thanks Chris - i think ill rub my chin and scratch my head a bit more before i decide between unipivot or SME venture.

Sorry for the first of several dumb questions:

How are you guys cleaning the ink out of the ballpoint pen?

A google search only turns up ways to get ink stains out of clothing....

How are you guys cleaning the ink out of the ballpoint pen?

A google search only turns up ways to get ink stains out of clothing....

removing ink...

penkosey: just cut the refill down or pull the nib off and clean it out using 99% rubbing alcohol and a tooth pick.

DL1000V: plenty good enough for a base. Nothing else is really required.

penkosey: just cut the refill down or pull the nib off and clean it out using 99% rubbing alcohol and a tooth pick.

DL1000V: plenty good enough for a base. Nothing else is really required.

Thanks for the response! I have read this extensive thread and saw that it was suggested to use a solvent to clean the pen--I just didn't know if that would melt the plastic or something, and wasn't sure what to clean it with.

I was wondering about actually cutting the entire pen to the desired size and using it as-is for the pivot holder, since it would be pretty solid. But then I was looking at the plastic cone at the end where the ballpoint sticks out, and wonder if the plastic edge (where the ballpoint tube assembly comes out) might bump or interfere with the set screw.

I'll try to consolidate the other questions I have when I get a chance, so as not to clutter this thread too much.

.

I was wondering about actually cutting the entire pen to the desired size and using it as-is for the pivot holder, since it would be pretty solid. But then I was looking at the plastic cone at the end where the ballpoint sticks out, and wonder if the plastic edge (where the ballpoint tube assembly comes out) might bump or interfere with the set screw.

I'll try to consolidate the other questions I have when I get a chance, so as not to clutter this thread too much.

.

Nobody building tonearms anymore?

Well, I do!

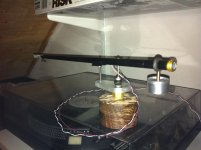

Made a neat solition for the counterweight en pulled some wires in the arm. Still puzzling what the armbase will be.....🙄

I'm progressing........slowly

Well, I do!

Made a neat solition for the counterweight en pulled some wires in the arm. Still puzzling what the armbase will be.....🙄

I'm progressing........slowly

Attachments

penkosey

The actual pen refill is not used (unless it has a metal tube), just the "nib" or ball point and ballpoint holder (on almost all "real" pens these are metal, but some like the ubiquitous BIC and Paper Mates "write bros" stick pens use plastic, these should not be used). If the only suitable thing you can get has a metal "nib", but a plastic tube then it will need to be attached to a piece of metal. The metal nibs are typically maybe a cm or so long.

You could use the pen, but the tube needs to be metal, as above. Then cut the body of the pen shorter by a cm or so , so that the nib end is at least 1 cm from the pen body itself.

dl1000v:

Thanks for the response! I have read this extensive thread and saw that it was suggested to use a solvent to clean the pen--I just didn't know if that would melt the plastic or something, and wasn't sure what to clean it with.

The actual pen refill is not used (unless it has a metal tube), just the "nib" or ball point and ballpoint holder (on almost all "real" pens these are metal, but some like the ubiquitous BIC and Paper Mates "write bros" stick pens use plastic, these should not be used). If the only suitable thing you can get has a metal "nib", but a plastic tube then it will need to be attached to a piece of metal. The metal nibs are typically maybe a cm or so long.

I was wondering about actually cutting the entire pen to the desired size and using it as-is for the pivot holder, since it would be pretty solid. But then I was looking at the plastic cone at the end where the ballpoint sticks out, and wonder if the plastic edge (where the ballpoint tube assembly comes out) might bump or interfere with the set screw.

You could use the pen, but the tube needs to be metal, as above. Then cut the body of the pen shorter by a cm or so , so that the nib end is at least 1 cm from the pen body itself.

Don't worry about cluttering this thread. I know it is a little long and some details get lost.I'll try to consolidate the other questions I have when I get a chance, so as not to clutter this thread too much.

dl1000v:

What you have looks good. The bigger issue is whether or not you want to attach the armboard to the existing turntable or have it free-standing. It seems like many go for a free-standing mount instead of an armboard.Well, I do!

Made a neat solition for the counterweight and pulled some wires in the arm. Still puzzling what the armbase will be.....🙄

I'm progressing........slowly

HI Stew,

In your opinion Which is the best protractor to set up a 12" uni pivot arm with, Iv'e read a little bit about 3 point protractors, (as opposed to a 2 point) but have not found any practical info on them. Do you have any info that might help to make one?

I will over the winter be building a new 319 unipivot using a Bakelite 1.1/4" dis tube that I will cut & shape down to a hexagonal or possibly 5 sided taper ! very retro as a homage to Alfons Mucha.

Lots of details to sort out Not least how to glue or bond Bakelite ?????? Anyone?

In your opinion Which is the best protractor to set up a 12" uni pivot arm with, Iv'e read a little bit about 3 point protractors, (as opposed to a 2 point) but have not found any practical info on them. Do you have any info that might help to make one?

I will over the winter be building a new 319 unipivot using a Bakelite 1.1/4" dis tube that I will cut & shape down to a hexagonal or possibly 5 sided taper ! very retro as a homage to Alfons Mucha.

Lots of details to sort out Not least how to glue or bond Bakelite ?????? Anyone?

protractor

I think that Conrad Hoffman's arc protractors work very well and you can make one specifically for the length of your tone am. For me, it seems that no matter how well I think I have the two points aligned there is still variation along the arc. You can download his arc generator at Vinyl Engine or at least you could when I got mine. It's free. YMMV

Steve

I think that Conrad Hoffman's arc protractors work very well and you can make one specifically for the length of your tone am. For me, it seems that no matter how well I think I have the two points aligned there is still variation along the arc. You can download his arc generator at Vinyl Engine or at least you could when I got mine. It's free. YMMV

Steve

HI Stew,

In your opinion Which is the best protractor to set up a 12" uni pivot arm with, Iv'e read a little bit about 3 point protractors, (as opposed to a 2 point) but have not found any practical info on them. Do you have any info that might help to make one?

I will over the winter be building a new 319 unipivot using a Bakelite 1.1/4" dis tube that I will cut & shape down to a hexagonal or possibly 5 sided taper ! very retro as a homage to Alfons Mucha.

Lots of details to sort out Not least how to glue or bond Bakelite ?????? Anyone?

gluing bakelite

HI Stew,

In your opinion Which is the best protractor to set up a 12" uni pivot arm with, Iv'e read a little bit about 3 point protractors, (as opposed to a 2 point) but have not found any practical info on them. Do you have any info that might help to make one?

I will over the winter be building a new 319 unipivot using a Bakelite 1.1/4" dis tube that I will cut & shape down to a hexagonal or possibly 5 sided taper ! very retro as a homage to Alfons Mucha.

Lots of details to sort out Not least how to glue or bond Bakelite ?????? Anyone?

3-point protractor? If two points are right any point would be right...

Regards

I agree!

However, if that's wrong, then I need to go back to school, because I must have missed a major concept in geometery.

😕

Best Regards,

TerryO

gluing bakelite, and cartridge alignment

Jay,

319?

Er 2 point vs. 3point? or do you mean a single point vs. the locations for 2 null points? Either can work as long as you are accurate.

As far as a protractor goes, I just use a single point type. I align at 66mm from the centre of the spindle. I just plunk the arm down, and move it around on its own base until I get proper alignment. If you were fixing the arm to a specific mounting distance, with a specific overhang, I would use the geometry from an existing design. For example, I think I was initially using the SEAC WE8000 effective length of 306 mm (O/H= 13mm, O/S= 18°), because it is one of the few arms that had a geometry where the O/H was a whole number measurement (13.0mm vs something like 15.2mm) as well as the O/S being measured in whole degrees (18° vs 17.3 °). This is one of the reasons that I left so much up to the end user/maker. It all depends on the dimension from stylus tip to the pivot (which must be measured accurately!). And it must be measured using your cartridge mounted for the effective length. I could draw up a protractor with your exact dimensions and provide you with the distances from the centre of the platter spindle if that might be helpful.

Be careful (as in a prudent amount of caution) so that you do not ruin the Bakelite. Once sanded it cannot be added to if you over-sand any part of it. As far as glue goes it is very tough as Bakelite is a thermoset plastic. I have a little kit that I bought called "Bondic". It is a UV curing resin that comes with the glue and the correct light to set the glue in 5-15 secs (depends on how thick you apply the glue. Problem is that it might not work with Bakelite, but should. Do a search for repairing Bakelite radios. There are a ton of links.

HI Stew,

In your opinion Which is the best protractor to set up a 12" uni pivot arm with, Iv'e read a little bit about 3 point protractors, (as opposed to a 2 point) but have not found any practical info on them. Do you have any info that might help to make one?

Jay,

319?

Er 2 point vs. 3point? or do you mean a single point vs. the locations for 2 null points? Either can work as long as you are accurate.

As far as a protractor goes, I just use a single point type. I align at 66mm from the centre of the spindle. I just plunk the arm down, and move it around on its own base until I get proper alignment. If you were fixing the arm to a specific mounting distance, with a specific overhang, I would use the geometry from an existing design. For example, I think I was initially using the SEAC WE8000 effective length of 306 mm (O/H= 13mm, O/S= 18°), because it is one of the few arms that had a geometry where the O/H was a whole number measurement (13.0mm vs something like 15.2mm) as well as the O/S being measured in whole degrees (18° vs 17.3 °). This is one of the reasons that I left so much up to the end user/maker. It all depends on the dimension from stylus tip to the pivot (which must be measured accurately!). And it must be measured using your cartridge mounted for the effective length. I could draw up a protractor with your exact dimensions and provide you with the distances from the centre of the platter spindle if that might be helpful.

I will over the winter be building a new 319 unipivot using a Bakelite 1.1/4" dis tube that I will cut & shape down to a hexagonal or possibly 5 sided taper ! very retro as a homage to Alfons Mucha.

Lots of details to sort out Not least how to glue or bond Bakelite ?????? Anyone?

Be careful (as in a prudent amount of caution) so that you do not ruin the Bakelite. Once sanded it cannot be added to if you over-sand any part of it. As far as glue goes it is very tough as Bakelite is a thermoset plastic. I have a little kit that I bought called "Bondic". It is a UV curing resin that comes with the glue and the correct light to set the glue in 5-15 secs (depends on how thick you apply the glue. Problem is that it might not work with Bakelite, but should. Do a search for repairing Bakelite radios. There are a ton of links.

Last edited:

To fix or not to fix..... The armbase. Well, due to the lack of space on my Technics TT, and the possibilty to use it on a renovated Lenco L75. I opt for a free standing armbase. The height adjustment for on or beside the deck will be the trick. And an armlift is still spooking around my brain, i refuse to make to make a good sounding tonearm out of spare and by an armlift for €50. Not my style!

Keep on the good work, Mark

Keep on the good work, Mark

Latest Version

Hi Everyone

Been a bit quiet of late-lots to do at work and in the house-I hate replacing silicone sealant in a shower!

Here are some pics of my latest arm. Let me know what you think.

Regards

Chris

Hi Everyone

Been a bit quiet of late-lots to do at work and in the house-I hate replacing silicone sealant in a shower!

Here are some pics of my latest arm. Let me know what you think.

Regards

Chris

Attachments

9 inch variant ? any ideas ?

Hi Folks ,

Went back reading this thread .. so many projects .. so little time 😉

Thanks for all the great reading stuff so far . now here my question :

I'm having a bunch of very delicate high compliant MM / MI carts here that would realy benefit from as low as arm mass as reasonably possible .

Any ideas about a 9 inch convert ? please chime in 😉

TIA

Paul

Hi Folks ,

Went back reading this thread .. so many projects .. so little time 😉

Thanks for all the great reading stuff so far . now here my question :

I'm having a bunch of very delicate high compliant MM / MI carts here that would realy benefit from as low as arm mass as reasonably possible .

Any ideas about a 9 inch convert ? please chime in 😉

TIA

Paul

Hi Paul

not sure what you mean by a '9 inch convert'? With my arms I've not had any problems with either MM or MC

Chris

not sure what you mean by a '9 inch convert'? With my arms I've not had any problems with either MM or MC

Chris

Hi Chris ,

Well , I was thinking about using the same design as per Nanook's .. but just a shorter arm tube in order to lower the effective arm mass , making it a better match for high compliant carts .

Cheers ,

Paul

Well , I was thinking about using the same design as per Nanook's .. but just a shorter arm tube in order to lower the effective arm mass , making it a better match for high compliant carts .

Cheers ,

Paul

Hi Chris ,

Well , I was thinking about using the same design as per Nanook's .. but just a shorter arm tube in order to lower the effective arm mass , making it a better match for high compliant carts .

Cheers ,

Paul

I can't see the problem Paul. Just shorten the rod and balance it with a somewhat lighter couterweight...

Regards

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- my latest iteration of "Nanook's 219 tonearm"..