You did fine. I am also a big fan of neat wiring, but in practice it can be downright ugly. I tend to like wire that minds what I tell it to do. In some cases that would be a solid core, but there are other stranded wires that do better than you might expect when it comes to dressing.

If you had the connectors, I wonder how much trouble it would be to make your own non-ribbon cable. Maybe a twisted sort of version. You would have to make up one end first, then twist it and then make up the last end. Or even soldering just one end.

If you had the connectors, I wonder how much trouble it would be to make your own non-ribbon cable. Maybe a twisted sort of version. You would have to make up one end first, then twist it and then make up the last end. Or even soldering just one end.

^ Once you get the hang of it, doing most types of connections isn't too bad. Key is the correct crimper to match the connector. I thought for a good 5 seconds about re-doing them all ... black... with color coded ends... I thought about putting black sheathing over the primaries, but then decided I liked the black and red... There was the whole "blacked out / stealth concept...

I thought about a lot of things that never materialized....

The one thing that didn't go in that I actually bought to use was to use the little PEM condom that Schurter makes to go with their PEMs. I either ordered the wrong one, or they're really not suited to be used with blade connectors... or it's user error... My gut tells me that I ordered the wrong one b/c the condom has a little nubbin' for the wire exit in the center, where this PEM has the wiring off to one side.

I thought about a lot of things that never materialized....

The one thing that didn't go in that I actually bought to use was to use the little PEM condom that Schurter makes to go with their PEMs. I either ordered the wrong one, or they're really not suited to be used with blade connectors... or it's user error... My gut tells me that I ordered the wrong one b/c the condom has a little nubbin' for the wire exit in the center, where this PEM has the wiring off to one side.

Thanks for all the input Patrick. Balanced Pre is on my to do list and the info you shared is very helpful for my planning. Especially trying to understand what chassis to get for use with Frank's Muse boards. I like the stacking idea.

I got a one of those Schurter RC320 dust covers for the DD12/DD14 on my Iron Pre SE and I agree that it is pretty awkward fitting even when it is the correct version for the PEM.

I got a one of those Schurter RC320 dust covers for the DD12/DD14 on my Iron Pre SE and I agree that it is pretty awkward fitting even when it is the correct version for the PEM.

Listening or measuring? It’s hard to tell with you sometimes 😜it's no secret that I really like this pre-amp.

Stumped again with minutia. The jumper, comprised of 3 legs fused in plastic, and a small plastic handle piece. Legs are isolated, so handle piece must also short 2 legs together?

Obviously handle piece must short 2 legs, but I think I have fit this thing only way I can see it going. It is very loose, so I'm likely doing something wrong? No good pics here to help either.

Are the three legs soldered in place on board, then the shorting cap on top to short two legs to pick gain? Here's a pic of my parts. Altogether different from XA 252 jumpers. It appears that inside the handle part I can see two metal contacts that line up with the width of two pins,

but it is super loose. I didn't want to force anything, it is very fragile There is also a slot opening in the center with a metal cross piece, but didn't come up with any arrangement plausible.

The best pics don't hold up under magnification to see other than a blob.

Build guide didn't show it either, so I have to ask! 😔

Obviously handle piece must short 2 legs, but I think I have fit this thing only way I can see it going. It is very loose, so I'm likely doing something wrong? No good pics here to help either.

Are the three legs soldered in place on board, then the shorting cap on top to short two legs to pick gain? Here's a pic of my parts. Altogether different from XA 252 jumpers. It appears that inside the handle part I can see two metal contacts that line up with the width of two pins,

but it is super loose. I didn't want to force anything, it is very fragile There is also a slot opening in the center with a metal cross piece, but didn't come up with any arrangement plausible.

The best pics don't hold up under magnification to see other than a blob.

Build guide didn't show it either, so I have to ask! 😔

Attachments

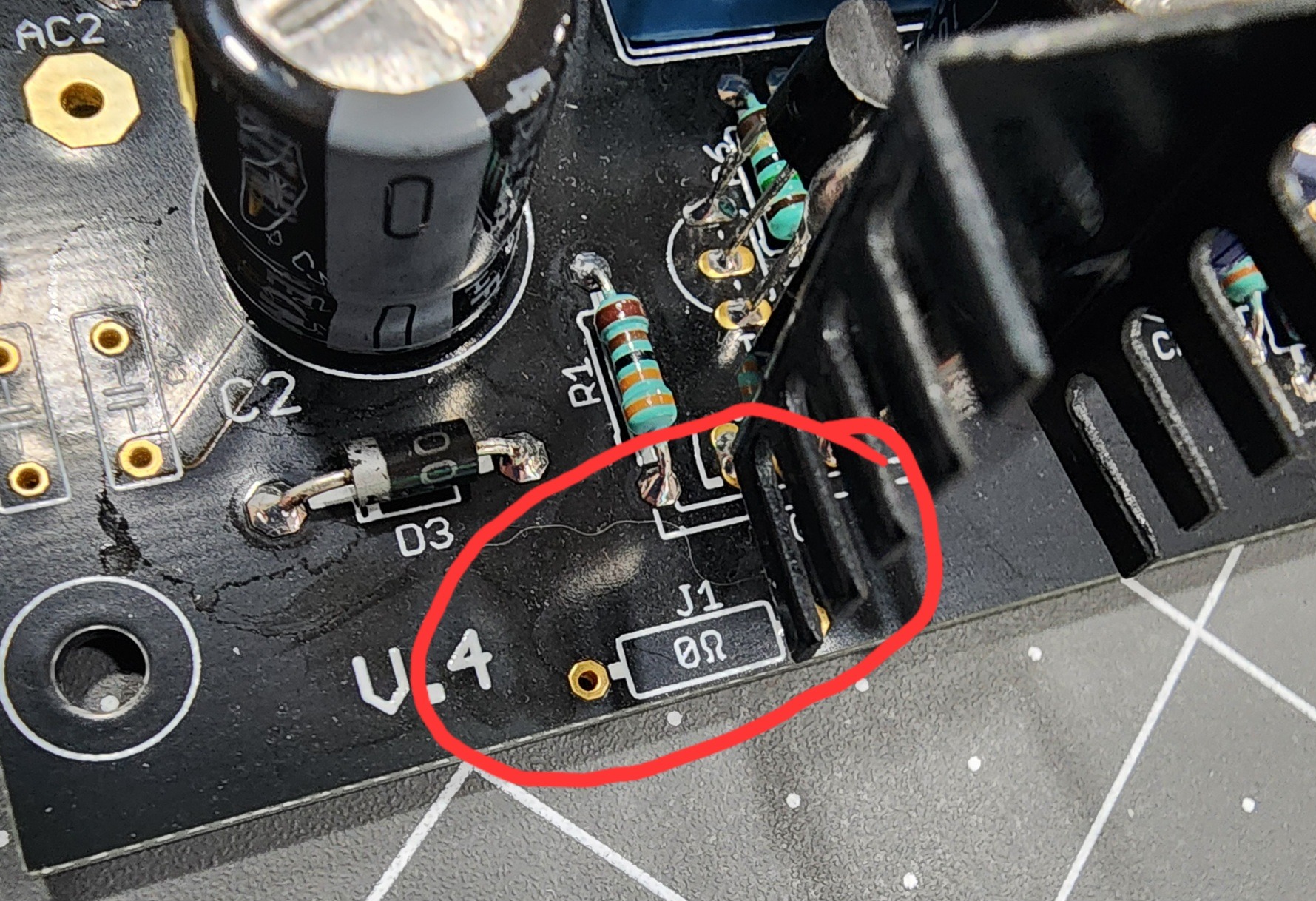

This is the jumper "J1" that I had missed

You make a wire jumper from a cut off resistor lead, or similar.

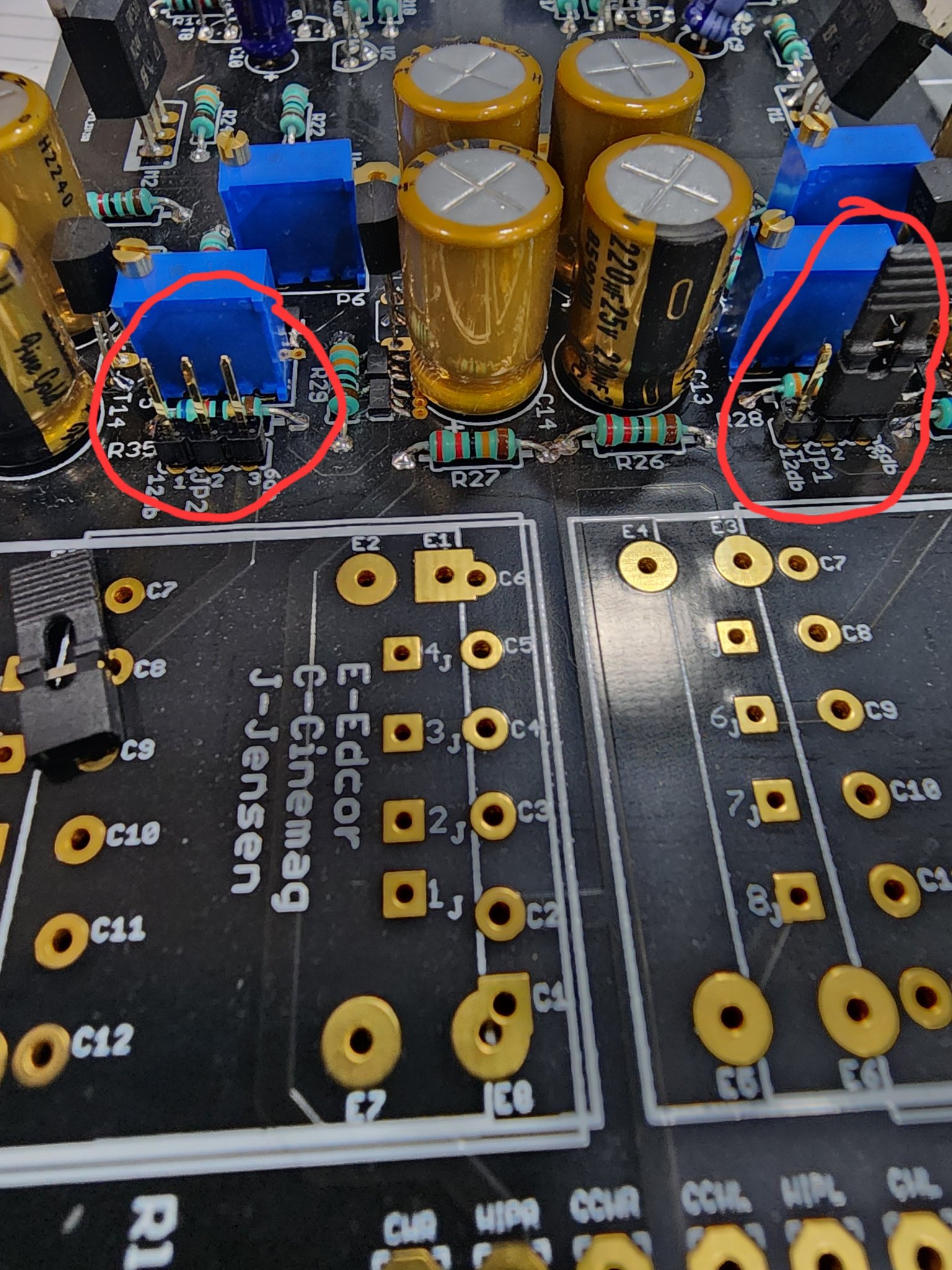

This is the jumpers you are referring to.

You need to hold with tape, then solder pins to pads on bottom of board.

You could hold the jumper in place on top of pcb with your finger and solder the bottom pin(s), but I'll let you know tape was less painful. 🔥

You make a wire jumper from a cut off resistor lead, or similar.

This is the jumpers you are referring to.

You need to hold with tape, then solder pins to pads on bottom of board.

You could hold the jumper in place on top of pcb with your finger and solder the bottom pin(s), but I'll let you know tape was less painful. 🔥

Last edited:

Stumped again with minutia. The jumper, comprised of 3 legs fused in plastic, and a small plastic handle piece. Legs are isolated, so handle piece must also short 2 legs together.

Obviously handle piece must short 2 legs, but I think I have fit this thing only way I can see it going. It is very loose, so I'm likely doing something wrong? No good pics here to help either.

Are the three legs soldered in place on board, then the shorting cap on top to short two legs to pick gain? Here's a pick of my parts. Altogether different from XA 252 jumpers,.

Obviously handle piece must short 2 legs, but I think I have fit this thing only way I can see it going. It is very loose, so I'm likely doing something wrong? No good pics here to help either.

Are the three legs soldered in place on board, then the shorting cap on top to short two legs to pick gain? Here's a pick of my parts. Altogether different from XA 252 jumpers,.

I don't have those boards. That is the extra jumper refered to in build guide, only on 2023 versions. Mine are 2021 boards with only two main jumpers. However, you show the same jumper piece I have! Yes! I guess it's just a very loose fit or do I just need to press harder?This is the jumper "J1" that I had missed.

View attachment 1299887

You make a wire jumper from a cut off resistor lead, or similar.

This is the jumpers you are referring to.

View attachment 1299888

You need to hold with tape, then solder pins to pads on bottom of board.

Mine don't have that third jumper position, just the other two you show, which use same parts, just loose.

No, I mean the way the handle part fits on the three pins, maybe I need to push harder?It's loose, use blue tape (or similar) to hold it while you solder.

With jumpers in place, I hear relays clicking, but no LEDs lighting up. Time to disassemble the twister LEDs, ugh. Oh well, could be worse.

Russellc

Russellc

Good news is relays are clicking...With jumpers in place, I hear relays clicking, but no LEDs lighting up. Time to disassemble the twister LEDs, ugh. Oh well, could be worse.

Russellc

If you have 2021 boards, you twister board should look like this on the side that matters...

The flat side of the LEDs (the cathode / negative / short leg) goes to the outside of the board.

From this pic... since you didn't trim the legs (that I can tell) just look down the line and check.

One looks suspect, and if one's wrong... the entire thing will act funky.

It's hard to tell from the picture.

I did trim the legs off even, just left some length. I oriented the short wires just like the picture in the guide. Not at home right now,Good news is relays are clicking...

If you have 2021 boards, you twister board should look like this on the side that matters...

View attachment 1300032

The flat side of the LEDs (the cathode / negative / short leg) goes to the outside of the board.

From this pic... since you didn't trim the legs (that I can tell) just look down the line and check.

One looks suspect, and if one's wrong... the entire thing will act funky.

It's hard to tell from the picture.

View attachment 1300036

Mine were all oriented the same way, and while difficult to tell on silk screen, one side the circular lines seemed to go behind the hole,

other one seems to hit it in the middle, I assumed that was flat side. Let me get some good pics, and post before I remove them all....that said I'm pretty sure they are backwards. Its a simple circuit with not much else to go wrong!

- Home

- Amplifiers

- Pass Labs

- Iron Pre Essentials Kits For The DIYA Store - Register Your Interest