Full thickness except at bracing where next to driver to allow more airflow. They are circa 12mm thick full size.

Sorry, I forgot the usual size of these melamine foam pads. They are closer to 10cm x 6cm x 2cm thick. So half thickness is about 10mm.

I was just about to say...

I took out a sponge and mine are 28mm thick.

Will hopefully finish one of the two in a couple of days, if the weather cooperates.

I took out a sponge and mine are 28mm thick.

Will hopefully finish one of the two in a couple of days, if the weather cooperates.

Everything for the first one is cut and glued... waiting for it to dry.

I couldn't use foam core on the K aperture baffle since it will be outside, so I'll try butyl tape instead. I also went with thinner wood than the box itself.

I couldn't use foam core on the K aperture baffle since it will be outside, so I'll try butyl tape instead. I also went with thinner wood than the box itself.

Maybe use thin half thickness melamine sponges on K aperture. It needs to soften the reflections not vibrations. The butyl won’t change reflectivity.

oops...

but foam core doesn't soften reflection either, especially mounted on the wood baffle.

I mounted the drivers, and closed it off.

I didn't have time, nor could play loudly, but had to give it a 30 sec tryout... Happy to report no boxiness to the sound this time.

Might have been because I have been a lot more careful this time assembling the whole thing, which took me a lot more time than I thought it would.

but foam core doesn't soften reflection either, especially mounted on the wood baffle.

I mounted the drivers, and closed it off.

I didn't have time, nor could play loudly, but had to give it a 30 sec tryout... Happy to report no boxiness to the sound this time.

Might have been because I have been a lot more careful this time assembling the whole thing, which took me a lot more time than I thought it would.

Attachments

perceval and jhofland,

What is the thickness of plywood you have used for these : 1/4" / 12mm or something different.

Thanks

What is the thickness of plywood you have used for these : 1/4" / 12mm or something different.

Thanks

X,

yes, 0.53x with dual TC9s. even with my limited test, I could hear that it does deliver more than the single. Soon to be painted white, as requested for the restaurant.

Kokanee, my outer box is 15mm ply, but the internals and the aperture are 5mm.

yes, 0.53x with dual TC9s. even with my limited test, I could hear that it does deliver more than the single. Soon to be painted white, as requested for the restaurant.

Kokanee, my outer box is 15mm ply, but the internals and the aperture are 5mm.

foam vs wood resonance

Could we get nearfield measurements for the same dimensions & drivers built from wood and foamcore from people who have built them and have a measuring mic?

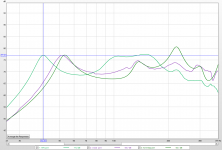

I've noticed an interesting thing, not sure if it was already mentioned here or in the foamcore thread: when prototyping, I've built a tqwt with the same internal dimensions from 1 cm thick XPS foam (no paper backing, but stiffer than the cheap foamcore, cannot be bent) and then from birch plywood, and the XPS seemed to be tuned almost 11 Hz lower! Port measurements of the two and a hornresp simulation are attached. (hornresp is even higher perhaps because I don't properly compensate for additional space added by folding and a bit different in upper bass because I can't approximate the effect of stuffing well enough)

I double checked the dimensions, and the XPS one was actually internally a bit smaller because it had bracing, while the wooden one did not. Other than that, no difference between the two except maybe stuffing, I used something like polyfill and the amount and location looked the same between the two, but I did not measure or weight it. I have since gotten similar result with a different tqwt which was tuned to about 58 Hz and the difference was only about 6 Hz, but was present.

So, the idea here is - what if this is happening with the Karlsonators as well and while copious damping helps, another reason might be that the wooden ones actually are tuned a bit higher and for that reason have some resonance in the midbass, which makes them sound boxy. In that case a simple rescale that tunes them a few Hz lower might help.

Could we get nearfield measurements for the same dimensions & drivers built from wood and foamcore from people who have built them and have a measuring mic?

I've noticed an interesting thing, not sure if it was already mentioned here or in the foamcore thread: when prototyping, I've built a tqwt with the same internal dimensions from 1 cm thick XPS foam (no paper backing, but stiffer than the cheap foamcore, cannot be bent) and then from birch plywood, and the XPS seemed to be tuned almost 11 Hz lower! Port measurements of the two and a hornresp simulation are attached. (hornresp is even higher perhaps because I don't properly compensate for additional space added by folding and a bit different in upper bass because I can't approximate the effect of stuffing well enough)

I double checked the dimensions, and the XPS one was actually internally a bit smaller because it had bracing, while the wooden one did not. Other than that, no difference between the two except maybe stuffing, I used something like polyfill and the amount and location looked the same between the two, but I did not measure or weight it. I have since gotten similar result with a different tqwt which was tuned to about 58 Hz and the difference was only about 6 Hz, but was present.

So, the idea here is - what if this is happening with the Karlsonators as well and while copious damping helps, another reason might be that the wooden ones actually are tuned a bit higher and for that reason have some resonance in the midbass, which makes them sound boxy. In that case a simple rescale that tunes them a few Hz lower might help.

Attachments

oops...

but foam core doesn't soften reflection either, especially mounted on the wood baffle.

I mounted the drivers, and closed it off.

I didn't have time, nor could play loudly, but had to give it a 30 sec tryout... Happy to report no boxiness to the sound this time.

Might have been because I have been a lot more careful this time assembling the whole thing, which took me a lot more time than I thought it would.

Looking good!

The duallies sure are nice, wait to you hear a pair with the Faital Pro 3FE25 drivers, it's a different league 😎

Could we get nearfield measurements for the same dimensions & drivers built from wood and foamcore from people who have built them and have a measuring mic?

I've noticed an interesting thing, not sure if it was already mentioned here or in the foamcore thread: when prototyping, I've built a tqwt with the same internal dimensions from 1 cm thick XPS foam (no paper backing, but stiffer than the cheap foamcore, cannot be bent) and then from birch plywood, and the XPS seemed to be tuned almost 11 Hz lower! Port measurements of the two and a hornresp simulation are attached. (hornresp is even higher perhaps because I don't properly compensate for additional space added by folding and a bit different in upper bass because I can't approximate the effect of stuffing well enough)

I double checked the dimensions, and the XPS one was actually internally a bit smaller because it had bracing, while the wooden one did not. Other than that, no difference between the two except maybe stuffing, I used something like polyfill and the amount and location looked the same between the two, but I did not measure or weight it. I have since gotten similar result with a different tqwt which was tuned to about 58 Hz and the difference was only about 6 Hz, but was present.

So, the idea here is - what if this is happening with the Karlsonators as well and while copious damping helps, another reason might be that the wooden ones actually are tuned a bit higher and for that reason have some resonance in the midbass, which makes them sound boxy. In that case a simple rescale that tunes them a few Hz lower might help.

What dimensions and driver did you use here? I'm considering a small wood set of K's and since I have both .40 and .53 scale on hand in black elmer's foamcore, it would be pretty easy to test both I suppose, but it'll be a long while yet before I can afford to have a set built or build a set myself.

What dimensions and driver did you use here? I'm considering a small wood set of K's and since I have both .40 and .53 scale on hand in black elmer's foamcore, it would be pretty easy to test both I suppose, but it'll be a long while yet before I can afford to have a set built or build a set myself.

I should have been more clear, the measurement is not a Karlsonator, rather a tqwt similar to a Cyburgs Pipe or something like that, using a TC9FD. So I'm interested to see whether this happens with a Karlsonator too or not. But I can't really measure it because a) I only have the XPS version and it might be different with the dollar store foamcore that most people use b) my 0.40x Karlsonator uses Visaton FRS8 which again almost nobody uses.

The reason I'm posting here is because if it was happening with the Karlsonators, it might explain part of the boxiness that people get with wood.

Thanks for sharing your observation Vozka. XPS might be showing lower bass reach because of secondary vibrations. I noticed this on a foam core front horn and when I added mass vibration damping, it went away. Also reduced mechanical vibration distortion too.

Usually reflex port tuning is function of volume and port size.

I am quite sure boxiness sound in wood has been solved - must use good absorber like melamine foam in back chamber surround driver as well as around front chamber where possible.

Usually reflex port tuning is function of volume and port size.

I am quite sure boxiness sound in wood has been solved - must use good absorber like melamine foam in back chamber surround driver as well as around front chamber where possible.

Dual 3FE25-16 Karlsonators powered with 11wrms MoFo single MOSFET amp and Melbourne preamp. Great combo. Really surprised at the synergy of a simple amp and good speakers.

Dual 3FE25-16 Karlsonators powered with 11wrms MoFo single MOSFET amp and Melbourne preamp. Great combo. Really surprised at the synergy of a simple amp and good speakers.

Very Nice XRK!

I´m about to build the "tall" ones i sent a render of earlier, and are wondering about the Slot. What is the benefit to not make it all the way to the top like you did here?

I 3d Printed some fixtures to make sure the angles stays correct during Gluing. Worked like a charm!

That.Is. So. Very. Cool. !!!!!

Last edited:

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs