Regarding loading, here's a bit of practical matter - a comparison of the same 1" driver in two different devices. (BEM+LE simulation)

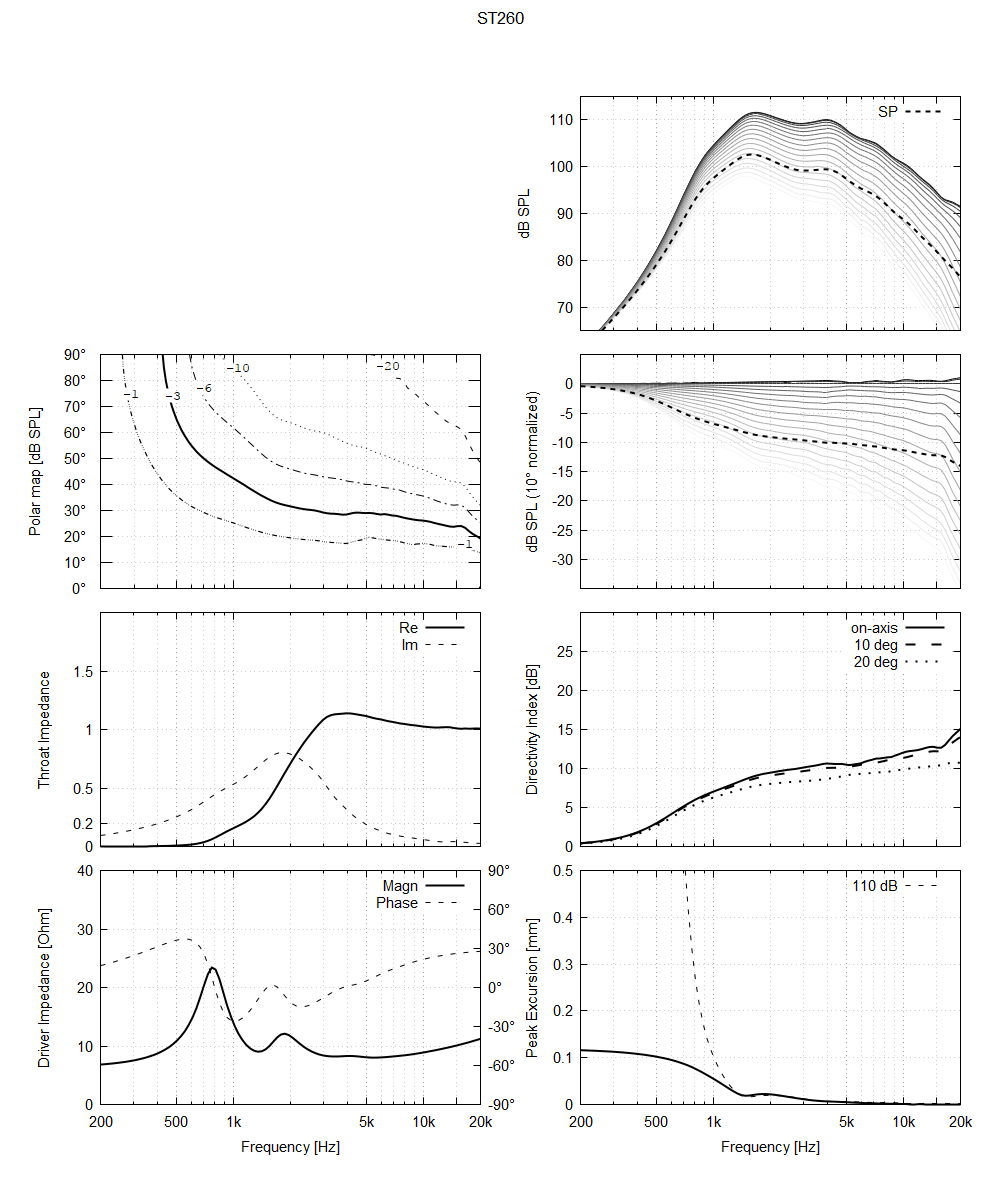

Device A:

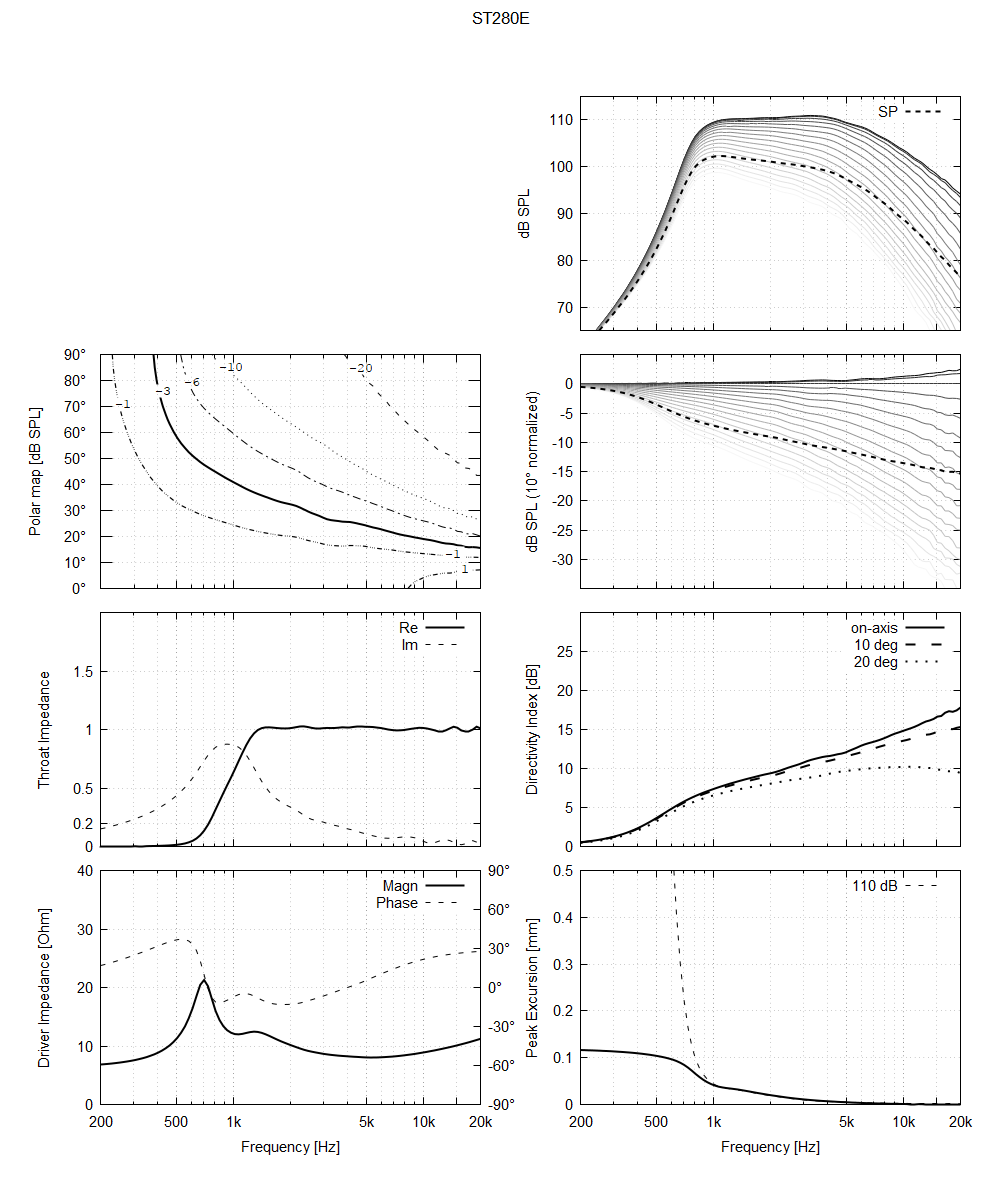

Device B:

Both devices have a similar diameter.

1) Notice the difference in "Throat impedance".

2) Notice the bottom-right graphs showing the peak excursion required for 110 dB SPL at 1m (the dashed line).

3) Notice the difference in HF beaming between the two.

By increasing loading, you gain a bit of efficiency and somewhat lower crossover point and also quite a bit of HF beaming, which can be really annoying and make it sounding unnatural. It's up to you to decide if it's worth it.

Device A:

Device B:

Both devices have a similar diameter.

1) Notice the difference in "Throat impedance".

2) Notice the bottom-right graphs showing the peak excursion required for 110 dB SPL at 1m (the dashed line).

3) Notice the difference in HF beaming between the two.

By increasing loading, you gain a bit of efficiency and somewhat lower crossover point and also quite a bit of HF beaming, which can be really annoying and make it sounding unnatural. It's up to you to decide if it's worth it.

Last edited:

New measurements, this time in the near field, closer to the horn mouth, without any smoothing or time-windowing.I'm using the Yuichi A-320FL model (also sometimes incorrectly referred to as A-290FL). It's very similar to the more famous A-290, but without the fins.

Its design parameters are Fc = 320Hz and T = 0.6.

I use it with a JBL 2450J 4" diaphragm/2" exit driver, equipped with a Truextent Beryllium diaphragm.

The internal geometry of this driver is an almost perfect match to this horn, in terms of maintaining the same flare rate at the transition between the driver's exit and the horn's throat - and that is an important factor in obtaining the best performance from any driver+horn combo.

Of course, this is no coincidence, since the Yuichi 2" horns were all designed for the TAD TD-4001 driver, which has an almost identical internal geometry to the JBL 2450...

Here is the on-axis frequency response, measured indoors at 1m, with no "protection" capacitor or any other high-pass filter, but with some slight high-frequency Eq. provided by a passive RC filter.

Good loading down to the cut-off frequency (-6dB @ 320Hz), and pretty flat and free from resonances up to 17kHz.

Marco

1) On-axis frequency + phase and impulse responses. No high-pass filter, with slight hi-freq. Eq. provided by passive RC filter:

2) Same frequency measurement as above, plus additional measurement (in green) with the addition of an active 24db/oct Linkwitz-Riley high-pass filter (this is how I am using this horn in my system at the moment):

Despite what has been said in this thread before, I believe these measurements confirm good horn loading down to approx. 300Hz.

They also show rather good linearity all the way from 320 Hz to 17kHz. Make of them what you will.

Best,

Marco

Marco,

so the red trace is the AC coupled and attenuated driver corresponding to the pure horn loading response and the green trace is that + the LR.

What is the cutoff of the LR filter? The response seems to be more linear than what was shown earlier with the different driver. Is that because of the better driver/horn match?

thanks

so the red trace is the AC coupled and attenuated driver corresponding to the pure horn loading response and the green trace is that + the LR.

What is the cutoff of the LR filter? The response seems to be more linear than what was shown earlier with the different driver. Is that because of the better driver/horn match?

thanks

This is the kind of explanation I was hoping to find. Thank you so much for sharing!

A couple days ago I looked into ordering the Kolbrek-Dunker horn book as it appears to be well reviewed (your support increases my confidence further) and I could not find another textbook on the topic! Alas shipping from the UK to Canada is expensive, so I am standing by to order it from the US when they receive a new shipment.

Also, I have enquired about having a custom throat adaptor made that precisely matches the exit angle of the Radian driver (4 degrees). If anybody knows suppliers or someone willing to make this, please PM me.

Just to clarify "flare rate". The driver exit has a particular cross section area, as does the horn's throat entrance. The rate the adapter area changes from driver to throat is the flare rate and determines the length of the adapter. You may not be able to match the driver's exit angle, but this is secondary.

Not sure exactly what you mean by "AC coupled" or "attenuated", but like I said, the red trace is the driver+horn+passive RC eq. without any high-pass filter.Marco,

so the red trace is the AC coupled and attenuated driver corresponding to the pure horn loading response and the green trace is that + the LR.

What is the cutoff of the LR filter? The response seems to be more linear than what was shown earlier with the different driver. Is that because of the better driver/horn match?

thanks

The green trace is the same, plus a 500Hz 4th order L-R high-pass.

The traces I had shared earlier in my first post in this thread were with the same driver and horn, but taken from further away and smoothed. These ones are in the near field, and unsmoothed.

Very useful measurements and example Marco. I was under the misconception that a 3 inch diaphragm would perform better than a 4 inch in flatness and top end extension. At least two of you have shown me otherwise. My purchase of the Radians 745NEO dates back to October 2013, just about when the new diaphragms became available. There was limited data to inform a decision back then.

Just to clarify "flare rate". The driver exit has a particular cross section area, as does the horn's throat entrance. The rate the adapter area changes from driver to throat is the flare rate and determines the length of the adapter. You may not be able to match the driver's exit angle, but this is secondary.

Thank you. I did not know whether it would be better to match driver exit angle and follow up with a conical-like expansion, or match the horn's flare rate. Your response settles this.

So I did a bit of math on a napkin and got this... The area of my driver's exit is 9.93 cm^2 and horn entrance 19.92 cm^2. The horn cutoff is 320 Hz and flare rate T=0.7. These numbers give me that the constant flare rate throat adaptor should be 7.5 cm long.

Interestingly, calculating the entrance angle of such an adaptor, I get 4.2 degrees. The driver's exit angle is 4 degrees. Nice that they land so close!

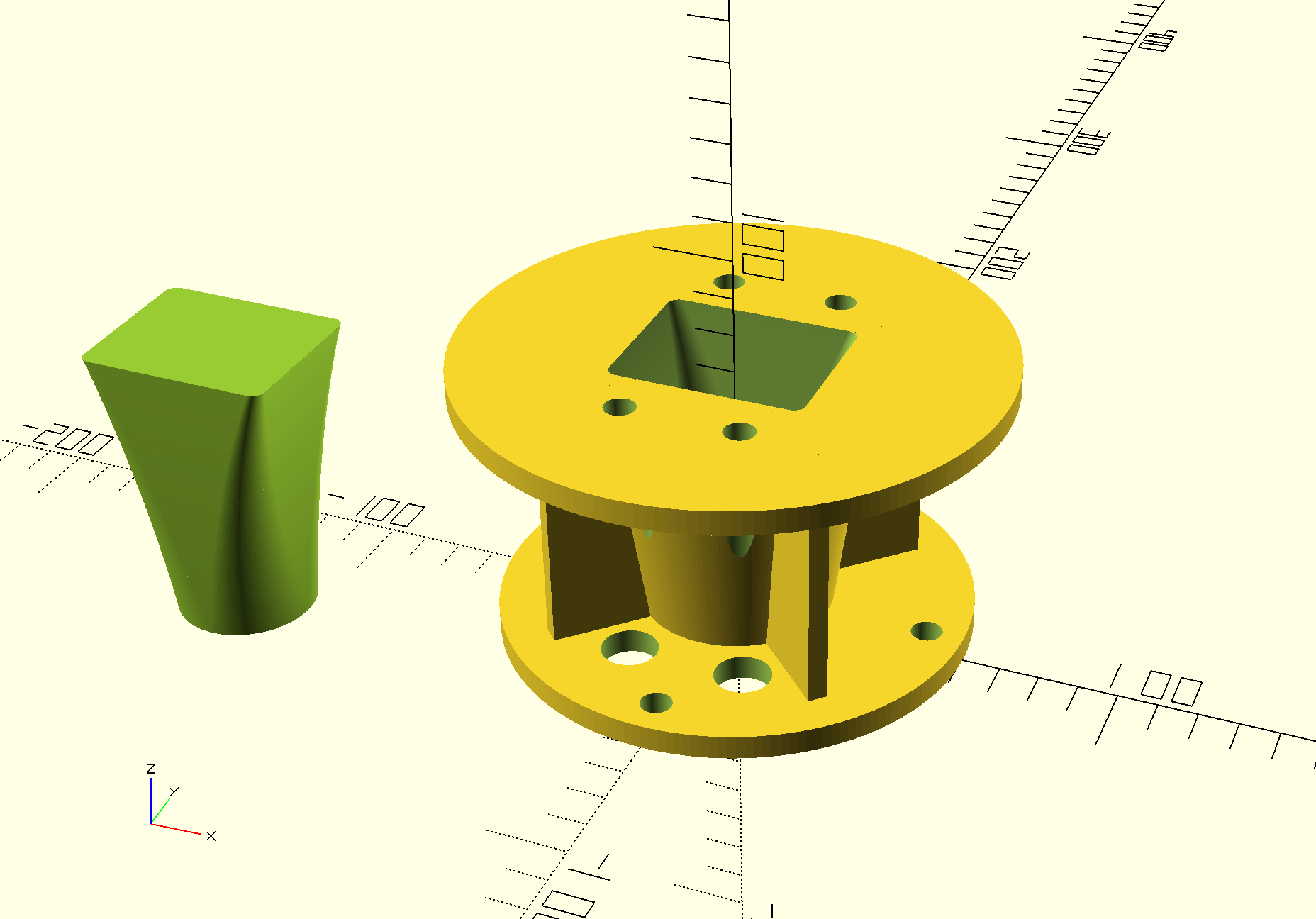

Just wanted to share that as a result of the good insights of fellow DIYers I am designing a custom throat adapter to fit my driver to the TAD horn.

The plan is to have a friend 3D print this, and then if all goes well I will remeasure the driver's impedance and response with it. It's a hypex T=0.7 starting at 4 degrees flare and shaped to fit the rectangular entrance of the TAD horn. The throat expansion is shown on the left, and adaptor itself would look something like the drawing on the right:

The plan is to have a friend 3D print this, and then if all goes well I will remeasure the driver's impedance and response with it. It's a hypex T=0.7 starting at 4 degrees flare and shaped to fit the rectangular entrance of the TAD horn. The throat expansion is shown on the left, and adaptor itself would look something like the drawing on the right:

I have lived that experience. Using a 2” BMS compression driver on a 1.4” Altec horn going backwards through an adapter - did not do wonders for the top octave. 🙁some drivers are not shown in their best light when fitted to adaptors and horns that are poor matches...

Many throat adapters do not seem to match the flare rate of the horn. That would seem a bad idea.

color(‘’YellowGreen’’)

(sorry could not resist…)

I will post but first I want to try changes to the expansion that have been suggested offline.

(sorry could not resist…)

I will post but first I want to try changes to the expansion that have been suggested offline.

Last edited:

OK🙂 I meant in general - which primitives were used, etc, I am not really interested in the particular shape, but I would like to learn how to go beyound a simple "hull" of two bodies.

Oh, I just stacked hull() shapes. As you noticed, calling hull() once for all slices does not give the desired result ;-).

I derive a function that plots a slice at height z having the surface area and shape I want.

Then in a for() loop, I call hull() for every pair of adjacent slices.

Here's my code, although you certainly don't need it:

for (z = [D/slices: D/slices: D]){

hull(){

plotslice(z-(D/slices));

plotslice(z); } }

where variables "D" and "slices" are the adaptor height and number of slices.

I derive a function that plots a slice at height z having the surface area and shape I want.

Then in a for() loop, I call hull() for every pair of adjacent slices.

Here's my code, although you certainly don't need it:

for (z = [D/slices: D/slices: D]){

hull(){

plotslice(z-(D/slices));

plotslice(z); } }

where variables "D" and "slices" are the adaptor height and number of slices.

this is much easier than my struggle to create a similar shape in fusion360: https://www.diyaudio.com/community/...per-scripts-and-m200-fun.385493/#post-7197793

A clarification: you're going from 2" to 1.4" and ten expanding in the horn? Wouldn't that adaptor need some type of phase plug? It seems totally different than what Pierre is doing.I have lived that experience. Using a 2” BMS compression driver on a 1.4” Altec horn going backwards through an adapter - did not do wonders for the top octave. 🙁

Many throat adapters do not seem to match the flare rate of the horn. That would seem a bad idea.

Yes. I’m doing it wrong because at the moment there is no choice.

I use it as illustration of a rather bad adapter, that have some obviously bad effects

Earlier in the thread it was mentioned that marching rate of expansion of the might be more important than matching the exit angle of the CD. I wonder how difficult this could be to do, given the expansion of something like a Smith horn or Yuichi.

In a very long horn like the WE 15A or Vitaphone 11’ the throat adapter is long and makes a gradual exponential change from small round to larger square. There is the room and distance to do it well. Designing a good adapter for horns with much faster expansion rates, and asymmetrical ones, has to be much more difficult. What are the best practices? What are the results of doing it wrong?

I use it as illustration of a rather bad adapter, that have some obviously bad effects

Earlier in the thread it was mentioned that marching rate of expansion of the might be more important than matching the exit angle of the CD. I wonder how difficult this could be to do, given the expansion of something like a Smith horn or Yuichi.

In a very long horn like the WE 15A or Vitaphone 11’ the throat adapter is long and makes a gradual exponential change from small round to larger square. There is the room and distance to do it well. Designing a good adapter for horns with much faster expansion rates, and asymmetrical ones, has to be much more difficult. What are the best practices? What are the results of doing it wrong?

Thanks Pano. Purely intuitively, the horn expansion should designed from the inner driver phase plug. Any discontinuity would be problematic.

I guess smart people can simulate the effect.

I guess smart people can simulate the effect.

My friend delivered Prototype 1 of the 3D printed custom adaptor today. Although the printer settings need adjustment, the approach is promising already. While I test Prototype 1 on the horn, my friend will print Prototype 2 using a different support structure and smaller vertical increment.[...] designing a custom throat adapter to fit my driver to the TAD horn. [...]

View attachment 1142477

- Home

- Loudspeakers

- Multi-Way

- JMLC and Yuichi horns measurements