Hey Guys

So the other day I picked up a used set of Martin Logan Aerius i ESL's in great shape and I have been really enjoying them. I was thinking it might be a good idea to think about replacing the 20+ year old electrolytic caps in the crossovers with something better such as Clarity caps. I'm fairly new to this but know this is popular with conventional style loudspeakers. I'm comfortable working through parts values but I'm not really 100% sure where my time and money would be best spent so I'm here to take in any info offered.

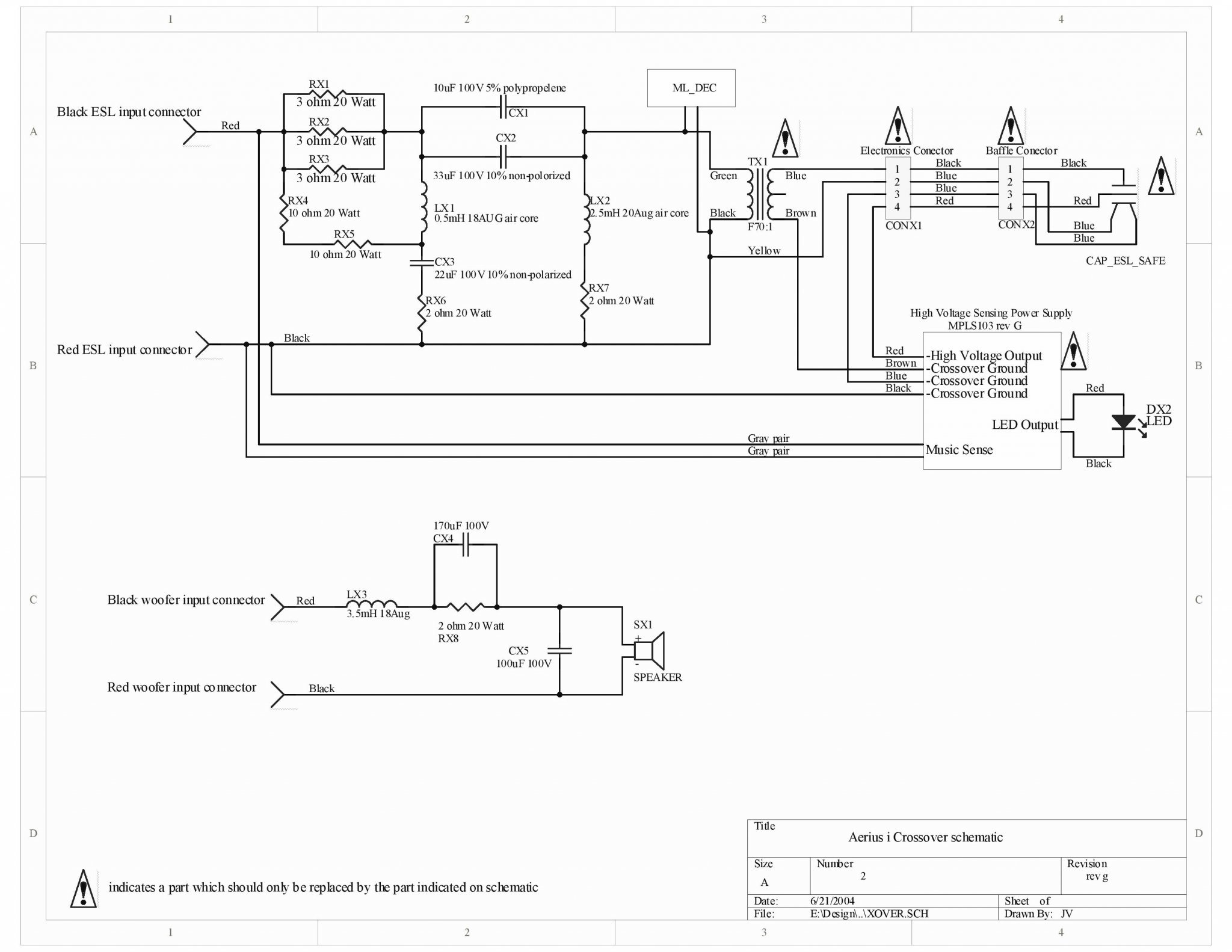

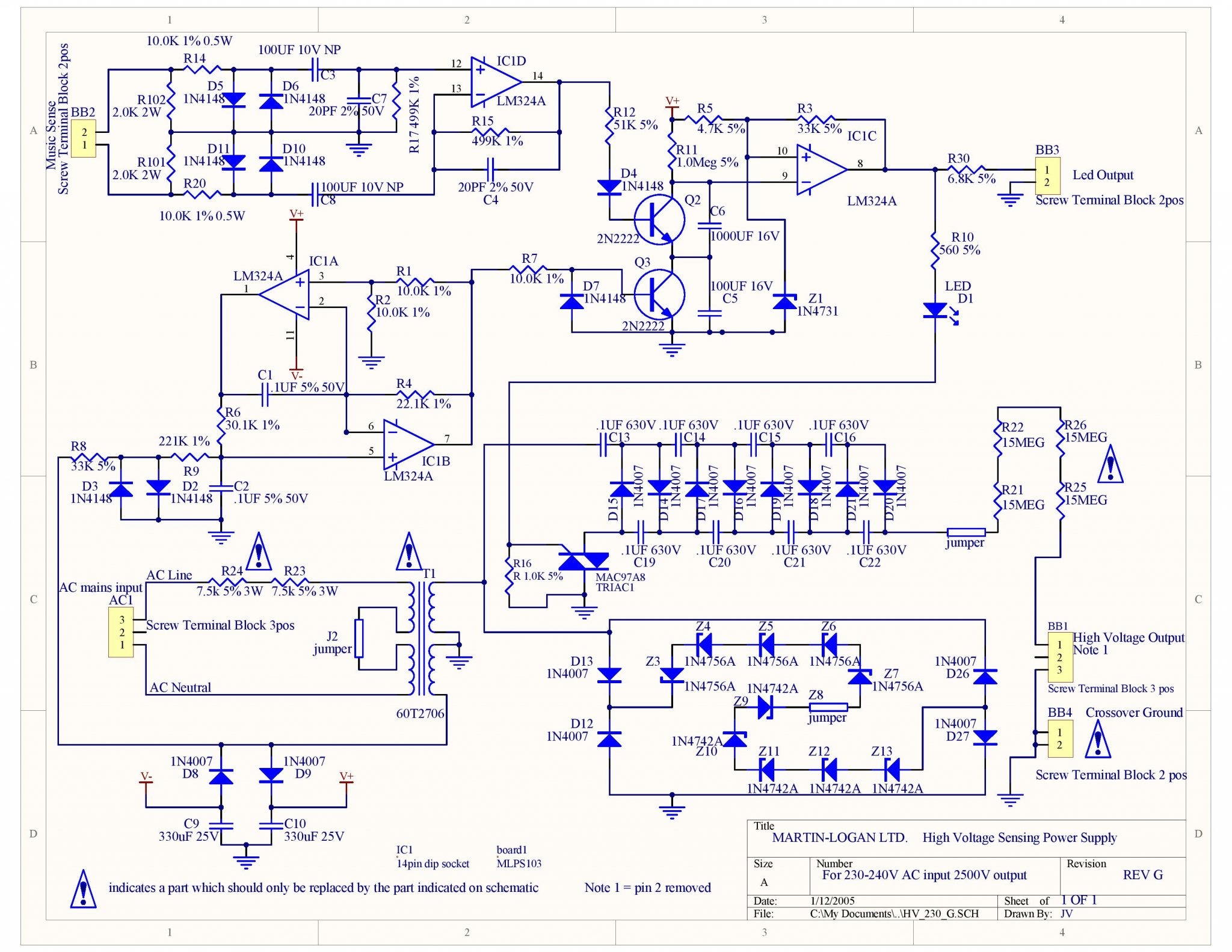

Martin Logan has proved to be extremely helpful and provided me with crossover schematics and a detailed electrical print on the whole speaker. I have not opened these up yet to take a look for myself but plan on doing so this week at some point. I've attached all the electrical info for everyone's viewing pleasure.

So the other day I picked up a used set of Martin Logan Aerius i ESL's in great shape and I have been really enjoying them. I was thinking it might be a good idea to think about replacing the 20+ year old electrolytic caps in the crossovers with something better such as Clarity caps. I'm fairly new to this but know this is popular with conventional style loudspeakers. I'm comfortable working through parts values but I'm not really 100% sure where my time and money would be best spent so I'm here to take in any info offered.

Martin Logan has proved to be extremely helpful and provided me with crossover schematics and a detailed electrical print on the whole speaker. I have not opened these up yet to take a look for myself but plan on doing so this week at some point. I've attached all the electrical info for everyone's viewing pleasure.

If you have a DVM capable of measuring low ohms accurately, check all the crossover resistor values.

If not, leave them alone unless they are obviously defective. Don't mess with the HV power supply at all.

Make sure your proposed replacement capacitors can physically fit properly on the boards before buying them.

For the woofer, replace capacitors CX4 and CX5. Check the value of resistor RX8.

For the panel, Replace capacitors CX1, 2, 3. Check the values of resistors RX1, 2, 3, 4, 5, 6.

If not, leave them alone unless they are obviously defective. Don't mess with the HV power supply at all.

Make sure your proposed replacement capacitors can physically fit properly on the boards before buying them.

For the woofer, replace capacitors CX4 and CX5. Check the value of resistor RX8.

For the panel, Replace capacitors CX1, 2, 3. Check the values of resistors RX1, 2, 3, 4, 5, 6.

Last edited:

We have a really good Fluke meter at work we use so I imagine that should read low enough. I will go through and see what kinds of values I find.If you have a DVM capable of measuring low ohms accurately, check all the crossover resistor values.

If not, leave them alone unless they are obviously defective. Don't mess with the HV power supply at all.

Make sure your proposed replacement capacitors can physically fit properly on the boards before buying them.

For the woofer, replace capacitors CX4 and CX5. Check the value of resistor RX8.

For the panel, Replace capacitors CX1, 2, 3. Check the values of resistors RX1, 2, 3, 4, 5, 6.

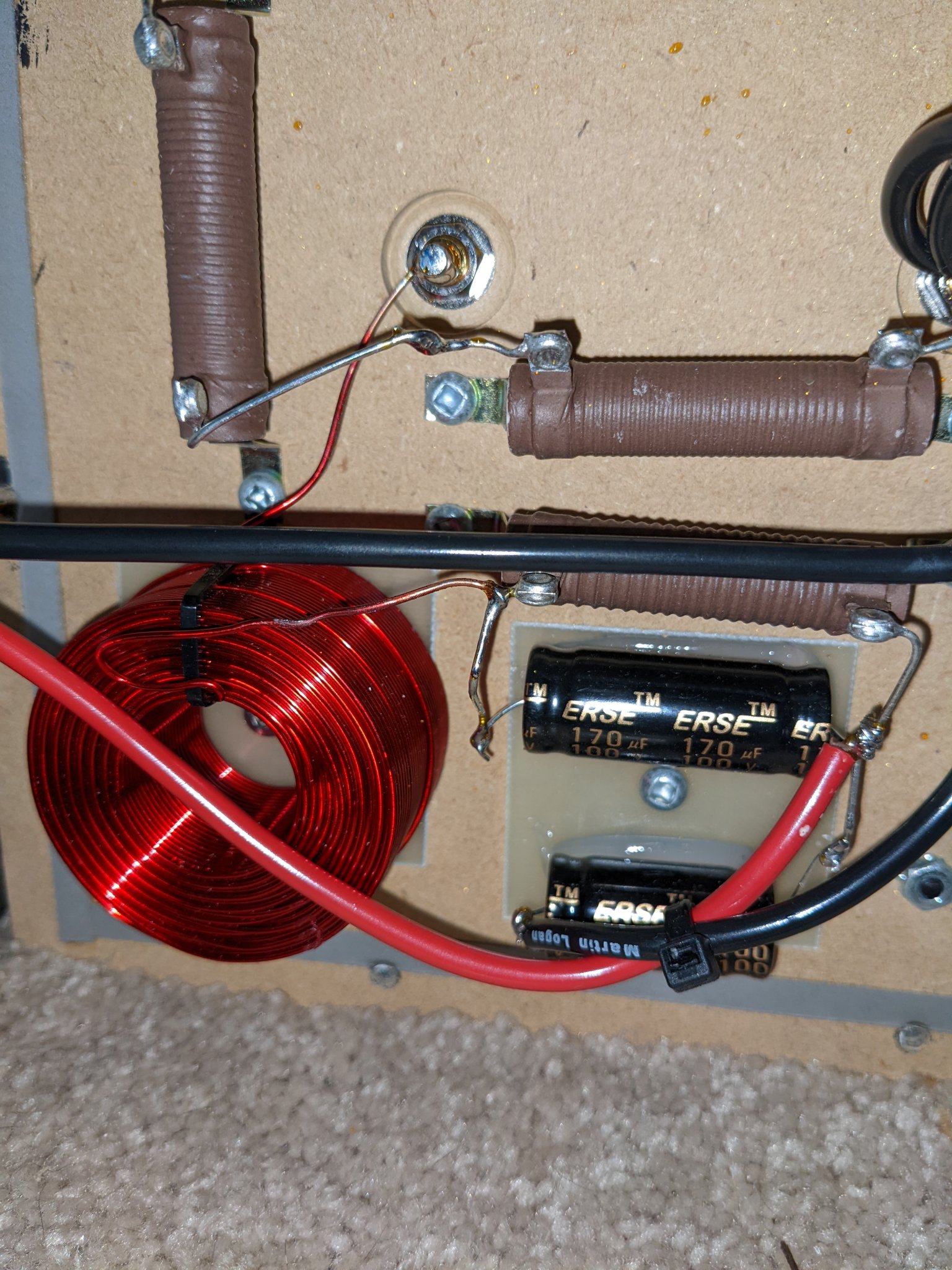

I have priced out the capacitors and the panel isn't overly expensive to do, but 100UF and 170UF caps in the woofer section get pretty up there in price if I'm shopping clarity caps. Would it be a no-no to use something more affordable in the woofer section? Your point about size is noted, I'll have to open up the cabinet and see what kind of space I have to work with.

Thanks for the straightforward info

I would measure the existing capacitors first. They will be much smaller than any film type of the same value.

The woofer will be less critical and less revealing than the panel, so bipolar electrolytics for woofers are widely used.

Try to use better capacitors for the panel. Check all capacitor values for reference to see if they have drifted much.

The woofer will be less critical and less revealing than the panel, so bipolar electrolytics for woofers are widely used.

Try to use better capacitors for the panel. Check all capacitor values for reference to see if they have drifted much.

Last edited:

noted, I will do this and see what the results are.I would measure the existing capacitors first. They will be much smaller than any film type of the same value.

The woofer will be less critical and less revealing than the panel, so bipolar electrolytics for woofers are widely used.

Try to use better capacitors for the panel though.

I had assumed that this would be the case with the woofer, thanks for the clarification. I'll see if I can find something a little more reasonable for the woofer section as the large values of clarity caps will set me back over $400 CAD 🤣. I really appreciate your input, this info is most helpful in making a bit more sense of things.

I have a pair of those also. The woofer is adequate but not a match for the panel.

One thing I've noticed is they are somewhat nasal-sounding when seated, but less so when standing.

Probably due to crossover driver interaction lobing, but haven't looked further into it yet. When there's time,

I plan to try a different woofer with the panel some time later on this year.

If you have to replace any resistors, make sure they are non-inductive types (with a special winding).

One thing I've noticed is they are somewhat nasal-sounding when seated, but less so when standing.

Probably due to crossover driver interaction lobing, but haven't looked further into it yet. When there's time,

I plan to try a different woofer with the panel some time later on this year.

If you have to replace any resistors, make sure they are non-inductive types (with a special winding).

I have also noticed some kind of "coloration" so to speak, I haven't had the time yet to really play with them to see what's causing it. I've told myself I will do a bit of room treatment behind the speakers before I spend any money on crossover components or anything else.I have a pair of those also. The woofer is adequate but not a match for the panel.

One thing I've noticed is they are somewhat nasal-sounding when seated, but less so when standing.

Probably due to crossover driver interaction lobing, but haven't looked further into it yet. When there's time,

I plan to try a different woofer with the panel some time later on this year.

If you have to replace any resistors, make sure they are non-inductive types (with a special winding).

I'd be really interested to see what results come from using different woofers. The cabinet could probably use some love inside I'd guess seeing as this is the "budget" model. From what I understand, electrostatic speakers aren't a whole lot different from one to the next so I thought these could be a fun project to tinker with and eventually see how good they could get.

I plan to try tilting the speaker vertically by adding a spacer under the rear edge of the cabinet.

That should send the lobe into the floor.

I won't replace the woofer driver, but instead will use only the panel via the top pair of terminals,

and then add a different speaker beside or in front of the existing woofer. I'll be using a Dynaco A-25

with the tweeter disconnected to try this out. The crossover point is about right, and the bass is far better.

That should send the lobe into the floor.

I won't replace the woofer driver, but instead will use only the panel via the top pair of terminals,

and then add a different speaker beside or in front of the existing woofer. I'll be using a Dynaco A-25

with the tweeter disconnected to try this out. The crossover point is about right, and the bass is far better.

This is a really interesting idea, I never thought of this.I plan to try tilting the speaker vertically by adding a spacer under the rear edge of the cabinet.

That should send the lobe into the floor.

I won't replace the woofer driver, but instead will use only the panel via the top pair of terminals,

and then add a different speaker beside or in front of the existing woofer. I'll be using a Dynaco A-25

with the tweeter disconnected to try this out. The crossover point is about right, and the bass is far better.

I have 4 old Denon 12" passive subwoofers I could play with. It might make for an interesting experiment if I ever decide to defeat the internal woofer.

I hate lousy bass, and the Dyna A-25 is really good. If the Denon efficiency doesn't match well enough,

you can always biamp.

you can always biamp.

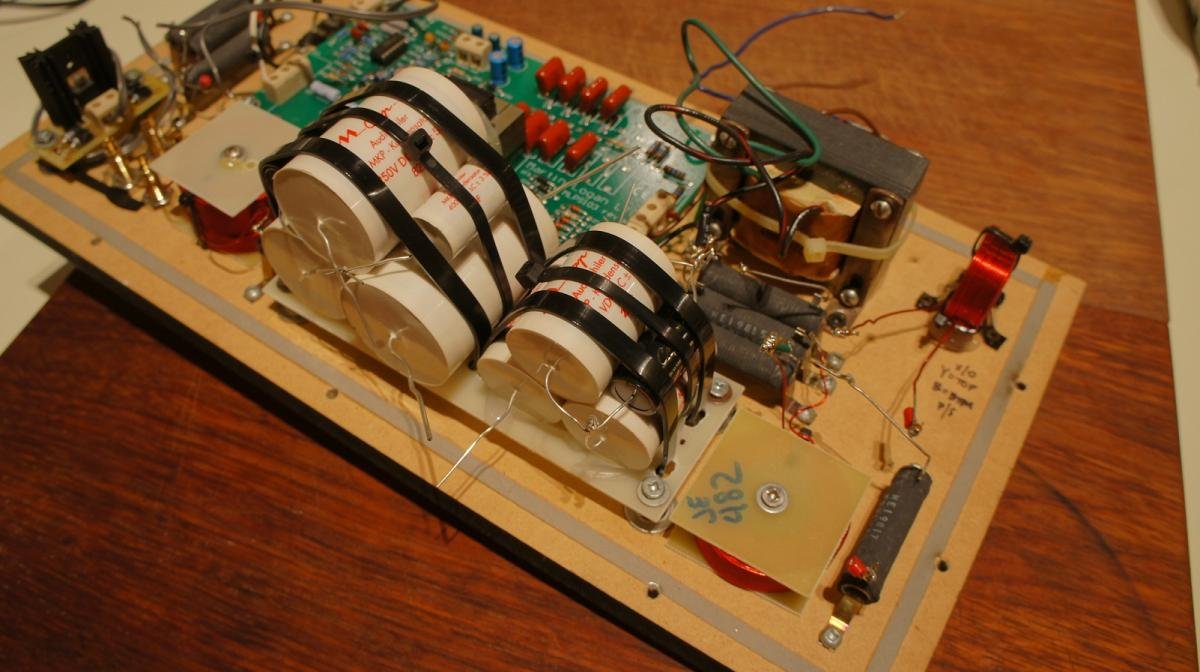

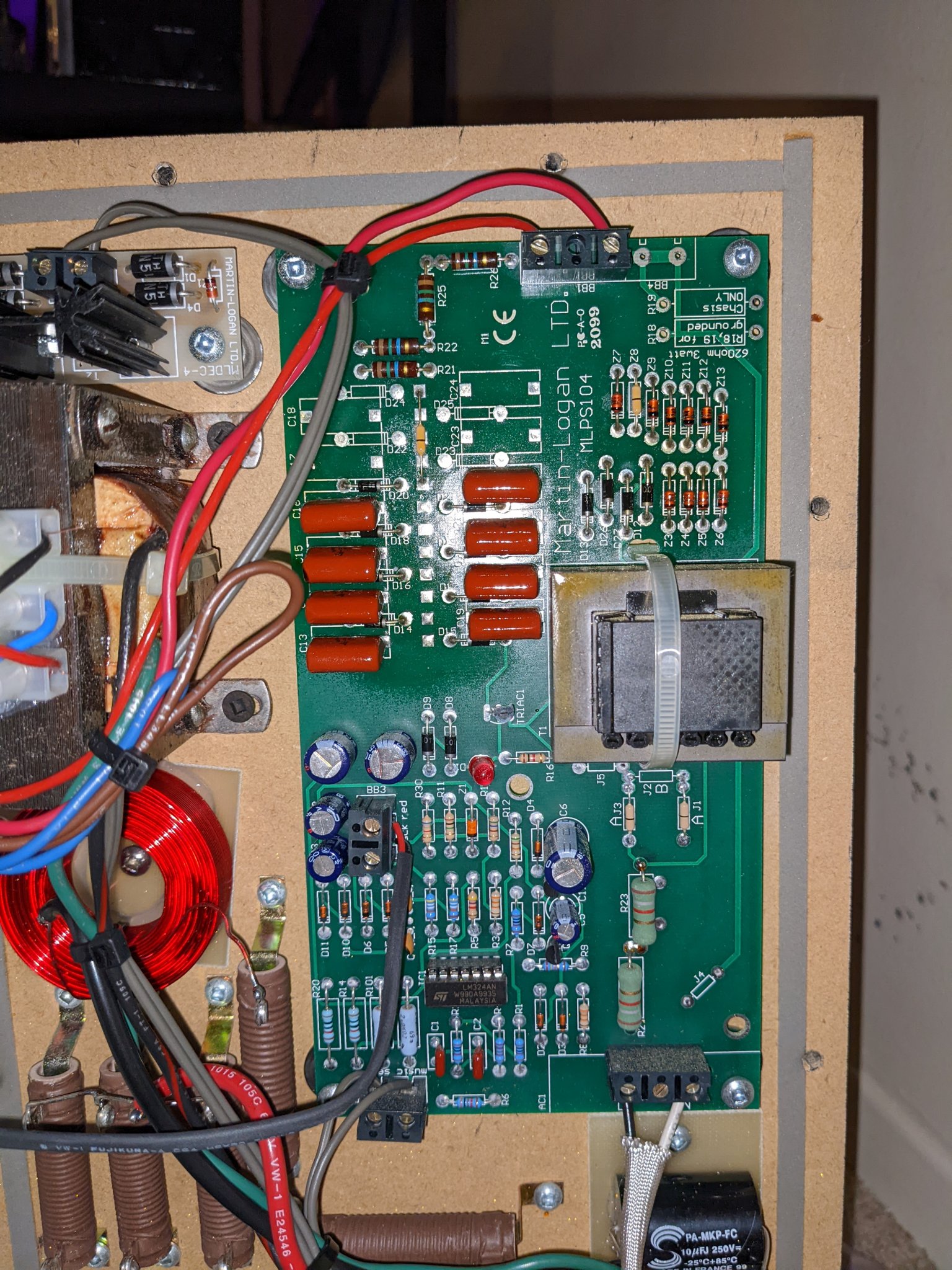

Through some internet searching I actually found this guy on another forum that is basically doing the exact same upgrade. Unfortunately it appears that he abandoned the project before it was completed. Fitment definitely looks tight but it should be manageable, the woofer enclosure looks like it could use some bracing for sure. Tonight or tomorrow I'll open mine up and see what's up inside.

e

e

Not much room, so go electrolytic for the woofer.

That fiberglass use is odd, it should be placed with the shiny side to the wood.

That fiberglass use is odd, it should be placed with the shiny side to the wood.

Regardless of room, have you looked at the cost of a 170uf film cap lmao!?Not much room, so go electrolytic for the woofer.

That fiberglass use is odd, it should be placed with the shiny side to the wood.

Are you talking about the dynamat? That's just how this stuff looks, the opposite side has the adhesive on it.

And there's no such thing as a 170uF capacitor. That would be custom made.

But that aluminum film coating will cause the sound inside the cabinet to bounce around.

There should be something else on top of it to absorb the sound from the back of the woofer.

Maybe there is, and it was removed for the photo. Most speakers have fiberglass etc. inside.

But that aluminum film coating will cause the sound inside the cabinet to bounce around.

There should be something else on top of it to absorb the sound from the back of the woofer.

Maybe there is, and it was removed for the photo. Most speakers have fiberglass etc. inside.

Yes, you're correct, more than one cap would be required to get the correct value.And there's no such thing as a 170uF capacitor. That would be custom made.

But that aluminum film coating will cause the sound inside the cabinet to bounce around.

There should be something else on top of it to absorb the sound from the back of the woofer.

Maybe there is, and it was removed for the photo. Most speakers have fiberglass etc. inside.

I would agree that there should be some kind of matting inside the box, it's probably just not pictured. My guess is my speaker probably already has some kind of filling inside from the factory. I can buy the stuff at walmart if I need to.

Dynamat is a mass loading membrane that will lower the resonant frequency of the panel it is attached to. The foil is for advertising as car stereo buyers think somehow it reduced heat transfer ( pointed the wrong way). The old paper faced stuff actually worked better. It is no more acoustically reflective than the cabinet panel. It's effectiveness in a speaker cabinet could be debated as it is intended to be on 22 gauge steel, but it won't hurt.And there's no such thing as a 170uF capacitor. That would be custom made.

But that aluminum film coating will cause the sound inside the cabinet to bounce around.

There should be something else on top of it to absorb the sound from the back of the woofer.

Maybe there is, and it was removed for the photo. Most speakers have fiberglass etc. inside.

I too would but a off-angle panel covered with felt or foam behind the woofer unless one was going to stuff the cabinet to lower the Q. ( It is sealed?)

If you want to put in polyfill, the WalMart stuff is very slippery and not as effective as the polyfill you get from places like Parts Express.

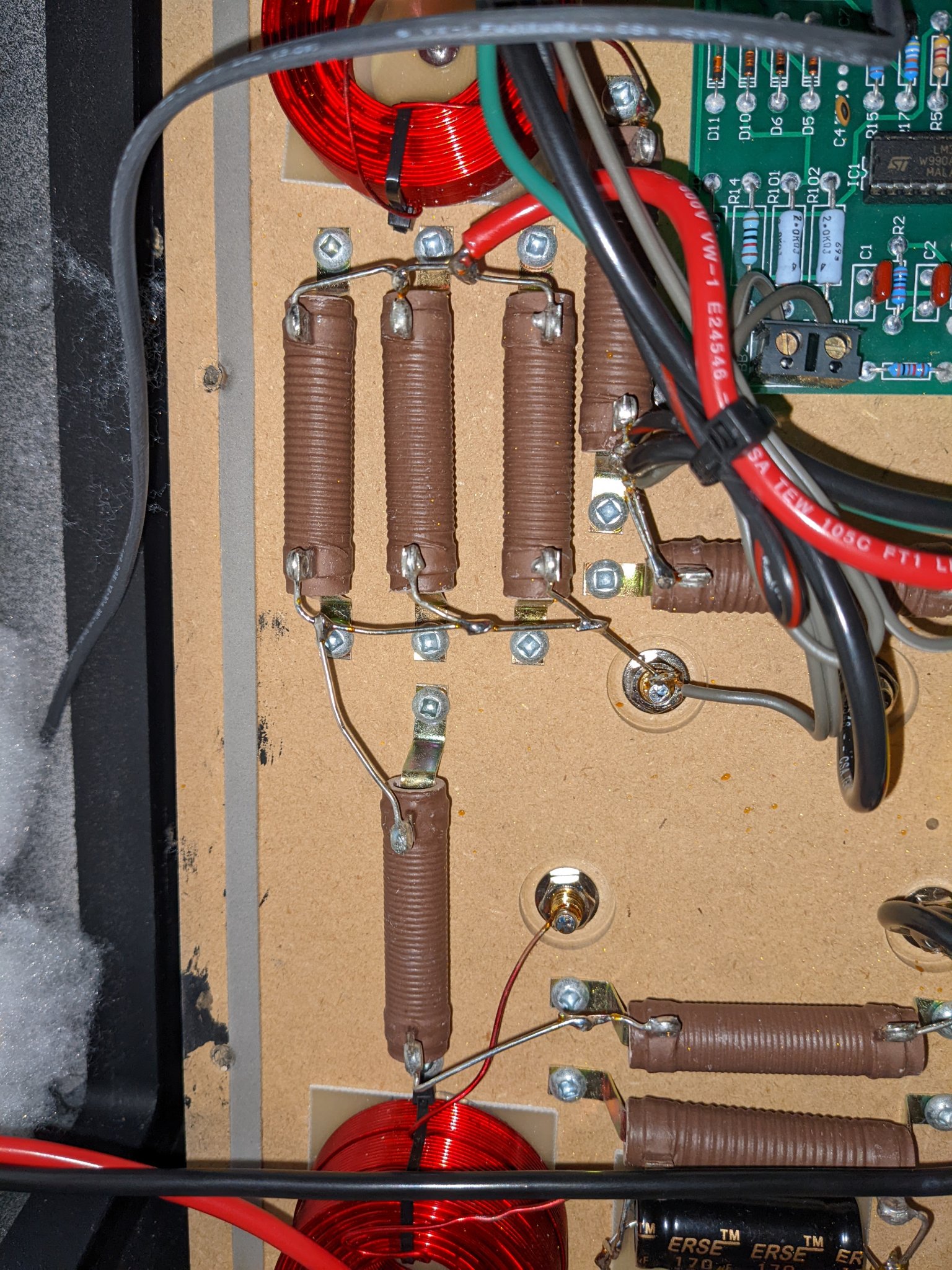

For your viewing pleasure, there's some pretty intense inductors and resistors in here for the price of these things. The cracks in the wood bracing could have been prevented with pre-drilling the wood, that's kinda sloppy.

I haven't measured anything yet

I haven't measured anything yet

Another thing I'm noticing is that the woofer enclosure on these things vibrate pretty bad, worse than most speakers I've encountered. I'll see about fixing that.

I bought these partly to tinker with them.

I bought these partly to tinker with them.

Remove those MDF braces and put a horizontal H brace spaced slightly off centerline or maybe even 2 braces

always asymetricaly spacing

1/2” mdf is plenty

always asymetricaly spacing

1/2” mdf is plenty

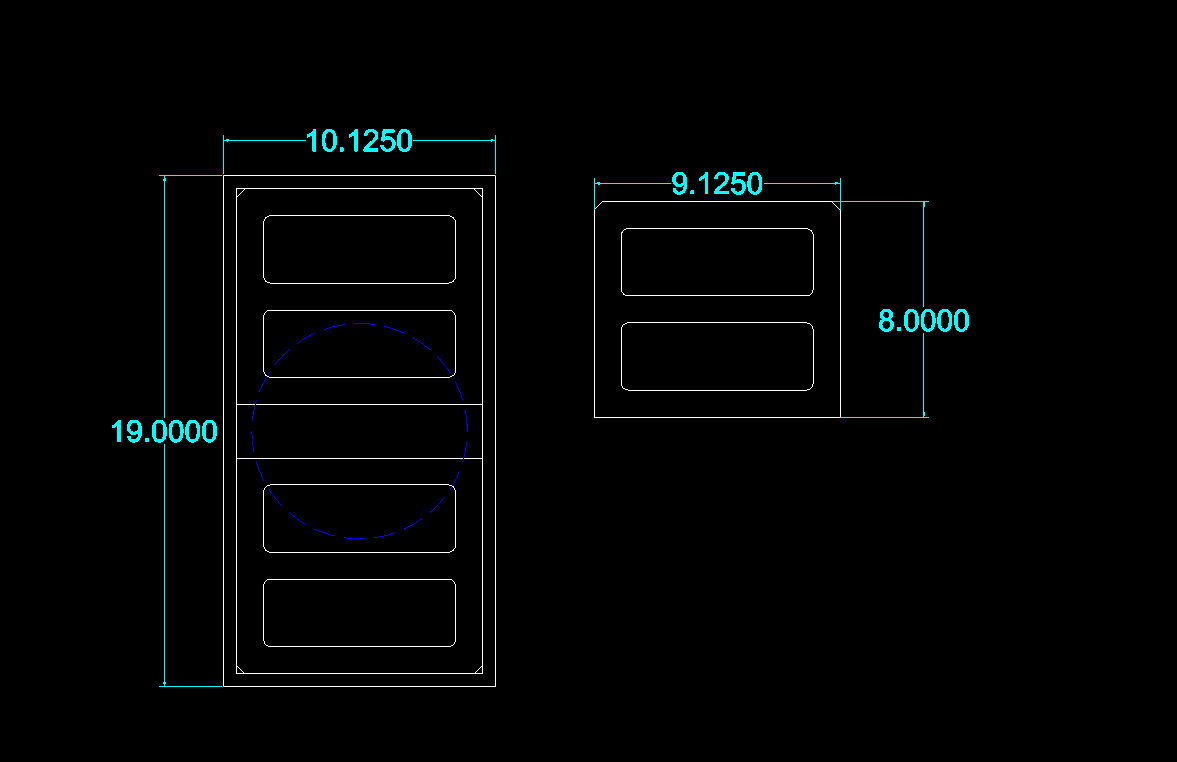

I took some measurements of the woofer cabinet last night and drew up some bracing. I'll be making 2, maybe 4 smaller braces instead of a single large one so I can actually get them inside the cabinet. I'll also be doubling up the wood on the rear panel on the outside, this will make it stick out a bit more but I don't think it'll be noticeable after I paint it black.

- Home

- Loudspeakers

- Planars & Exotics

- Martin Logan Aerius i crossover upgrades