I had an American girl friend, we were out walking and she said, "I'll just put this is my fanny pack", she didn't understand why I burst out laughing.

That's funny! An incorrect semantics assumption on my part🙂, but I can see cotton bath towels working excellent too.

Probably the best thing(For my needs) would be to use high density industrial wool felt, which is VERY expensive and very heavy. It would probably cost at least a couple hundred dollars to fill both cabinets. Ain't gonna happen! The dryer balls are much cheaper and I don't have to cut anything, I just have to wedge them in. They'll cost around $50.00 for both cabinets, and that's filled to the brim.

F-1 Industrial Felt By Foot

– thefeltstore.com

Probably the best thing(For my needs) would be to use high density industrial wool felt, which is VERY expensive and very heavy. It would probably cost at least a couple hundred dollars to fill both cabinets. Ain't gonna happen! The dryer balls are much cheaper and I don't have to cut anything, I just have to wedge them in. They'll cost around $50.00 for both cabinets, and that's filled to the brim.

F-1 Industrial Felt By Foot

– thefeltstore.com

Last edited:

Size comparison for scale..

An externally hosted image should be here but it was not working when we last tested it.

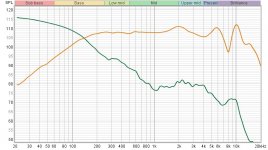

This is the absorption response, 10cm thick of the current, high density felt I'm using, with no added airspace between the mic and the driver, vs nothing.

As you can see, it's either resonating at certain frequencies, or it's completely transparent at certain frequencies. Either way, it's totally unacceptable. The null at 300hz, and another at 150hz makes me think it's a resonance problem

As you can see, it's either resonating at certain frequencies, or it's completely transparent at certain frequencies. Either way, it's totally unacceptable. The null at 300hz, and another at 150hz makes me think it's a resonance problem

Attachments

Last edited:

The above test doesn't show exactly what's going on in the cabinet, but it does show that the product is crap, and I shouldn't have believed the absorption coefficient graph that came with it🙁

F-11 or F-13 felt may be a better and less expensive choice for noise damping.

SAE Chart - Sutherland Felt Company

SAE Chart - Sutherland Felt Company

The test was performed with 10cm of material in front of the speaker, which is inside the speaker also. The first few posts on this thread explains what was done with the material on the inside.

Sounds like someone needs some rePhase in their life!Step response of my 5 way, 8th order, active dsp based system. Gulp..

F-11 or F-13 felt may be a better and less expensive choice for noise damping.

SAE Chart - Sutherland Felt Company

You're absolutely right, those would be, but the cutting part to fill a cabinet completely really sucks and I don't want to go through that again. These 100% wool dryer balls seem to have the perfect amount of density and size for what I'm trying to atchieve, and they'll conform to the corners and walls when wedged in together. I'll see how it goes. Should be interesting. I'll take some pictures too.

Sounds like someone needs some rePhase in their life!

I've looked into that!🙂 It has such a mild effect on sound quality though for how much I'd have to reinvest. If the Behringer Ultradrive's break in the future(Very likely), I'll definitely take the mini-dsp route. It's a much better product.

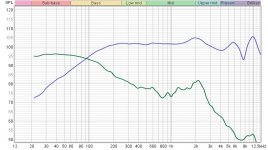

My scientific curiosity finally got the best of me. I put so much work into this that I had to see exactly what was going on inside the cabinet, so I drilled a hole in the bottom(mic barrel diameter) and stuck the mic in. The news is very good! No resonances at all, with a smooth downward trend through the midrange. Exactly what I was hoping! Driver amplitude remained the same for both measurements.

It's actually kind of cool to have mic access to the inside of the cabinet. Since it was drilled on the bottom, there's no cosmetic sacrifice.

There was a small amount of air leakage from the hole(tiny port, which could effect the low end of the measurement), so the next measurement will be with the mic sealed in.

Orange - Direct driver response

Green - Response from inside the cabinet

It's actually kind of cool to have mic access to the inside of the cabinet. Since it was drilled on the bottom, there's no cosmetic sacrifice.

There was a small amount of air leakage from the hole(tiny port, which could effect the low end of the measurement), so the next measurement will be with the mic sealed in.

Orange - Direct driver response

Green - Response from inside the cabinet

Attachments

Last edited:

The response I'm getting does corespond very well to their published coifficiency curve. It is a little off because of how I'm using it.

Attachments

Last edited:

I've wondered what would happen if you "listen" inside a cabinet. Supposedly only standing waves are an issue. What is the mic actually measuring, pressure or sound? 🙂

Without ears to hear it, and a brain to proccess it, it's only pressure waves, kind of like the old "If a tree falls in the woods" question.

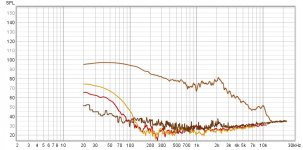

Here's an interesting measurement. Internal(Sealed in mic) Fundamental, HD and noise floor..

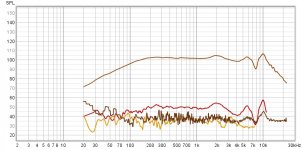

Also at the same amplitude, but outside, on axis..

Correction- There is no such thing as "coefficiency", only "coefficient", and the plural.

Also at the same amplitude, but outside, on axis..

Correction- There is no such thing as "coefficiency", only "coefficient", and the plural.

Attachments

Last edited:

True. Where the dimensions relative to frequency are small enough for the air inside to act as a pure compliance the "sound" is not an issue, kinda thing 😉

Scottjoplin

I did some calculations, and sure enough, internally there is..

a peak at 2.1 khz corresponding exactly to the internal width.

a peak at 1.2khz corresponding to exactly the internal height.

It also looks like below 800hz(Below the wavelengths of the internal dimensions) the internal cabinet pressure starts increasing more and more.

I did some calculations, and sure enough, internally there is..

a peak at 2.1 khz corresponding exactly to the internal width.

a peak at 1.2khz corresponding to exactly the internal height.

It also looks like below 800hz(Below the wavelengths of the internal dimensions) the internal cabinet pressure starts increasing more and more.

Last edited:

That's where the air volume becomes pure compliance, so pressure builds but sound can't escape, I think, can someone explain it?

- Home

- Loudspeakers

- Multi-Way

- Midrange experiment with Auto sound panel deadener and high density acoustic felt..