Hey X- I've got a pair of TB W3-881SJF drivers. Would I need to adjust the 0.04X dimensions or can I go with the straight re-sizing.

cheers

Prezden,

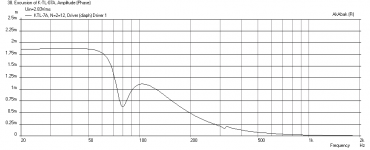

The W3-881SJF sims very nicely in a 0.4x in height and depth and 0.33x in width. However, the 0.5mm xmax may be an issue if you want to listen to it above 1 watt. I am not sure what the x_mechanical (damage) is, I have to imagine it is several mm. I would not let the xmax issue dissuade you and try it. You can always put another driver in place later or use it within its limits. It should sound real nice though.

X

Attachments

Is this to actual scale?

Yes it is to scale. However, lots of things can go wrong with digital images. It should be fine if you downloaded it directly from my google gallery 'Stupid Hifi Tricks'. Download is available under the 'More' in the menu. If you got it somewhere else, it might not be to scale. Make sure you print it at 100% with no scaling. Even so, printers will usually distort the dimensions a little bit, so default to the specified dimensions.

The black and white stripe on the left of the drawing is there in order to verify scale. Each segment represents one inch, and should measure 1/4" on the print.

https://plus.google.com/u/0/photos/...5680514503473417410&oid=100545049816297868412

So I'll hold off on printing to size, Kinkos.

IN the mean time getting ready to crunch the numbers

based on X's optimization.

I had to tweak the x-over somewhat.

cap was 3.9uF and inductor .41 mH.

for a 6db slope at the 4000 Hz with the

crossover being hi pass only 12db/octive.

Close enought for government work I found

some 3.75 uf 50V caps and

390 uf coilcraft inductors, which I had saved

from the dumpster some 20 years ago.

Moving forward:

+peerless driver ----------+3.75cap-(minus)----+tweeter

..peerless driver .................................390uH.tweeter

- peerless driver...........................................-tweeter

There is one peerless driver and one tweeter per cabinet.

Not the 390uH is connected across the tweeter.

The peerless runs free to over 5k Hz then falls off,

the TN46 Focal tweeter is wired in through the

cross over and inductor.

IN the mean time getting ready to crunch the numbers

based on X's optimization.

I had to tweak the x-over somewhat.

cap was 3.9uF and inductor .41 mH.

for a 6db slope at the 4000 Hz with the

crossover being hi pass only 12db/octive.

Close enought for government work I found

some 3.75 uf 50V caps and

390 uf coilcraft inductors, which I had saved

from the dumpster some 20 years ago.

Moving forward:

+peerless driver ----------+3.75cap-(minus)----+tweeter

..peerless driver .................................390uH.tweeter

- peerless driver...........................................-tweeter

There is one peerless driver and one tweeter per cabinet.

Not the 390uH is connected across the tweeter.

The peerless runs free to over 5k Hz then falls off,

the TN46 Focal tweeter is wired in through the

cross over and inductor.

Hi X,

I'm trying to figure out how to draw up my front panels before

I cut them.

I'm about 1/2 way laying out the everything on the white panels before I start cutting on them. Will have to sharpen op and exacto blade...

like you. ; )

It's okay, though if you sharpen them yourself, the end up a lot better

than out of the box. The same thing with the box cutter blades.

Anyway, how do I adjust your formula for my box. I'm doing the

.6 hight and depth, .4 width.

Now, I'm not sure how to plot the nine sets of plots...x 2,, or more.

Also what function are you using?

I thought the Karlson was conic section type slot,

from a parabala or something, then split down the middle

separated by the 1/4 and folded over (one for each side).

Any way I appreciates eveyrones ideas and help.

I'm trying to figure out how to draw up my front panels before

I cut them.

I'm about 1/2 way laying out the everything on the white panels before I start cutting on them. Will have to sharpen op and exacto blade...

like you. ; )

It's okay, though if you sharpen them yourself, the end up a lot better

than out of the box. The same thing with the box cutter blades.

Anyway, how do I adjust your formula for my box. I'm doing the

.6 hight and depth, .4 width.

Now, I'm not sure how to plot the nine sets of plots...x 2,, or more.

Also what function are you using?

I thought the Karlson was conic section type slot,

from a parabala or something, then split down the middle

separated by the 1/4 and folded over (one for each side).

Any way I appreciates eveyrones ideas and help.

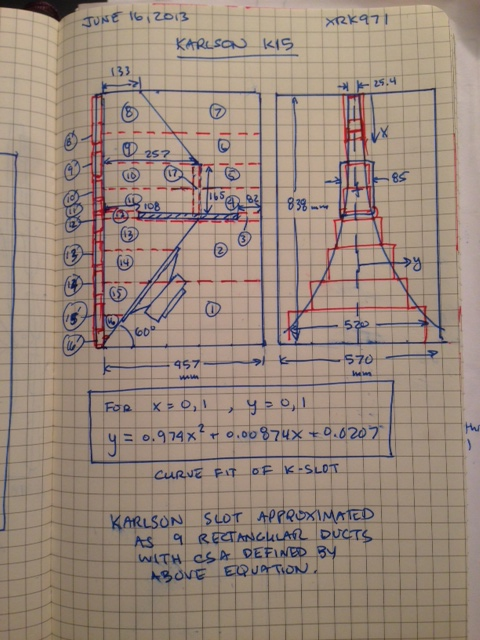

TB46,

I can help you with how the script goes, I just didn't have time. It is described in earlier posts on the Karlson thread here (http://www.diyaudio.com/forums/full-range/213594-karlson-10.html#post3528706). Basically, I fitted the Karlson aperture curve to a non dimensional function as y= f(x) for x[0,1], and y[0,1]. The function is given by Y=0.974X^2+0.00874X+0.0207. This is for X=0,1 and Y=0,1. Simply scale function for any slot based on max height and width at Y(X=1).

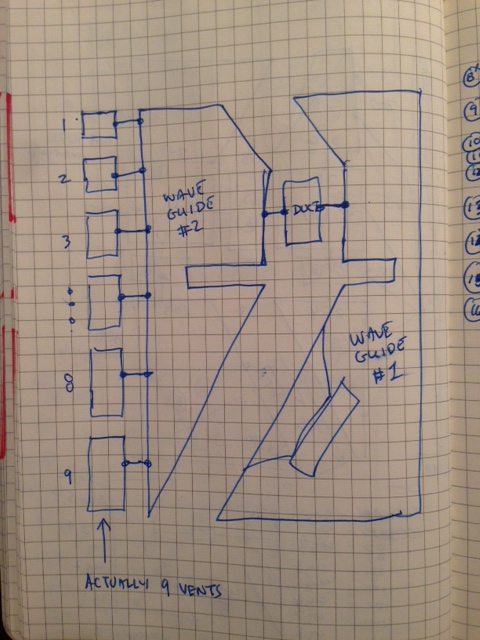

Using that function, I can then apply scaling of any arbitrary K slot final width and length, and also an offset which determines initial gap width. Having this function, use to specify the width and height of a series of rectangular ports (vents) located along the front. The width will be given by f(x)*Y_scale, the width height will equal front panel height/number_vents. I used 9 vents for the front K-aperture. I tried 14 and found negligible difference. So step through the 9 vents and adjust the port width for each successive one according to the equation. You need to model the front chamber as a series of waveguides (following the cross sectional area profile of the front chamber). I chose 9 because that is how many segments were required to model the front chamber to include all the expansions, contractions, vent tubes, etc. The distance of each segment actually determines the height of the vent. At the node connecting each waveguide segment on the front chamber, connect that node to a duct leading to a front radiator associated with that duct. See diagram here

The tricky part is to code each duct radiator so that it is appropriately physically located in the correct place on the front panel relative to the driver position. Also, you need to specify the extent of the baffle width and height at the position of the duct vent radiator. All this is rather tedious coding and much of it is manually done. I figured out how to link it all together to the non-dimensional X and Y positions of the individual Karlson ducts.

I hope that helps. Think about it some and let me know if you have questions.

Regards,

X

Sync,

Wow, people actually read what I wrote about sharpening xacto blades! After all these FC projects I am still using the same one.

Regarding the shape of the front aperture. I used a function for the model so that I could automatically scale it. For actual construction I hand drew the curve by setting the gap from where it starts on top and drawing a smooth curve that is tangent from the gap which starts out straight for a couple of inches. The gap width and where it starts are probably more critical than the shape of the exact curve. The smaller the gap and the more delayed it is the deeper the bass extension. Don't worry about the exact shape. If you are really determined to use a mathematical function then plot the equation I have on graph paper. It is a simple quadratic.

X

Wow, people actually read what I wrote about sharpening xacto blades! After all these FC projects I am still using the same one.

Regarding the shape of the front aperture. I used a function for the model so that I could automatically scale it. For actual construction I hand drew the curve by setting the gap from where it starts on top and drawing a smooth curve that is tangent from the gap which starts out straight for a couple of inches. The gap width and where it starts are probably more critical than the shape of the exact curve. The smaller the gap and the more delayed it is the deeper the bass extension. Don't worry about the exact shape. If you are really determined to use a mathematical function then plot the equation I have on graph paper. It is a simple quadratic.

X

Fran,

The strip is to brace the aperture and give it stiffness so it's location is not critical. You have it drawn correctly so go with your plan. Nice drawings by the way. If you make the front out of plywood it is probably stiff enough that I would skip the brace.

The strip is to brace the aperture and give it stiffness so it's location is not critical. You have it drawn correctly so go with your plan. Nice drawings by the way. If you make the front out of plywood it is probably stiff enough that I would skip the brace.

Thanks X! I'll skip the brace then.

My attachment is just a screenshot from Oliver's (tb46) plans found in page 20 of this thread. He made a great job and his plans helped me a lot.

My attachment is just a screenshot from Oliver's (tb46) plans found in page 20 of this thread. He made a great job and his plans helped me a lot.

Sync,

Wow, people actually read what I wrote about sharpening xacto blades! After all these FC projects I am still using the same one.

Well I took notice because that is what I do too, I haven't changed

it is years. I've got to sharpen before I start cutting.

Got the main boards drawn out and the speaker board

drawn too.

Regarding the shape of the front aperture. I used a function for the model so that I could automatically scale it. For actual construction I hand drew the curve by setting the gap from where it starts on top and drawing a smooth curve that is tangent from the gap which starts out straight for a couple of inches. The gap width and where it starts are probably more critical than the shape of the exact curve. The smaller the gap and the more delayed it is the deeper the bass extension. Don't worry about the exact shape. If you are really determined to use a mathematical function then plot the equation I have on graph paper. It is a simple quadratic.

X

Well I was going to start mine right on top with a bout 1/8 or 1/16 inch

slot. I"m trying to figure out how the function works and where the

origin is? Is the origin 0,0 right in the middle of the top?

I guess it is better to have ti closed at top then an inch or two later

have the 1/8 or 1/16 slot start?

Function...oh yeah, that works for anything I plug into it right?

Recall I'm a product of "new math" where you didn't learn squat

except what goes in and a 3 on the box, and this comes out the

end. So put in a 2, with 3 on top, that is 6.

I have to figure out how you did the cross brace stiffeners.

Is the top chamber above the cone used? or is that just

space to put the stiffeners in?

Getting closer....

Sync,

I made my slot start at 3/16 in wide and 3 inches from the top. This have it more bass punch I think. Regarding the formula - it is a normalized function scaled to 1. So think of y as the value out and x as the value in. X varies from 0 to 1 with 0 being at the top edge and 1 at the bottom. The answer is gives out varies from the gap width relative to 1. So if you have a 15 in tall box multiply the number in by 15 to get true position. Multiply the answer out by width of cabinet/w and that is distance from the centerline to the edge of the aperture at the given x position.

The chamber above the driver is part of the TL and helps to smooth the response and extend bass.

I made my slot start at 3/16 in wide and 3 inches from the top. This have it more bass punch I think. Regarding the formula - it is a normalized function scaled to 1. So think of y as the value out and x as the value in. X varies from 0 to 1 with 0 being at the top edge and 1 at the bottom. The answer is gives out varies from the gap width relative to 1. So if you have a 15 in tall box multiply the number in by 15 to get true position. Multiply the answer out by width of cabinet/w and that is distance from the centerline to the edge of the aperture at the given x position.

The chamber above the driver is part of the TL and helps to smooth the response and extend bass.

Hi X,

I finished the dual TC9 mini-Karlsonator a few weeks back, but have been too busy to post about it.

Pics below: first during the build before I put in the last of the braces; then the finished product sitting on top of my Fonken Prime FE127e (for comparison).

I put PE AcoustaStuf in the snub and 0.5" thick PE acoustic barrier foam on the bottom and surfaces behind the drivers.

They sound very good! Not as good as the Fonkens, but what would you expect?

I took them over to the studio today (I’m a volunteer sound tech for the Schenectady Theater for Children) to see how they would work in a large space— and to compare them with the mini-FH3 (also TC9 drivers) I built earlier. The rehearsal space is long & narrow; probably 20’ X 70’. Speakers were placed mid-way on the long walls, angled out 45 degrees. The mini-FH3 were seriously lacking in mid-bass, but presented the mids & highs beautifully with a great ‘disappearing act’. The mini-Karlsonator was clearly superior, with a nice mid-bass. In that space, they can’t provide ear bleed SPLs, but they are more than sufficient to provide music for rehearsals. My thought is to use them in the studio when the main system (EV 300 speakers IIRC) is out with our touring show.

So I may need to build a couple pairs in plywood. (Foam core might not last very long in that environment.)

OTOH, I’m wondering if a larger driver might be a better choice for that application? How do you think the Fostex FF165wk would work in a properly scaled Karlsonator?

The Madisound Speaker Store

Again, my thanks for enabling another fun build!

Cheers, Jim

I finished the dual TC9 mini-Karlsonator a few weeks back, but have been too busy to post about it.

Pics below: first during the build before I put in the last of the braces; then the finished product sitting on top of my Fonken Prime FE127e (for comparison).

I put PE AcoustaStuf in the snub and 0.5" thick PE acoustic barrier foam on the bottom and surfaces behind the drivers.

They sound very good! Not as good as the Fonkens, but what would you expect?

I took them over to the studio today (I’m a volunteer sound tech for the Schenectady Theater for Children) to see how they would work in a large space— and to compare them with the mini-FH3 (also TC9 drivers) I built earlier. The rehearsal space is long & narrow; probably 20’ X 70’. Speakers were placed mid-way on the long walls, angled out 45 degrees. The mini-FH3 were seriously lacking in mid-bass, but presented the mids & highs beautifully with a great ‘disappearing act’. The mini-Karlsonator was clearly superior, with a nice mid-bass. In that space, they can’t provide ear bleed SPLs, but they are more than sufficient to provide music for rehearsals. My thought is to use them in the studio when the main system (EV 300 speakers IIRC) is out with our touring show.

So I may need to build a couple pairs in plywood. (Foam core might not last very long in that environment.)

OTOH, I’m wondering if a larger driver might be a better choice for that application? How do you think the Fostex FF165wk would work in a properly scaled Karlsonator?

The Madisound Speaker Store

Again, my thanks for enabling another fun build!

Cheers, Jim

Attachments

Jim,

Very nice build there! I like the black and white treatment. It doesn't surprise that they work well to fill a large space. I recommended them to the guy who was looking for some speakers for his pub space where people play darts. It was poo poo'd as an idea but your experience confirms my suspicion.

Isn't that the best complement when a FC build graduates to a I should build one in wood? I have always liked these as one of my favorite all a rounders.

Thanks for sharing. I will look into one with the FF165wk for you. Is your goal studio use or filling sound in the hall like a PA?

Cheers,

X

Very nice build there! I like the black and white treatment. It doesn't surprise that they work well to fill a large space. I recommended them to the guy who was looking for some speakers for his pub space where people play darts. It was poo poo'd as an idea but your experience confirms my suspicion.

Isn't that the best complement when a FC build graduates to a I should build one in wood? I have always liked these as one of my favorite all a rounders.

Thanks for sharing. I will look into one with the FF165wk for you. Is your goal studio use or filling sound in the hall like a PA?

Cheers,

X

Hi X,

Thanks for looking into the the FF165wk. I am wondering if it might be sufficient for auditorium use. Folks complain about hauling around the EV300; these are pretty decent sounding speakers, but they are moderately heavy--as one would expect for pro sound gear that can 'take a licking and keep on ticking'. They keep asking if there isn't something smaller/lighter we could use.

An ex-executive producer went out & bought a Roland Cube Street powered guitar speaker w/ twin 6" drivers which we use for vocal reproduction in our Great Minds series; it's small, light, and can run on 6 AA batteries. Usable for voice, but for music I'm not pleased with the sound quality-- although I do employ it as a stage monitor so the actors can stay in sync with the music when they sing.

So I keep looking for modest cost options.

Cheers, Jim

Thanks for looking into the the FF165wk. I am wondering if it might be sufficient for auditorium use. Folks complain about hauling around the EV300; these are pretty decent sounding speakers, but they are moderately heavy--as one would expect for pro sound gear that can 'take a licking and keep on ticking'. They keep asking if there isn't something smaller/lighter we could use.

An ex-executive producer went out & bought a Roland Cube Street powered guitar speaker w/ twin 6" drivers which we use for vocal reproduction in our Great Minds series; it's small, light, and can run on 6 AA batteries. Usable for voice, but for music I'm not pleased with the sound quality-- although I do employ it as a stage monitor so the actors can stay in sync with the music when they sing.

So I keep looking for modest cost options.

Cheers, Jim

I've not been able to build anything recently plus never a good woodworker. An internally mounted K-tube with cheap compression driver can provide good highs. One inch pipe at ~5.3" long works well.

Here's two of Carl Neuser's Ks - one for 15" one for 8s and 10s (the baffle is removable I think) in later versions of the little 15K, he curved the baffle.

the tallest K I have is ~41.5" and runs an 18 plus can run a K-tube inside - it was very good on opera!

I'm about wore out for this world and hope the K will pick up interest

here's a some muck copy and pasted from a post I made today at fullrangedriver dot com

I've played with some drivers but only two so far in a single driver Karlsonator-Six - most of my piddling has been with standard aspect Ks

here's a few suggestions for smaller Ks - I'm pretty sure a Nirvana Cast Super10 would work in classic K12 - if they can be mounted

Peavey SC15 15" woofer in X15 - good quality, expensive driver - a bit more mellow

than EV15B with less peaking at the top of its range

EV 15B (vintage) - in good shape, a very good driver for Acoustic 115BK type K-couplers such

as this KK-Audio unit

Visaton BG20 in K12 - cheap - tuneful - good vocals

Eminence Kappa 12A and Eminence-Pyle PYM1298 in K12

high power handling - excellent drum transients - use a low xover to the K-tube

B&C 12PE32 in K12 - very sensitive (101dB rated) driver - it with the K-tube

must be at least 13dB louder than my Advent (I do love Henry Kloss's work)

TSG custom Eminence 12CX in K12 - very nice - but not as sensitive as 12PE32

this 4-inch coil coax should handle good amounts of power

Eminence Beta 10CX with ASD1001, etc. in K12

good value - stronger & deeper bass than 12LTA

Eminence Cannabis Rex in K12 - not much bass impact but good midrange

plus can double as a good souring guitar cabinet. I'd like to see Eminence make a

new 12LT with this cone, cloth surround and a bigger magnet

Eminence Commonwealth 12 in K12 - -strong tough driver with 109oz magnet

slug and four-inch coil - has some characteristic tone like classic JBL due to

its aluminum dust cap

Eminence Martin 12CX model 1114 (discontinued) 80oz magnet - low mass - my favorite

overall of modern 12CX

Eminence's Delta10A is suitable for 10" size K-couplers, powerful, and cheap - it needs an appropriate lowpass

filter (see the Econowave schematic for a Deltalite 10)

As to the 8-inch driver couplers, there are several choices ranging

from the classic little K8 to the "SK8" project to Greg B's Karlsonator8,

with the Karlsonator having the deepest bass extension.

here's the size difference between a K8 and the SK8

here's Lapaire's Karlsonator8 and Karlsonator6 prototypes next to his K15 setup

FE206EN worked well in the rough Karlsonator8 prototype - other drivers should too.

SK8 with Tangband W8-1772 - - nice quality in a small K-coupler

SK8 with Nirvana stamped frame Super 8 - another nice combo just as was FE206EN with SK8

SK8 with Eminence Delta8A - this should make a strong "X8" in conjunction with a K-tube mounted on its

lower reflector panel and driven with a decent compression driver.

K8 size - here's Art Welter's dad's interpretation of a "K8" - it sounds very nice

with a Wild Burro Audio Labs BetsyK and should do about as well with the Visaton BG20.

Greg B's little Karlsonator6 is very nice and provides deeper bass than a factory K8

Here's two of Carl Neuser's Ks - one for 15" one for 8s and 10s (the baffle is removable I think) in later versions of the little 15K, he curved the baffle.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

the tallest K I have is ~41.5" and runs an 18 plus can run a K-tube inside - it was very good on opera!

An externally hosted image should be here but it was not working when we last tested it.

I'm about wore out for this world and hope the K will pick up interest

here's a some muck copy and pasted from a post I made today at fullrangedriver dot com

I've played with some drivers but only two so far in a single driver Karlsonator-Six - most of my piddling has been with standard aspect Ks

here's a few suggestions for smaller Ks - I'm pretty sure a Nirvana Cast Super10 would work in classic K12 - if they can be mounted

Peavey SC15 15" woofer in X15 - good quality, expensive driver - a bit more mellow

than EV15B with less peaking at the top of its range

An externally hosted image should be here but it was not working when we last tested it.

EV 15B (vintage) - in good shape, a very good driver for Acoustic 115BK type K-couplers such

as this KK-Audio unit

An externally hosted image should be here but it was not working when we last tested it.

Visaton BG20 in K12 - cheap - tuneful - good vocals

An externally hosted image should be here but it was not working when we last tested it.

Eminence Kappa 12A and Eminence-Pyle PYM1298 in K12

high power handling - excellent drum transients - use a low xover to the K-tube

An externally hosted image should be here but it was not working when we last tested it.

B&C 12PE32 in K12 - very sensitive (101dB rated) driver - it with the K-tube

must be at least 13dB louder than my Advent (I do love Henry Kloss's work)

An externally hosted image should be here but it was not working when we last tested it.

TSG custom Eminence 12CX in K12 - very nice - but not as sensitive as 12PE32

this 4-inch coil coax should handle good amounts of power

An externally hosted image should be here but it was not working when we last tested it.

Eminence Beta 10CX with ASD1001, etc. in K12

good value - stronger & deeper bass than 12LTA

An externally hosted image should be here but it was not working when we last tested it.

Eminence Cannabis Rex in K12 - not much bass impact but good midrange

plus can double as a good souring guitar cabinet. I'd like to see Eminence make a

new 12LT with this cone, cloth surround and a bigger magnet

An externally hosted image should be here but it was not working when we last tested it.

Eminence Commonwealth 12 in K12 - -strong tough driver with 109oz magnet

slug and four-inch coil - has some characteristic tone like classic JBL due to

its aluminum dust cap

An externally hosted image should be here but it was not working when we last tested it.

Eminence Martin 12CX model 1114 (discontinued) 80oz magnet - low mass - my favorite

overall of modern 12CX

An externally hosted image should be here but it was not working when we last tested it.

Eminence's Delta10A is suitable for 10" size K-couplers, powerful, and cheap - it needs an appropriate lowpass

filter (see the Econowave schematic for a Deltalite 10)

An externally hosted image should be here but it was not working when we last tested it.

As to the 8-inch driver couplers, there are several choices ranging

from the classic little K8 to the "SK8" project to Greg B's Karlsonator8,

with the Karlsonator having the deepest bass extension.

here's the size difference between a K8 and the SK8

An externally hosted image should be here but it was not working when we last tested it.

here's Lapaire's Karlsonator8 and Karlsonator6 prototypes next to his K15 setup

FE206EN worked well in the rough Karlsonator8 prototype - other drivers should too.

An externally hosted image should be here but it was not working when we last tested it.

SK8 with Tangband W8-1772 - - nice quality in a small K-coupler

An externally hosted image should be here but it was not working when we last tested it.

SK8 with Nirvana stamped frame Super 8 - another nice combo just as was FE206EN with SK8

An externally hosted image should be here but it was not working when we last tested it.

SK8 with Eminence Delta8A - this should make a strong "X8" in conjunction with a K-tube mounted on its

lower reflector panel and driven with a decent compression driver.

An externally hosted image should be here but it was not working when we last tested it.

K8 size - here's Art Welter's dad's interpretation of a "K8" - it sounds very nice

with a Wild Burro Audio Labs BetsyK and should do about as well with the Visaton BG20.

An externally hosted image should be here but it was not working when we last tested it.

Greg B's little Karlsonator6 is very nice and provides deeper bass than a factory K8

Last edited:

Here is my bass rig:

Real Karlson 15 inch bass cab.

Mesa Boogie M-190 amp

Red Knob preamp from San Francisco,

thank you Jerry Garcia - keep on truckin'

enjoy

Real Karlson 15 inch bass cab.

Mesa Boogie M-190 amp

Red Knob preamp from San Francisco,

thank you Jerry Garcia - keep on truckin'

enjoy

An externally hosted image should be here but it was not working when we last tested it.

Freddi,

Wow that is a lot of Karlsons! Nice collection photos there.

Sync,

Cool rig - what brand of K15 I that - they still sell these? You personally know Jerry Garcia ?

Oh, I thought this was a Karlsonator thread ? 😉

Wow that is a lot of Karlsons! Nice collection photos there.

Sync,

Cool rig - what brand of K15 I that - they still sell these? You personally know Jerry Garcia ?

Oh, I thought this was a Karlsonator thread ? 😉

Last edited:

Here is my bass rig:

Hey Freddi, I have one also

I might need another though, unless you

need another, kinda like you can never have

too many.

I don't know if mine originally had the EV.

It came with a JBL D140 which I repurposed.

Currently it has a Gauss 15.

The guy I got the Gauss from wanted it back

and said he'd give me an Original Celestion 15 Bass speaker

for exchange. Not sure if it is the edgewound sidewinder type

or not.

On mine I painted the inside black as the raw wook showing

through just bugged me. Yeah I, know but still.

That Boogie is a real rare amp. Only

one of 100 made. When I called and spoke

to Mike B. at the factory, he himself had never

even seen one. Randal Smith build them all himself.

6 x 6L6 has good power.

Been recapped with really dead caps which

deadens the amp. The old white film/foil sonic cap.

I really should recap it to liven it up.

And then the gift. The original alembic pre amp

from the man who made them famous and loved

to keep on Truckin' Red Knob preamp from San Francisco,

thank you Jerry Garcia - keep on truckin'

enjoy

Hey Freddi, I have one also

I might need another though, unless you

need another, kinda like you can never have

too many.

I don't know if mine originally had the EV.

It came with a JBL D140 which I repurposed.

Currently it has a Gauss 15.

The guy I got the Gauss from wanted it back

and said he'd give me an Original Celestion 15 Bass speaker

for exchange. Not sure if it is the edgewound sidewinder type

or not.

On mine I painted the inside black as the raw wook showing

through just bugged me. Yeah I, know but still.

That Boogie is a real rare amp. Only

one of 100 made. When I called and spoke

to Mike B. at the factory, he himself had never

even seen one. Randal Smith build them all himself.

6 x 6L6 has good power.

Been recapped with really dead caps which

deadens the amp. The old white film/foil sonic cap.

I really should recap it to liven it up.

And then the gift. The original alembic pre amp

from the man who made them famous and loved

to keep on Truckin' Red Knob preamp from San Francisco,

thank you Jerry Garcia - keep on truckin'

enjoy

I'll be using a tpa3110 amp with these speakers and thought it'd be great to integrate the amp inside one of the speakers, so I drilled a coupe of holes through one of the back plates and wired the amp in place.

An externally hosted image should be here but it was not working when we last tested it.

I am listening to my mini Karlosnators right now with a stock Sure TPA3110D2 powered with a 19v laptop smps brick and it sounds wonderful. It can get quite loud for a 8 watt amp. I think it is closer to 12 or 15 watts when running from a 19v supply.

This sounds really good on this speaker:

http://www.youtube.com/watch?v=TE5or92yoMM

You won't be disappointed! Can't wait to hear your impressions in an all wood 0.53x scale Karlsonator.

You must be very close to first sound by now 😀

Last edited:

hi SyncTronX - was your little X15 size K built by KK-Audio like mine?

These are smaller than K15 and have higher cutoff - they're basically like Acoustic Control's 115BK except for fancier reflector and my pair has a rear shelf/choke (hot sure if that does any good to the response)

KK-K

These are smaller than K15 and have higher cutoff - they're basically like Acoustic Control's 115BK except for fancier reflector and my pair has a rear shelf/choke (hot sure if that does any good to the response)

KK-K

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs