach the arm at the end of a record.

Hi Stew,

Do you have a drawing of the arm lift? Will it lift and drop vertically without going in an arc? The lift I made goes in an arc and dropping the stylus to a desired groove position is at best an imprecise operation. Not acceptable, so I removed it.

Do you have a drawing of the arm lift? Will it lift and drop vertically without going in an arc? The lift I made goes in an arc and dropping the stylus to a desired groove position is at best an imprecise operation. Not acceptable, so I removed it.

jls001,

Very nice job on that arm. Check out post 307 in this link for a DIY arm lift possibility.

http://www.diyaudio.com/forums/analogue-source/13372-diy-schroeder-tonearm-31.html

Very nice job on that arm. Check out post 307 in this link for a DIY arm lift possibility.

http://www.diyaudio.com/forums/analogue-source/13372-diy-schroeder-tonearm-31.html

jls001,

Very nice job on that arm. Check out post 307 in this link for a DIY arm lift possibility.

http://www.diyaudio.com/forums/analogue-source/13372-diy-schroeder-tonearm-31.html

Thanks so much, Doug. I think that picture on post #307 is enough to set me off on a truly DIY armlift. I will attempt it and report back🙂

I have only recently seen this thread but have been suitably enthused by the DIY tonearms on here.

My brother in law, who is a top rank design engineer, is putting together a new design of linear tracker we have thought up but more in keeping with my simple mind, I thought I'd have a go at yours.

Early days as I'm still waiting for the wiring kit but the basics are done. The arm tube is from some kitchen drawer supports, the weight is an old Garrard SP25 model. The arm lift WILL work when I sort it out and I've had it tracking at just under a gramme quite happily but will probably not be secure enough at that weight. I expected there to be more instability but it looked rock solid. Can't wait to get it working.

I'll pretty up the woodwork when I know it all works.

My brother in law, who is a top rank design engineer, is putting together a new design of linear tracker we have thought up but more in keeping with my simple mind, I thought I'd have a go at yours.

Early days as I'm still waiting for the wiring kit but the basics are done. The arm tube is from some kitchen drawer supports, the weight is an old Garrard SP25 model. The arm lift WILL work when I sort it out and I've had it tracking at just under a gramme quite happily but will probably not be secure enough at that weight. I expected there to be more instability but it looked rock solid. Can't wait to get it working.

I'll pretty up the woodwork when I know it all works.

An externally hosted image should be here but it was not working when we last tested it.

gus 3049,

Do you have pictures of your linear tracker? When you are ready please start a thread of your linear tracker tonearm.

Do you have pictures of your linear tracker? When you are ready please start a thread of your linear tracker tonearm.

gus 3049,

Do you have pictures of your linear tracker? When you are ready please start a thread of your linear tracker tonearm.

Hi,

That will depend on my brother in law. As it's, as far as we can see, an original idea, he feels it may have commercial potential.

I am not too convinced about it but will bow to his judgement. So there are two things involved, possibly the most important being that the thing actually works🙂

Prototype for arm lift:

The black barrel is from a pen cap🙂

From another angle:

Yet another angle:

The cam:

The cam from a different angle:

The picture below is the shaft for vertical lift. The spring is a mess. I first tried a spring of a much thicker gauge and found that it literally sprung when released. So I tried a much thinner and softer one, much like the one found in ball pens, enlarged the diameter gradually till it fit the shaft. The drop is now much gentler, but I'm yet to try it out on the arm. I hope it works with at least some amount of damping.

In the pic below, the shaft is narrowed on the left so that it fits the hole on the narrow end of the barrel. This acts as a guide so that the shaft doesn't have unnecessary play. Note the two nuts on the other end. The larger is filed to snugly fit the inner diameter of the barrel. Together with the hole at the other end, this also serves as guide to the shaft and avoids play in horizontal plane.

There is about 2.5 mm of movement when the arm is lifted/dropped. I thought that it is quite less, and was sorely tempted to try and extend the cam lip (as is done on some arm lifts). Then I measured the actual vertical travel of a Rega arm lift - it moves just about the same distance. I think this will be enough to leverage a clean lift off at the cartridge end.

The lift lever is from a bicycle spoke. It's much too heavy so I've replaced it with bamboo.

The hole for inserting the lift lever is at the wrong angle. That's the reason why there is one unnecessary right angle bend. I'll have to drill another cross to the current hole.

Any suggestions on how this may be improved further (especially improved damping)?

The black barrel is from a pen cap🙂

From another angle:

Yet another angle:

The cam:

The cam from a different angle:

The picture below is the shaft for vertical lift. The spring is a mess. I first tried a spring of a much thicker gauge and found that it literally sprung when released. So I tried a much thinner and softer one, much like the one found in ball pens, enlarged the diameter gradually till it fit the shaft. The drop is now much gentler, but I'm yet to try it out on the arm. I hope it works with at least some amount of damping.

In the pic below, the shaft is narrowed on the left so that it fits the hole on the narrow end of the barrel. This acts as a guide so that the shaft doesn't have unnecessary play. Note the two nuts on the other end. The larger is filed to snugly fit the inner diameter of the barrel. Together with the hole at the other end, this also serves as guide to the shaft and avoids play in horizontal plane.

There is about 2.5 mm of movement when the arm is lifted/dropped. I thought that it is quite less, and was sorely tempted to try and extend the cam lip (as is done on some arm lifts). Then I measured the actual vertical travel of a Rega arm lift - it moves just about the same distance. I think this will be enough to leverage a clean lift off at the cartridge end.

The lift lever is from a bicycle spoke. It's much too heavy so I've replaced it with bamboo.

The hole for inserting the lift lever is at the wrong angle. That's the reason why there is one unnecessary right angle bend. I'll have to drill another cross to the current hole.

Any suggestions on how this may be improved further (especially improved damping)?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- my latest iteration of "Nanook's 219 tonearm"..