This guy: https://www.nisshinbo-microdevices.co.jp/en/MUSES/series/MUSES72320.html

It's used in a number of nice preamps, including the Pass XP30.

There are a number of DIY implementations around. For example:

https://www.diyaudio.com/community/threads/muses-volume.322983/

https://www.academyaudio.com/product-page/vcu-hi-end-muses-micro-volume-control-board

It's used in a number of nice preamps, including the Pass XP30.

There are a number of DIY implementations around. For example:

https://www.diyaudio.com/community/threads/muses-volume.322983/

https://www.academyaudio.com/product-page/vcu-hi-end-muses-micro-volume-control-board

Wow! I'm vary glad to see so much attention.

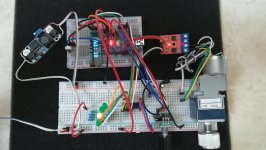

My project is based on Arduino nano. With 16 MHz clock it has enough capacity to do the job like remote control.

At the beginning the ALPS pot will be calibrated, the time for a full turn around is measured and duration of one

step is calculated for max volume scale. The max volume value can be defined as needed.

Pot calibration has to be done once only.

The last selected input and last volume value are saved in EEPROM because pot always knows its position.

A rotary encoder on face plate allows to control volume and input selection directly on device.

There is no need to have the pot shaft and knob on face plate. All control is done with the rotary encoder.

You can add your remote control modifying existing software module or add a new. There is a library for

nearly any vendor. My over 30 years old JVC remote works perfect with it.

Testing on my test bed has been ok. Now I'm waiting for the first prototype PCB.

If everything goes well, I will provide the software and the PCB data.

My project is based on Arduino nano. With 16 MHz clock it has enough capacity to do the job like remote control.

At the beginning the ALPS pot will be calibrated, the time for a full turn around is measured and duration of one

step is calculated for max volume scale. The max volume value can be defined as needed.

Pot calibration has to be done once only.

The last selected input and last volume value are saved in EEPROM because pot always knows its position.

A rotary encoder on face plate allows to control volume and input selection directly on device.

There is no need to have the pot shaft and knob on face plate. All control is done with the rotary encoder.

You can add your remote control modifying existing software module or add a new. There is a library for

nearly any vendor. My over 30 years old JVC remote works perfect with it.

Testing on my test bed has been ok. Now I'm waiting for the first prototype PCB.

If everything goes well, I will provide the software and the PCB data.

Attachments

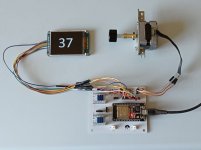

Not trying to steal your thunder, ACnotDC, but I just want to show the remote control project that I'm busy with. Yours will by much more affordable though.

The stepper motor is being used as a high res rotary encoder, because I like the smooth tactile feel and 200 steps. The 2.4 inch LCD screen allows the use of big fonts, which in turn requires more memory than an Arduino has. I therefore have to use the ESP32. It's Arduino compatible and lightning fast.

The stepper motor is being used as a high res rotary encoder, because I like the smooth tactile feel and 200 steps. The 2.4 inch LCD screen allows the use of big fonts, which in turn requires more memory than an Arduino has. I therefore have to use the ESP32. It's Arduino compatible and lightning fast.

Attachments

Last edited:

Skylar88, don't worry, it's great when we have a wide range of possible solutions and

people can choose one that suits them best.🙂

Your use of the stepper motor as a high-resolution rotary encoder is very clever,

and your choice of the ESP32 to handle the large fonts shows your understanding

of your project's requirements.

I have a question: Have you found an ALPS pot that can be controlled with stepper motor?

How is the volume controlled in your project?

people can choose one that suits them best.🙂

Your use of the stepper motor as a high-resolution rotary encoder is very clever,

and your choice of the ESP32 to handle the large fonts shows your understanding

of your project's requirements.

I have a question: Have you found an ALPS pot that can be controlled with stepper motor?

How is the volume controlled in your project?

From the start I knew that I wanted balance control. Therefore I decided to use two stepper motors to turn two Cermet pots.

I used tiny Nema-8 steppers and TMC2130 drivers.

Note the resistors and opamp on the board to amplify the tiny signals coming from the rotary encoder.

Hopefully there will be enough flash RAM to fit in a few splash screens as well.😉

I used tiny Nema-8 steppers and TMC2130 drivers.

Note the resistors and opamp on the board to amplify the tiny signals coming from the rotary encoder.

Hopefully there will be enough flash RAM to fit in a few splash screens as well.😉

Last edited:

The attention to detail and precision demonstrated in your use of two stepper motors to control two Cermet pots is truly impressive. 👍

Overall, the pictures you have shared showcase the incredible technical skill that went into this project. It is clear that every detail was carefully considered and executed. Well done!

Overall, the pictures you have shared showcase the incredible technical skill that went into this project. It is clear that every detail was carefully considered and executed. Well done!

Projects like yours and mine just show what is possible when we get restless while waiting for the Iron Pre kits. 😎

I have to admit that I think your remote controlled attenuator is probably more practical and certainly much cheaper and less finicky. It will also be easier to share with others.

I have to admit that I think your remote controlled attenuator is probably more practical and certainly much cheaper and less finicky. It will also be easier to share with others.

I will be watching. I've got one on the bench sitting and waiting. The site gives pretty much all the info to use it with BA 2018, will have to adapt to this pre.I’m going to attempt to build a iron pre se with one of these : https://www.academyaudio.com/

Russellc

Here's a photo of the Muses VC system I bought waiting for the pre. The VC with OLED display is by Frank Wilker with description here Muses. I bought this during the Covid era (2020) and still have not installed it yet.

I was also looking at the Muse solution, but I've found that Muse chip need an output buffer and all the project I've seen around are using an integrated IC to implement this buffer.

So the question is: do it have any meaning to insert in the audio signal path an integrated operational circuit in this Iron Pre that is full discrete preamp project ?

So the question is: do it have any meaning to insert in the audio signal path an integrated operational circuit in this Iron Pre that is full discrete preamp project ?

You already have a buffer on the input of the IP so you can connect directly the muse and enjoy.

I'm referring to already available solutions that use Muse IC like the one Amandarae suggested (just as one of the many other available). All these project have already a output buffer as per manufacturer requirement.

To avoid this, one should make a project tailored for the IP only instead of using a ready made ones.

https://www.nisshinbo-microdevices.co.jp/en/pdf/datasheet/MUSES72320_E.pdf

To avoid this, one should make a project tailored for the IP only instead of using a ready made ones.

https://www.nisshinbo-microdevices.co.jp/en/pdf/datasheet/MUSES72320_E.pdf

This is really something 😳🙂! I love the precision approach and the large screen. Have you documented the project anywhere?From the start I knew that I wanted balance control. Therefore I decided to use two stepper motors to turn two Cermet pots.

I used tiny Nema-8 steppers and TMC2130 drivers.

Note the resistors and opamp on the board to amplify the tiny signals coming from the rotary encoder.

Hopefully there will be enough flash RAM to fit in a few splash screens as well.😉

No, only what I've posted here. It's a developing project, and I'm adding features as I go along. I might post a build thread later if it turns out the way I hope it will. Seeing that we're both in SA, you're welcome to send me a PM for more details.

There exists in the world actual chassis samples on the workbench of a most venerable captain....(they have as much ZM-ness as could be reasonably infused.)

Last edited:

- Home

- Amplifiers

- Pass Labs

- Iron Pre Essentials Kits For The DIYA Store - Register Your Interest