CERNs main involvement at this time is providing the servers. Most of the developers are volunteers or paid by a commercial support services company

I don't understand your point?

Jan

Its MUCH better to support an open source project like KiCAD from taxes, than to sink the same money in worthless projects or give it to companies like MS, autodesk or google. Better support something available for many people.

I would also love to see government money supporting open source operating systems and office software, instead of feeding MS for example by buying tons of licenses for gov computers... Thats my point. Wasnt meant offensive, just that in my opinion this money is well spent.

I've used OrCad, Altium, Protel, and KiCad. I would say that KiCad can pretty much do anything the others can do except in some very specialized areas like microwave design.

Note that a single full altium license currently runs about $7000 USD per seat, OrCad is considerably friendlier with personal licenses available periodically for the basic version for about $400 USD. (I have one) OrCad comes with zero footprint libraries and a very small selection of symbols - most you will have to create yourself. This is pretty much true for Altium as well last time I was paying attention.

KiCad comes with a very large symbol library, the symbols are easily modified, there is a huge footprint library as well - again easily modified. Creating new libraries for symbols and footprints is a little arcane, but little worse than required for OrCad at least.

KiCad supports hierarchical sheets.

I can't remember the last time KiCad crashed.

I can't remember the last time I was not able to open an older schematic or board in KiCad. If you have legacy symbols there is an inconvenient way to deal with it, or you can ignore it. (That's what I usually do)

It's got an integrated gerber viewer.

DRC works well - never had a PCB that had fab problems or was defective because the tool didn't catch a mistake.

The 3D viewer is boss... 😀

Note that a single full altium license currently runs about $7000 USD per seat, OrCad is considerably friendlier with personal licenses available periodically for the basic version for about $400 USD. (I have one) OrCad comes with zero footprint libraries and a very small selection of symbols - most you will have to create yourself. This is pretty much true for Altium as well last time I was paying attention.

KiCad comes with a very large symbol library, the symbols are easily modified, there is a huge footprint library as well - again easily modified. Creating new libraries for symbols and footprints is a little arcane, but little worse than required for OrCad at least.

KiCad supports hierarchical sheets.

I can't remember the last time KiCad crashed.

I can't remember the last time I was not able to open an older schematic or board in KiCad. If you have legacy symbols there is an inconvenient way to deal with it, or you can ignore it. (That's what I usually do)

It's got an integrated gerber viewer.

DRC works well - never had a PCB that had fab problems or was defective because the tool didn't catch a mistake.

The 3D viewer is boss... 😀

Its MUCH better to support an open source project like KiCAD from taxes, than to sink the same money in worthless projects or give it to companies like MS, autodesk or google. Better support something available for many people.

I would also love to see government money supporting open source operating systems and office software, instead of feeding MS for example by buying tons of licenses for gov computers... Thats my point. Wasnt meant offensive, just that in my opinion this money is well spent.

OK, clear. But of course governments cannot compete with commercial companies. They can't spend taxpayers money to compete with taxpayers jobs ...

Jan

OK, clear. But of course governments cannot compete with commercial companies. They can't spend taxpayers money to compete with taxpayers jobs ...

Jan

Depends. This could cerate new jobs for example if you switch to Linux on gov computers. You would not pay MS, instead you would need local companies, who help to maintain the systems...

I contacted KiCAD with the bug I found.

Apparently my ticket number is 9480 so I suspect they have had one or two bugs in the past ! Going by the forum there are a lot of bugs in it.

Turns out there is a fix for the bug buts its an app you have to load.

They didnt say if it worked for hierarchical sheets too.

Apparently my ticket number is 9480 so I suspect they have had one or two bugs in the past ! Going by the forum there are a lot of bugs in it.

Turns out there is a fix for the bug buts its an app you have to load.

They didnt say if it worked for hierarchical sheets too.

I here you Suzy 🙂

In my case I use a gerber viewer (GerbTool) as my verification tool before I submit for fab. I use jlcpcb, one advantage is that they also display the fab data for you to, yet again do another visual check before production. It has saved me from a fault too.

I do agree that any and every tool available should be used to insure correctness.Also being able to see the bare board like you’re holding it in your hands is valuable. The number of times I haven’t spotted a dodgy pour or wrong hole size until I got the boards is embarrassingly high. This sorts that

In my case I use a gerber viewer (GerbTool) as my verification tool before I submit for fab. I use jlcpcb, one advantage is that they also display the fab data for you to, yet again do another visual check before production. It has saved me from a fault too.

Last edited:

We all write bugs. Then we fix them. It doesn't matter how good we are, it happens.

It depends on how those bugs are dealt with.

A previous message on this thread says it took KiCAD a year to fix an important bug.

I looked up my last CAD bug fix and it was 10 minutes from bug alert to download available on the internet.

I had a customer today complain about a scope I sold them.

2 hours to fix it and chips in the post to them straight away.

I had a bug report back from KiCAD.

It looks they arent sure what to do about it according to this message.

It looks they arent sure what to do about it according to this message.

Currently, inserting footprints via Update PCB from Schematic leaves them in neat piles according to their hierarchical sheet origin.

In case of designs with multiple copies of a sub-circuit, there used to be replicate_layout ( GitHub - MitjaNemec/Kicad_action_plugins: Kicad action plugins ), which is unlikely to be reworked to accommodate format / API changes that break it for current nightlies by the time v6 is released.

Potential v7 plans to work towards design reuse aside, Update PCB from Schematic seems to be a good place to offer an option to insert new footprints not in an arbitrary pile but with relative placement gleaned from a preexisting portion of the layout. Even if replicate_layout is eventually upgraded to work with v6, arranging footprints with more meaning could be worthwhile.

Currently I don't see how layout replication would be possible at all. It seems there isn't even a way to list or highlight layout items that hold the same position / function in other copies of the same sheet and do everything manually.

Nigel,

There no question that the support of your product is unheard of, where you can converse directly to the developer and get near immediate bug fixes. Everyone would love that and take note developers/companies of what it takes to provide that level of support.

It really comes down to S/W QC and the mind set to write error free code. I was/am a H/W guy, and always said if we designed H/W like they wrote S/W nothing would ever work first time. And I mean chips too, I worked on a project where I was supposed to do one most two revisions of a pcb. HP kept track of how many pcb spins to manufacture release. I think it was something like 1.3, which is damn good. This was by first design with HP. well the TI ASICs were brain dead, we had to put a mess of CPLD,FPGA around the data path(ASIC) to work out all the bugs, then do a final layout with the new logic to support the brain dead ASIC. I did 10 pcb spins to get to MR. It was just going to be too much time to spin the ASIC, fab, it was never in the budget, this was at HP. I know long story but I get your point, the rest of the world is well writing buggy code, what can I say anymore 🙂 I remember these discussions with Mentor BS support, why are you writing code for new features when you have serious bugs in your existing code? They abandoned the whole buggy BS layout code and bought Veribest code which if you can believe is the really old Cadnetix beginnings, I think they do hierarchical annotation blocks properly 🙂 Okay enough from me enjoy your KiCad.

One last thought, with H/W logic and even analog, one has the ability to simulate to great accuracies. With S/W the ability to simulate just ain't there, it requires someone to push the buttons and exercise all the branches or end cases I assume. This is an audio forum damn it, back to work, I have shipping to do before bed.

There no question that the support of your product is unheard of, where you can converse directly to the developer and get near immediate bug fixes. Everyone would love that and take note developers/companies of what it takes to provide that level of support.

It really comes down to S/W QC and the mind set to write error free code. I was/am a H/W guy, and always said if we designed H/W like they wrote S/W nothing would ever work first time. And I mean chips too, I worked on a project where I was supposed to do one most two revisions of a pcb. HP kept track of how many pcb spins to manufacture release. I think it was something like 1.3, which is damn good. This was by first design with HP. well the TI ASICs were brain dead, we had to put a mess of CPLD,FPGA around the data path(ASIC) to work out all the bugs, then do a final layout with the new logic to support the brain dead ASIC. I did 10 pcb spins to get to MR. It was just going to be too much time to spin the ASIC, fab, it was never in the budget, this was at HP. I know long story but I get your point, the rest of the world is well writing buggy code, what can I say anymore 🙂 I remember these discussions with Mentor BS support, why are you writing code for new features when you have serious bugs in your existing code? They abandoned the whole buggy BS layout code and bought Veribest code which if you can believe is the really old Cadnetix beginnings, I think they do hierarchical annotation blocks properly 🙂 Okay enough from me enjoy your KiCad.

One last thought, with H/W logic and even analog, one has the ability to simulate to great accuracies. With S/W the ability to simulate just ain't there, it requires someone to push the buttons and exercise all the branches or end cases I assume. This is an audio forum damn it, back to work, I have shipping to do before bed.

Last edited:

Total novice here. I bought Spring Layout 5.0 several years ago and actually made a bit of progress and did a couple of small designs with it. Didn't keep with it as I was using bootcamp to do windows on a mac. I did buy a copy of Nigel's software. Again windows only. I couldn't even begin with it, I had no idea where to start. And, the graphics didn't agree with me (sorry, personal preference). Diptrace and Kicad seem to both have good Mac versions. I've now started on Kicad. I'm taking the course on Udemy and we'll see where I get to. Perhaps it's too late to teach this old dog new tricks, we'll see 🙂

Steve.

Steve.

I am not saying I write perfect code. No one does.

It doesnt matter too much so long as you test it thoroughly.

You can write a great pile of garbage but as long as you debug it right then you get 99% good code out the other end. Garbage in, good code out !

I can see KiCAD's problem in that its a huge piece of very complicated code.

With complicated code comes complicated bugs.

I prefer to keep it simple where possible but often get slammed for it.

KiCAD has 20+ programmers.

Good communication in that scenario is critical.

It doesnt matter too much so long as you test it thoroughly.

You can write a great pile of garbage but as long as you debug it right then you get 99% good code out the other end. Garbage in, good code out !

I can see KiCAD's problem in that its a huge piece of very complicated code.

With complicated code comes complicated bugs.

I prefer to keep it simple where possible but often get slammed for it.

KiCAD has 20+ programmers.

Good communication in that scenario is critical.

Total novice here. I bought Spring Layout 5.0 several years ago and actually made a bit of progress and did a couple of small designs with it. Didn't keep with it as I was using bootcamp to do windows on a mac. I did buy a copy of Nigel's software. Again windows only. I couldn't even begin with it, I had no idea where to start. And, the graphics didn't agree with me (sorry, personal preference). Diptrace and Kicad seem to both have good Mac versions. I've now started on Kicad. I'm taking the course on Udemy and we'll see where I get to. Perhaps it's too late to teach this old dog new tricks, we'll see 🙂

Steve.

I thought this was a KICAD thread ?

You obviously either didnt read the manual or watch the demo video !

Seems more like the sour grapes thread. My Kicad content was that based on many recommendations, including susyj’s strong endorsement, I’m giving it a shot.

Simple is good if it gets the job done. I've design a lot of complicated boards with no 3D so I think it is a waste of code to have to QA that code. But I do not run the show, I just use it and complain and find work arounds to the bugs, if they exist.I can see KiCAD's problem in that its a huge piece of very complicated code.

With complicated code comes complicated bugs.

I prefer to keep it simple where possible but often get slammed for it.

I never did understand S/W QA, I could find a bug in a new S/W release pretty fast. It really is a mind set of the QA process, because it involves someone pushing the right buttons.

It is not about sour grapes at all, we are talking about S/W QA and the users are the QA department, it has been like this for years, so the best that people help each other deal with the bugs and document the work arounds all the better for everyone. Just announcing about the TO-126 footprint being wrong at 100mil is a great help.

When Suzy J says it is a decent piece of code I believe her, she has pcbs to prove it, so do others, as long as your pcb gets made correctly all is good.

Last edited:

including susyj’s strong endorsement,

Personally I saw it as gross spam and was offended by it.

When Suzy J says it is a decent piece of code I believe her, she has pcbs to prove it, so do others, as long as your pcb gets made correctly all is good.

What about KiCAD 8450 tickets for bugs ? And their forum full of complaints ? Always two sides to every story.

Your obviously a braver man than me.

Last edited:

It was, until you barged in.

Sorry Nigel, but you trying to compare your product with KiCad is laughable. I haven't tried to run your CAD system, but I can tell from the screen grabs on your webpage that it's firmly stuck in 1993. I used to run Protel AutoTrax and Schedit on DOS machines, and it looked remarkably similar. Big, chunky graphics that were optimised for EGA and VGA. Text based menus, because they're quick and easy to code. No fonts, so your silkscreens and schematics come out barely legible.

The screen-grabs you show for your product do nothing for it. The PCB you feature is the sort of thing that, had one of my techs produced it, I'd have spent some time with them teaching them how to design a decent board. Little things, like bevelling corners at 45 degrees (and sticking to 45 and 90 degree tracks unless there's a good reason not to), honouring minimum feature size for via annular rings, not having acute angles where tracks join. Cleaning up after you've done a copper pour so there's no mess.

And your schematics are barely readable. The whole idea of design is to make something that's manufacturable and maintainable, and those designs you show are neither.

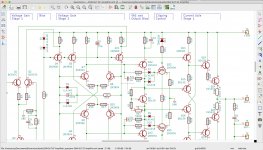

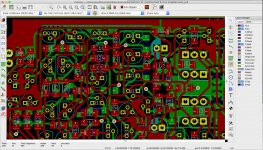

KiCad, on the other hand, creates very manufacturable boards, and really beautiful schematics. I've attached a couple of screen-grabs from the board I'm currently working on. It's a dense little guy, with a whole lot of transistors, but that's how I like to do things. KiCad makes the job of producing a really clean schematic and layout straightforward.

I think you should stop bagging something where it's obvious you've got a clear financial motive to do so. We get you're bitter. Now rack off please.

Sorry Nigel, but you trying to compare your product with KiCad is laughable. I haven't tried to run your CAD system, but I can tell from the screen grabs on your webpage that it's firmly stuck in 1993. I used to run Protel AutoTrax and Schedit on DOS machines, and it looked remarkably similar. Big, chunky graphics that were optimised for EGA and VGA. Text based menus, because they're quick and easy to code. No fonts, so your silkscreens and schematics come out barely legible.

The screen-grabs you show for your product do nothing for it. The PCB you feature is the sort of thing that, had one of my techs produced it, I'd have spent some time with them teaching them how to design a decent board. Little things, like bevelling corners at 45 degrees (and sticking to 45 and 90 degree tracks unless there's a good reason not to), honouring minimum feature size for via annular rings, not having acute angles where tracks join. Cleaning up after you've done a copper pour so there's no mess.

And your schematics are barely readable. The whole idea of design is to make something that's manufacturable and maintainable, and those designs you show are neither.

KiCad, on the other hand, creates very manufacturable boards, and really beautiful schematics. I've attached a couple of screen-grabs from the board I'm currently working on. It's a dense little guy, with a whole lot of transistors, but that's how I like to do things. KiCad makes the job of producing a really clean schematic and layout straightforward.

I think you should stop bagging something where it's obvious you've got a clear financial motive to do so. We get you're bitter. Now rack off please.

Attachments

- Home

- Design & Build

- Software Tools

- KiCad 5.1