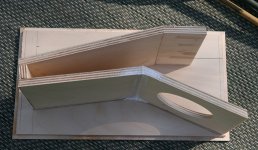

Karlsonator "8" progress, slow but steady!! I can not wait to hear these😀

Looks great! Keep plugging away you are close.

Mctavish and Prezden:

Don't forget to line the inside surfaces adjacent to driver with open cell foam or felt, or similar padding to prevent back reflections from showing up at cone and causing cancelation dips. Also, I find lining the front chamber behind the wing (and wing itself) with felt improves the HF sound and imaging. I find that disposable mop head pads (Swifter) when double layered work well in front chamber. Can be cut to size and hot melt glued in place.

Don't forget to line the inside surfaces adjacent to driver with open cell foam or felt, or similar padding to prevent back reflections from showing up at cone and causing cancelation dips. Also, I find lining the front chamber behind the wing (and wing itself) with felt improves the HF sound and imaging. I find that disposable mop head pads (Swifter) when double layered work well in front chamber. Can be cut to size and hot melt glued in place.

put some fluffed polyfil in the section above the rear of the driver - the front chamber might not need much treatment - - that's a very stout and nice build.

Mctavish and Prezden:

Don't forget to line the inside surfaces adjacent to driver with open cell foam or felt, or similar padding to prevent back reflections from showing up at cone and causing cancelation dips. Also, I find lining the front chamber behind the wing (and wing itself) with felt improves the HF sound and imaging. I find that disposable mop head pads (Swifter) when double layered work well in front chamber. Can be cut to size and hot melt glued in place.

Swifter pads huh? 😀 I think that is pretty similar to the disposable shipping blanket material I used in my mini Karlsonators.

Yeah, it will improve HF sound and imaging, but if you get carried away with it they will start to sound lifeless. The drivers Mctavish is using would normally require a contour filter for flat-ish response. In this case the felt lining and k-chamber will do this job, so the drivers are probably going to be fine direct wired. There is some room to play. With Prezden's TC9FD, I'd be a little more conservative with the felt in the front chamber.

I don't think a mini-Karlsonator will ever image as well as a direct radiator with a well radiused baffle and clean recessed installation, but they have some redeeming qualities, in my incredibly biased opionion. 😉 (namely, bigger and more effortless sound, no need for BSC, etc)

BTW, I agree with Freddi's suggestion for polyfill in the little stub behind and above the driver only, the rest of the chamber around the driver is better with carpet pad or thick felt only, at least it was with my setup.

This was my initial damping scheme. I think I ended up adding a bit more felt on the sides, extending it to the back.

Note that there is also felt on the internal divider just behind the driver.

Note that there is also felt on the internal divider just behind the driver.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Hello again,

Most of these Karlsonator designs are working with 3" or 3,5" drivers. Would they work with 4" driver, such as this TB W4-657SC? I have a pair in hand I bought second hand, and I'm currently juggling idea what I should do with these. Other possibility is active monitors with some tweeter taking the top end and PLLXO before the amplifiers. Maybe even Karlsonator active monitors with tweeter... 😀

Datasheet

Most of these Karlsonator designs are working with 3" or 3,5" drivers. Would they work with 4" driver, such as this TB W4-657SC? I have a pair in hand I bought second hand, and I'm currently juggling idea what I should do with these. Other possibility is active monitors with some tweeter taking the top end and PLLXO before the amplifiers. Maybe even Karlsonator active monitors with tweeter... 😀

Datasheet

Last edited:

Got a few pounds of acousti-stuff for the spaces behind the drivers in the "wedge", and some 8mm felt for the inside as well as the front wings...

I also have some 6mm cork sheets for flush-ing the driver. I decided to do it this way in case I wanna switch out the Seas for the FE203En-S...

More pics tomorrow!😀

I also have some 6mm cork sheets for flush-ing the driver. I decided to do it this way in case I wanna switch out the Seas for the FE203En-S...

More pics tomorrow!😀

This was my initial damping scheme. I think I ended up adding a bit more felt on the sides, extending it to the back.

Note that there is also felt on the internal divider just behind the driver.

Looks really nice. That felt may need a second layer in the driver chamber right behind driver and on the bottom.

Looks really nice. That felt may need a second layer in the driver chamber right behind driver and on the bottom.

Good call. That is in fact what I did. I prefer to start with minimal stuffing and add as needed.

Got a few pounds of acousti-stuff for the spaces behind the drivers in the "wedge", and some 8mm felt for the inside as well as the front wings...

I also have some 6mm cork sheets for flush-ing the driver. I decided to do it this way in case I wanna switch out the Seas for the FE203En-S...

More pics tomorrow!😀

A few pounds!! 😕 You may find that is just a bit more than you need... 😉 I'd guesstimate you'll need only around a couple ounces (50-60g) per box, so I guess you'll have plenty leftover for that giant TL sub you always wanted... 😀😉

GregB,

I forgot to ask you what size miniK you are building and what driver you will be using?

I'm not building any new mini K. The photo is of the pair I built for Markaudio CHR70's a few months back.

post #649

Good call. That is in fact what I did. I prefer to start with minimal stuffing and add as needed.

A few pounds!! 😕 You may find that is just a bit more than you need... 😉 I'd guesstimate you'll need only around a couple ounces (50-60g) per box, so I guess you'll have plenty leftover for that giant TL sub you always wanted... 😀😉

I only meant I have a few pounds on hand, never hurts to have a bit extra🙂

More pics; next comes the felt dampening, some more bracing, and the 6mm cork sheets to flush-mount the drivers...

oh yeah, and sanding, sanding, some more sanding, the front wings, lacquer of about ten coats, ect. ........😀

Attachments

Lot's of builds going on - hope to hear first sound from you guys soon. Nice work there Mctavish.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs